Plate frame filtering device for ventilating system

A technology of plate and frame filtration and ventilation system, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inability to meet the use in industrial applications, achieve the passage of a large amount of air, ensure the passage of air, The effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

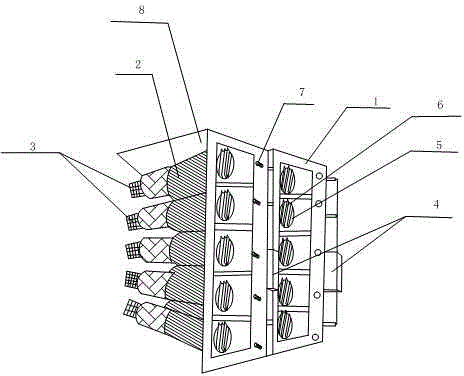

[0016] Such as figure 1 As shown, the present invention includes a plurality of mounting plates 1, a plurality of filter cores 2, an adsorption layer 3, an air outlet and a plurality of pulse dust collectors 4, and two adjacent mounting plates 1 are fixed by a plurality of fastening bolts 7, A plurality of filtering cylinders 2 are vertically connected on each mounting plate 1, an adsorption layer 3 is arranged at the air inlet end of each filtering cylinder 2, and a plurality of air outlets 5 are evenly arranged on the surface of each mounting plate 1, each The air outlet 5 is correspondingly connected to a filtering cylinder 2, and a plurality of fan blades 6 are arranged on each air outlet 5; a pulse dust collector 4 is installed on each mounting plate 1.

[0017] The airflow that needs to be exchanged first passes through the adsorption of the adsorption layer, and then enters the multiple filter elements installed on the mounting plate through the air inlet to achieve the...

Embodiment 2

[0020] In this embodiment, the following technical features are added on the basis of Embodiment 1: one end of the mounting plate 1 is vertically connected with a rainproof shed 8 . It is used to block rainwater, prevent rainwater from entering the filter element, dissolve dust, corrode the filter element, and lose the filtering effect.

[0021] The shape of each filter core 2 is a columnar structure. The inflow area of the airflow can be increased.

[0022] A plurality of fan blades 6 are also arranged on each air outlet 5 to be parallel to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com