Manufacturing method of dental occlusion recording device and dental occlusion recording device

The technology of a recording device and a manufacturing method is applied in the manufacture of a dental occlusal recording device and the field of a dental occlusal recording device, and can solve the problems of difficult observation of the restoration space of the posterior tooth region, difficulty in judging treatment needs, and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

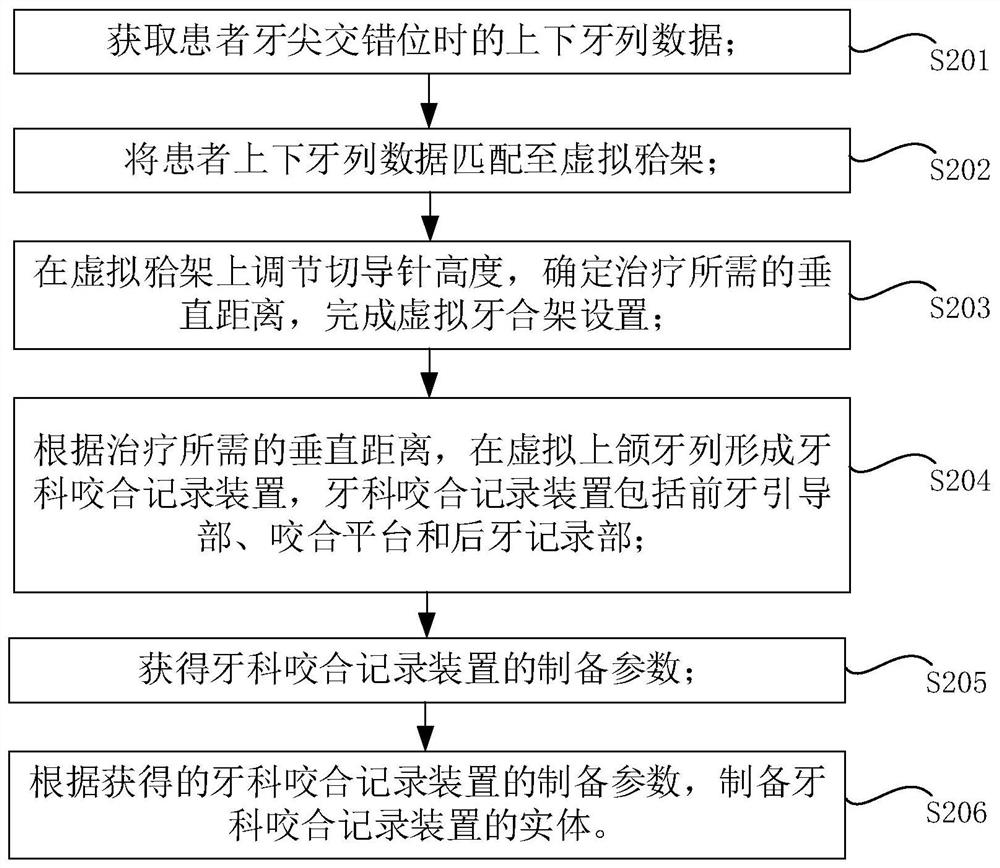

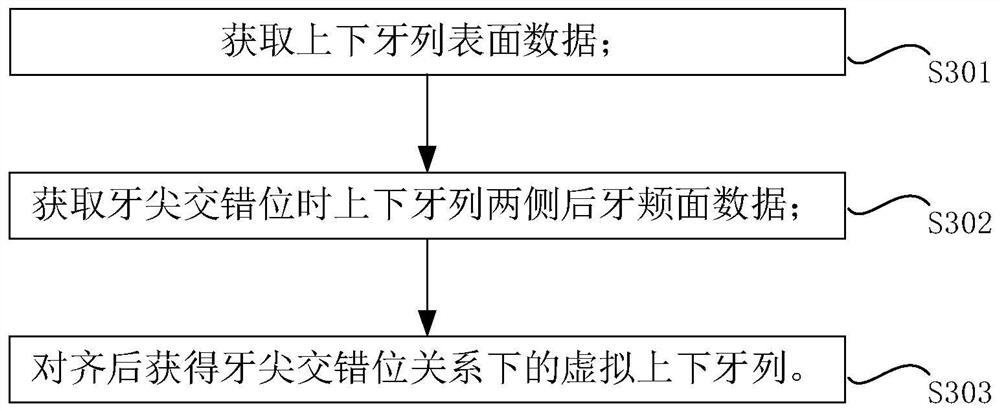

[0049]The following will clearly and completely describe the technical solutions in the exemplary embodiments of the present disclosure with reference to the accompanying drawings in the exemplary embodiments of the present disclosure. The exemplary embodiments described herein are for illustrative purposes only, and are not intended to limit the protection scope of the present disclosure, so it should be understood that various modifications can be made to the exemplary embodiments without departing from the protection scope of the present disclosure. modifications and changes.

[0050] In the description of the present disclosure, unless otherwise clearly specified and limited, the terms "first" and "second" are only used for the purpose of description, and cannot be understood as indicating or implying relative importance; the term "plurality" is means two or more; the term "and / or" includes any and all combinations of one or more of the associated listed items. In particu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com