Patents

Literature

97 results about "Endodontic instrument" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

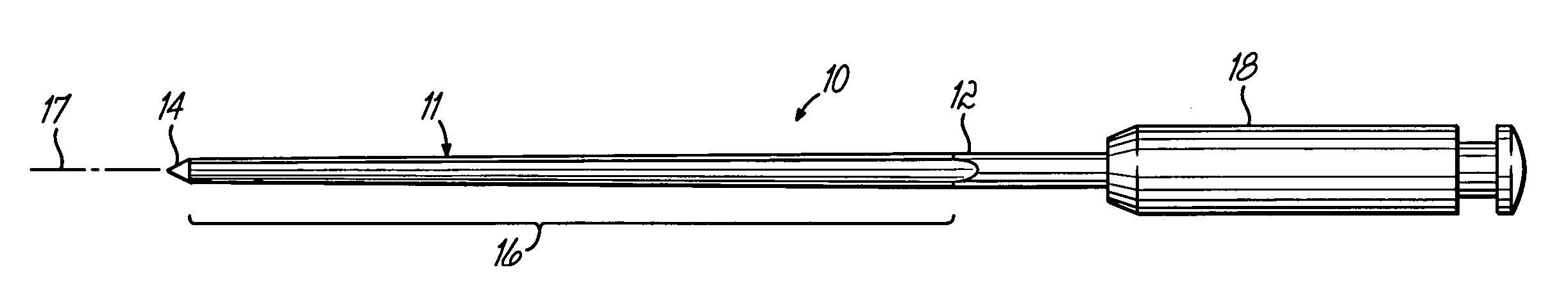

