Boiler waste heat utilization device

A technology of boiler waste heat and heat exchange device, which is applied in heat exchangers, heat transfer modification, indirect heat exchangers, etc. The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

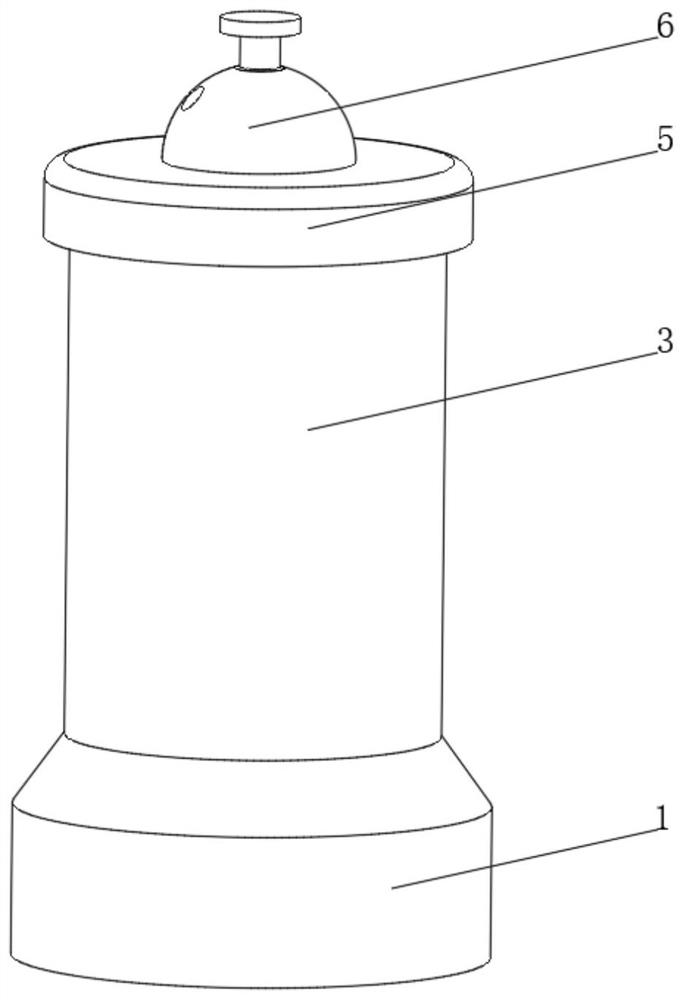

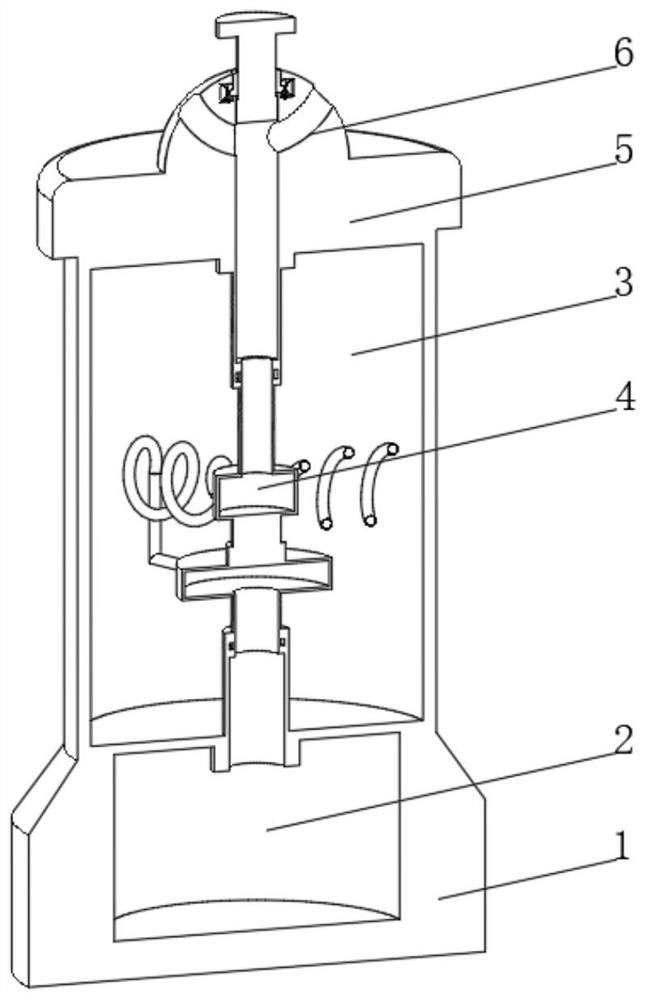

[0037] See Figure 1-3 The present invention provides a technical solution: a boiler waste heat utilization device, specifically includes:

[0038] Base 1, the rear space 2 is opened inside, and the heating space 2 is provided with a dispensing port;

