Installation method of special-shaped and curved-surface suspension type steel structure system

An installation method and hanging technology, which is applied in special structures, building components, building structures, etc., can solve the problems of difficulty in guaranteeing construction accuracy, long construction period, and many hidden dangers at high altitudes, and achieve reduced construction costs, high installation efficiency, and The effect of reducing operational security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

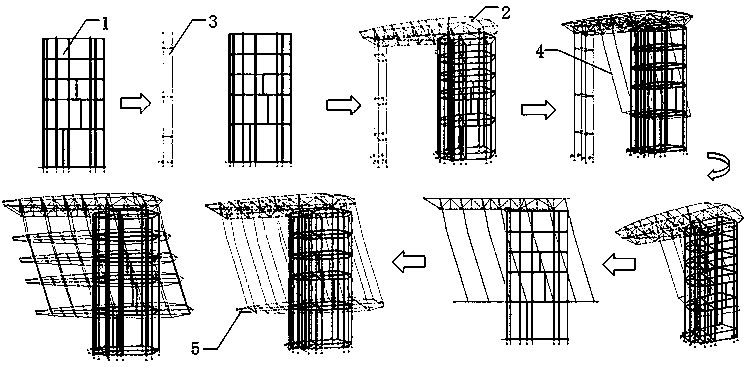

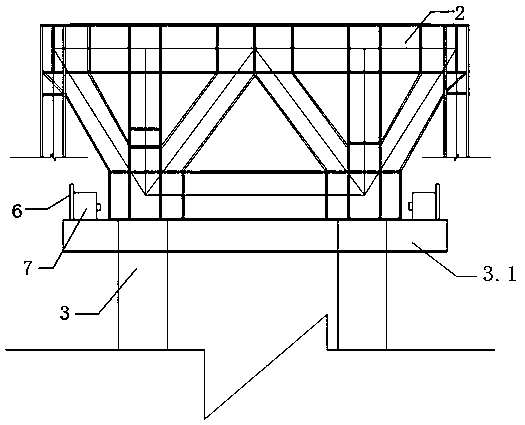

[0047] In conjunction with the description of the accompanying drawings, the specific embodiments of the present invention are further described:

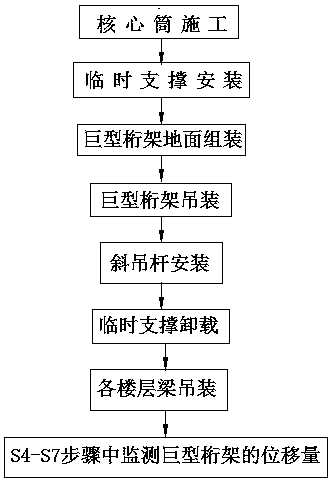

[0048] refer to Figure 1-Figure 4 , the present invention provides an installation method of a special-shaped, curved surface suspended steel structure system, including a core tube 1, a giant truss 2, a temporary support 3, an inclined suspender 4 and each floor beam 5; the installation method is as follows:

[0049] S1: Construction of the core tube 1; the core tube 1 is equipped with steel bars and stiff columns for supporting the giant truss 2;

[0050] Build the steel frame of the core tube 1, process the stiff column, review the baseline of the stiff column before leaving the factory, and install the stiff column; the stiff column is lifted by a truck-type crane, and the lifting safety factor is selected as 1.25. Before hoisting, according to the site and the occupancy conditions of the crane, carry out three-dimensional si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com