Segmental comparison processing method for reinforcement cage

A processing method and steel cage technology, which is applied in the field of bridge engineering, can solve problems such as uneven spacing of main reinforcement cages, increase the risk of pile hole collapse, and affect pile foundation construction efficiency, so as to improve construction efficiency, shorten process cycle time, Guarantee the effect of the overall construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

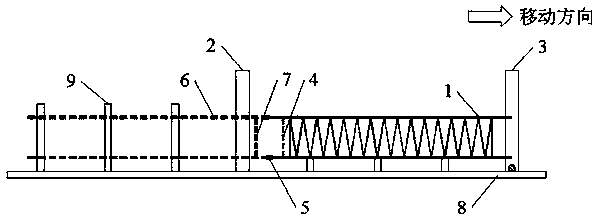

[0025] Example: In the process of using the seam welding machine to process the steel cage of bridge pile foundation, when the length of the steel cage is longer than that of the seam welder, it must be processed in sections. . When the reinforcement cage is lengthened, each main reinforcement at the segmental joint must be mechanically connected one by one. Due to the large number of main reinforcements in a reinforcement cage, in order to ensure that the reinforcement cages of each segment can be quickly connected after being transported to the site, it is necessary to ensure that the positions and lengths of each main reinforcement of the reinforcement cage are accurately matched.

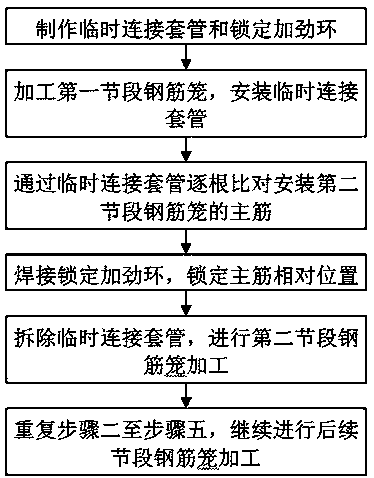

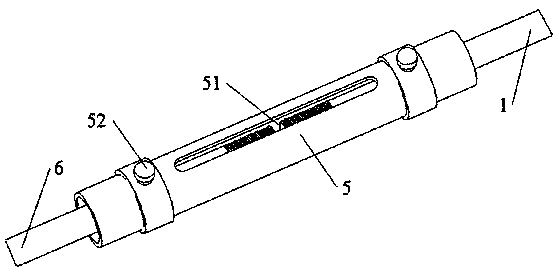

[0026] In order to achieve this purpose, the present invention provides a segmental comparison processing method for steel cages. In the process of segmental processing of steel cages using a seam welding machine, the main bars of the processed segmental reinforcement cages are used as a referen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com