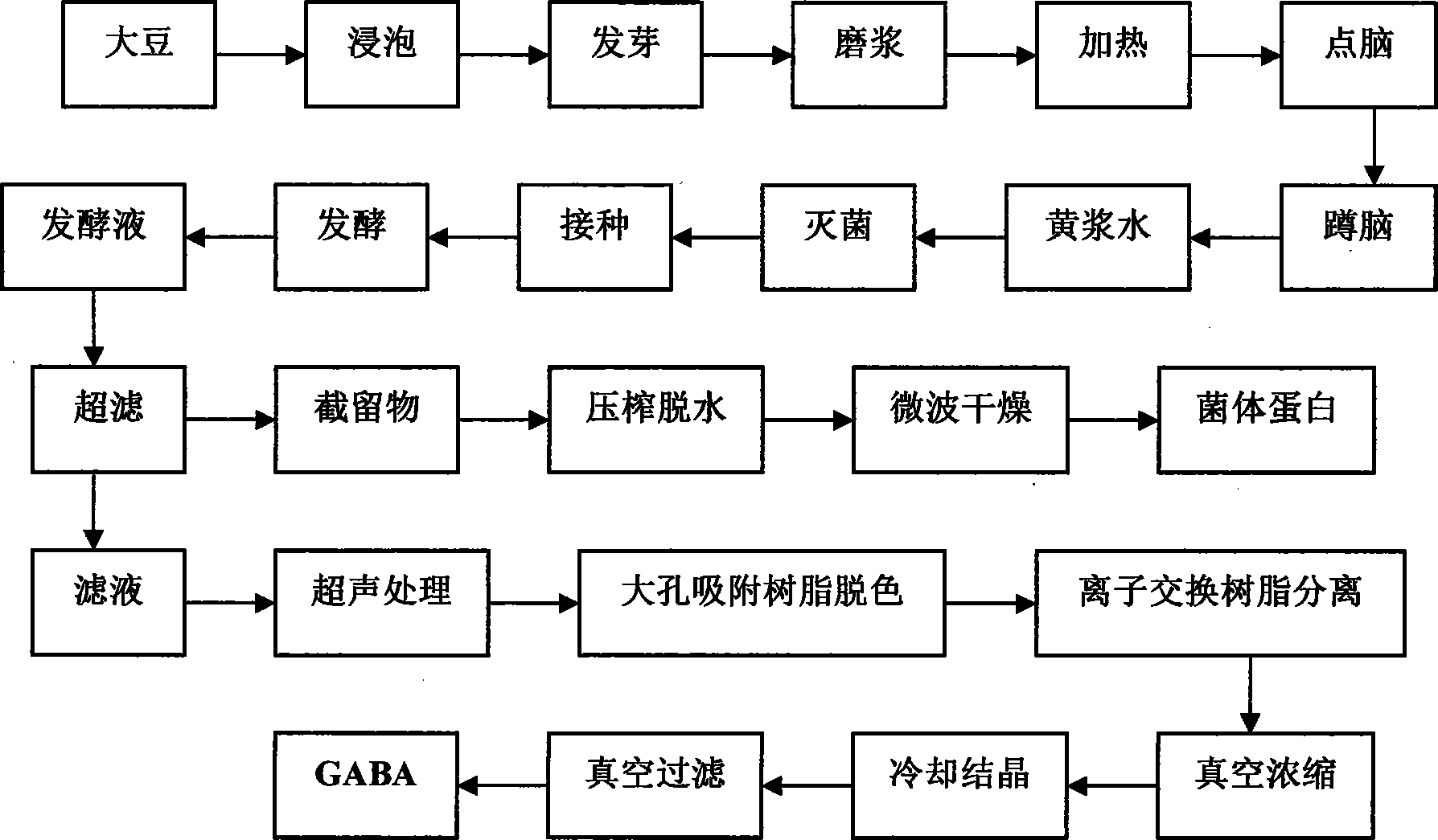

Method for preparing GABA from yellow serofluid through fermention by microorganisms

A technology of microbial fermentation and yellow pulp water, applied in the direction of fermentation, can solve the problem of no GABA enrichment and recovery research, and achieve the effects of shortening fermentation time, improving fermentation efficiency, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] After the soybeans are soaked, the germination temperature is 28°C for 72 hours. The germinated soybeans are refined to obtain soy milk. The soybean milk is heated, brained, and squatted to obtain yellow water. The yeast and lactic acid bacteria are separated. The compound bacteria were mixed at a compound ratio of 1:3, and the compound bacteria were inoculated into the sterilized yellow syrup water under the condition that the compound bacteria inoculation amount was 2% and the fermentation temperature was 36°C, and the fermentation broth was obtained for 20 hours. Carry out ceramic membrane ultrafiltration treatment. After ultrafiltration, the retentate and filtrate are obtained. The retentate is dehydrated by hydraulic pressure and then microwave-dried to obtain bacterial protein. The filtrate is subjected to ultrasonic treatment for 30 minutes under the conditions of ultrasonic power of 120W and ultrasonic temperature of 50℃. After ultrasonic treatment, decolorization...

Embodiment 2

[0020] After soaking the soybeans, carry out a germination treatment at a germination temperature of 26°C for 80 hours. The germinated soybeans are refined to obtain soy milk. The soybean milk is heated, brained, and squatted to obtain yellow water. The yeast and lactic acid bacteria are separated. The compound bacteria were mixed at a compound ratio of 1:2, and the compound bacteria were inoculated into the sterilized yellow syrup water under the condition of 3% compound bacteria inoculation amount and 38°C fermentation temperature to obtain fermentation broth. Perform ceramic membrane ultrafiltration treatment. After ultrafiltration, the retentate and filtrate are obtained. The retentate is dehydrated by hydraulic pressure and then microwave-dried to obtain bacterial protein. The filtrate is ultrasonicated for 40 minutes under the conditions of ultrasonic power of 100W and ultrasonic temperature of 60℃ After ultrasonic treatment, decolorization of D101 macroporous adsorption r...

Embodiment 3

[0022] After soaking the soybeans, carry out a germination treatment at a germination temperature of 30°C for 64 hours. The germinated soybeans are refined to obtain soy milk, and the soy milk is heated, brained, and squatted to obtain yellow water. The yeast and lactic acid bacteria are separated The compound bacteria were mixed in a compound ratio of 1:4, and the compound bacteria were inoculated into the sterilized yellow syrup water under the condition that the compound bacteria inoculation amount was 2% and the fermentation temperature was 34°C. The fermentation broth was obtained for 25 hours. Carry out ceramic membrane ultrafiltration treatment. After ultrafiltration, the retentate and filtrate are obtained. The retentate is dehydrated by hydraulic pressure and then microwave-dried to obtain bacterial protein. The filtrate is subjected to ultrasonic treatment for 20 minutes under the conditions of ultrasonic power of 120W and ultrasonic temperature of 40℃. After ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com