Compound down feather separator

A kind of wool separator and composite technology, which is used in solid separation, fiber separation, separation of solids from solids by air flow, etc., can solve the problems of troublesome production process, waste of manpower, etc., to improve product quality and reduce processing. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

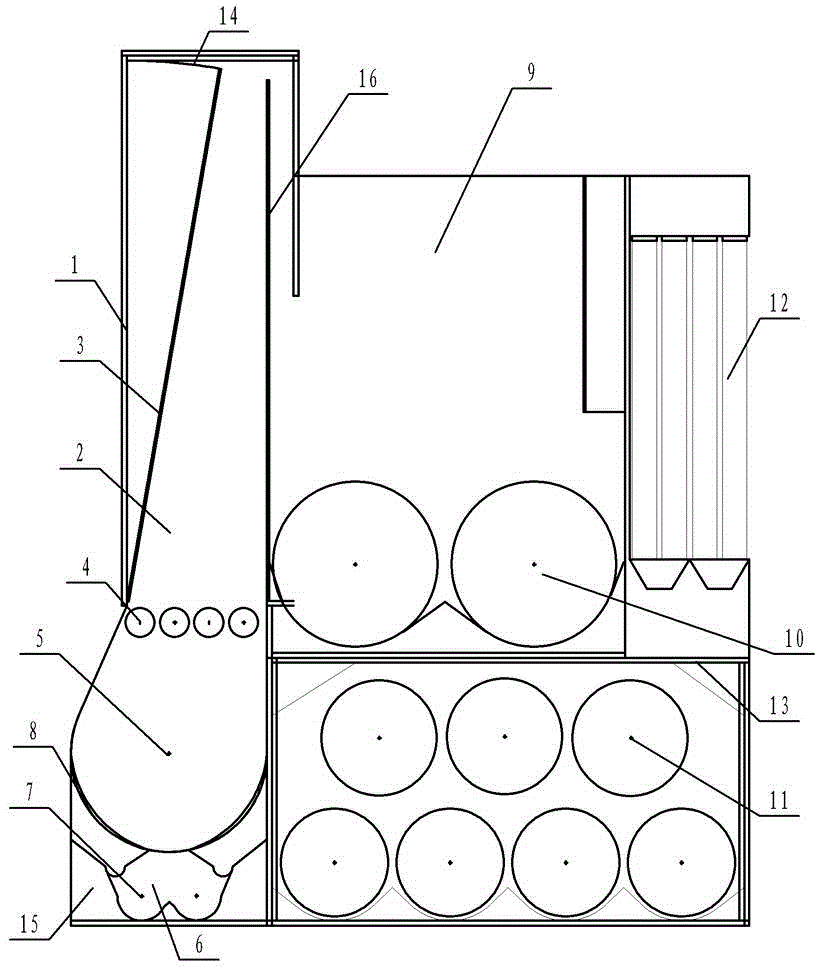

[0010] The composite down hair sorting machine includes a box body. The space inside the box is divided into a raw material box and a finished product box by a baffle plate. The raw material box and the finished product box are connected through the top of the baffle plate.

[0011] A movable partition is set in the raw material compartment, the lower end of the movable partition is hinged with the raw material compartment, and the upper end of the movable partition is connected with a pull rope, which can make the movable partition move left and right, thereby changing the size of the box, changing the flow rate and velocity of the wind , so as to obtain the required down, reduce down processing procedures, improve product quality,

[0012] There are two layers of screens at the bottom of the raw material box, a blanking bin is set in the middle of the bottom of the sieve plate, and impurity boxes are set on both sides of the blanking bin. The mesh of the screen is rectangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com