[0039] The water storage cylinder 3 is disposed at the top of the base 1, and the heat exchange device 4 is provided inside the water storage cylinder 3, and the heat exchange device 4 is in communication with the bottom of the heating space 2;

[0040] The top cover 5 is provided at the top of the water storage cylinder 3, and the top cover 5 is disposed inside the top cover 5, and the adjustment device 6 is provided, and the adjustment device 6 is connected to the top of the heat exchange device 4;

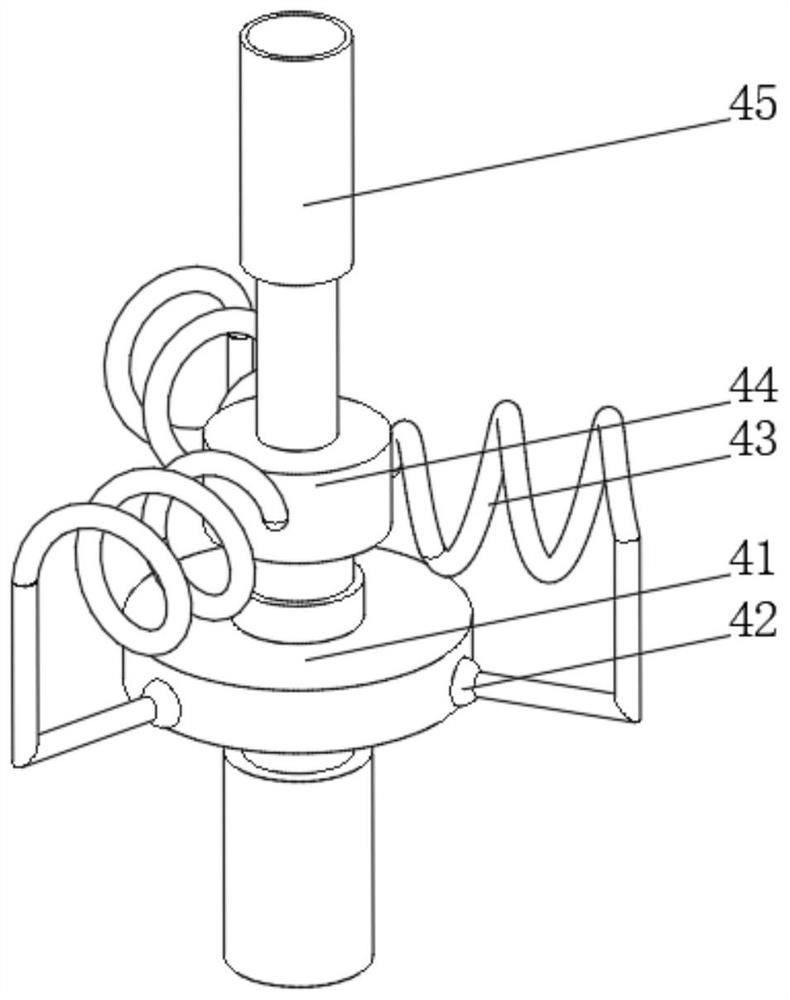

[0041] The heat exchange device 4 includes:

[0042] The split disk 41 is provided with a spiral heat transfer tube 43, a rotating device 42, and a helix heat transfer pipe 43, by the rotating device 42.

[0043] The gas disc 44, the b...

Embodiment 2

[0047] See Figure 1-4 Based on the example one, the present invention provides a technical solution: the rotating device 42 includes a rotating seat 421, and the inner wall of the rotating seat 421 is rotatably connected to the seal ball 422, and the sealing ball 422 is penetrated and fixed to the metal hose. 423. The rotating seat 421 is connected to the side of the seal ball 422 and the split disk 41, and the metal hose 423 is in communication with the helix heat transfer pipe 43, and a rotating device is provided, and the heat exchange device 4 is required to be maintained. Or replacement, the distance between the dividing disk 41 and the gas disc 44 can be shortened by controlling the telescopic rod between the split disk 41 and the gas disc 44, thereby taking it from the connecting pipe 45, convenient for later maintenance and Replacement parts.

Embodiment 3

[0049] See Figure 1-5 The present invention provides a technical solution in the present invention, and the adjustment device 6 includes a mount 61, and an airway 62 is opened inside the mount 61, and there is a vent 63 on both sides of the airway 62. The top of the airway 62 is threaded with a seal piston 64 by the thread sleeve 65, and the mount 61 is located on the portion of the thread sleeve 65, and the buckle groove 66 is opened, the buckle groove 66 is rotated to connect to the ball buckle 67, A curved spring is provided between the ball buckle 67 and the inner wall of the snap groove 66, and the mount 61 is disposed at the top of the water storage cylinder 3, and the airway 62 is connected to the connecting pipe 45 at the top of the gas disc 44, the thread sleeve 65 is located in the card The partial setting inside the buckle 66 is a snap ball 68 that is adapted to the ball head card buckle 67.

[0050] The adjustment device 6 is provided, and the inside of the adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com