Barrel butt-joint transfer trolley

A transfer vehicle and cylinder technology, which is applied in the directions of transportation and packaging, manual conveying devices, etc., can solve the problems of difficult cylinder rotation and adjustment, and achieve the effect of ensuring the accuracy of docking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

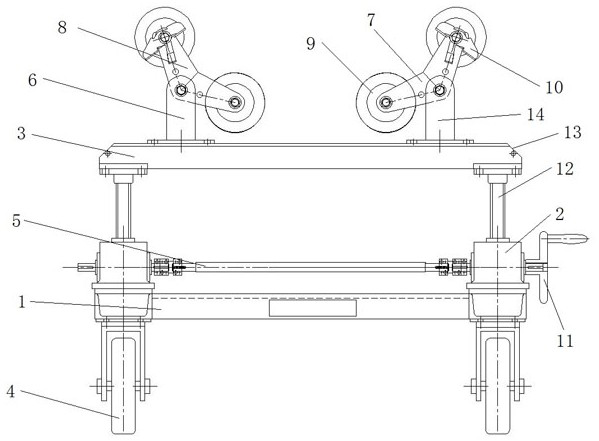

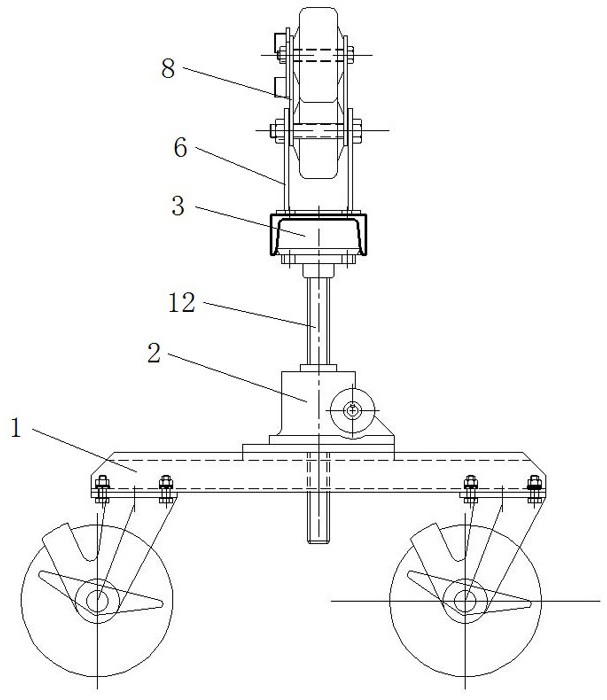

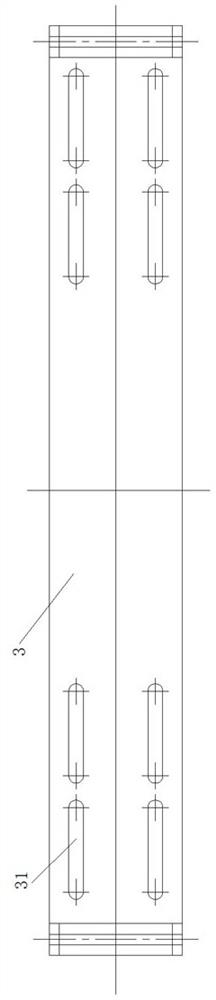

[0033] Such as Figure 1 to Figure 6 As shown, the cylinder docking transfer vehicle includes a vehicle frame, and the vehicle frame includes a base 1, an intermediate support structure 2 and a crossbeam 3, and moving wheels 4 are respectively installed at the four corners of the bottom of the base 1, and the four moving wheels 4 are universal wheel. The intermediate supporting structure 2 is supported and assembled between the base 1 and the beam 3 for adjusting the height of the beam 3 .

[0034] Left and right wheel frames are arranged symmetrically along the left and right directions on the beam 3. The left wheel frame includes a left wheel frame base 6 and a left wheel frame body 8. The left wheel frame body 8 is hingedly assembled on the left wheel frame base 6. The right wheel frame includes a right wheel frame. The base 14 and the right wheel frame body 7 are hingedly assembled on the right wheel frame base 14 .

[0035] Two support wheels 9 are respectively arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com