A 90° angle tire transfer device

A conveying device and tire technology, which is applied to conveyor objects, transportation and packaging, etc., can solve problems such as appearance quality defects, potential safety hazards, and scratched tires, so as to avoid tire appearance damage, save energy, and reduce friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

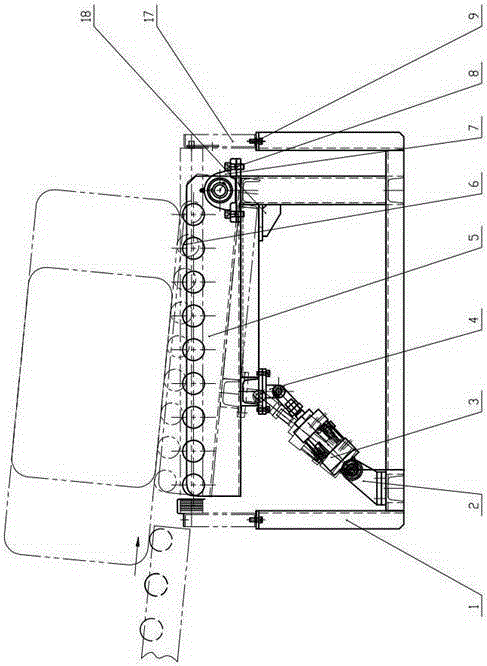

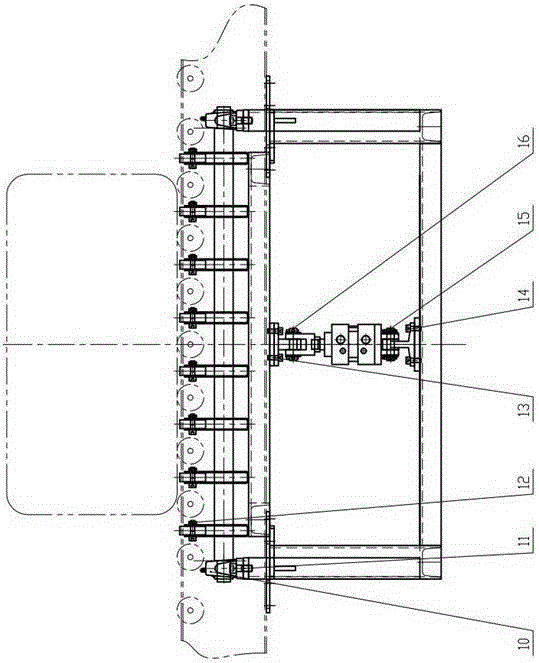

[0028] Embodiment: This embodiment is a 90° angle tire transfer device applied to the defective product discharge conveyor line of the finished tire inspection line. A 90° angle tire transmission device of the present invention consists of a frame body (1), a cylinder base (2), a cylinder assembly (3), a single lug seat (4), a swing arm (5), a wheel (6), and a bearing I (7), screw fixing assembly I (8), screw fixing assembly II (9), bearing II (10), screw fixing assembly III (11), screw fixing assembly IV (12), screw fixing assembly V (13), The screw fixing assembly VI (14), the pin shaft I (15), the pin shaft II (16), the vertical conveying roller table frame (17) and the mechanical limit plate (18) are composed.

[0029] For tires with an outer diameter of 400-850mm, the swing arm uses 8 sets of U-shaped grooves, and each set of U-shaped grooves is equipped with 9 wheels (6). The distance between each set of U-shaped grooves is 100mm, and the distance between the wheels is 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com