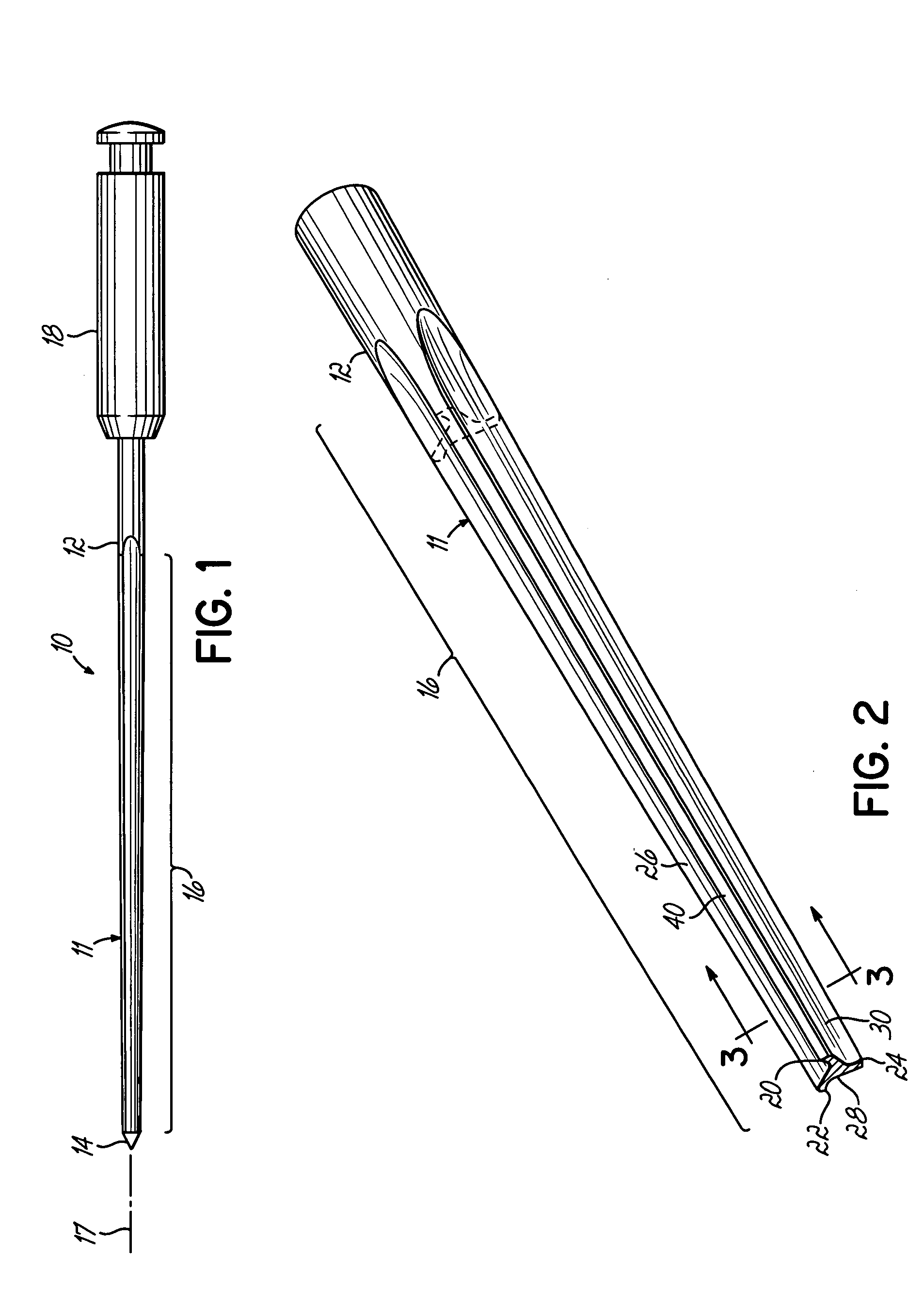

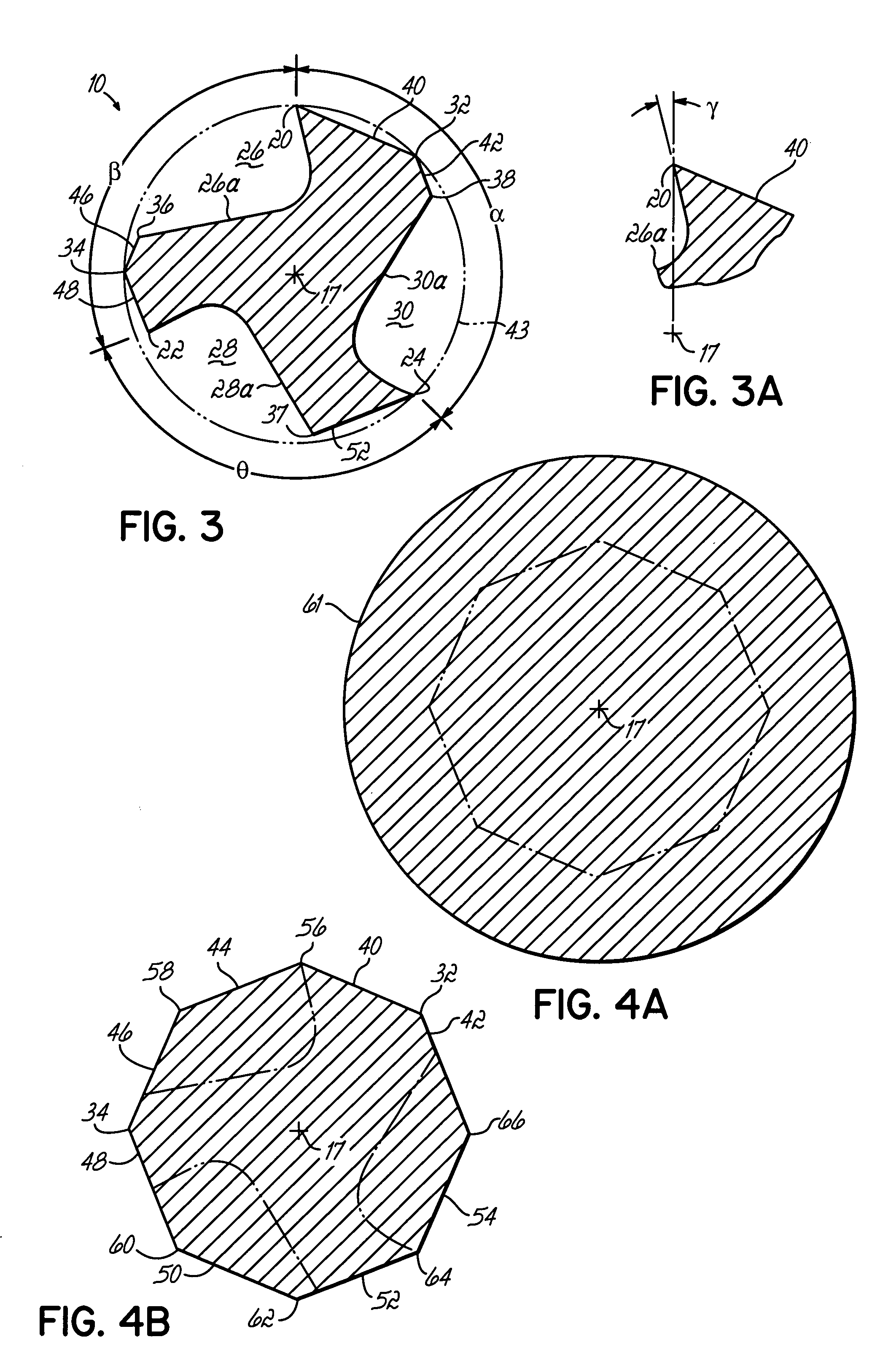

