Hole-punching and switching mechanism of mould

A switching mechanism and punching technology, which is applied in the field of punching die devices, can solve the problems of high development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

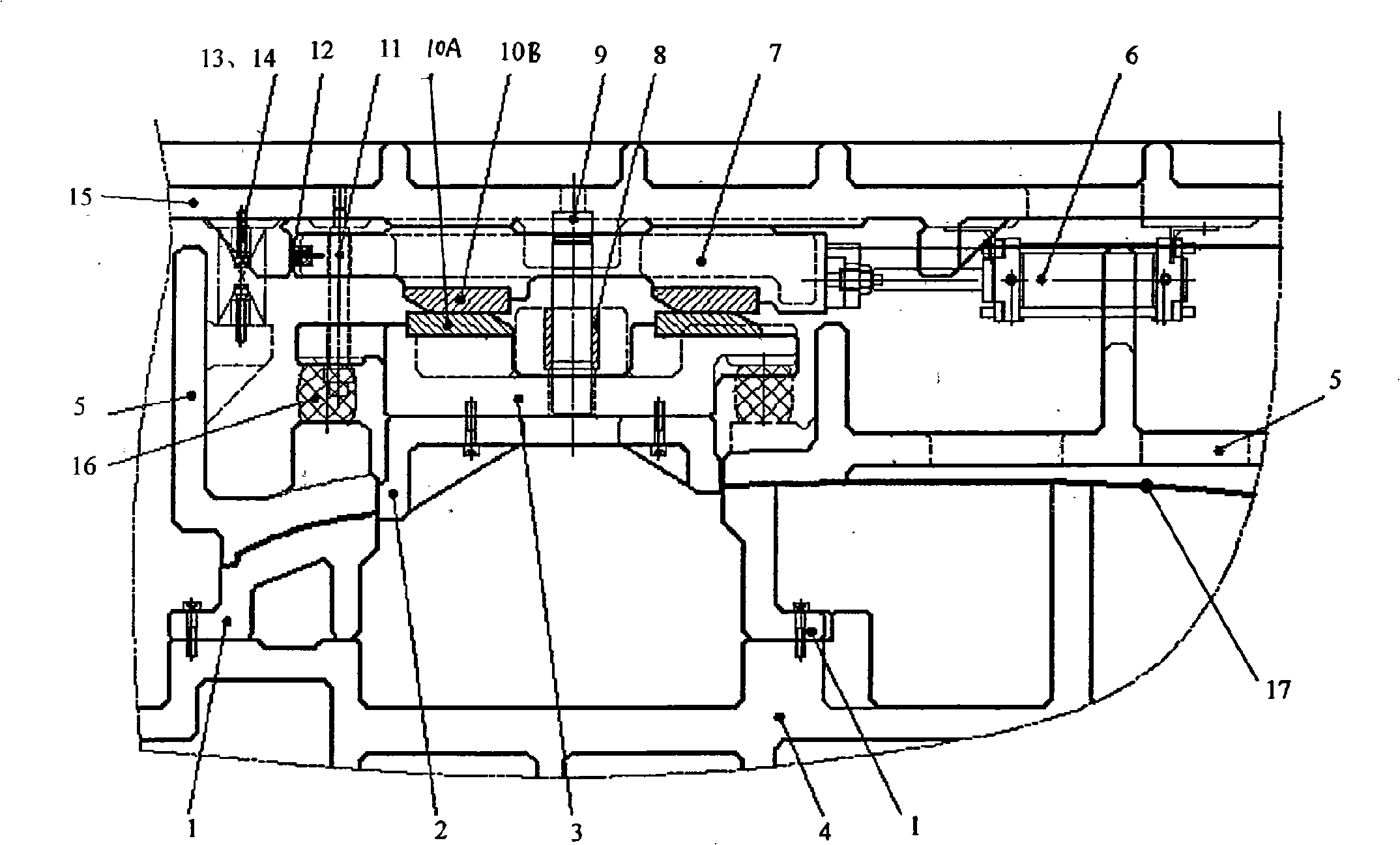

[0011] Taking the production of automobile roof as an example below, the present invention will be described in further detail in conjunction with the accompanying drawings and specific embodiments.

[0012] Such as image 3 As shown, the switching mechanism consists of punching die 1, punching punch 2, punch mounting seat 3, lower die base 4, presser 5, air cylinder 6, driver 7, guide sleeve 8, guide post 9, wedge Sliding plate, safety screw 11, polyurethane buffer pad 12, spring guide pin 13, spring 14, upper mold base 15 and polyurethane spring 16 etc. are formed. The punching die 1 is fixed on the lower die base 4, the punching punch 2 is fixed on the punch mounting base 3, the edge of the punch mounting base 3 is supported on the presser 5 by the polyurethane spring 16, and the punch mounting base 3 The upper part of the upper part is fixed with a wedge slide 10A; the air cylinder 6 is fixed on the upper mold base 15, and its movable end is connected with the driver 7, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com