Automatic or electric adjusting thin blade type cutting groove mechanism of print fluting machine for paper carton

A carton printing and slotting machine technology, which is applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc. It can solve the problems of uneven cutting edges, paper tearing, and affecting the working efficiency of the cutting machine, so as to achieve neat cuts, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

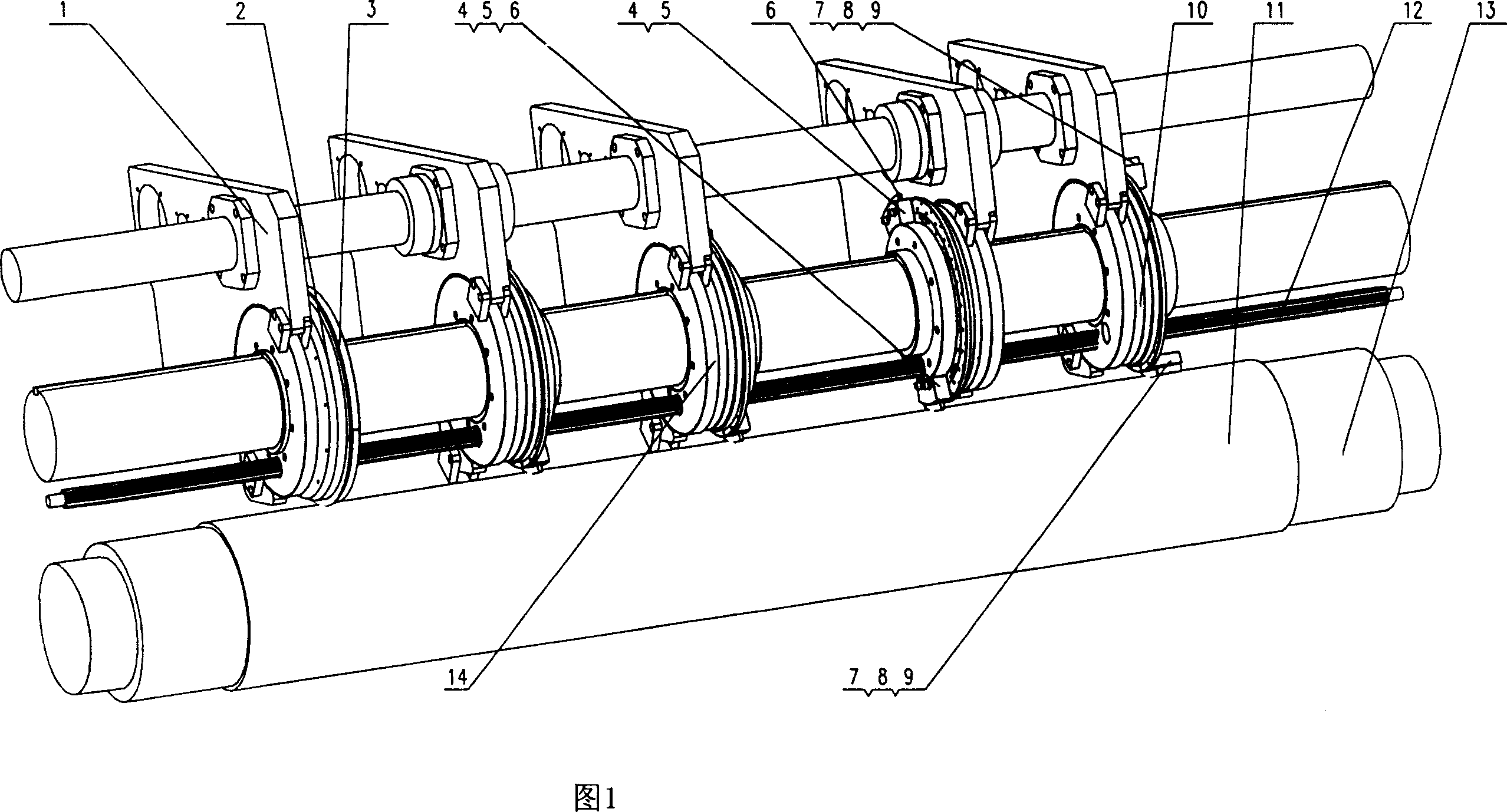

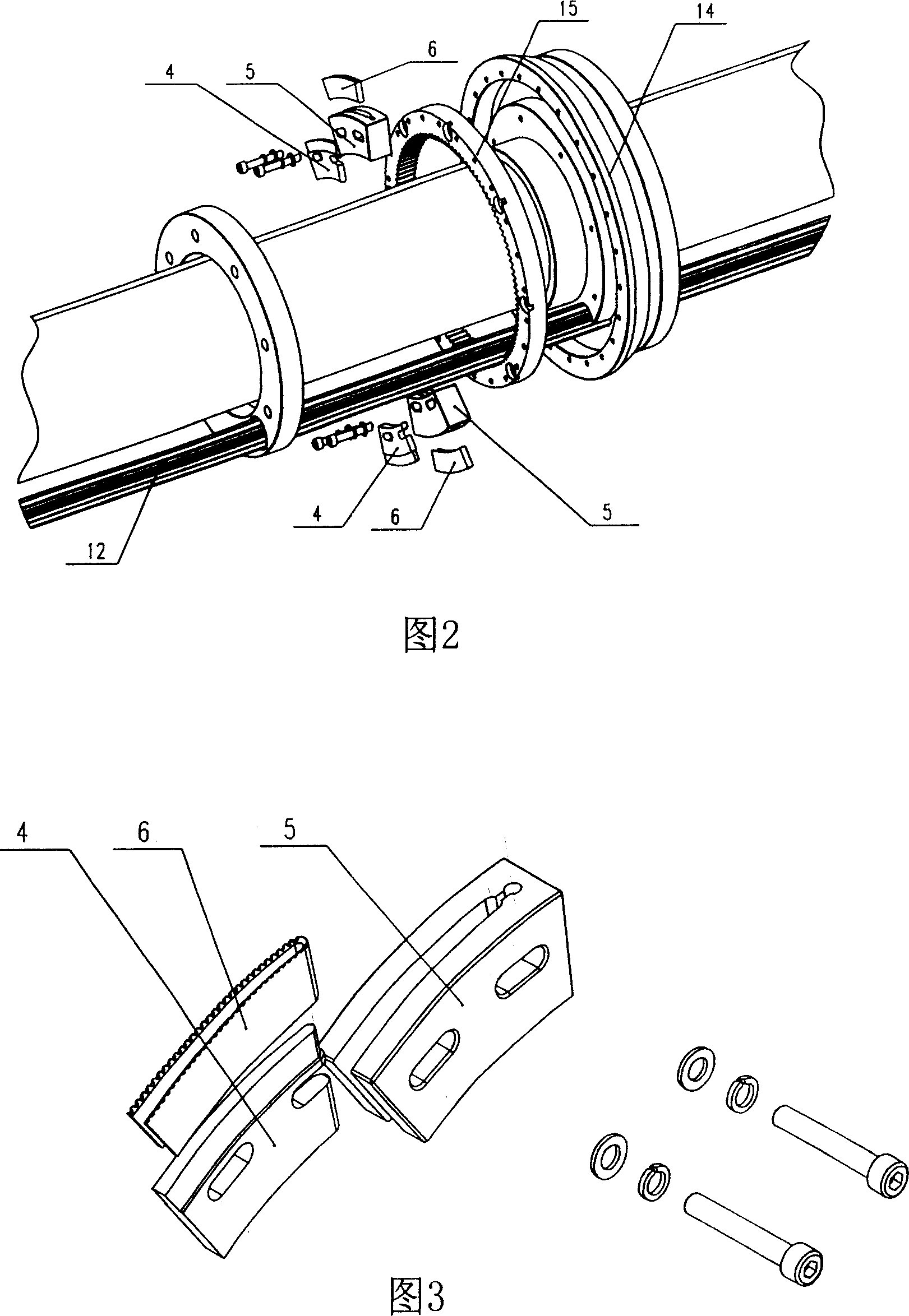

