Integrated fixture of laser chip

A chip and laser technology, used in manufacturing tools, workpiece clamping devices, parts of electrical measuring instruments, etc., can solve the problems of easy blockage of vacuum holes, deviation from the initial position, increase processing difficulty, etc., and reduce the loading time. Difficulty, Guaranteed Accuracy, Ingenious Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

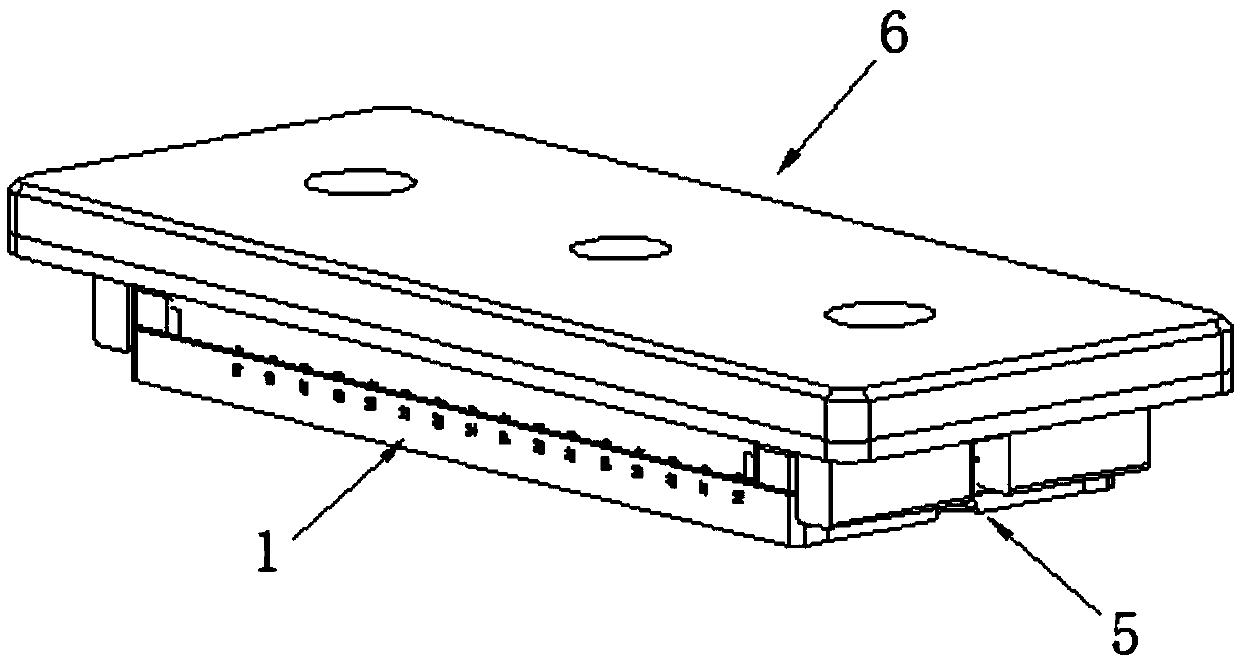

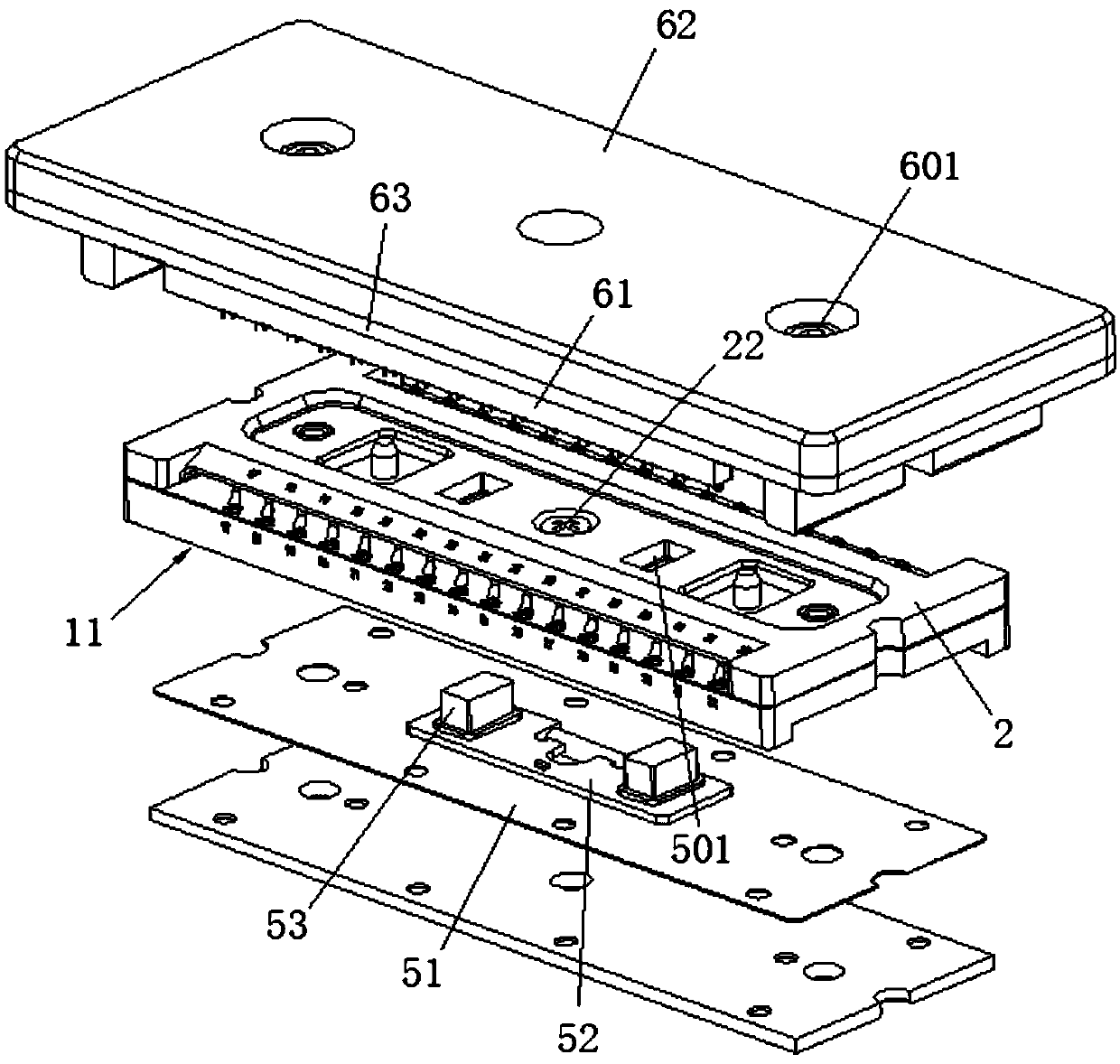

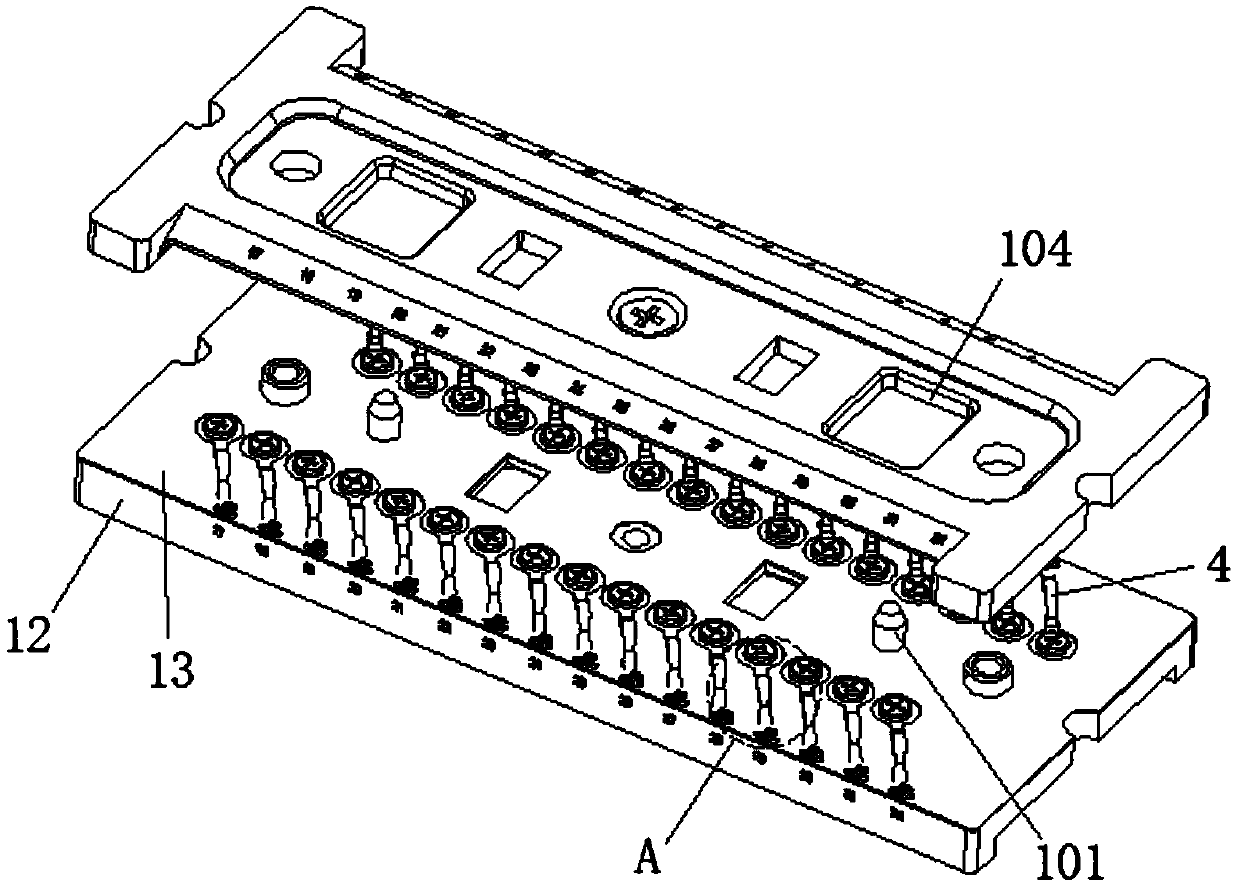

[0029] Embodiment 1: A kind of integrated fixture of laser chip, refer to attached Figure 1-6 , including a chip positioning seat 1 for loading a chip 7, a test assembly 6 and a heating assembly 5, the test assembly 6 is located above the chip positioning seat 1, the heating assembly 5 is located below the chip