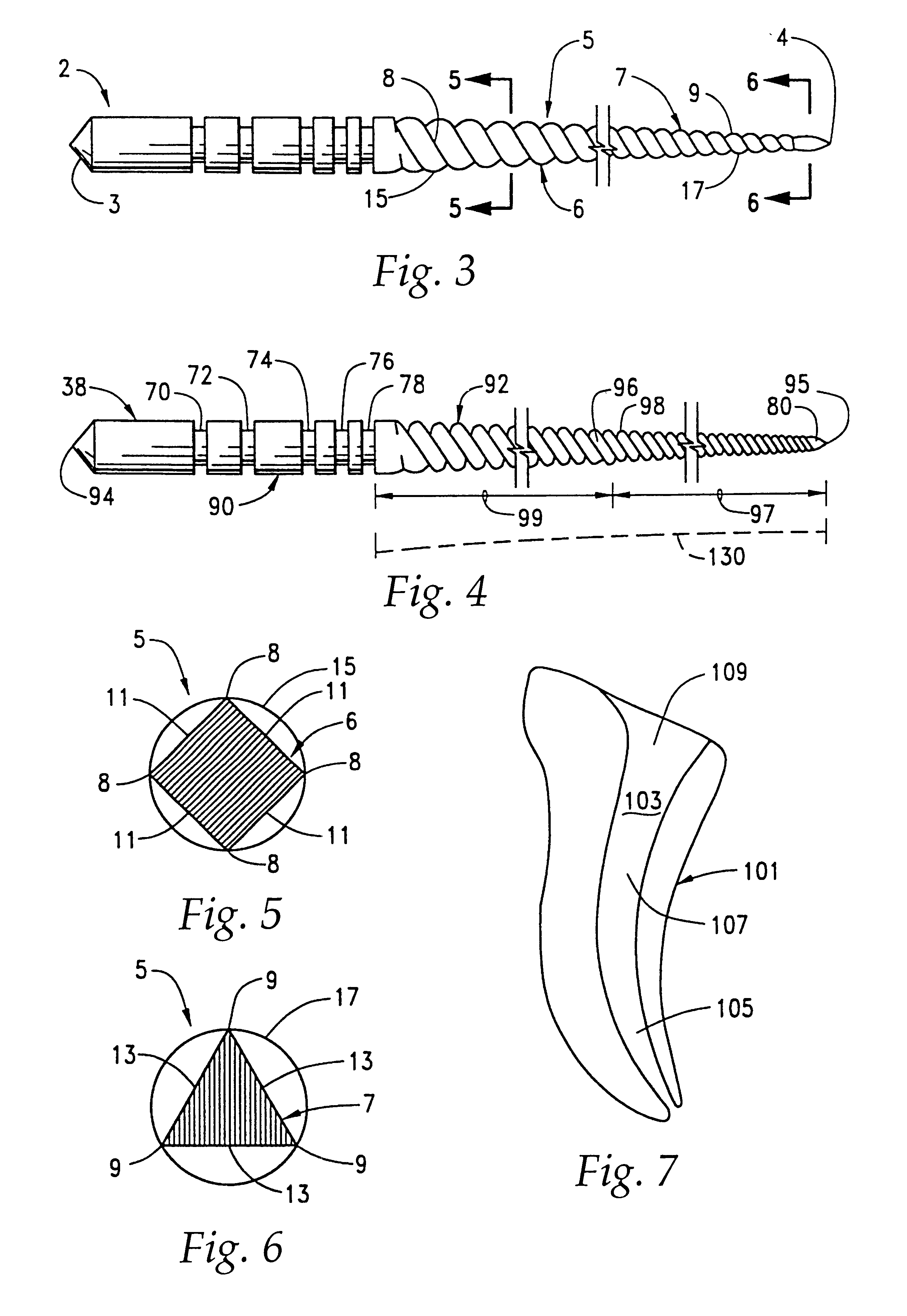

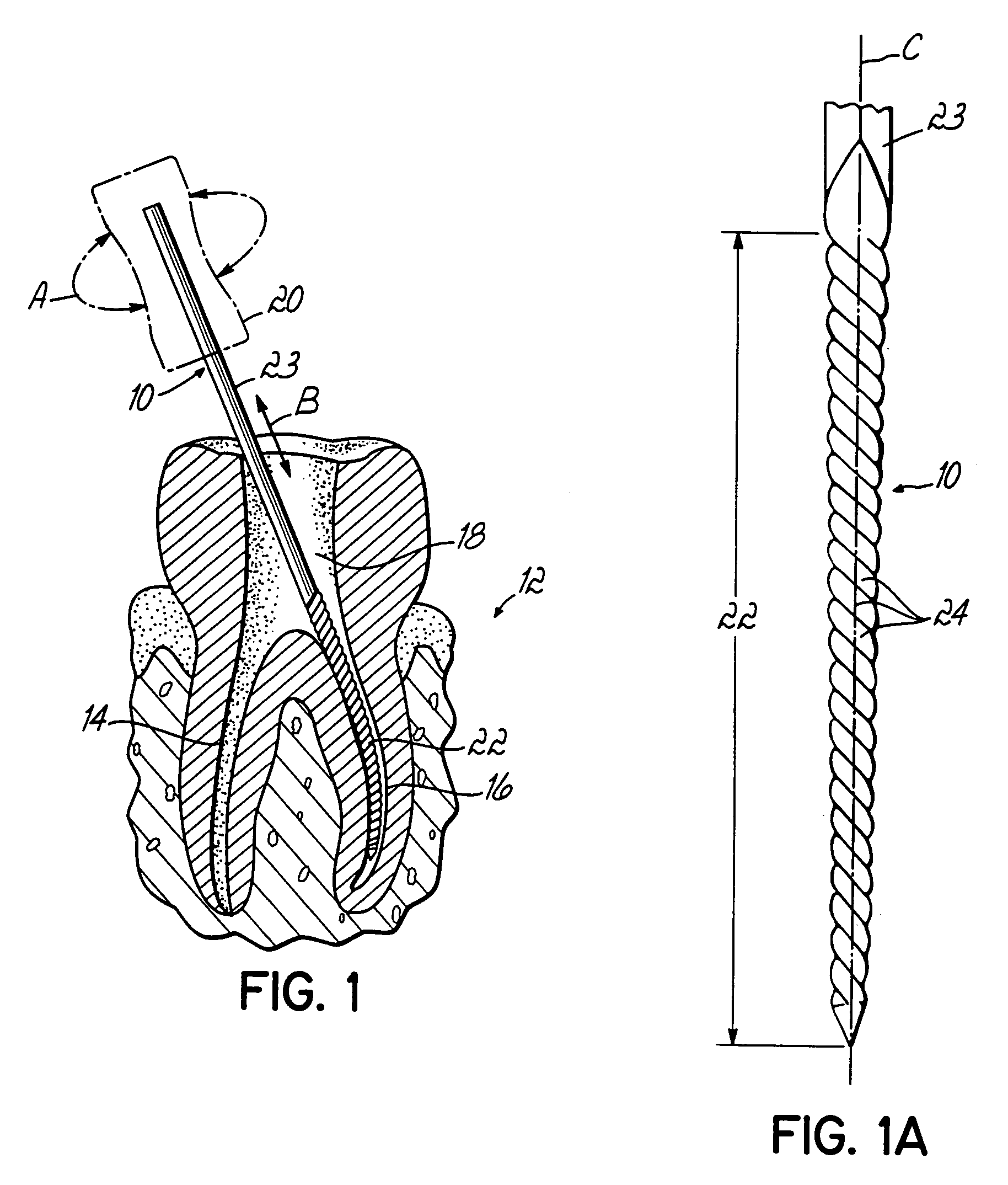

