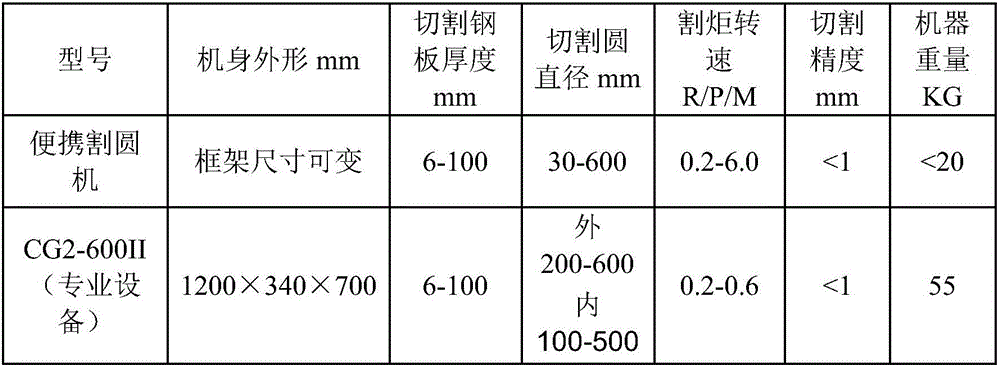

Portable circle cutting machine suitable for circular thick plate cutting and cutting method thereof

A cutting machine, portable technology, applied in welding equipment, gas flame welding equipment, metal processing equipment and other directions, can solve the problems of difficult to ensure smooth cutting surface, high cost cutting, etc., achieve smooth incision, save purchase cost, high cutting cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

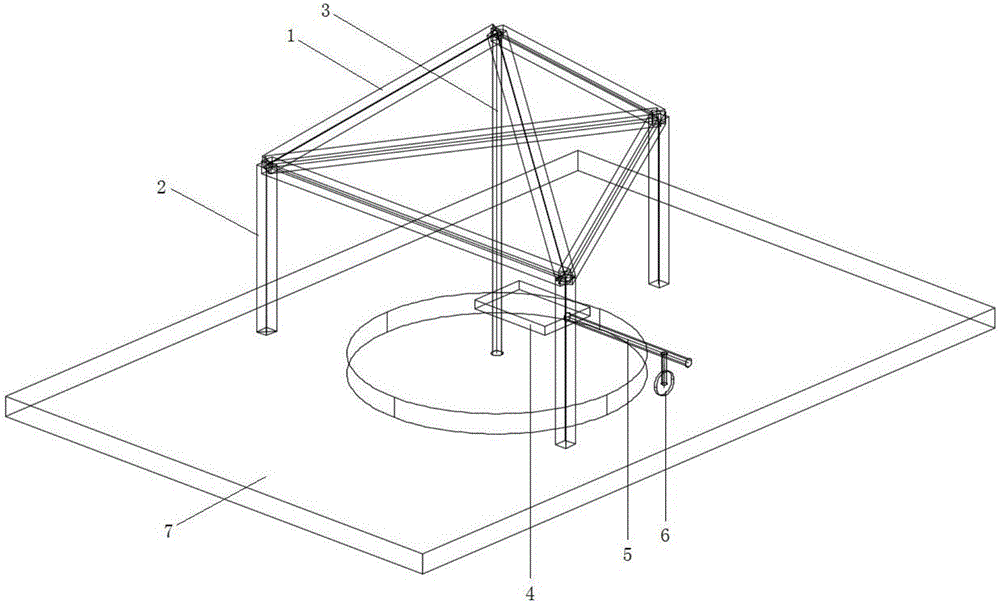

[0022] as attached figure 1 As shown, a portable circular cutting machine suitable for circular thick plate cutting, including cutting machines such as manual cutting torches and orbital semi-automatic cutting machines. In addition, the portable circle cutting machine of the present invention also includes a triangular pyramid-shaped frame 1, which is composed of four triangles and has optimal deformation resistance, and the size of the frame 1 can be adjusted according to the radius of the cutting circle. The three apexes of the bottom surface of the frame 1 are respectively provided with support legs 2 for fixing the frame 1 on the steel plate 7 to be cut. Support to eliminate lateral deformation; the bottom of each support leg 2 is provided with a permanent magnet for fixing the support leg 2 on the steel plate 7 to be cut, which can be adsorbed on a horizontal or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com