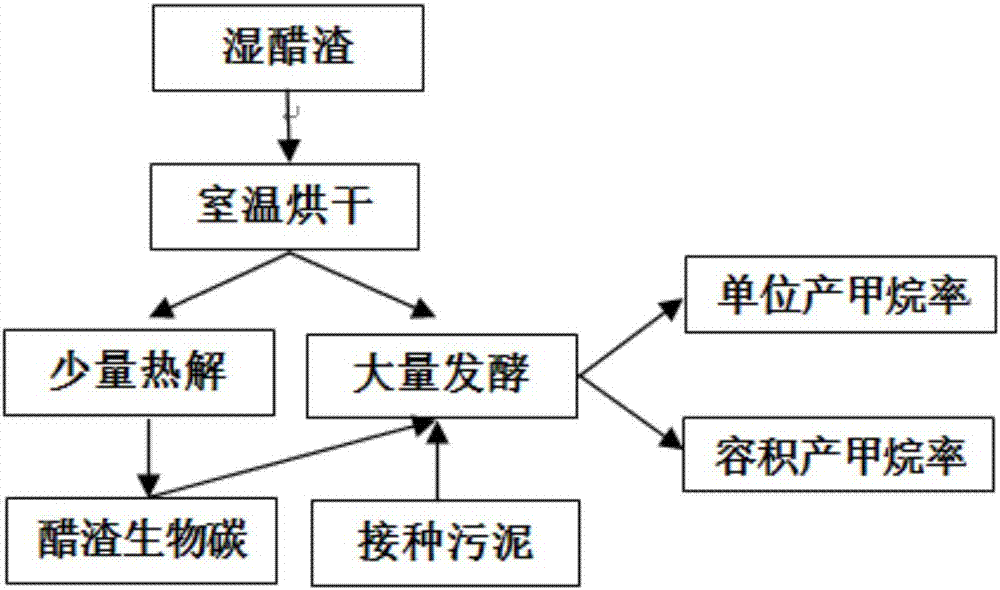

Industrial vinegar residue waste solid anaerobic fermentation methanogenesis method

A solid-state anaerobic fermentation and waste technology, applied in fermentation, waste fuel and other directions, can solve the problems of long reaction time, large demand for inoculum, and the solid-state fermentation process of vinegar residue has not been well developed and utilized. Achieve the effect of improving fermentation efficiency and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Pyrolysis of industrial vinegar residue to produce biochar: First, spread the vinegar residue on the ground, place it for 3 days, and then dry it naturally. Take about 100 g of vinegar residue with a total solid content of TS=95.5% and a volatile solid content of VS=90.1%, and place it in a 500 mL fixed-bed pyrolysis and carbonization furnace. After heating for 30 minutes, the temperature was raised from room temperature to 400 °C and maintained at this temperature for 1.5 h, and then naturally cooled to room temperature, the biochar yield could reach 34.8%.

[0018] 2) Solid-state anaerobic fermentation of vinegar residue: get 300g of vinegar residue and add it to a 5L anaerobic reactor. 1302g of inoculated sludge with a solid content of VS=11.0% was added to a 5L anaerobic reactor, and 308g of water was added to make the system TS=15%. Then, according to the mass value being 0.5% of the TS value of the added vinegar residue, 1.432 g of biochar produced after the a...

Embodiment 2

[0020] 1) Pyrolysis of industrial vinegar residue to produce biochar: First, spread the vinegar residue on the ground, place it for 3 days, and then dry it naturally. Take about 100 g of vinegar residue with a total solid content of TS=95.5% and a volatile solid content of VS=90.1%, and place it in a 500 mL fixed-bed pyrolysis and carbonization furnace. After heating for 30 minutes, the temperature was raised from room temperature to 450 °C, maintained at this temperature for 2 hours, and then naturally cooled to room temperature.

[0021] 2) Solid-state anaerobic fermentation of vinegar residue: get 400g vinegar residue and join in 5L anaerobic reactor, according to the ratio of the volatile solid content of vinegar residue and inoculation sludge is 2.5, take total solid content TS=20.5%, volatile 1389g of inoculated sludge with a solid content of VS=11.0% was added to a 5L anaerobic reactor, and 139g of water was added to make the system TS=20%. Then, according to the mass ...

Embodiment 3

[0023] 1) Pyrolysis of industrial vinegar residue to produce biochar: First, spread the vinegar residue on the ground, place it for 3 days, and then dry it naturally. Take about 100 g of vinegar residue with a total solid content of TS=95.5% and a volatile solid content of VS=90.1%, and place it in a 500 mL fixed-bed pyrolysis and carbonization furnace. After heating for 30 minutes, the temperature was raised from room temperature to 500 °C, maintained at this temperature for 2.5 h, and then cooled to room temperature naturally.

[0024] 2) Solid-state anaerobic fermentation of vinegar dregs: 500 g of vinegar dregs is added to a 5L anaerobic reactor. According to the ratio of the volatile solid content of vinegar dregs to inoculated sludge is 3, the total solid content TS=20.5%, the volatile 1446g of inoculated sludge with solid content VS=11.0% was added to a 5L anaerobic reactor, and 66.1g of water was added to make the system TS=24%. Then, according to the mass value being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com