Crystal blank automatic polishing system and docking mechanism thereof

A docking mechanism and docking machine technology, applied in grinding/polishing equipment, grinding machines, spherical grinders, etc., can solve problems such as low processing efficiency, difficulty in removing fixtures, and long waiting time, so as to improve processing efficiency and ensure bonding Firmness and the effect of shortening the occupation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

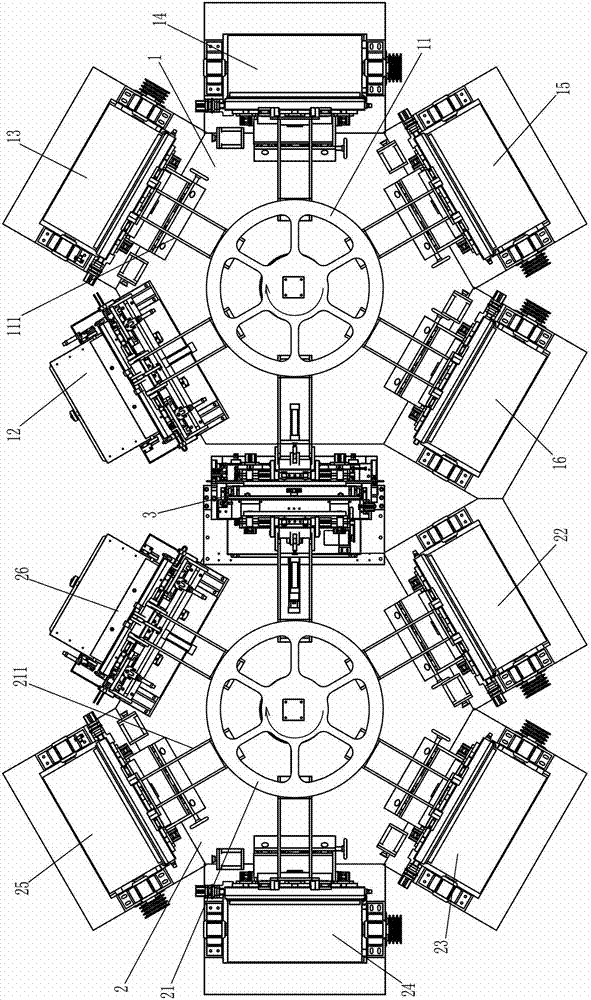

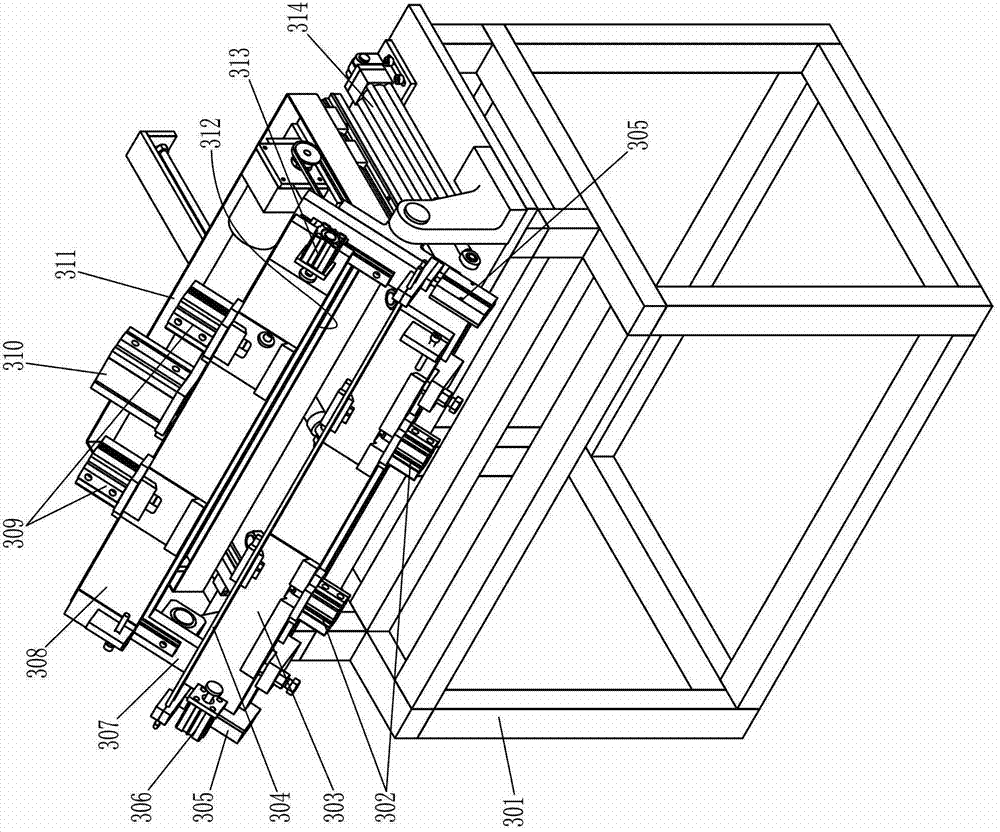

[0032] Such as figure 1 A kind of crystal blank automatic grinding and polishing system shown, comprises: the first rotating frame 11 that is installed on the first frame 1, is provided with feeding station 12, two pairs of crystal blanks around the first rotating frame 11 The upper hemisphere grinding station 13,14 for grinding the upper hemisphere of the upper hemisphere of the crystal blank, the upper hemisphere polishing station 15,16 and the docking station 3 for polishing the upper hemisphere of the crystal blank, the first rotating frame 11 It can be rotated and positioned and is provided with six manipulators 111 capable of picking up and putting down fixtures; the second rotating frame 21 installed on the second frame 2 is provided with the docking station 3, two Lower hemisphere grinding stations 22, 23 for grinding the lower hemisphere of the crystal blank, two lower hemisphere polishing stations 24, 25 and blanking station 26 for polishing the lower hemisphere of t...

Embodiment 2

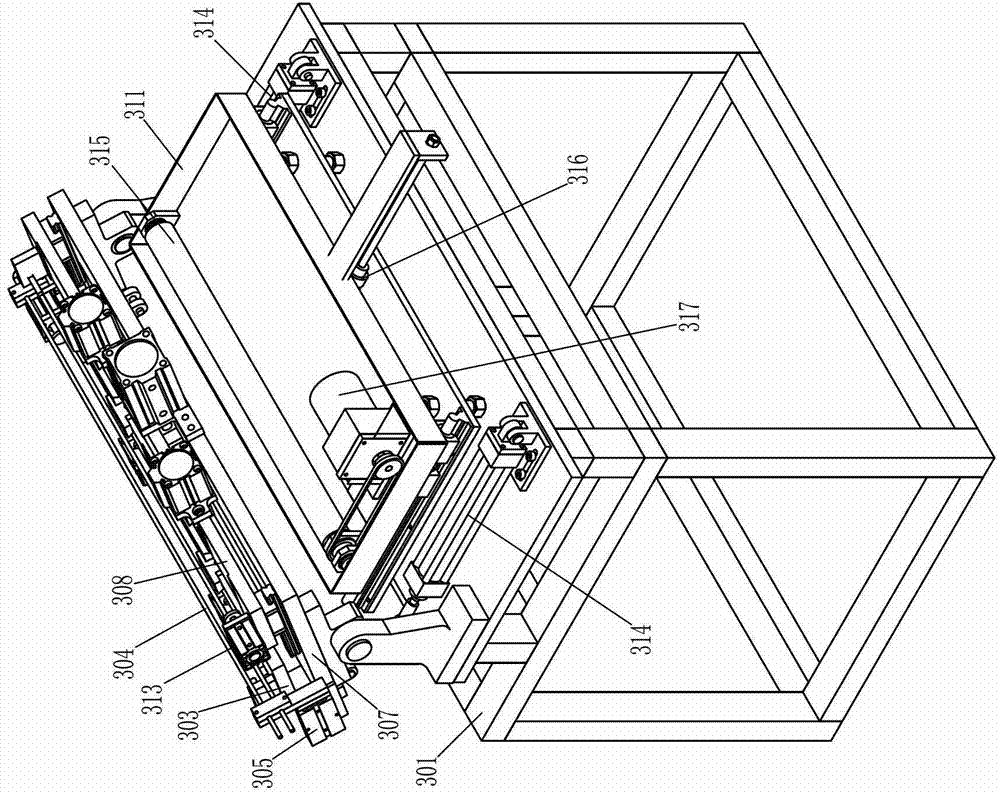