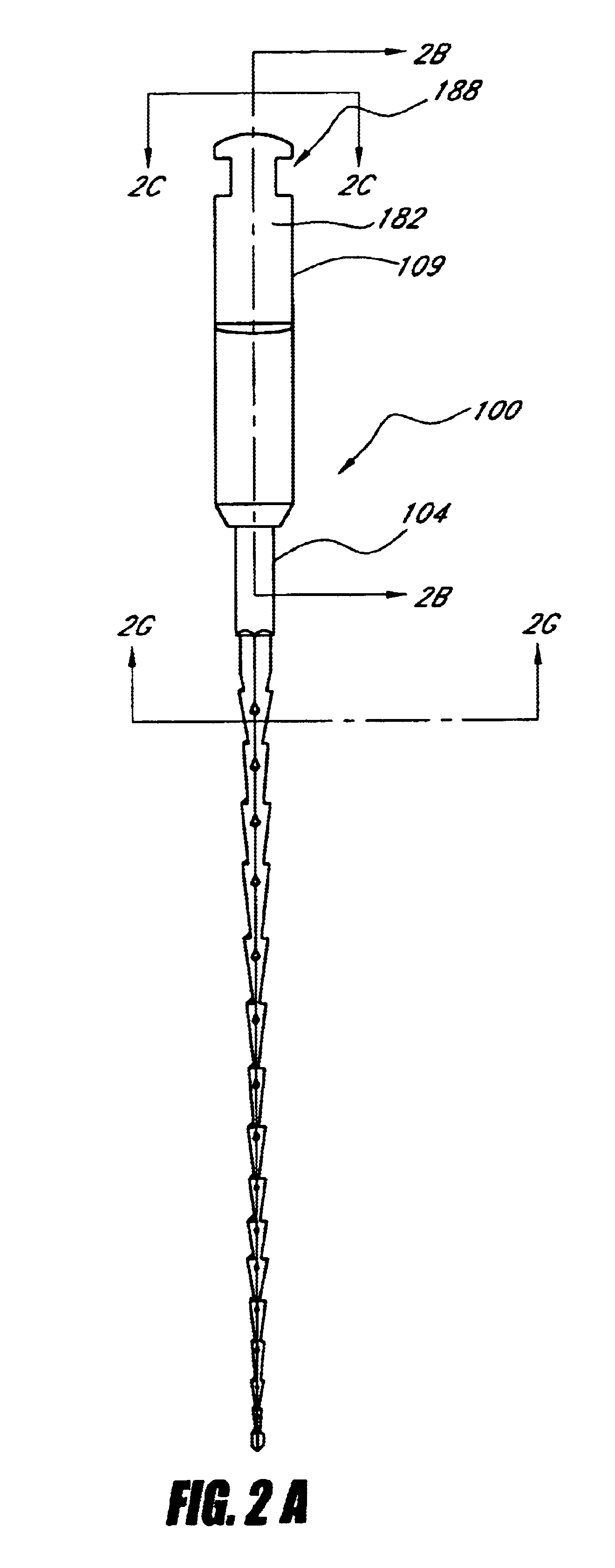

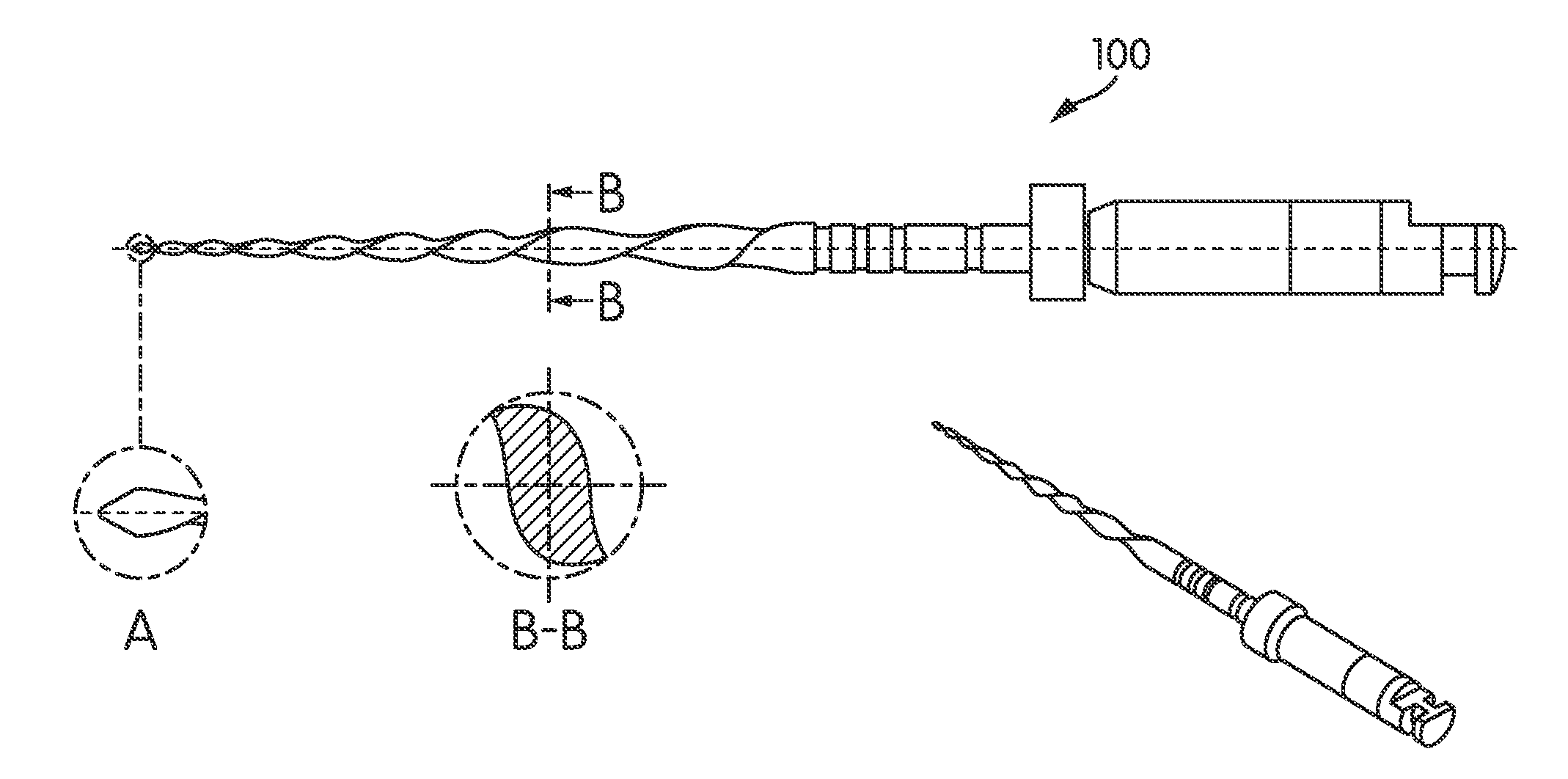

