Bag feeding manipulator

A technology of manipulators and upper arms, applied in the field of manipulators, can solve the problems of complex structure, low production efficiency, poor reliability, etc., and achieve the effect of simple structure and action, easy maintenance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings and embodiments.

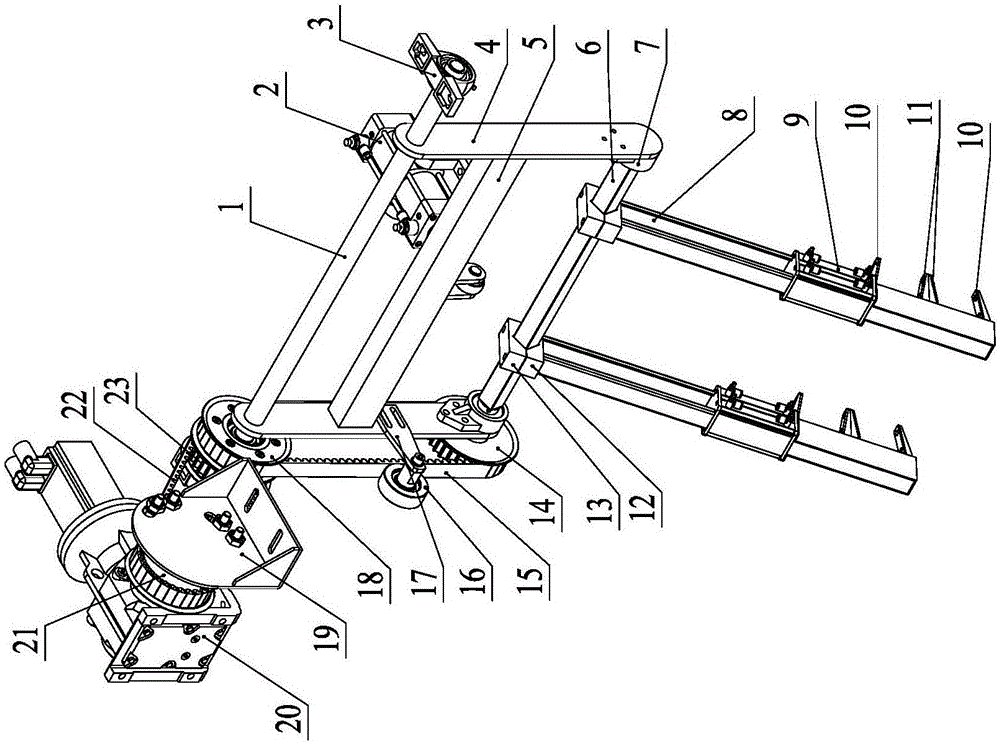

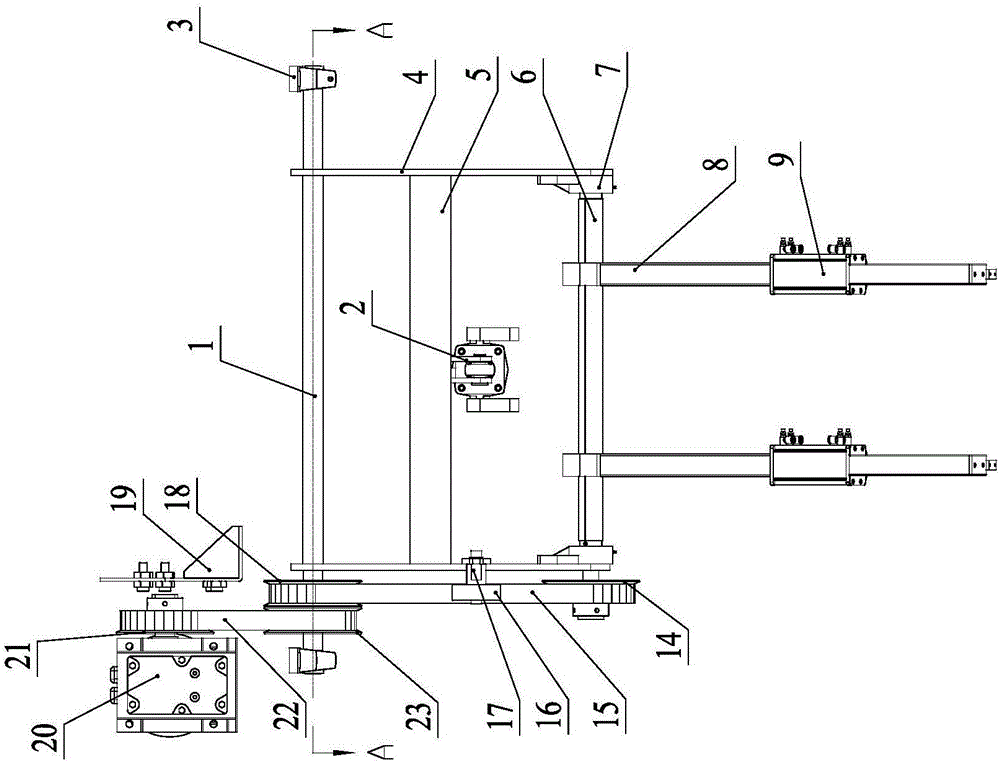

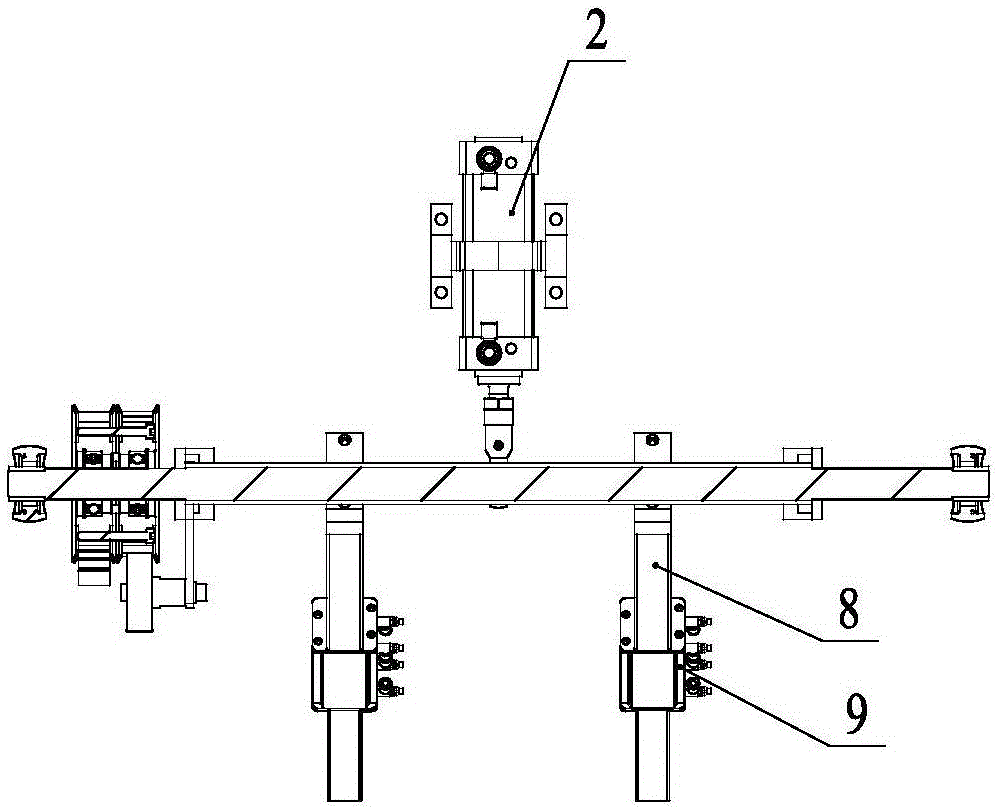

[0022] As shown in the figure: the bag-loading manipulator in the embodiment is mainly composed of a support shaft 1, a first bearing with seat 3, a driving wheel 18, an upper arm 4, a second bearing with a seat 7, a swing shaft 6, a driven wheel 14, a first synchronous Belt 15, push-pull cylinder 2, driving mechanism and bag clamping and supporting mechanism; the two ends of the support shaft 1 are respectively supported and installed in two first bearings with seats 3, and the two first bearings with seats 3 are fixed during installation and use. On the equipment frame, the supporting shaft 1 is driven to rotate through the driving structure, and a driving wheel 18 is installed at the end of the supporting shaft 1; the two upper arms 4 are arranged parallel to each other, and the upper ends of the two upper arms 4 are respectively connected to the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com