Heating plug for loading and unloading plastic bottle blank by rotary lifting

A plastic bottle and rotary technology, applied in the field of plastic machinery, can solve the problems of affecting the heating quality of plastic preforms, not suitable for automatic loading and unloading of preforms, and unable to achieve uniform heating, etc., and achieves easy size exchange, flexible use, and uniform heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

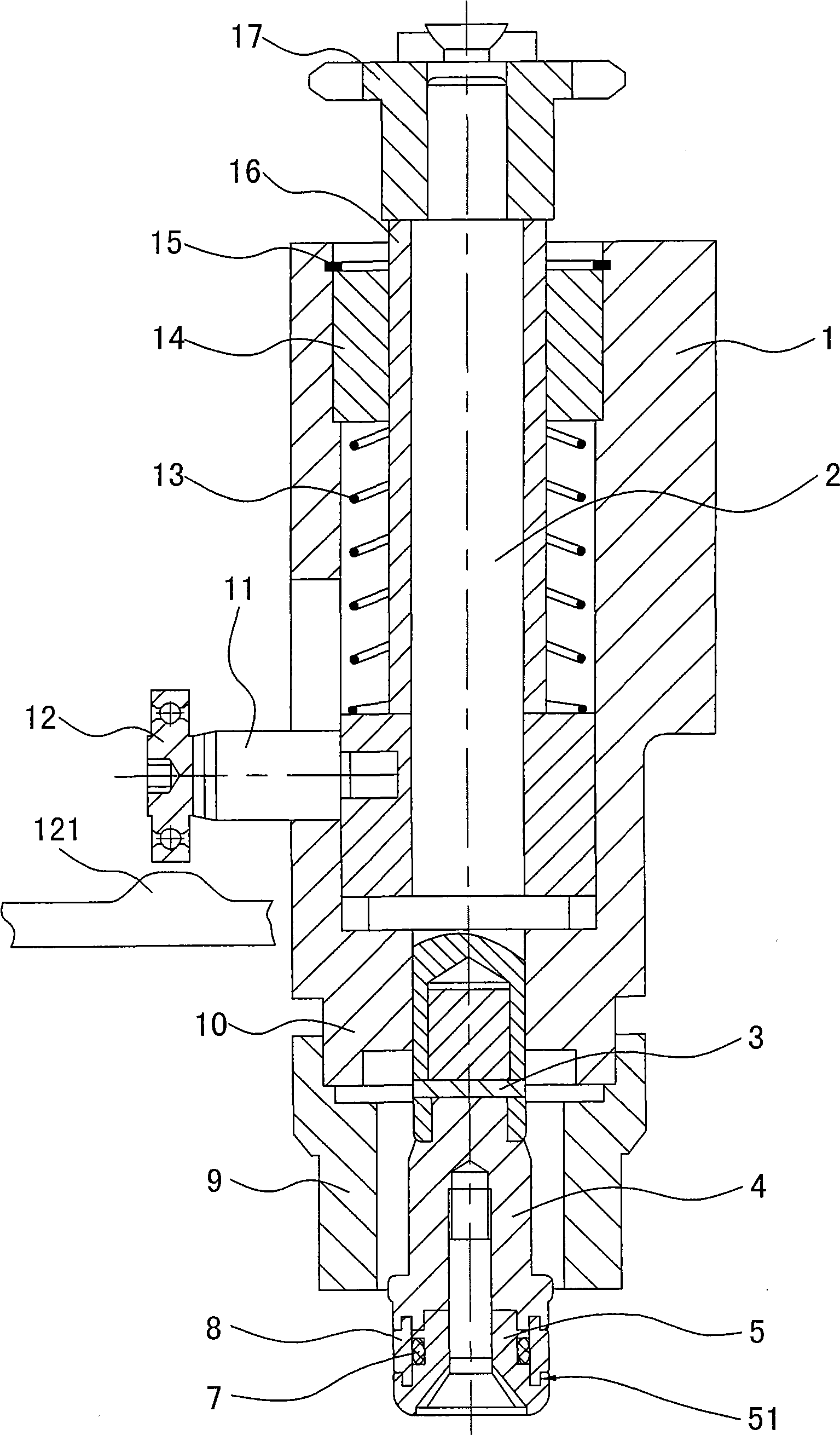

[0008] The invention relates to a rotary lifting loading and unloading plastic bottle preform heating plug, such as figure 1 As shown, it includes a body 1 connected to the heater operating mechanism, a mandrel 2 is installed in the body, the end of the mandrel is connected to a plug head 5, the outer wall of the head is made with a movable groove 51, and an expansion sleeve 8 is installed in the movable groove , One end of the expansion sleeve 8 is fixed by a limit block, and the inner side of the expansion sleeve is equipped with an elastic ring 7, which is characterized in that an upper retaining ring 14, a spring 13 and a sliding sleeve 10 are mounted on the mandrel 2, and the sliding sleeve 10 is connected to the shaft pin 11, A roller 12 is installed on the shaft pin, and the pushing convex rail 121 is in contact with the roller 12, and a blanking sleeve 9 is connected to the lower part of the machine body 1. When working, the entire plug moves with the operating mechanism o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com