Complete dentition full denture finished product resin tooth and preparation method thereof

A technology for complete dentures and resin teeth, applied in the field of oral materials, can solve the problems of shortening the consultation time, complicated design process, and small selectivity of clinicians, so as to shorten the consultation time, reduce the cost, and reduce the clinical blending time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

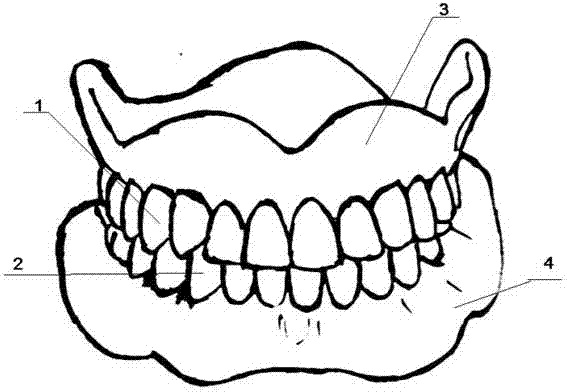

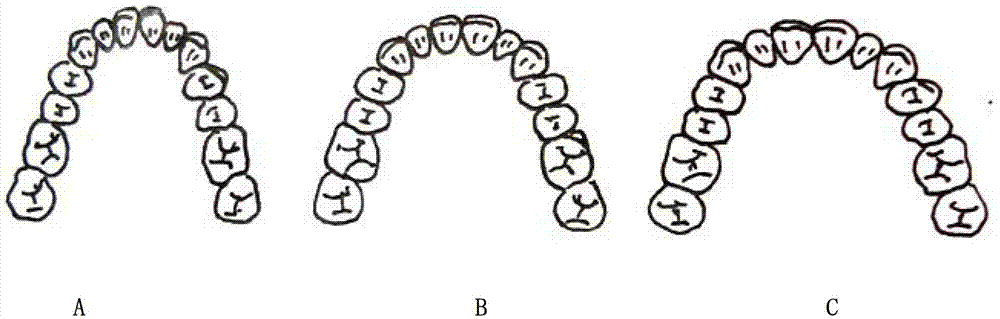

[0040] A finished resin tooth with a full denture complete denture, comprising an upper tray 3, a lower tray 4, an upper dentition 1 fixedly connected to the upper tray 3, and a lower dentition 2 fixedly connected to the lower tray 4; The upper dentition 1 and the lower dentition 2 occlude with each other; the upper dentition 1 and the lower dentition 2 are integral dentition respectively. The shape of the whole dentition is pointed circle A, oval B or square circle C.

[0041] The upper dentition 1 and the lower dentition 2 are made of polymethacrylic resin.

[0042] The material of the upper tray 3 and the lower tray 4 is polymethacrylic resin.

Embodiment 2

[0044] A kind of preparation method of complete dentition complete denture finished resin tooth as described in embodiment 1, comprises steps as follows:

[0045] (1) According to the shape and size of the patient's dental arch, produce upper dentition 1 and lower dentition 2 of corresponding shape and size;

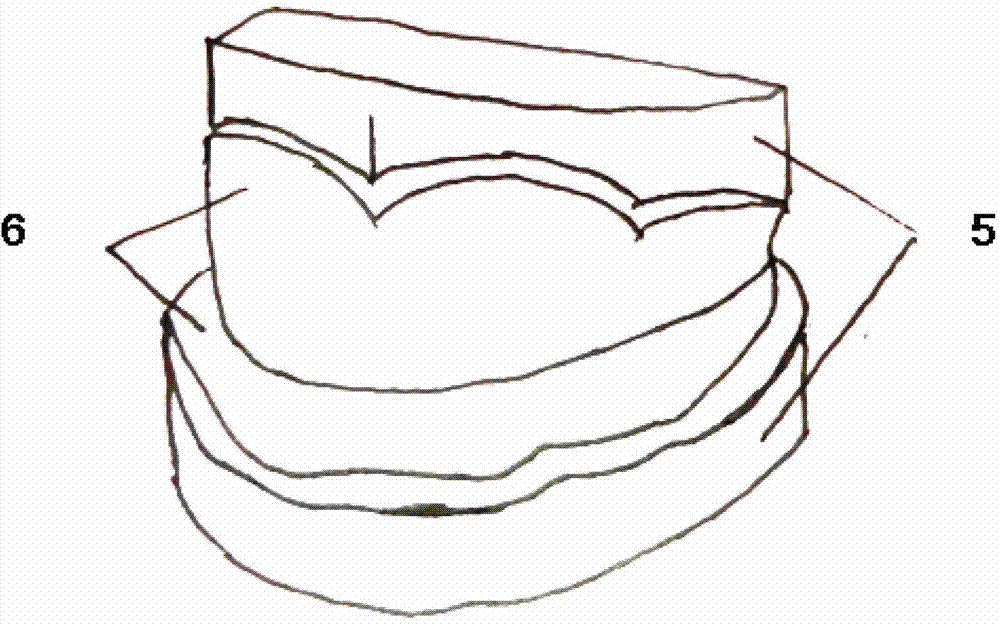

[0046] (2) Making a waxed occlusal tray: the dental technician transfers the obtained jaw position relationship to the jaw frame to make a plaster model 5, and uses wax to make a waxed occlusal tray on the plaster model 5, and the waxed occlusal tray includes wax base and wax dentition embankment 6;

[0047] (3) Tooth arrangement: Arrange the upper dentition 1 and lower dentition 2 of the corresponding shape and size produced in step (1) on the wax occlusal bracket described in step (2), and adjust the upper dentition 1 and the lower dentition 2, so that the upper dentition 1 and the lower dentition 2 form an occlusion, forming a complete denture model with a wax base; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com