Extruder with adjustable product bulk density

A technology of puffing machine and bulk density, which is applied in food forming, food science, application, etc. It can solve the problems of troublesome replacement of discharging device, influence on production efficiency, and heavy disassembly and assembly workload, so as to improve production efficiency, increase pressure, Guarantee the effect of maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

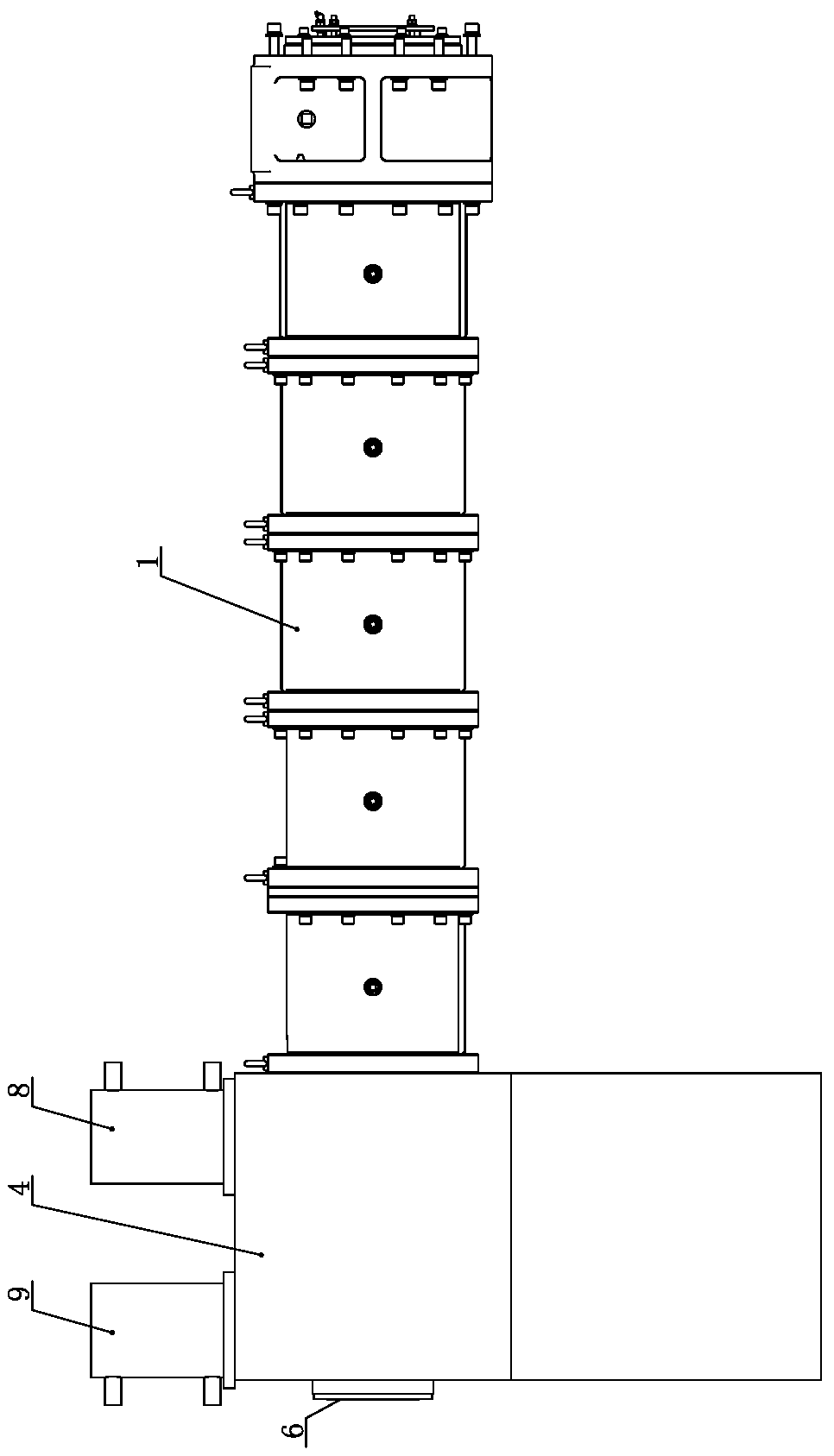

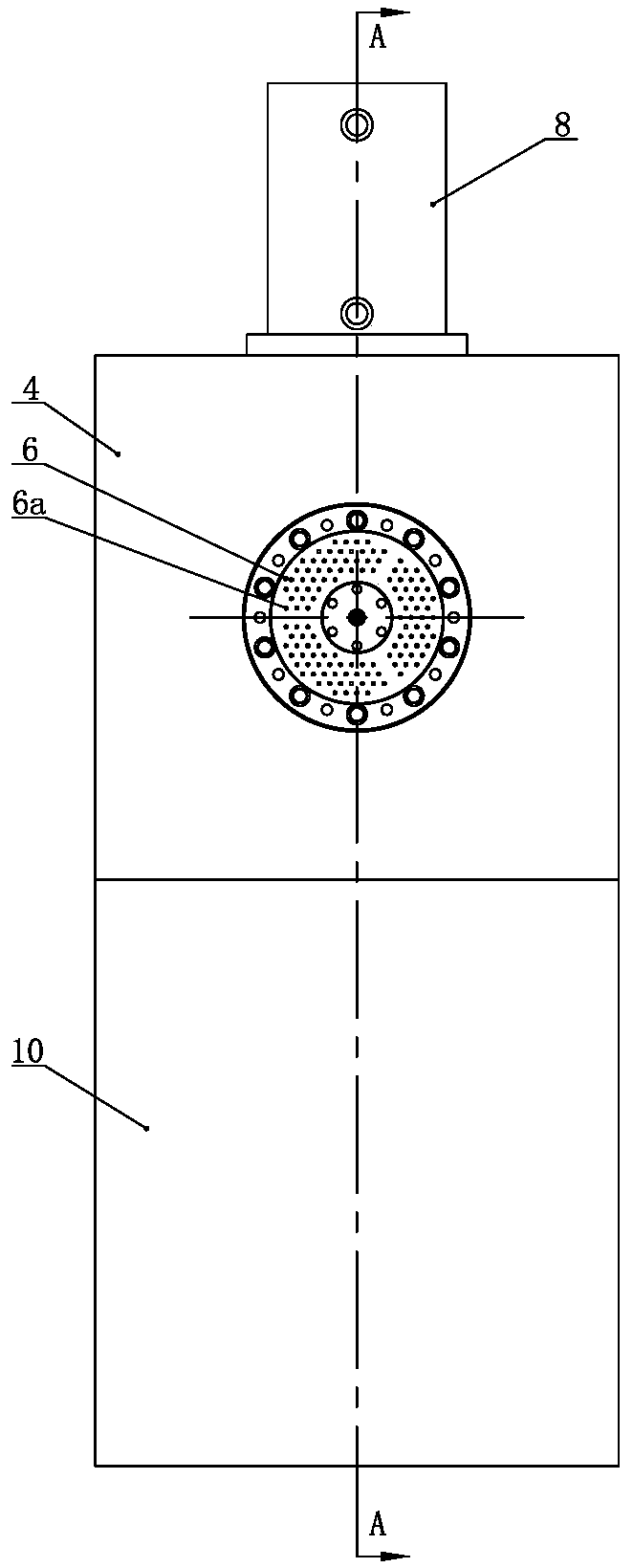

