Optical fiber stripping device

A wire stripping device and optical fiber technology, applied in light guides, optics, optical components, etc., can solve the problems of easily damaged sleeves and Kevlar wires, large shearing force, and hand injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

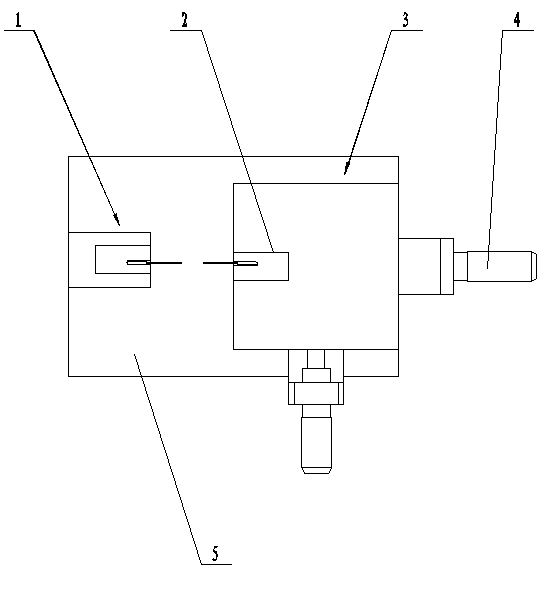

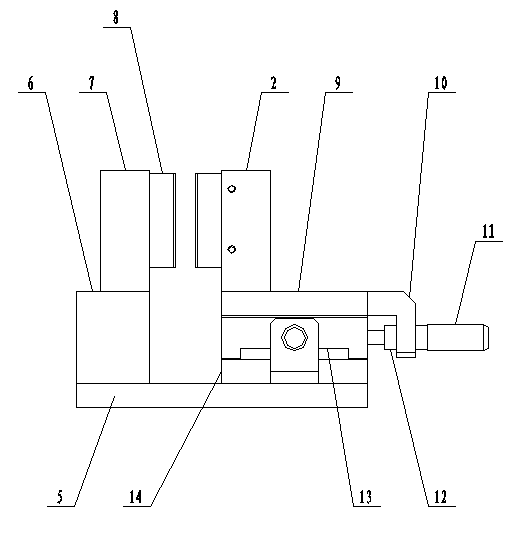

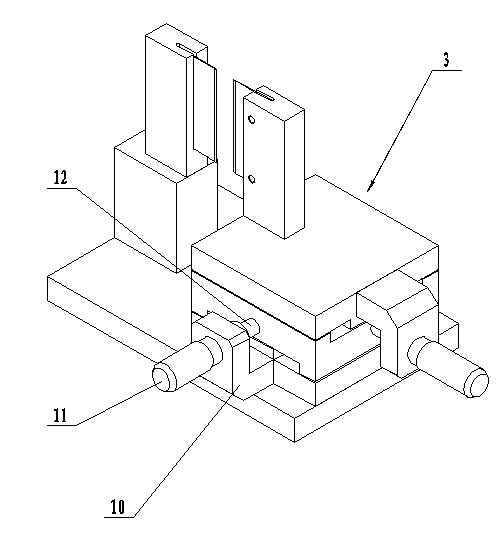

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0015] like Figure 1 to Figure 3 As shown, an optical fiber stripping device includes two parallel-installed cutter assemblies 1, a height block 6, a slide table 3 and a base 5,. The cutter assembly 1 includes a wire stripping blade 8 and a knife holder. The two stripping blades 8 are respectively installed on the left and right relative fixed knife rest 7 and the movable knife rest 2, wherein the fixed knife rest 7 is installed on the height block 6, and the height block 6 is installed on the base 5, which is placed on the left side of the base The position on the side; the movable knife rest 2 is installed on the top layer 9 of the slide table 3, and the slide table 3 is placed on the right side of the base.

[0016] The slide table 3 includes a bottom layer 14 , a middle layer 13 and a top layer 9 connected from bottom to top. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com