Cutting device for machining building materials

A technology for cutting devices and building materials, applied in shearing devices, pipe shearing devices, metal processing equipment, etc., can solve problems affecting normal use, pipe angle errors, etc., to achieve beautiful incisions, high precision, and improve the effect of cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

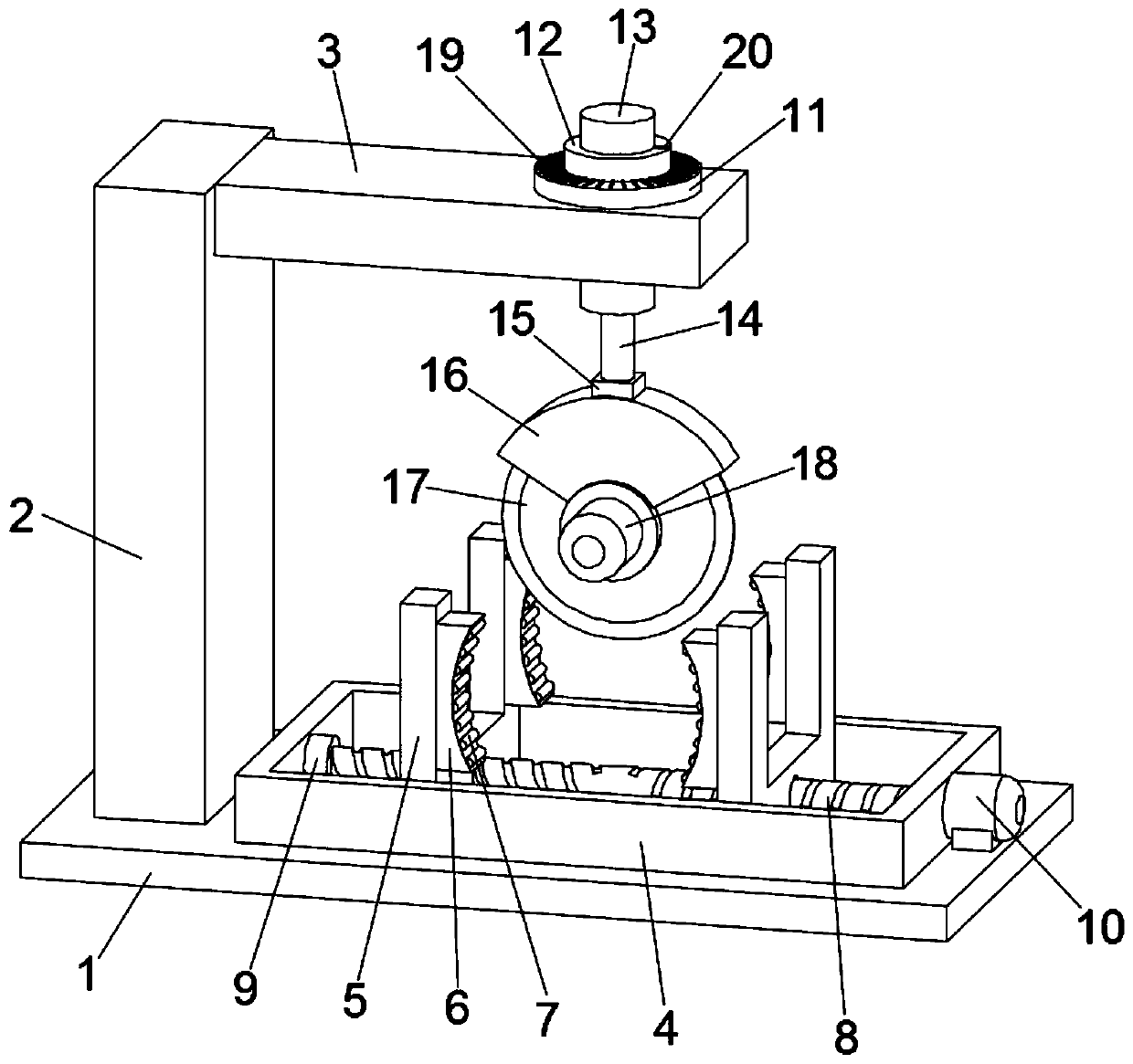

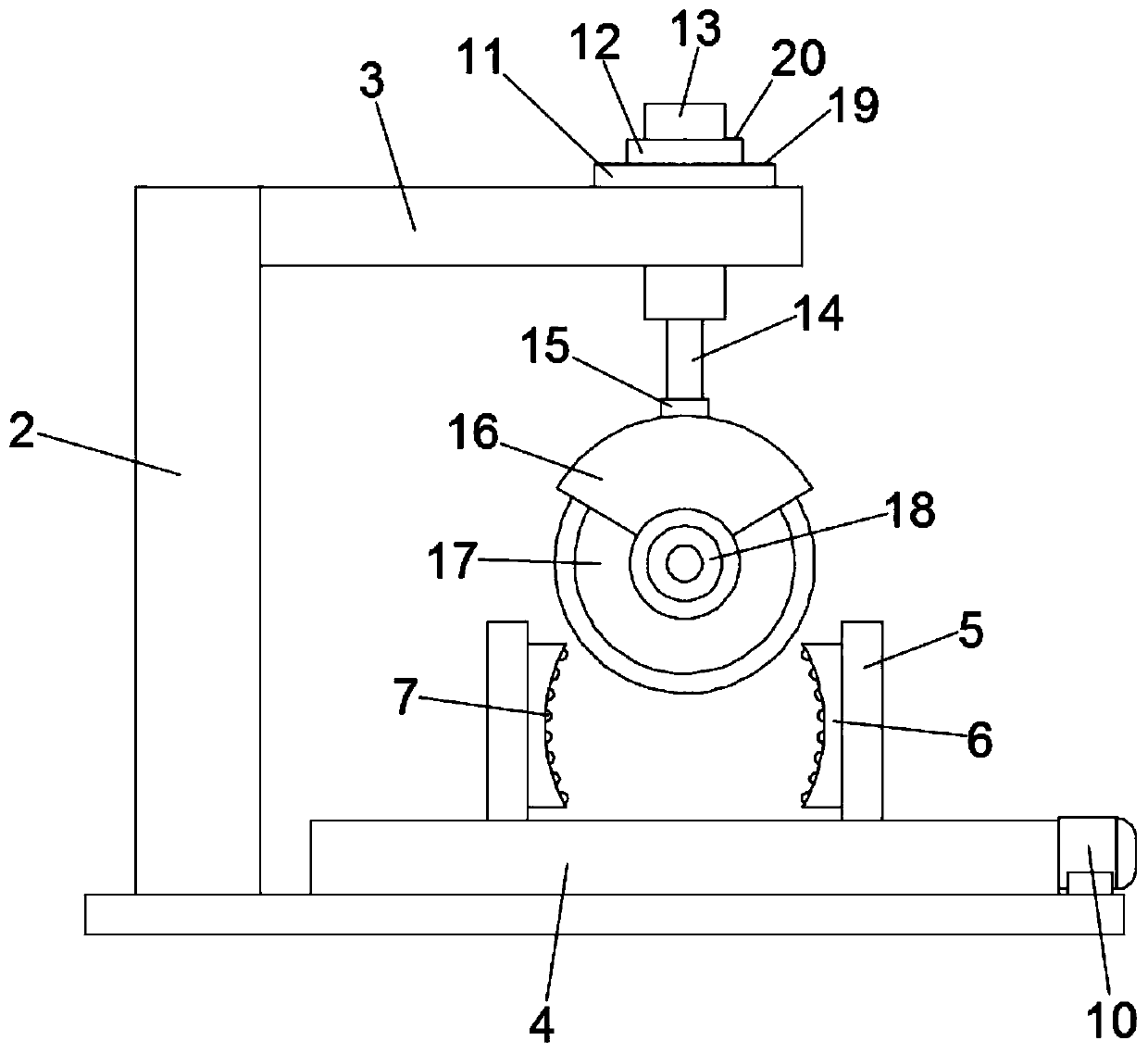

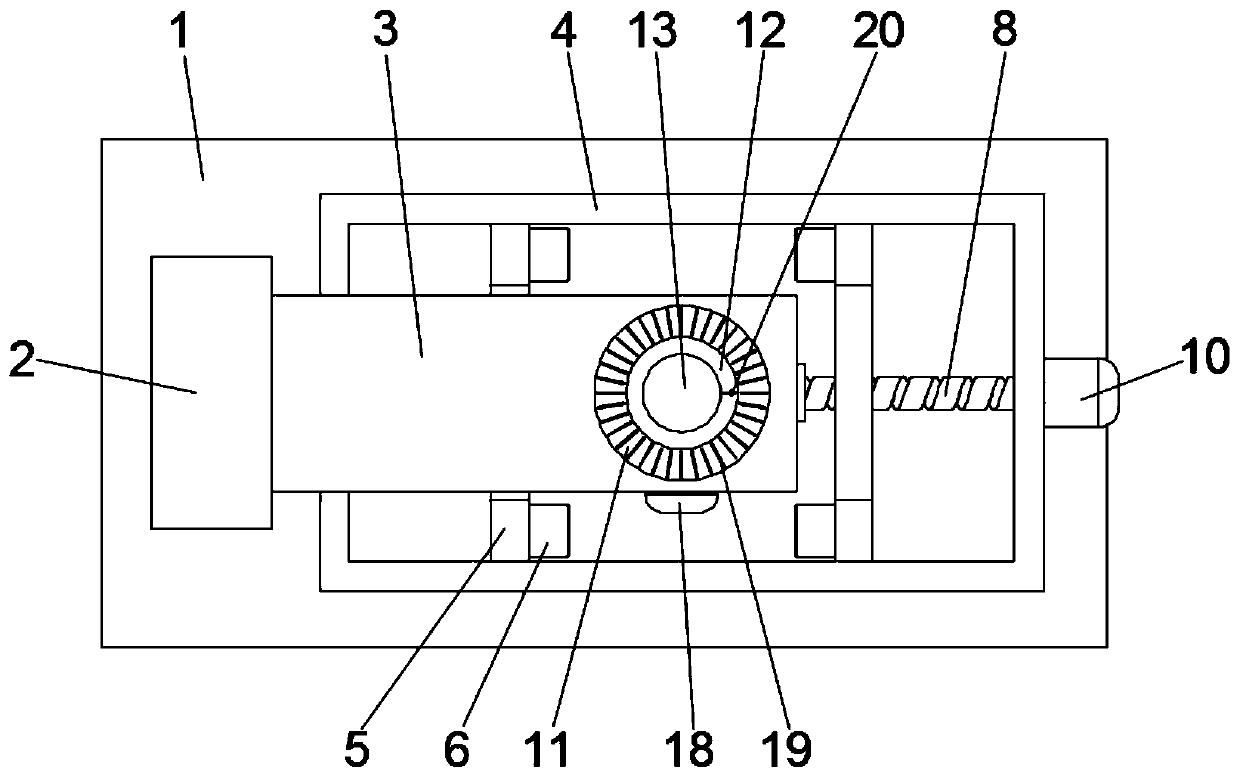

[0024] see figure 1 , a cutting device for building materials processing, comprising a base plate 1 and a support plate 2, the support plate 2 is vertically installed on one side of the base plate 1, a top plate 3 is fixed on the top of the support plate 2, and a chute is also fixed on the base plate 1 4. Two sliders 5 are embedded symmetrically