[0037] An automatic grinding and polishing system and docking mechanism for crystal blanks, the only difference from Embodiment 1 is that the mounting plate 307 has two rotation stop positions: when the mounting plate 307 rotates to the first rotation stop position, the mounting plate 307 is In the vertical state, the second clamp seat 308 is located above the first clamp seat 303; as Figure 7 As shown, when the mounting plate 307 rotates to the second rotation stop position, the mounting plate 307 is in a horizontal state, and the first clamp seat 303 and the second clamp seat 308 are both on the mounting plate 307 .

Embodiment 3

[0039] An automatic grinding and polishing system for crystal blanks, comprising: a first rotating frame, at least one upper hemisphere grinding station for grinding the upper hemisphere of the crystal blank and at least one pair of crystal blanks are arranged around the first rotating frame The upper hemisphere polishing station for polishing the upper hemisphere of the workpiece, the first rotating frame can be rotated and positioned and is provided with at least two machine heads capable of installing fixtures; the second rotating frame is provided with at least one pair of The lower hemisphere grinding station for grinding the lower hemisphere of the crystal blank and at least one lower hemisphere polishing station for polishing the lower hemisphere of the crystal blank, the second rotating frame can be rotated and positioned and is provided with at least two A machine head capable of installing fixtures; feeding station is provided with a feeding mechanism that can fix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com