A Robotic Spiral Hole Making System

A robot and screw technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of small hole diameter, large axial force, low processing efficiency, etc. The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

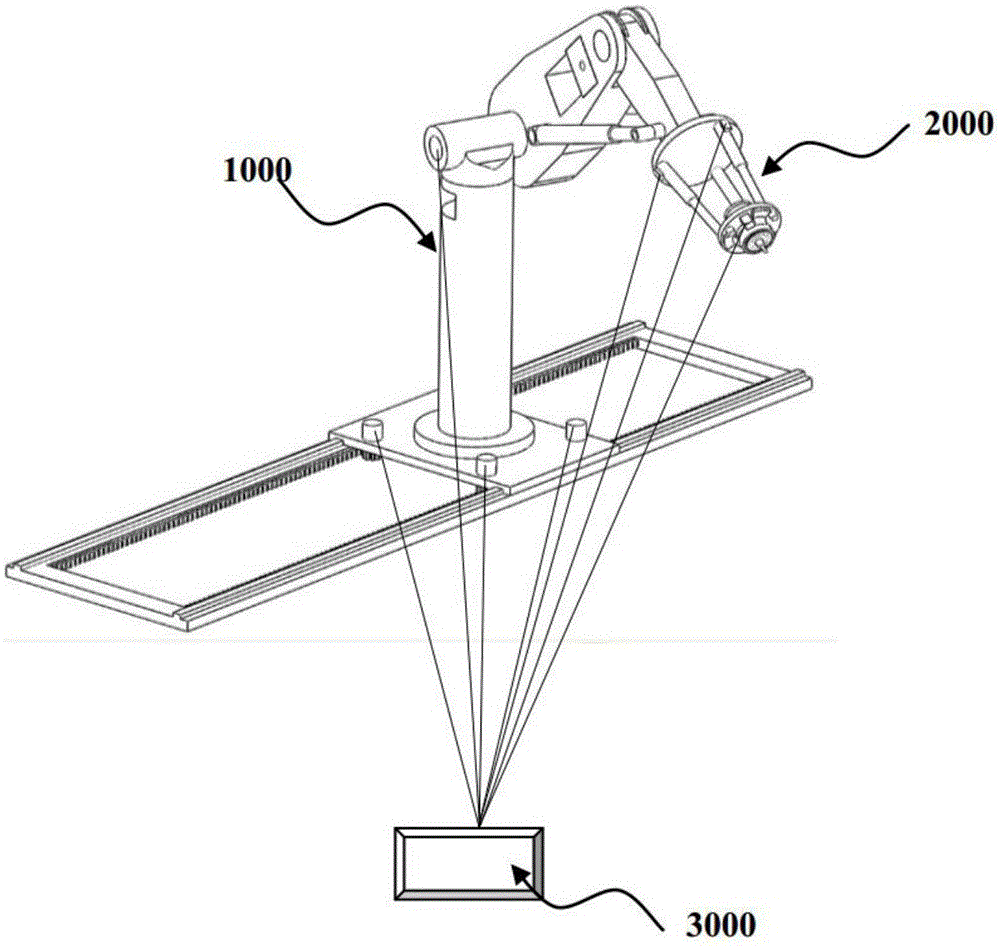

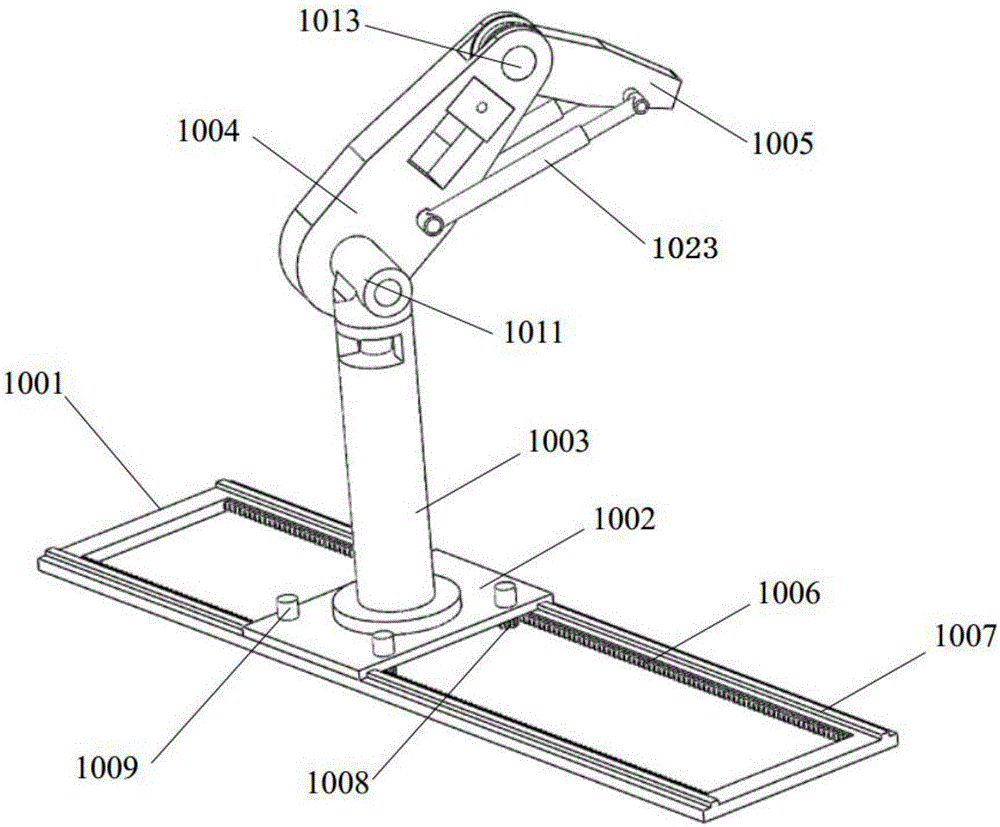

[0029] like Figure 1-9 As shown, the robotic screw drilling system of the present invention includes a four-degree-of-freedom serial robot 1000, a terminal drilling unit 2000, and a system controller 3000;

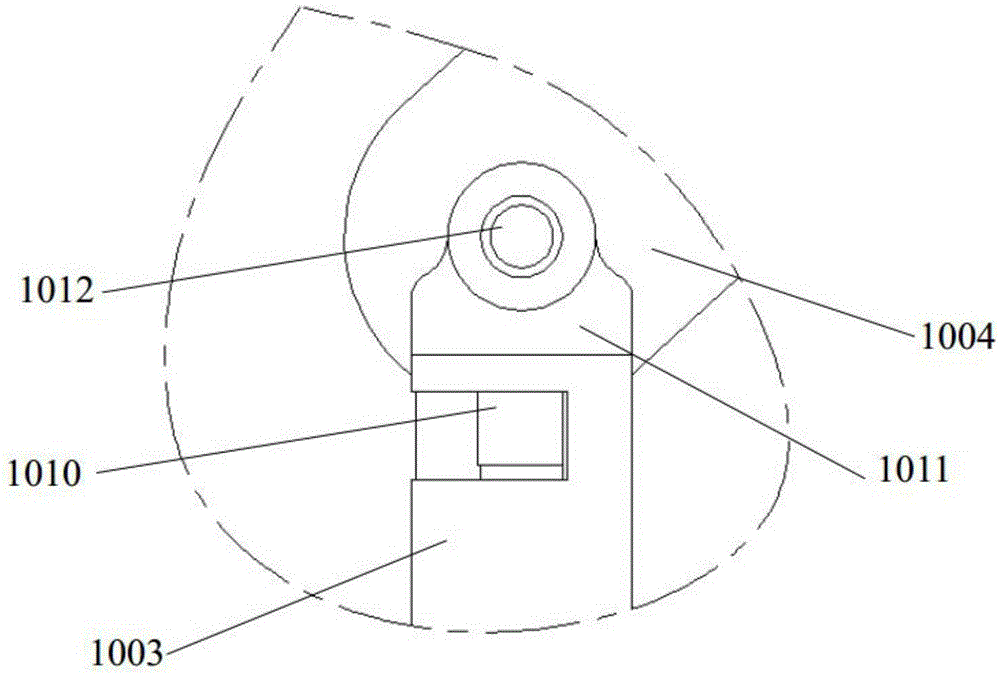

[0030] Among them, the four-degree-of-freedom serial robot 1000 includes a rectangular frame base 1001, a supporting plate 1002, a column 1003, a large arm 1004, and a small arm 1005; a longitudinal rack 1006 is provided on the opposite inner sides of the two length frames of the rectangular frame base 1001, Longitudinal guide rails 1007 are provided on the upper sides of the two length frames; two bottom slide grooves are provided on the bottom surface of the pallet 1002, and the two bottom slide grooves are respectively embedded in the two longitudinal guide rails 1007, and can be moved along the two longitudinal guide rails. The guide rail 1007 slides back and forth; a longitudinal driving motor 1009 is respectively provided at the four corners of the supporting plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com