Wear-resistant full-raw material super-flat thick polishing glaze and application thereof

A technique of thick polishing glaze and raw material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

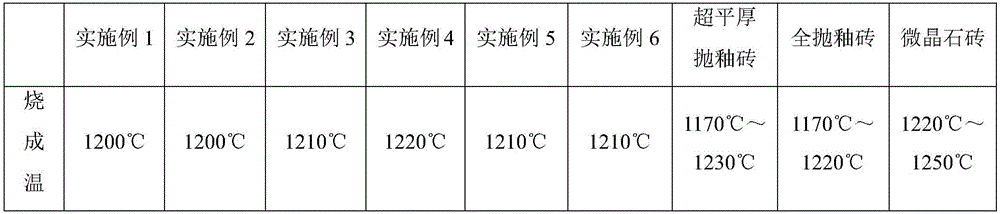

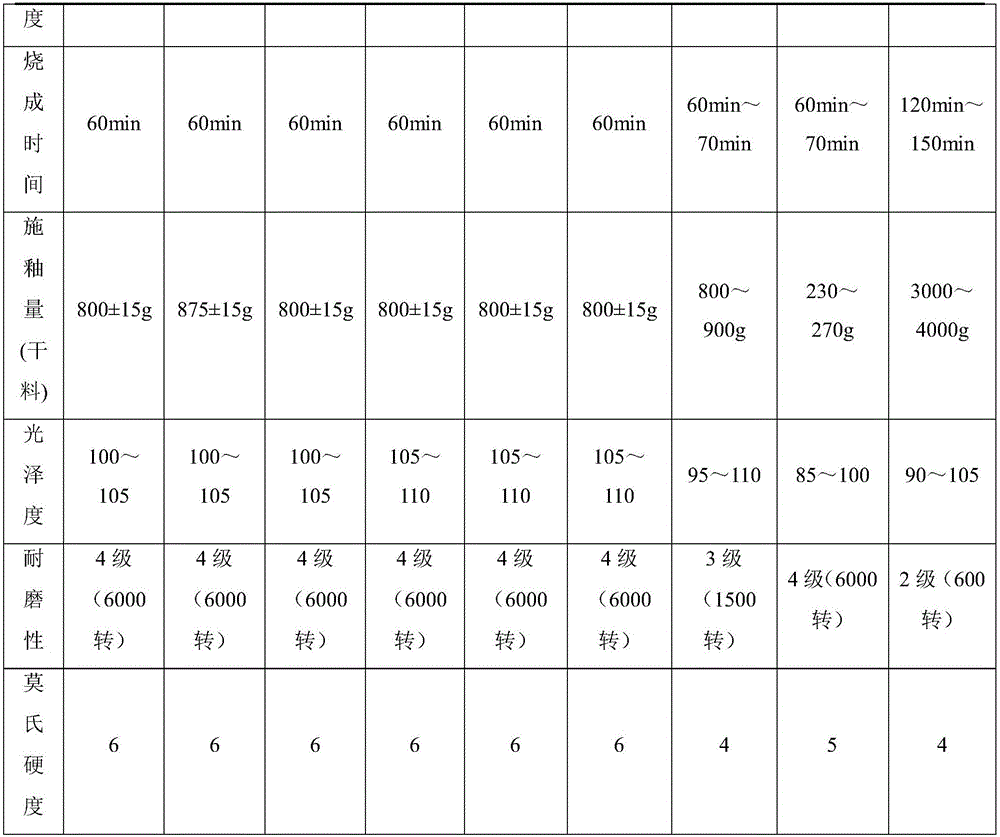

Embodiment 1

[0020] A kind of wear-resisting whole raw material ultra-flat and thick cast glaze, its composition mass percentage is: potassium feldspar 5%, albite feldspar 40%, washed kaolin 5%, barium carbonate 10%, strontium carbonate 2%, zinc oxide 10%, calcite 5%, dolomite 3%, quartz 6%, white corundum 14%, of which K feldspar K 2 O content is 11.1%, Na 2 The O content is 2.3%, the Na of albite 2 The O content is 10.3%, and the particle size of white corundum is 10-23um. After mixing all the raw materials according to the ratio, add water and additives, and ball mill to form a glaze slurry. The residue on a 325-mesh sieve is 0.08% (mass fraction);

[0021] On the 900×900mm green body, apply a layer of make-up soil, inkjet printing, apply wear-resistant full raw material super flat and thick glaze slurry in 2 times using bell jar glaze, the amount of glaze slurry for the first application is 600± 10 g / piece, the amount of glaze slurry for the second application is 500±10 g / piece, fire...

Embodiment 2

[0023] A kind of wear-resisting whole raw material ultra-flat and thick cast glaze, its composition mass percentage is: potassium feldspar 10%, albite feldspar 40%, washed kaolin 7%, barium carbonate 3%, strontium carbonate 2%, zinc oxide 12%, calcite 3%, dolomite 3%, quartz 5%, white corundum 15%, of which K feldspar K 2 O content is 10.5%, Na 2 The O content is 2.2%, the Na of albite 2 The O content is 10.4%, and the particle size of white corundum is 10-18um. After mixing all the raw materials according to the ratio, add water and additives and ball-mill to form a glaze slurry with a 325-mesh sieve. The residue is 0.06% (mass fraction);

[0024] On the 900×900mm green body, apply a layer of make-up soil, inkjet printing, apply wear-resistant full raw material super flat and thick glaze slurry in 2 times using bell jar glaze, the amount of glaze slurry for the first application is 600± 10 g / piece, the amount of glazing slurry for the second time is 600±10 g / piece, fired at...

Embodiment 3

[0026] A kind of wear-resisting whole raw material ultra-flat and thick cast glaze, its composition mass percentage is: potassium feldspar 7%, albite feldspar 40%, washed kaolin 8%, barium carbonate 5%, strontium carbonate 5%, zinc oxide 9%, calcite 5%, dolomite 5%, quartz 2%, white corundum 14%, of which K feldspar K 2 O content is 11.1%, Na 2 The O content is 2.2%, the Na of albite 2 The O content is 10.2%, and the particle size of white corundum is 10-23um. After mixing all the raw materials according to the ratio, add water and additives to ball mill to form a glaze slurry, and the residue on a 325-mesh sieve is 0.06% (mass fraction);

[0027] On the 900×900mm green body, apply a layer of make-up soil, inkjet printing, apply wear-resistant full raw material super flat and thick glaze slurry in 2 times using bell jar glaze, the amount of glaze slurry for the first application is 600± 10g / piece, the amount of glaze slurry for the second application is 500±10g / piece, fired ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com