Processing method of high-brightness black tea

A processing method and technology for black tea, applied in the field of tea processing and processing of high-brightness black tea, can solve the problems that restrict the rapid development of the black tea industry and the improvement of economic benefits, the lack of black tea proprietary raw material bases in black tea production areas, and the poor quality of black tea. Stability and other issues, to achieve the effect of facilitating the formation of high-brightness shape and soup color, promoting mass production, and excellent shape and soup color brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

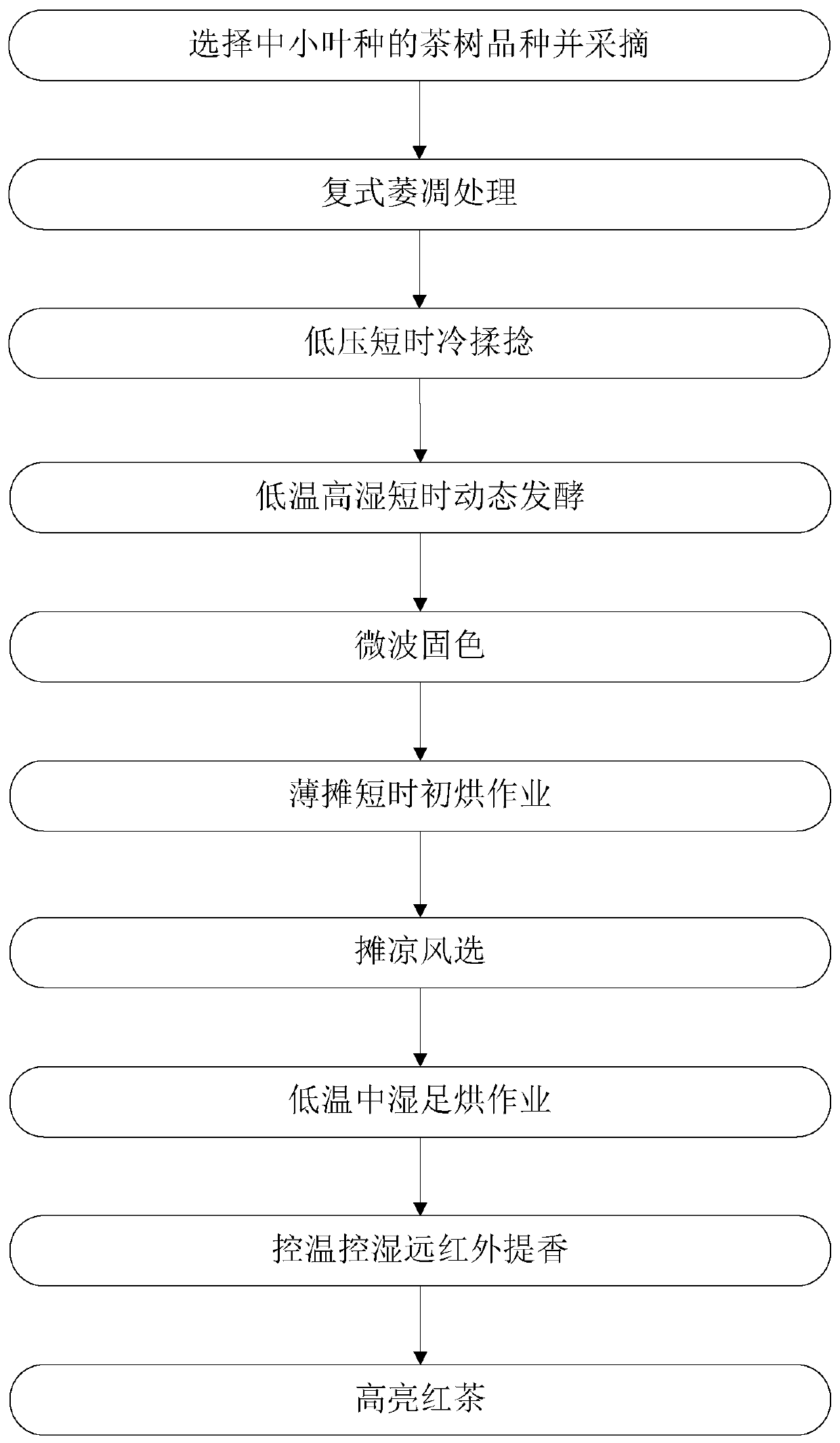

[0044] Such as figure 1 Shown, a kind of processing method of bright black tea comprises:

[0045] (1) select the tea tree variety of the medium and small leaf species suitable for black tea as raw material, wherein:

[0046] The medium and small-leaf tea tree variety suitable for making black tea is Fuding Dabai;

[0047] (2) In late March (March 29), the fresh leaves of the above-mentioned small and medium-leaved tea trees suitable for black tea were harvested. The amino acid content of tea leaves is 3.0wt%, and the tea polyphenols content of fresh leaves is 25wt%;

[0048] (3) Place the fresh leaves harvested in step (2) into a continuous withering system for withering treatment to obtain withered leaves, wherein:

[0049] The ambient temperature of the withering treatment is controlled at 24°C, the relative humidity is controlled at 80%, and the thickness of the spread leaves is 2cm. The compound withering combination of hot air red light withering and cold air white li...

Embodiment 2

[0060] A processing method of bright black tea, comprising:

[0061] (1) select the tea tree variety of the medium and small leaf species suitable for black tea as raw material, wherein:

[0062] The medium and small leaf tea tree variety suitable for black tea is Jiukeng;

[0063] (2) In the first ten days of May, the fresh leaves of the tea tree of the above-mentioned small and medium-sized leaf species suitable for black tea are collected and processed. The tenderness of the fresh leaves is 1 bud, 2 leaves-1 bud, 3 leaves, and the amino acid content of the fresh leaves is 5.0wt. %, the tea polyphenols content of fresh leaves is 0wt%;

[0064] (3) Place the fresh leaves harvested in step (2) into a continuous withering system for withering treatment to obtain withered leaves, wherein:

[0065] The ambient temperature of the withering treatment is controlled at 28°C, the relative humidity is controlled at 70%, and the thickness of the spread leaves is 6cm. The compound with...

Embodiment 3

[0076] A processing method of bright black tea, comprising:

[0077] (1) select the tea tree variety of the medium and small leaf species suitable for black tea as raw material, wherein:

[0078] The medium and small-leaf tea tree variety suitable for making black tea is Quan Yeqi;

[0079] (2) In mid-April, the fresh leaves of the above-mentioned medium and small-leaf tea trees suitable for making black tea are collected, and the tenderness of the fresh leaves is 1 bud 1 leaf-1 bud 2 leaves for the first development or 1 bud 2 leaves-1 bud 3 leaves Initial development, the amino acid content of fresh leaves is 4wt%, and the tea polyphenols content of fresh leaves is 27wt%;

[0080] (3) Place the fresh leaves harvested in step (2) into a continuous withering system for withering treatment to obtain withered leaves, wherein:

[0081] The environmental temperature of the withering treatment is controlled at 26°C, the relative humidity is controlled at 75%, and the thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com