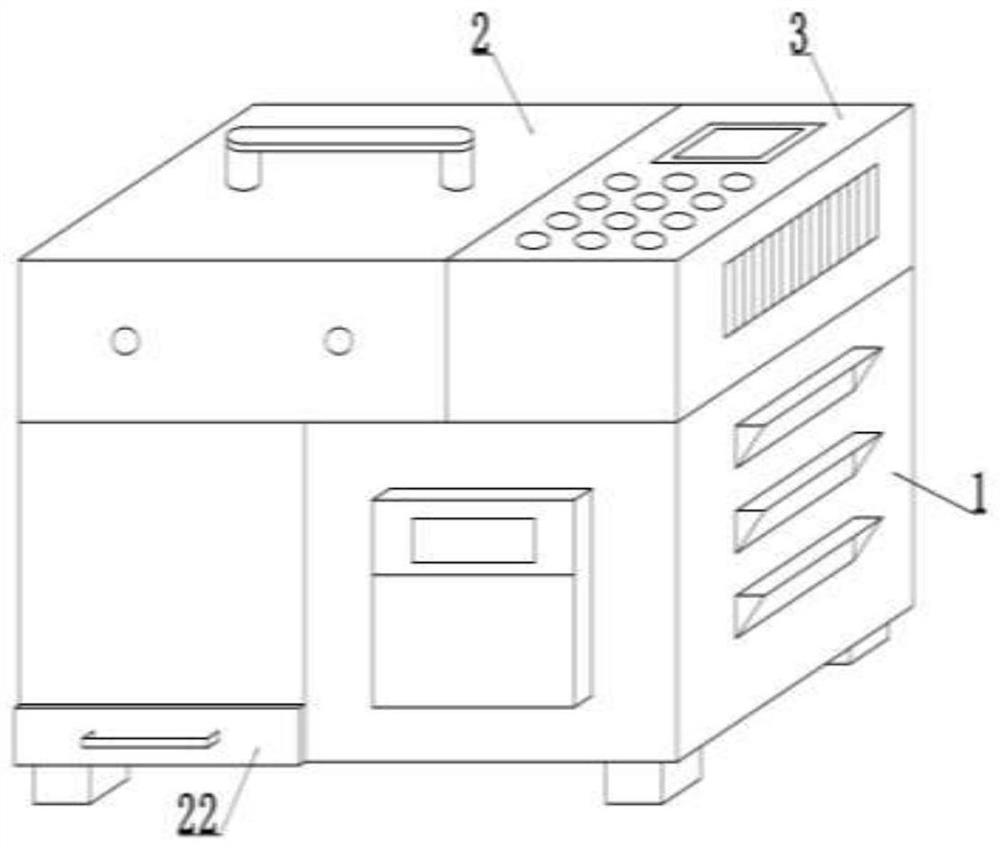

Bread slicing machine

A slicer and bread technology, applied in metal processing, etc., can solve the problem that the thickness of bread slices cannot be accurately grasped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

