Cross slider type sliding plug door mechanism

A cross-slider and slider-type technology, which is applied in the door device, railway car body parts, transportation and packaging, etc., can solve the problems of unfixed main shaft, poor main shaft stability, large size, etc., and achieve reliable movement of the sliding door. Effect of increasing reliability and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

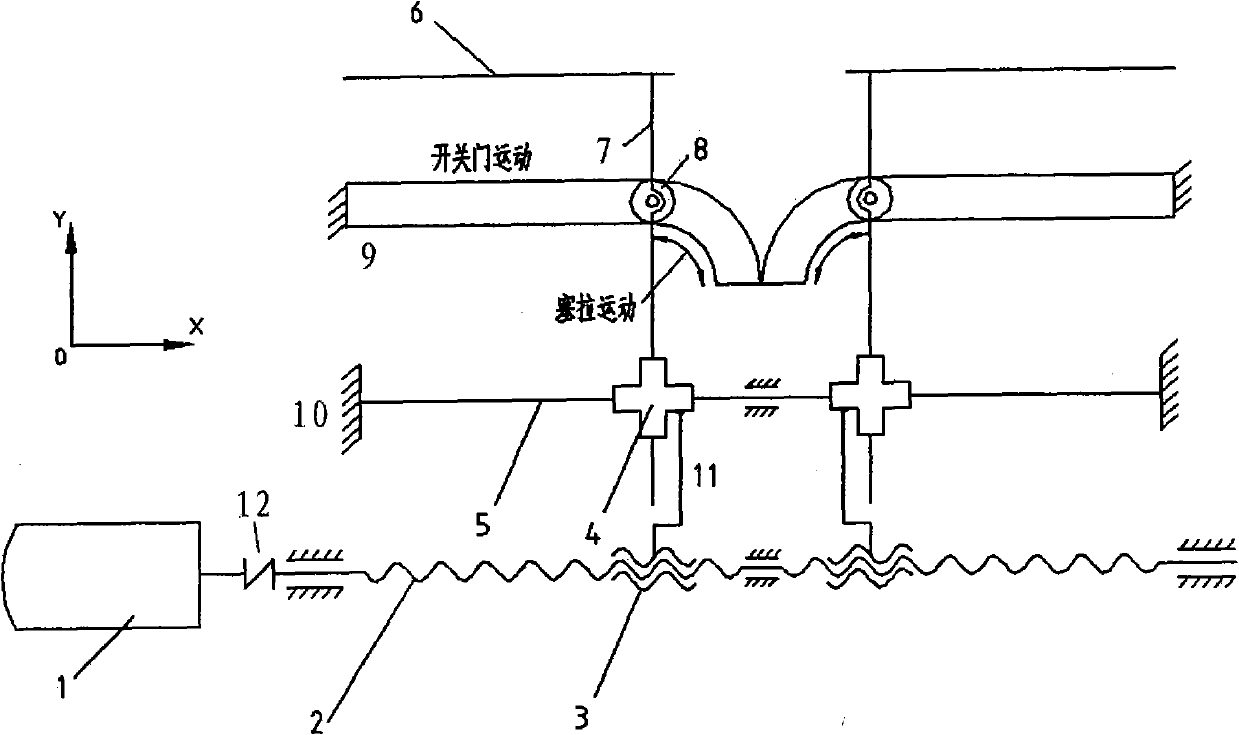

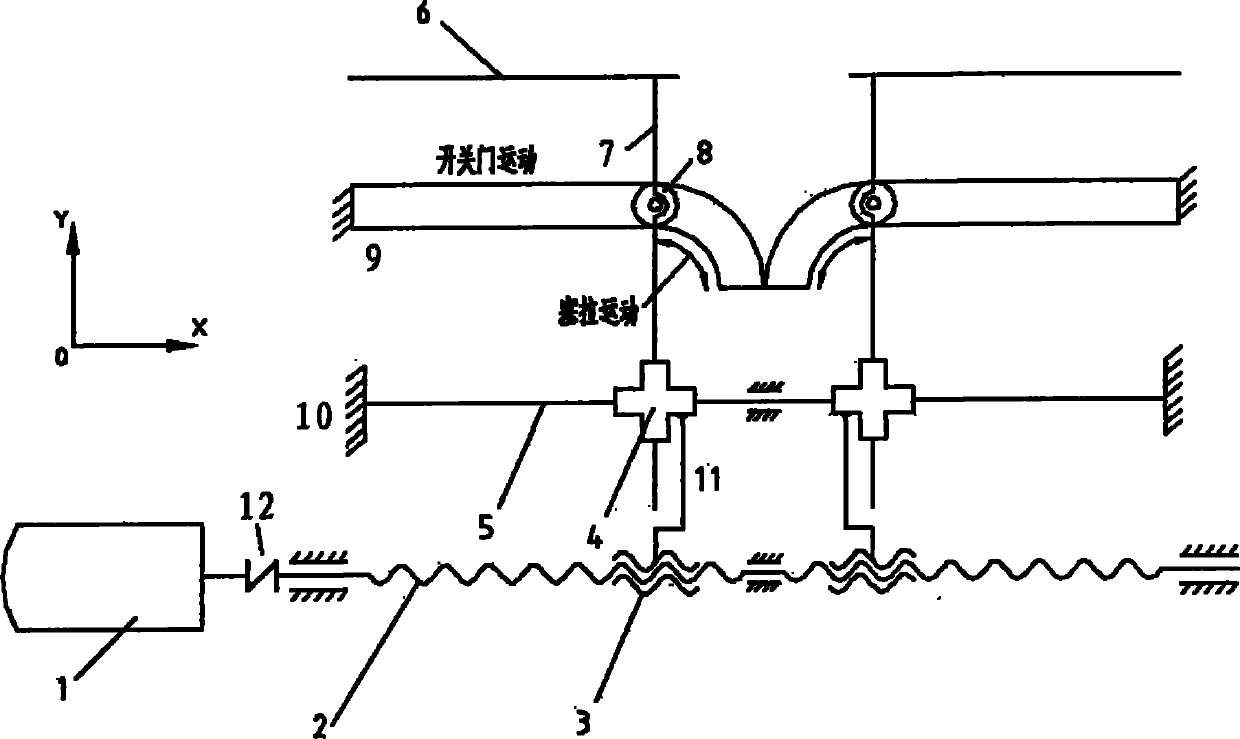

[0013] Refer to attached figure 1 , the cross slider type plug door mechanism consists of a stepping motor 1, a screw 2, a screw nut 3, a support 10, a spindle 5, a cross slider 4, a guide rod 7, a plug door body 6, a guide wheel 8, Guide groove 9 forms.

[0014] The main shaft 5 is fixed on the support 10, one of the holes of the cross slider 4 cooperates with the main shaft 5 and can easily slide along the main shaft 5, and the other vertical hole of the cross slider 4 cooperates with the guide rod 7, and the plug door Body 6 is fixedly connected with this guide rod 7 with screws, and guide wheel 8 is housed on guide rod 7, and guide wheel 8 is limited to move in guide groove 9, and guide groove 9 is made into the shape that straight line adds arc, when guide wheel 8 is in When the cross slider 4 moves along the straight line of the guide groove 9, it will drive the plug door 6 to go straight to realize the opening and closing of the door. When the guide wheel 8 reaches the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com