Fiber blanket slitter

A technology of slitting machine and fiber blanket, applied in the field of slitting machine equipment, can solve the problems of uneven incision at the incision, the finished product is not so beautiful, and the filaments run out, so as to achieve beautiful incision, convenient collection, and reduce trouble. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

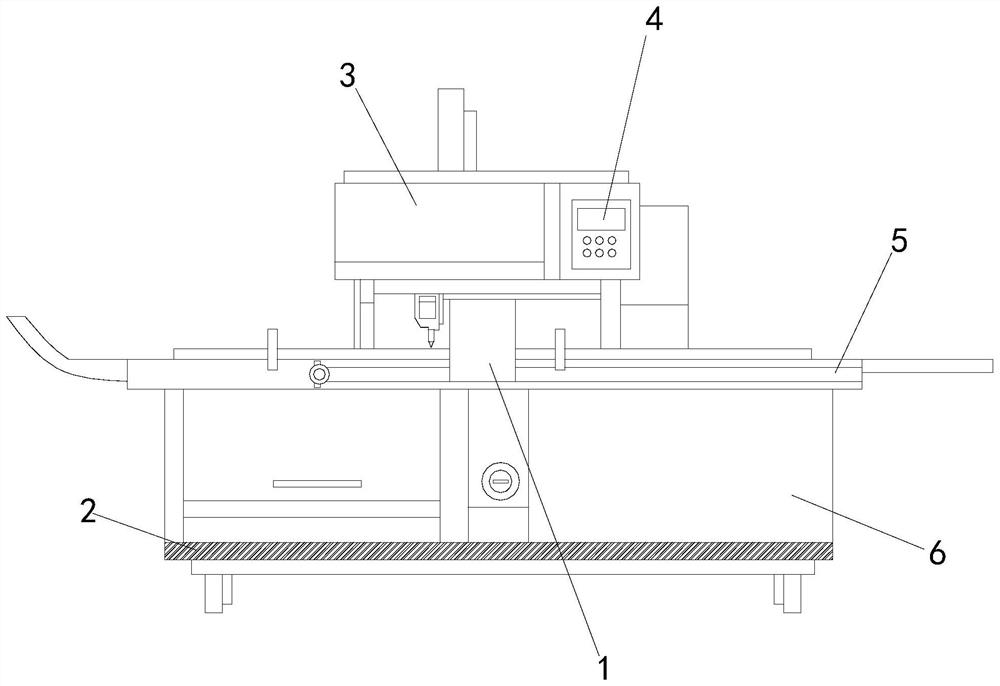

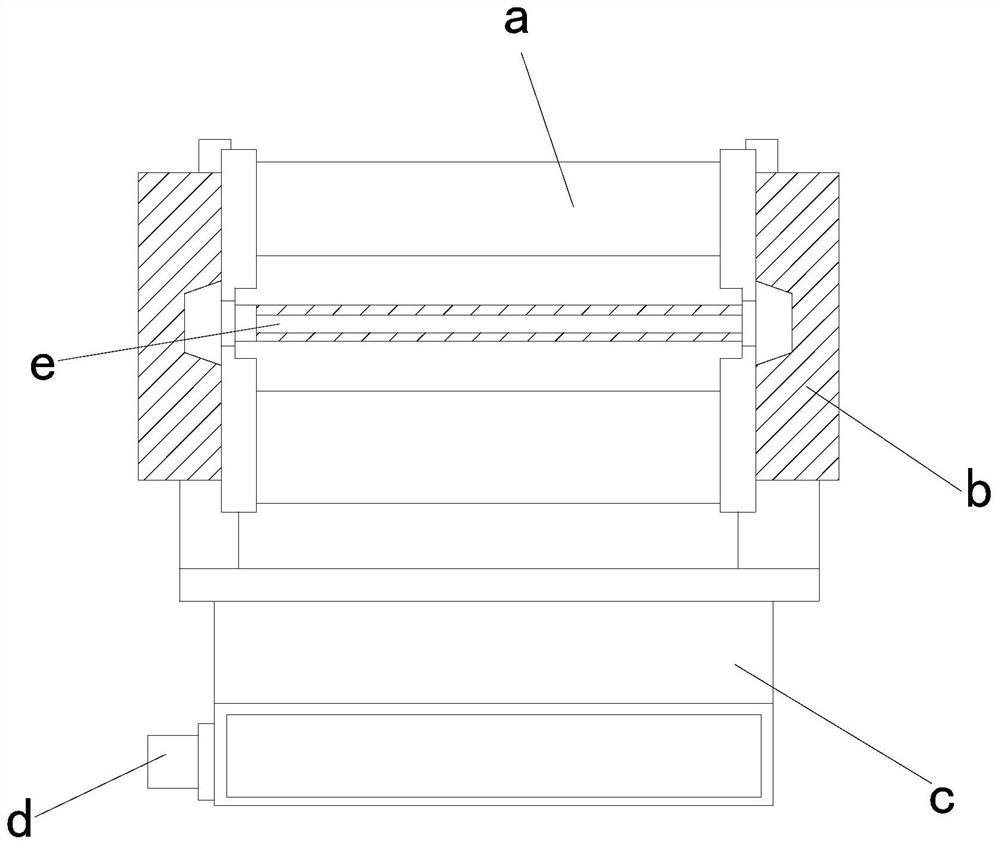

[0025] see Figure 1-Figure 2 , the present invention provides a technical solution for a fiber blanket slitting machine: its structure includes: a hinge frame body 1, a base plate 2, a slitting box device 3, a controller 4, a processing table 5, a loading table 6, the base plate 2 installed under the loading platform 6 and locked with the loading platform 6, a processing platform 5 is provided above the loading platform 6, and a hinge frame body 1 is provided on the middle side of the processing platform 5, and the hinge frame body 1 is connected to the The processing table 5 is locked, the side of the hinge frame body 1 is provided with a cutting box device 3, and the right side of the cutting box device 3 is provided with a controller 4, and the controller 4 is electrically connected to the cutting box device 3. connected, the wire frame body 1 includes a twisting roller device a, a power tank device b, a funnel tank c, a recovery cylinder device d, and an alignment groove ...