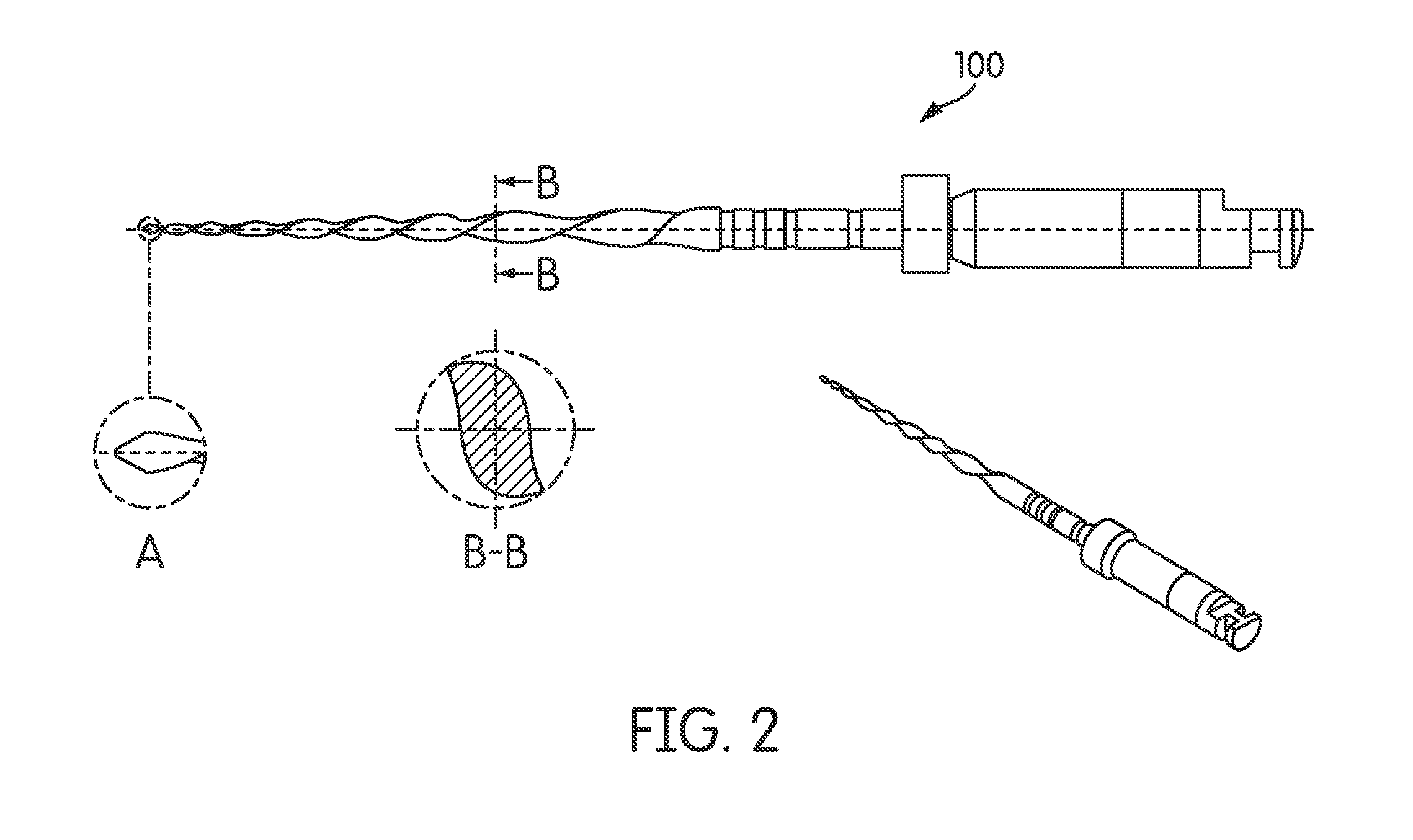

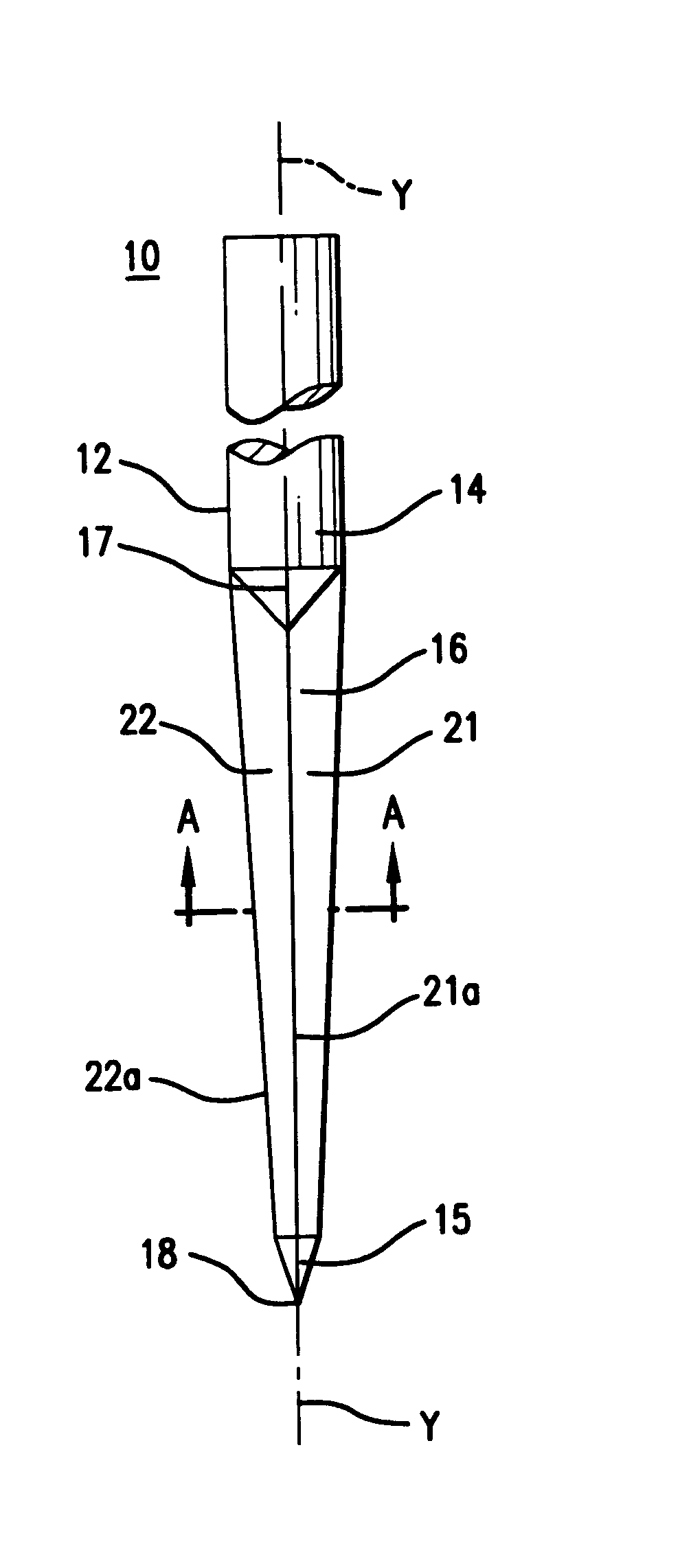

