Trolley for open cut culvert and tunnel wall reinforcement mesh frame horizontal moving assembly system and construction method

A steel grid frame and assembly system technology, which is applied in hoisting devices, portable lifting devices, etc., can solve problems such as full coverage of hoisting in areas where construction cannot be carried out, restrictions on the size and weight of steel bars, energy and material consumption, etc., to achieve simple structure and reduce Maintenance cost, effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

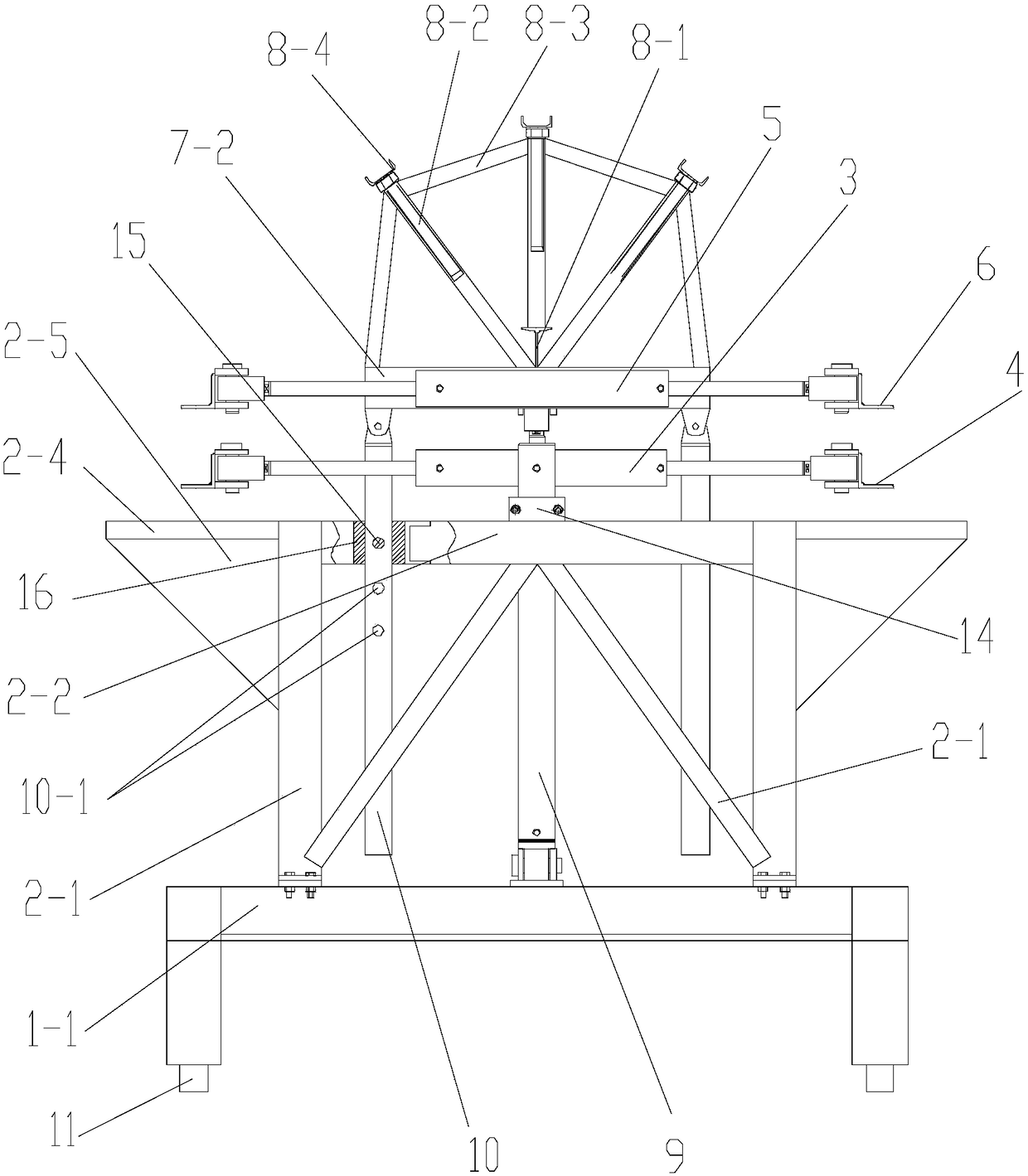

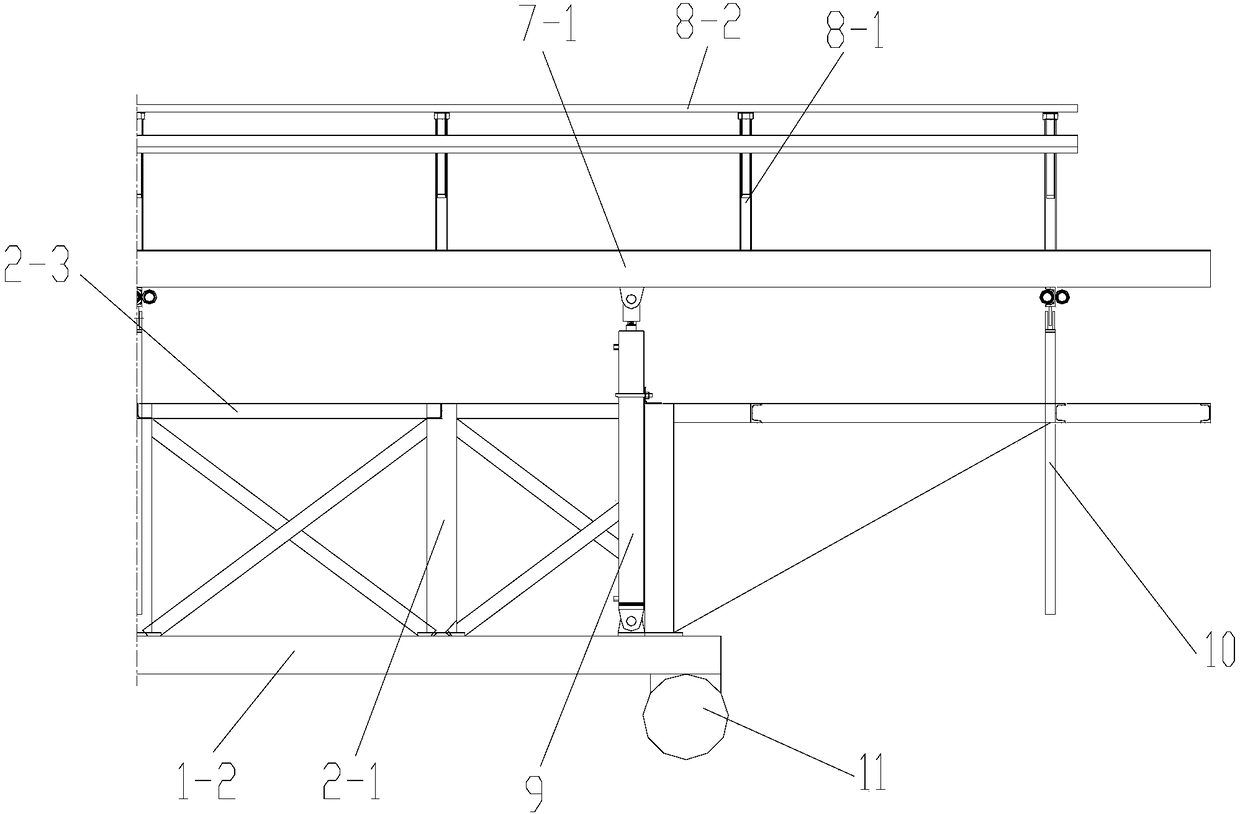

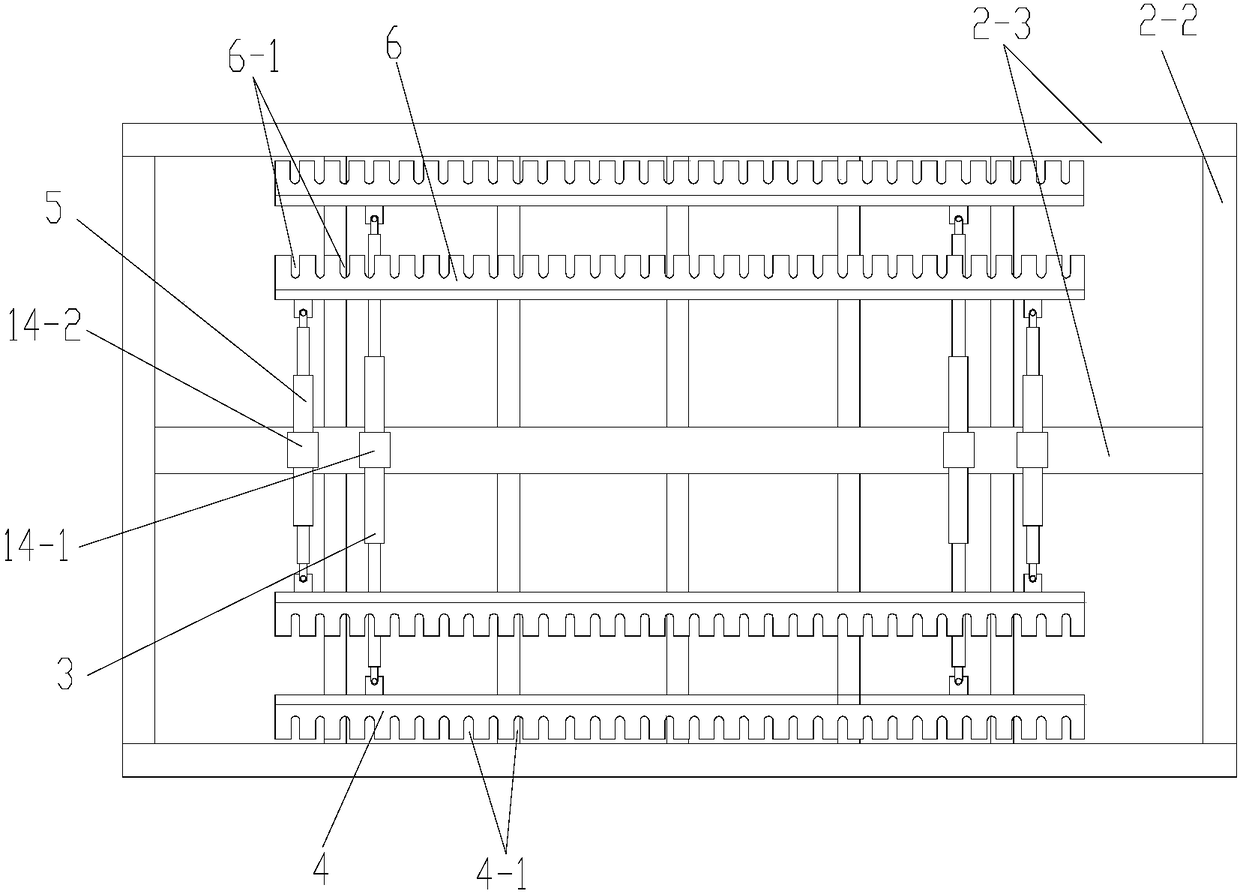

[0058] Such as figure 1 , figure 2 , image 3 with Figure 7 Shown is a trolley for the translational assembly system of open-cut culverts and tunnel pipe wall reinforced grid frames, including a bottom frame, a main body frame set above the bottom frame, and a walking mechanism set below the bottom frame, and a set The jacking device on the main frame and the horizontal positioning device for aligning the relative position of the inner layer joint steel bar 12 of the abutment steel bar grid frame and the relative position of the inner layer joint steel bar 13 of the arch body steel bar grid frame, the jacking device includes vertical The jacking oil cylinder 9 installed directly on the bottom frame, the horizontal frame arranged on the top of the extended end of the jacking oil cylinder 9, the bracket arranged above the horizontal frame and the auxiliary frame arranged below the horizontal frame The support rod 10, the auxiliary support rod 10 is fixedly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com