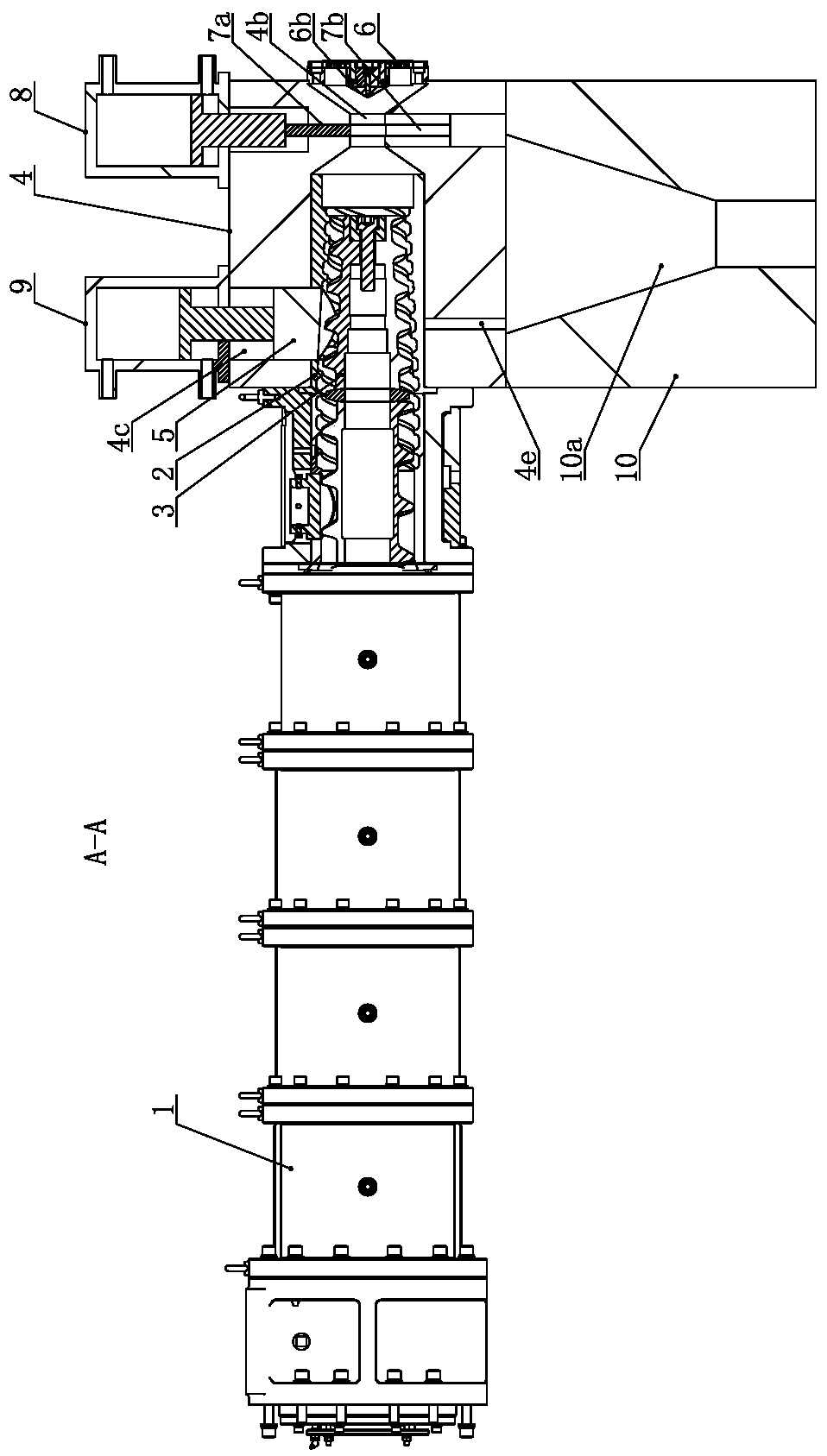

[0029] Such as Figure 1 to Figure 8 As shown, the extruder with adjustable product density of the present invention comprises an extruder body 1, a feed inlet 1a is provided above the feeding section of the extruder body 1, and a wear-resistant bushing is provided on the inner wall of the extrusion chamber of the extruder body 1 2. The inner cavity of the wear-resistant bushing 2 is provided with a screw rotor 3, the outlet end of the extruder body 1 is connected with a discharge device 4, and the inlet section of the discharge device 4 is provided with a final extrusion chamber 4a, and the screw rotor 3 extends In the final extrusion cavity 4a, a Venturi throat 4b is provided near the outlet of the discharge device 4, and a discharge template 6 is installed at the outlet end of the discharge device 4, and the discharge template 6 faces the Venturi throat The center of the inner wall of 4b is equipped with a splitter cone 6b, and a plurality of die holes 6a are distributed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com