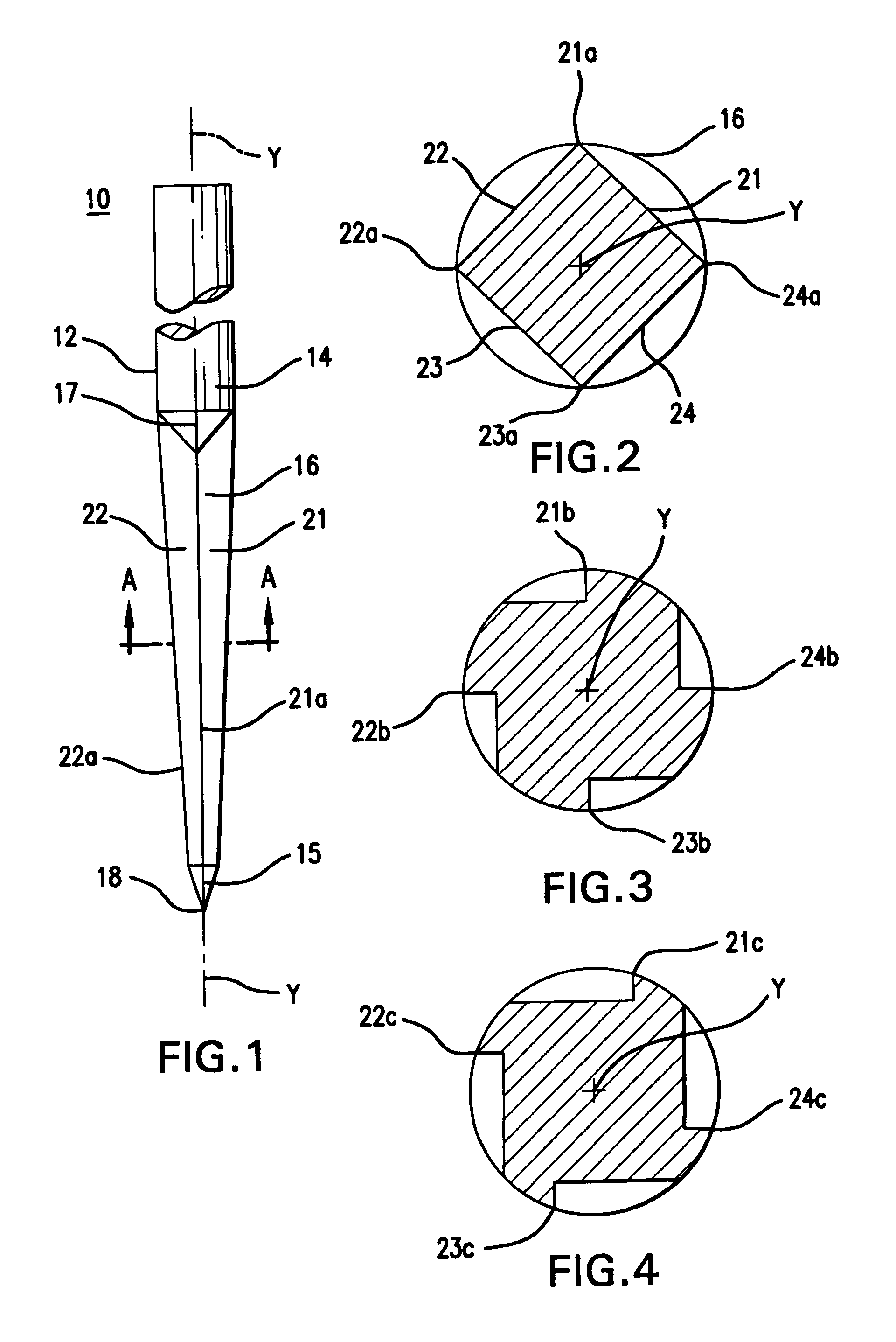

Non-landed endodontic instrument and methods