positioning seat 1, and the chip positioning seat 1 includes a base 11, a shrapnel 4 installed on the base 11 and a shrapnel gland 2 located above the base 11. The upper surface of the base 11 is provided with a number of positioning grooves 3 for inserting the chip 7. The shrapnel 4 includes The connecting part 41 on the 11, the deformation part 42 bent to the side of the shrapnel gland 2, and the positioning part 43 located in the positioning groove 3, the connecting part 41 and the positioning part 43 are connected by the deformation part 42, and the positioning groove 3 There is a positioning right angle 31, the end of the positioning part 43 is provided with a rig...

Embodiment 2

[0035] Embodiment 2: a kind of integrated fixture of laser chip, refer to attached Figure 1-6 , including a chip positioning seat 1 for loading a chip 7, a test assembly 6 and a heating assembly 5, the test assembly 6 is located above the chip positioning seat 1, the heating assembly 5 is located below the chip positioning seat 1, and the chip positioning seat 1 includes a base 11, a shrapnel 4 installed on the base 11, and a shrapnel gland 2 located above the base 11. The upper surface of the base 11 is provided with a number of positioning grooves 3 for inserting the chip 7. The shrapnel 4 includes The connecting part 41 on the 11, the deformation part 42 bent to the side of the shrapnel gland 2, and the positioning part 43 located in the positioning groove 3, the connecting part 41 and the positioning part 43 are connected by the deformation part 42, and the positioning groove 3 There is a positioning right angle 31, the end of the positioning part 43 is provided with a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com