Preparation method of beer through mixed fermentation of zygosaccharomyces cidri and saccharomyces cerevisiae

The technology of Saccharomyces cerevisiae and aroma-producing yeast, which is applied in the field of beer brewing, can solve the problems of insignificant beer flavor, etc., and achieve the effect of simple preparation method, increasing the content of ester aroma substances, and strong ester aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

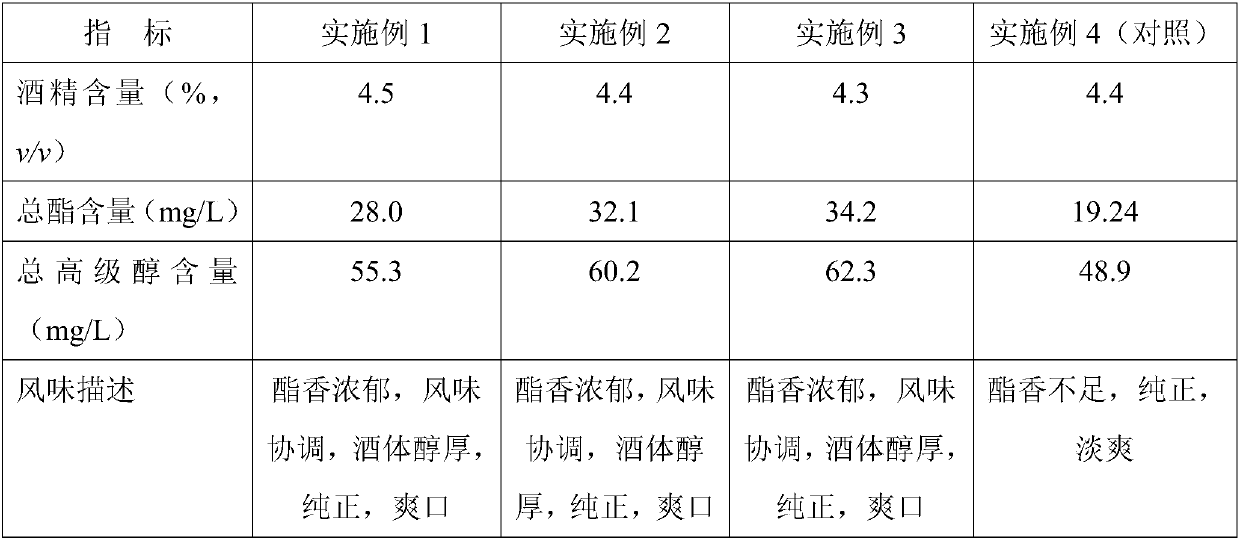

[0020] Example 1 The beer fermented by aroma-producing yeast and Saccharomyces cerevisiae

[0021] (1) Inoculate Saccharomyces cerevisiae and Pichia pastoris on the slant in 12°P whole-wheat wort, culture on a shaker at 28°C for 24 hours, and transfer 5% of the inoculum into a triangular flask containing 50mL whole-wheat wort After culturing on a shaker (150rpm) at 20°C for 36h, transfer to 300mL of fresh whole wheat wort, culture on a shaker at 16°C / 100rpm for 72h, then centrifuge at 15°C / 6000rpm for 10min to collect yeast sludge.

[0022] (2) After crushing the malt (20 kg), mix it evenly with water according to the material-to-water ratio of 1:3. Put it in a mash pot, and carry out saccharification according to the saccharification process of holding at 45°C for 30 minutes, heating to 63°C for 60 minutes, heating to 72°C for 10 minutes, and then heating to 78°C for 10 minutes; (The amount of hops added is 1.5g / L, and it is added in batches to the boiled wort), and the wort...

Embodiment 2

[0024] Example 2 The beer mixed with aroma-producing yeast and Saccharomyces cerevisiae

[0025] (1) Inoculate Saccharomyces cerevisiae and Pichia pastoris on the slant in 12°P whole-wheat wort, culture on a shaker at 28°C for 24 hours, and transfer 5% of the inoculum into a triangular flask containing 50mL whole-wheat wort After culturing on a shaker (150rpm) at 20°C for 36h, transfer it to 300mL of fresh 12°P whole wheat wort, cultivate it on a shaker at 18°C / 110rpm for 65h, then centrifuge at 15°C / 6000rpm for 10min to collect yeast sludge.

[0026] (2) After crushing the malt (20 kg), mix it evenly with water according to the material-to-water ratio of 1:3. Put it in a mash pot, and carry out saccharification according to the saccharification process of holding at 45°C for 30 minutes, heating to 63°C for 60 minutes, heating to 72°C for 10 minutes, and then heating to 78°C for 10 minutes; (The amount of hops added is 1.6g / L, and it is added in batches to the boiled wort), a...

Embodiment 3

[0028] Embodiment 3 beer fermented by aroma-producing yeast and Saccharomyces cerevisiae

[0029] (1) Inoculate Saccharomyces cerevisiae and Pichia pastoris on the slant in 12°P whole-wheat wort, culture on a shaker at 28°C for 24 hours, and transfer 5% of the inoculum into a triangular flask containing 50mL whole-wheat wort After culturing on a shaker (150rpm) at 20°C for 36h, transfer to 300mL of fresh 12°P whole wheat wort, and after culturing on a shaker at 18°C / 120rpm for 68h, centrifuge at 15°C / 6000rpm for 10min to collect yeast sludge.

[0030](2) After crushing the malt (20 kg), mix it evenly with water according to the material-to-water ratio of 1:3. Put it in a mash pot, and carry out saccharification according to the saccharification process of holding at 45°C for 30 minutes, heating to 63°C for 60 minutes, heating to 72°C for 10 minutes, and then heating to 78°C for 10 minutes; (The amount of hops added is 1.6g / L, and it is added in batches to the boiled wort), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com