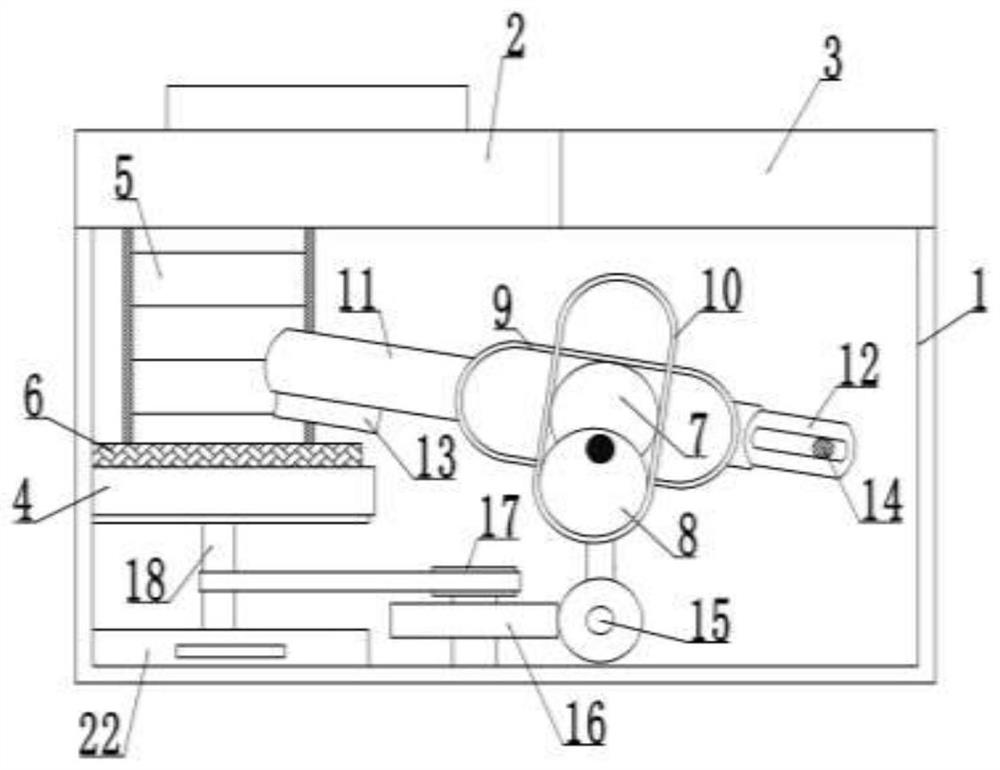

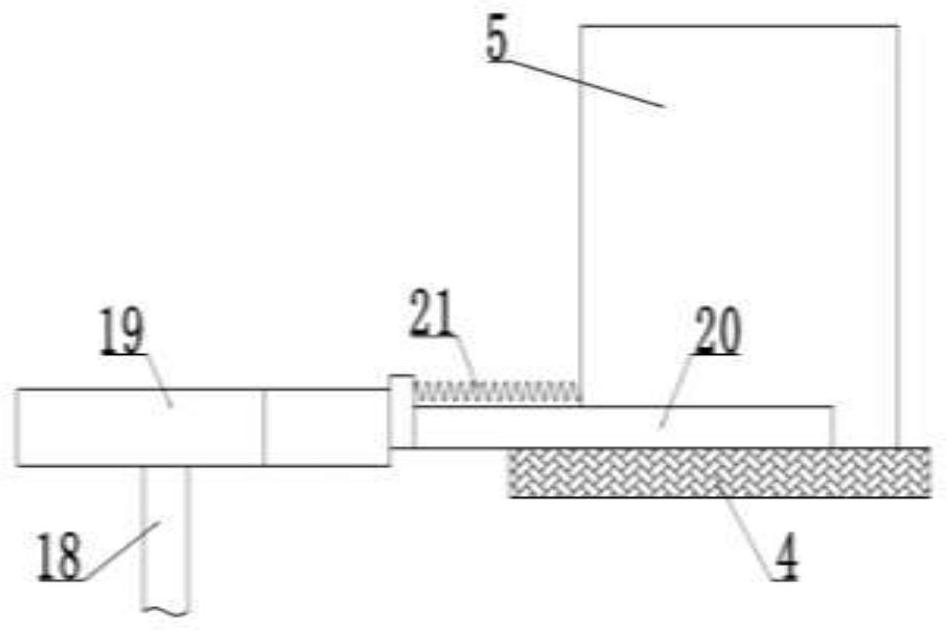

[0028] The specific embodiment: when carrying out batch slicing of bread, open the machine cover 2 at the feeding port, and put the bread to be sliced into the material holding box 5 sequentially through the feeding port. Start the motor, the motor rotates, and drives the first eccentric wheel 7 and the second eccentric wheel 8 connected coaxially with it to rotate, and the first eccentric wheel 7 and the second eccentric wheel 8 are respectively in the first ring member 9 and the second ring member 10 Sliding, the first eccentric wheel 7 drives the first ring member 9 to reciprocate in the horizontal direction during the sliding process in the first ring member 9, and the second eccentric wheel 8 drives the second ring member 10 during the sliding process. The component 10 reciprocates in the vertical direction, and the strut 14 is slidably connected in the elongated mouth, so the first connecting rod 11 drives the cutter 13 to reciprocate up and down and left and right at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com