in the chute 4, and a block 6 for fixing the pipe is installed on the side wall of the slider 5, and a screw 8 is installed horizontally in the chute 4, so that The two ends of the screw rod 8 are provided with threads with opposite directions of rotation, and the two sliders 5 are respectively helically sleeved on the threads at both ends of the screw rod 8. One end of the screw rod 8 is rotated with a bearing seat 9, and the other end is connected with a mobile motor 10; A fixed disk 11 is installed on the upper end surface of the top plate 3, and a damping drum 12 is provided in the rotation sleeve of the fixed disk 11, and a dial 1...

Embodiment 2

[0034] A cutting device for building material processing, comprising a base plate 1 and a support plate 2, the support plate 2 is vertically installed on one side of the base plate 1, a top plate 3 is fixed on the top of the support plate 2, and a chute 4 is also fixed on the base plate 1 , two sliders 5 are installed symmetrically in the chute 4, blocks 6 for fixing pipes are installed on both sides of the slider 5, a screw 8 is horizontally installed in the chute 4, and the two sides of the screw 8 are The ends are provided with threads with opposite directions of rotation, and the two sliders 5 are respectively helically sleeved on the threads at both ends of the screw rod 8. One end of the screw rod 8 is rotated with a bearing seat 9, and the other end is connected with a mobile motor 10; A fixed disk 11 is installed on the end surface, and a damping drum 12 is set in the rotation sleeve of the fixed disk 11. A dial 19 is arranged on the upper end surface of the fixed disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com