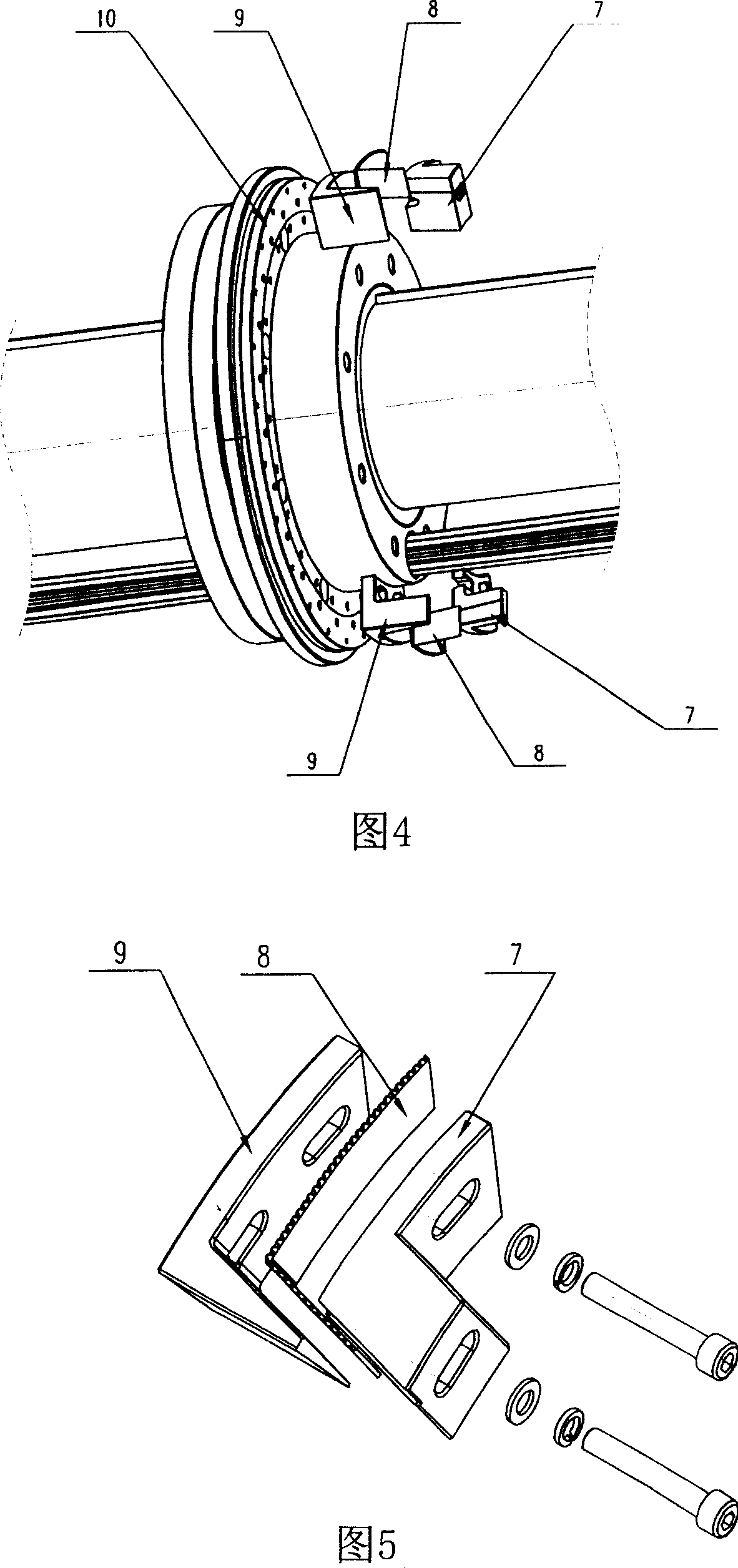

[0015] Referring to Figures 1 to 9: the carton printing slotting machine of this embodiment automatically or electrically adjusts the thin-blade grooving mechanism is composed of a thin-cut grooving knife 6, a thin-cut corner cutter 8, and a thin-cut edge cutter 3 , grooving knife fixed core plate 4, grooving knife fixed clamping plate 5, corner cutter fixed core plate 9, corner knife fixed pressure plate 7 and grooving rubber pad 11 and grooving rubber pad roller 13 are formed.

[0016] The front portion of the slice type grooving knife 6 is made into an arc shape, and the two sides meet the front portion arc and form a V shape (Fig. 7). The shapes of 6 are consistent, and the inner surface of the grooving knife fixed splint 5 is consistent with the shape of the sheet type grooving knife 6. The inner surface of sheet type grooving knife 6 is attached to the outer surface of grooving knife fixed core plate 4, and the outer surface of sheet type grooving knife 6 is attached to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com