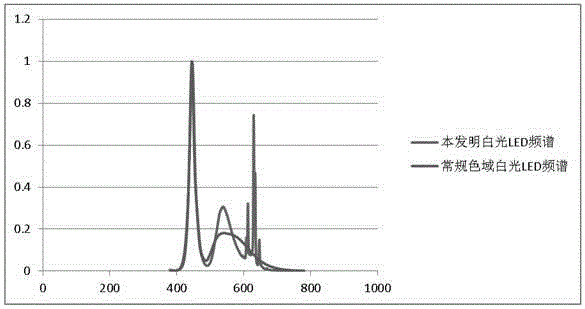

Preparation method of high-gamut white-light LED by using green fluorescent powder matched with red fluorescent powder

A technology of red fluorescent powder and fluorescent powder, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low color reproduction, low color saturation, and low color gamut coverage of white LED backlight. Achieve the effect of adjustable color gamut coverage and high light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

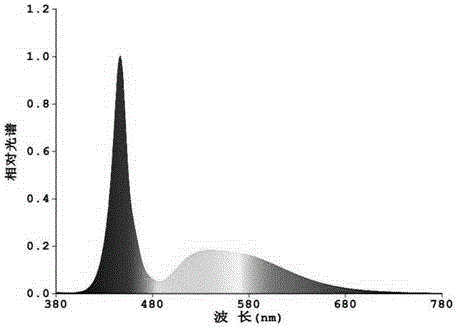

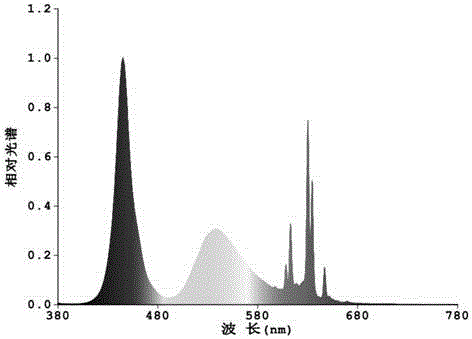

[0022] A mixed phosphor that uses green light and red light, and the green phosphor is Si 6-Z Al Z o Z N 8-Z :Eu green phosphor,

[0023] Red phosphor is K x GeF y :Mn 4+ Red phosphor.

[0024] The emission wavelength of the blue light chip used to excite green light phosphors and red light phosphors is 445-465nm: Si used in the present invention 6-Z Al Z o Z N 8-Z :Eu green phosphor and K x GeF y :Mn 4+ Red light phosphor, its excitation peak is located in the range of 280-480nm; because the strong blue light and ultraviolet light produced when it is less than 445nm will cause harm to human eyes, further the wavelength used in the present invention is greater than 445nm, and when the wavelength of blue light is greater than 465nm, it will reduce In order to reduce the quantum efficiency of the fluorescent powder due to the excitation photon energy, the present invention further requires that the emission wavelength of the used blue light chip is 445-465nm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com