Improved polyoxin fermentation culture medium and fermentation process

A fermentation medium, polyoxin technology, applied in the direction of fermentation, microorganism-based methods, biochemical equipment and methods, etc., can solve the problem that the viscosity and the elimination of foam during sterilization cannot be scientifically controlled, and there is no special research Over-fermentation medium quality stability, medium quality instability and other issues, to achieve the effect of shortening the fermentation cycle, reducing air demand, and reducing ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Fermentation medium of the present invention: take by weighing 1.5% of corn flour, 2.0% of soybean cake powder, 2.0% of maltose, KH 2 PO 4 0.1%, NaCl 0.1%, CaCO 3 0.3%, (NH 4 ) 2 SO 4 0.5%, antifoaming agent 0.035%, adjust the pH to 6.5 before adding the antifoaming agent, and sterilize at 121°C for 30min to obtain the fermentation medium of the present invention.

Embodiment 2

[0034] The fermentation medium of Example 1 adopts the fermentation process of the present invention as follows: inoculate the spores of Streptomyces aureus chromogenes slant spores of type 4896 into seed shake flasks at 28° C. and 220 rpm for 30 h, and bottle them into shake flask seeds. The shake flask seeds were inoculated into the primary seed tank at 28°C for 24 hours, transplanted into the sterilized fermentation medium prepared in Example 1, at 28°C, 110rpm, tank pressure 0.05MPa, ventilation rate 0.5-1.0L / min continues to ferment. When cultured to 10h, feed was added (NH 4 ) 2 SO 4 and ammonia water, while adjusting the pH to maintain 6.3-6.5, supplement the nitrogen source, and put the tank into the tank after culturing for 113 hours.

Embodiment 3

[0036] The experimental results of comparative examples 1 and 2 and embodiment 1 and 2 are compared as follows:

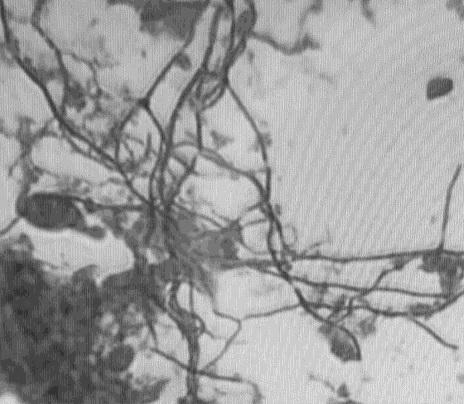

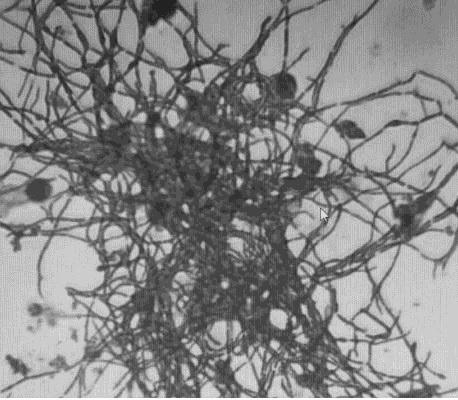

[0037] figure 1 It is the original fermentation process using the original fermentation medium, that is, comparative example 2, the figure of the mycelia at 30h, it can be seen that it forms a small net, and the mycelia are long and few. figure 2 For adopting the fermentation process of the fermentation medium of the present invention, i.e. embodiment 2, the figure of mycelium at 30h, it can be seen that it forms a medium net to a large net, and the mycelium is long and complexly cross-linked, with few mycelia and deep staining. .

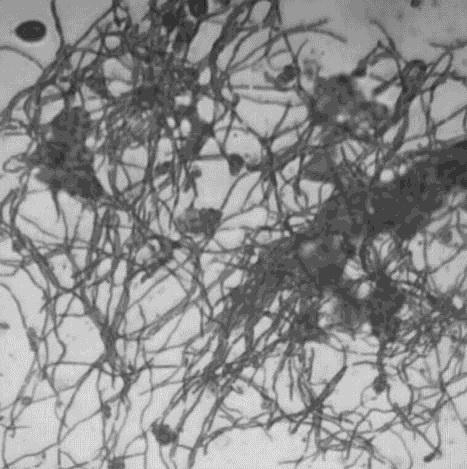

[0038] image 3 It is the original fermentation process using the original fermentation medium, that is, comparative example 2, the diagram of the hyphae at 68 hours, it can be seen that it forms a large network, and the mycelium is long and complexly cross-linked. Figure 4 For the fermentation process using the fermentation medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com