Cutting and conveying device and method for inner frame paper of reversible hard box cigarette pack

A technology of conveying device and inner frame paper, which is applied in the directions of packaging material feeding device, packaging, transportation packaging, etc., can solve the problem that the specification and size of the inner frame paper cannot be changed, the burr phenomenon in the incision of the inner frame paper, the processing and manufacturing difficulties of the cutting roller, etc. problems, to achieve the effect of convenient installation and debugging, compact structure, low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

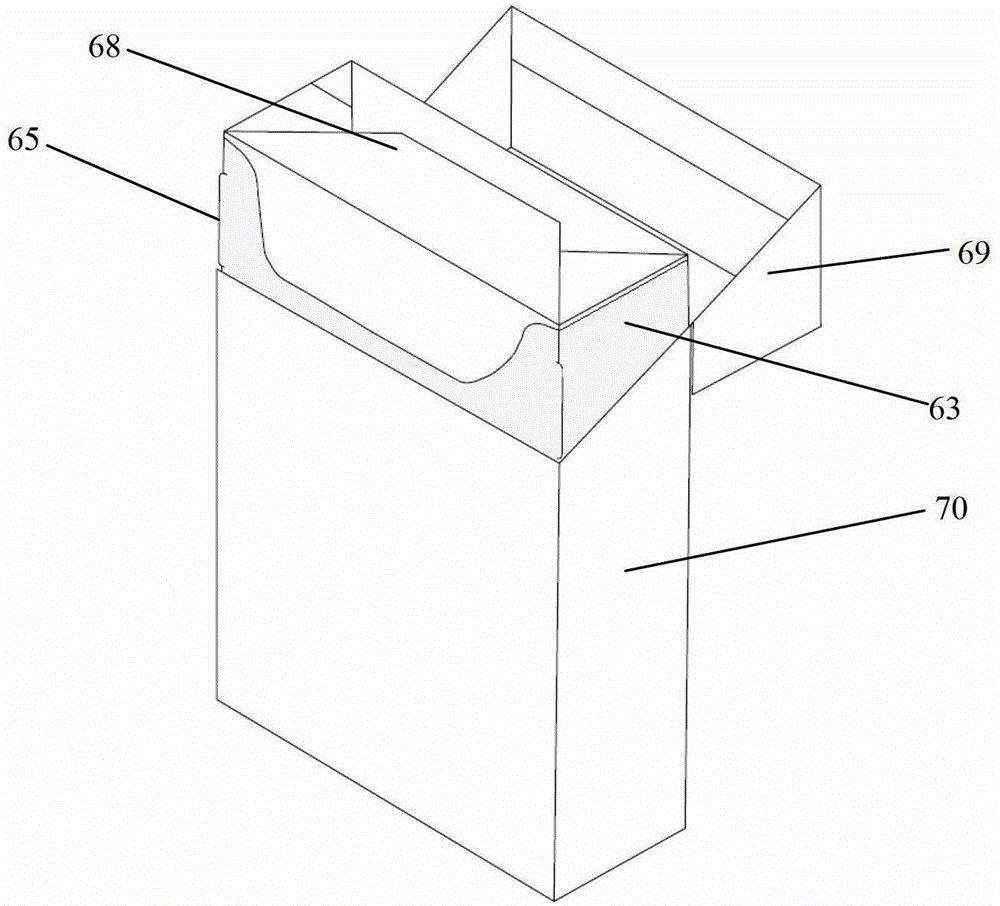

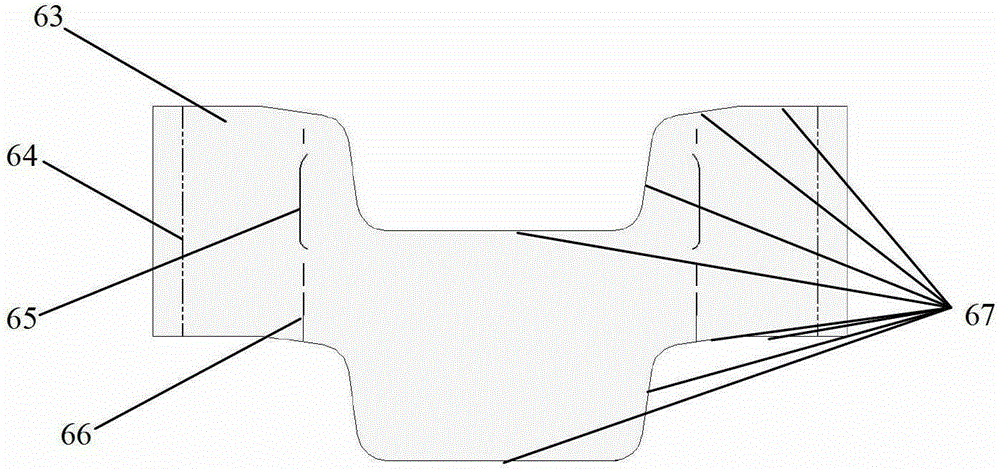

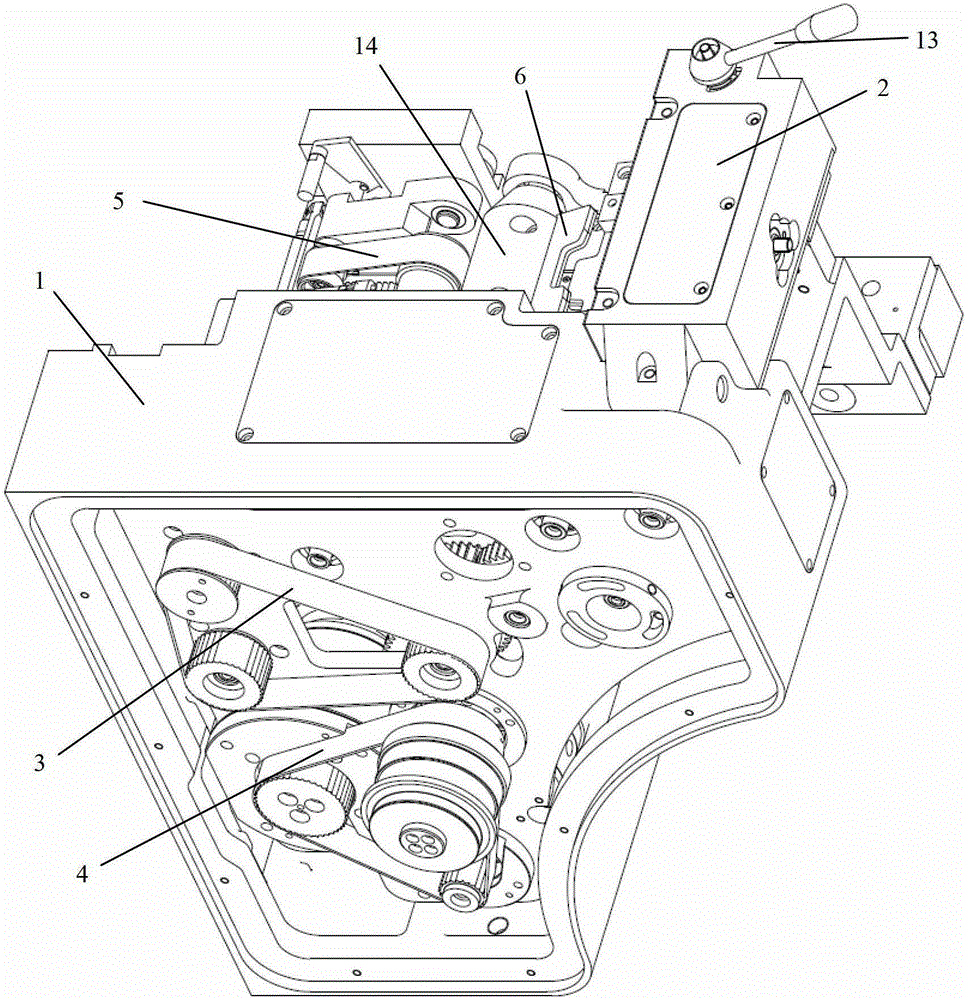

[0091] Such as Figure 3 to Figure 7 As shown, the cutting and conveying device for the inner frame paper of flip-type hard box cigarette packs of the present invention includes a scoring roller assembly 2, and the scoring roller assembly 2 includes a scoring roller 17 and a pair of scoring rollers 18 matched therewith; The outer edge of the roller 17 is circumferentially provided with multiple pairs of cutting edges, each pair of cutting edges can form an indentation 64, an incision 65 and a dotted line score 66 on an inner frame paper; Scoring the frame paper tape and conveying the scored inner frame paper tape forward; the output end of the scoring roller assembly 2 is provided with an inner frame paper cutting mechanism;

[0092] The scoring roller 17 and the scoring counter-roller 18 are driven by two pairs of gears, so that the rotation of the two is opposite and the rotation speed is consistent; the scoring roller 17 is provided with a rubber conveying roller, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com