Rapid connecting and replacing device and method for robot end effector

An end effector and robot technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of time-consuming, laborious and difficult end effectors, and achieve the effect of fast disassembly and assembly process, good reliability and large load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

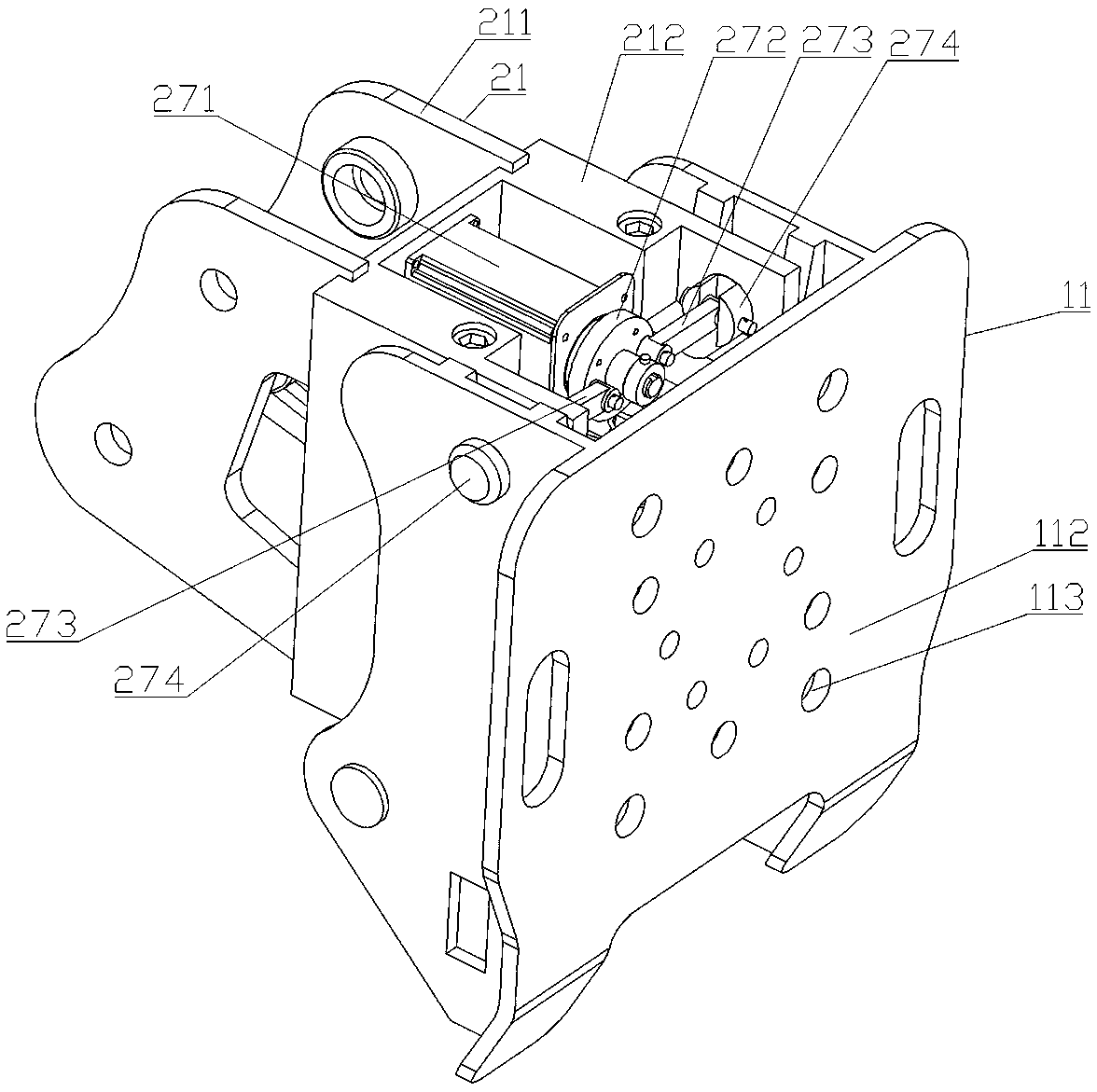

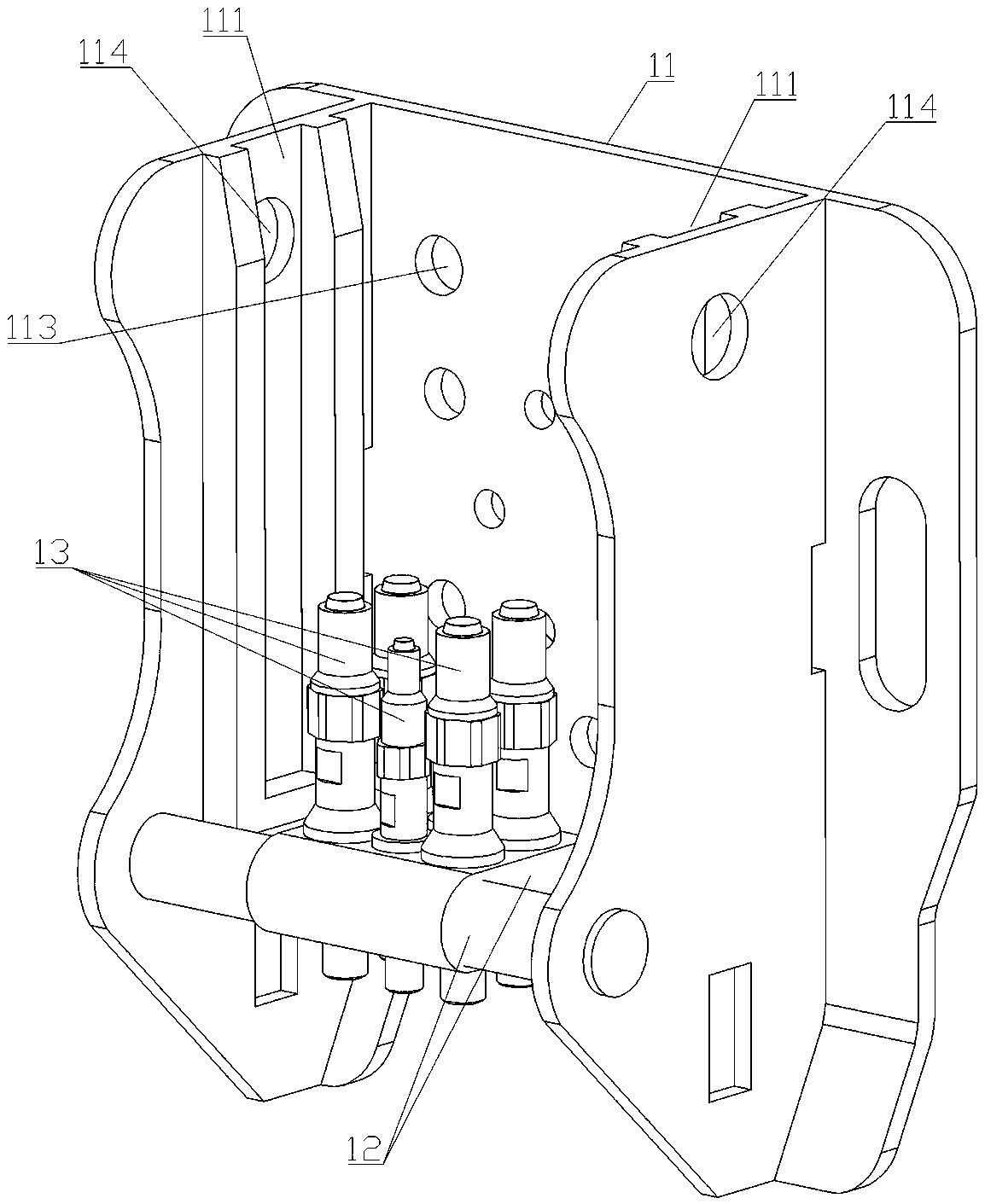

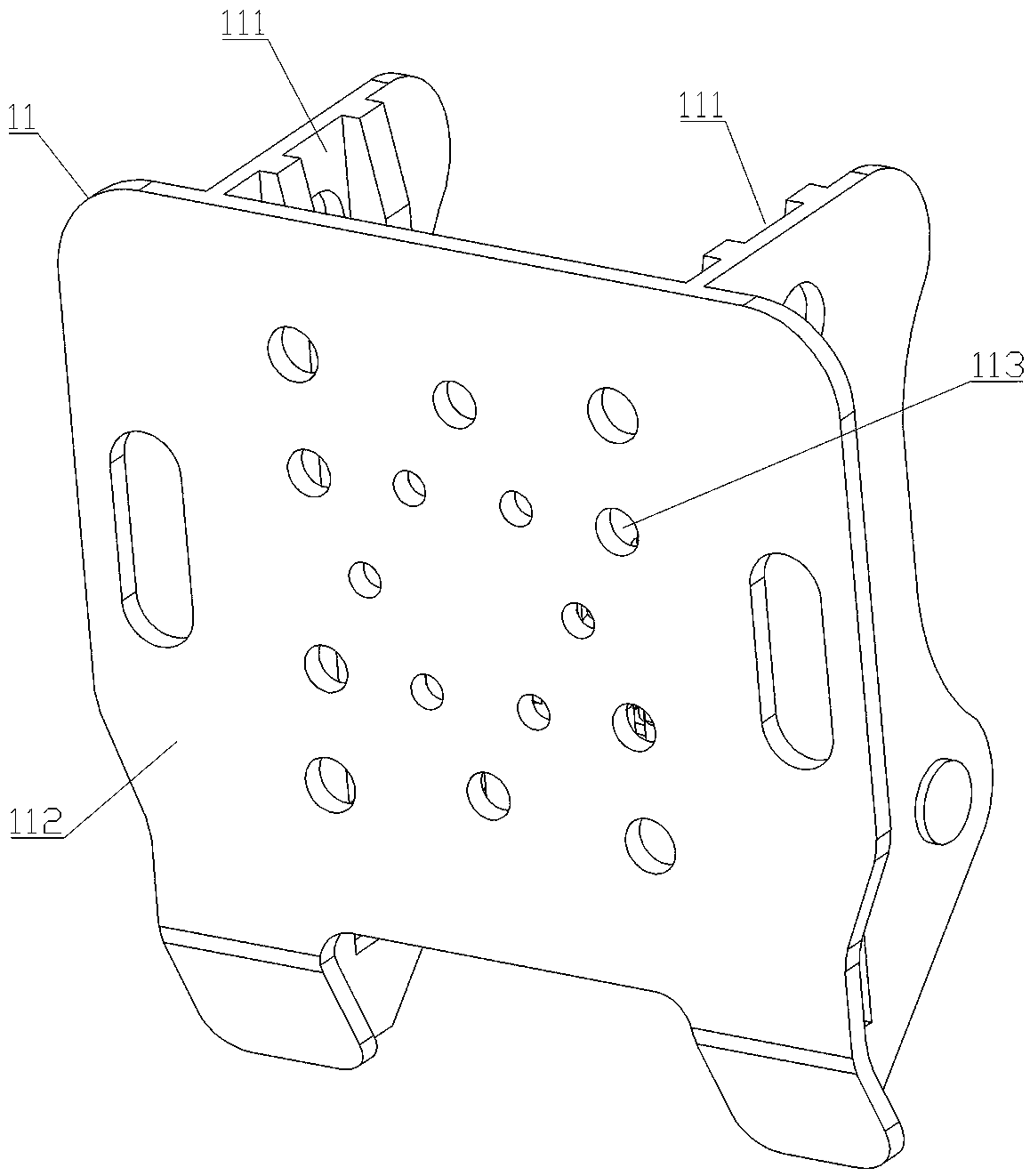

[0041] Such as Figure 1-7 As shown, the quick-change device for the end effector of the robot includes a first assembly and a second assembly.

[0042] The first assembly includes a tool tray 11 , a male connector seat 12 and a male connector 13 . The tool tray 11 is provided with an engaging portion A111 and a tool connecting surface 112 , and the tool connecting surface 112 is provided with a tool mounting hole 113 . A pin hole A114 is also provided on the tool tray 11 .

[0043] The male connector seat 12 is fixedly mounted on the tool tray 11 .

[0044] The male connector 13 is mounted on the male connector seat 12 .

[0045] The second assembly includes a connection seat 21 , a female joint 22 , a female joint seat 23 , a guide rod 24 , a spring 25 , a limiting block 26 and a locking assembly.

[0046] Two ends of the connecting seat 21 are respectively a robot docking end 211 and a tool tray docking end 212 , and the tool tray docking end 212 is provided with an eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com