Coke oven coking end monitoring system

A monitoring system and coke oven technology, which is applied in coke ovens, coke oven heating, combustible gas heating coke ovens, etc., can solve problems affecting the personal safety of technical workers, poor accuracy, and high requirements for technical workers, so as to ensure coke quality, Achieve automation, reduce visible pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The coke oven fire fall monitoring system of the present invention will be further described below.

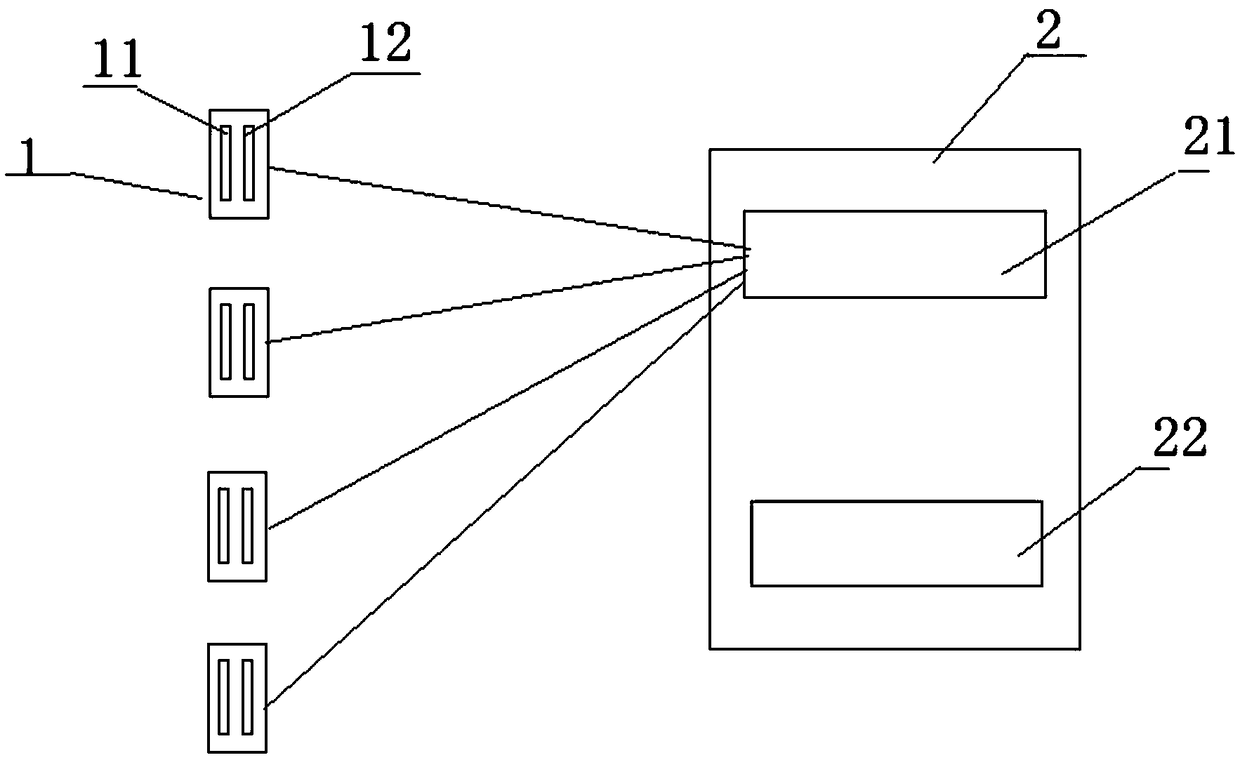

[0032] Coke oven fire fall monitoring system, see figure 1 , including a raw gas temperature detection device (1), and a data acquisition and control device (2).

[0033] The raw gas temperature detection device (1) includes a group of thermocouples (11), a group of high temperature resistant compensation wires (12), and the thermocouples (11) are arranged at the connection between the rising pipe and the bridge pipe of the carbonization chamber of the coke oven. At the tee, the high temperature resistant compensation wire (12) is located near the thermocouple (11); the thermocouple (11) is an armored K-type thermocouple resistant to famine gas corrosion; the high temperature resistant compensation wire (12 ) is provided with a ceramic fiber heat insulation layer; the thermocouple (11) and the high temperature resistant compensation wire (12) are arranged in pairs.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com