no. 2 example

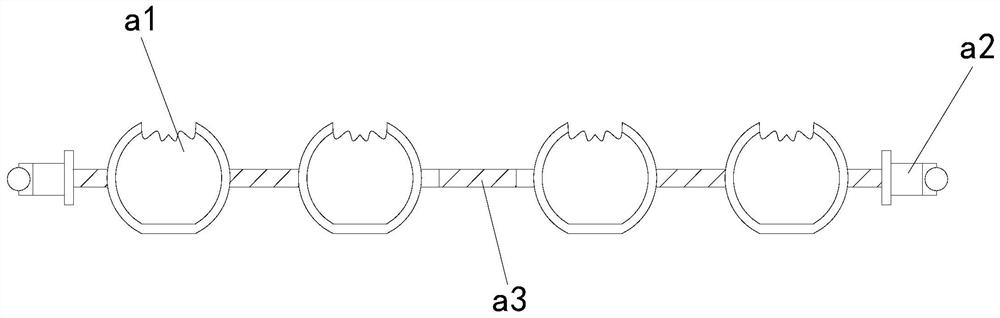

[0028] see Figure 3-Figure 5 , the present invention provides a technical solution for a fiber blanket slitting machine: its structure includes: the twisting roller device a includes a clamping head a1, a linkage head a2, and an insertion rod a3, and the linkage head a2 is installed on two sides of the insertion rod a3 end and fastened with the insertion rod a3, and the middle part of the insertion rod a3 is connected with the clamping head a1.

[0029] The clamping head a1 includes a stress block a11, a blade a12, a spring a13, a fixed cover a14, and a buffer software a15. The blade a12 is installed on the top of the fixed cover a14 and locked with the fixed cover a14. There is a spring a13, the inner side of the spring a13 is provided with a stress block a11, the stress block a11 is fastened with the spring a13, and the outer side of the stress block a11 is provided with a cushioning software a15.

[0030] The recovery cylinder device d includes a collection cylinder d1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com