of making such endodontic instruments

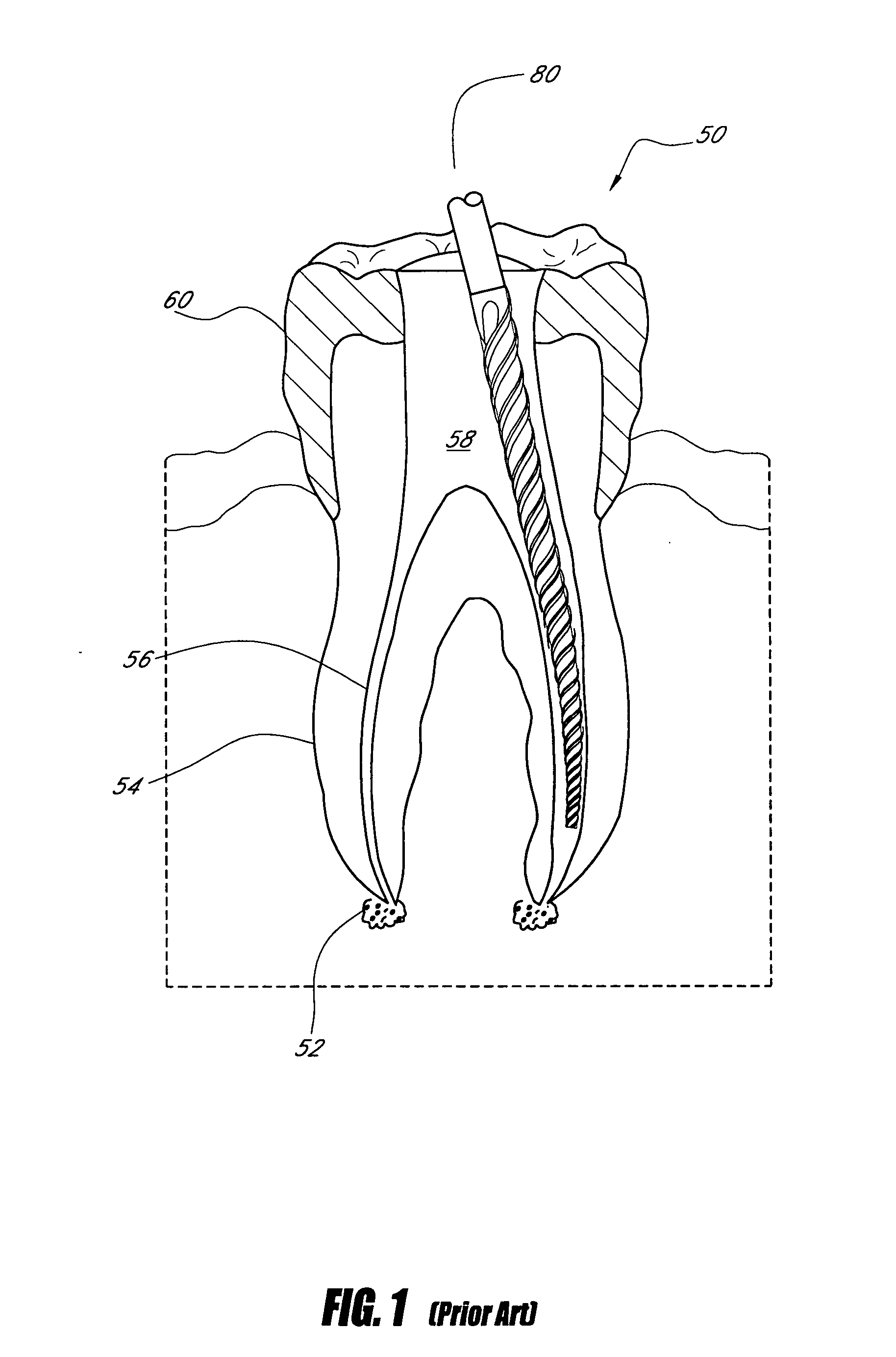

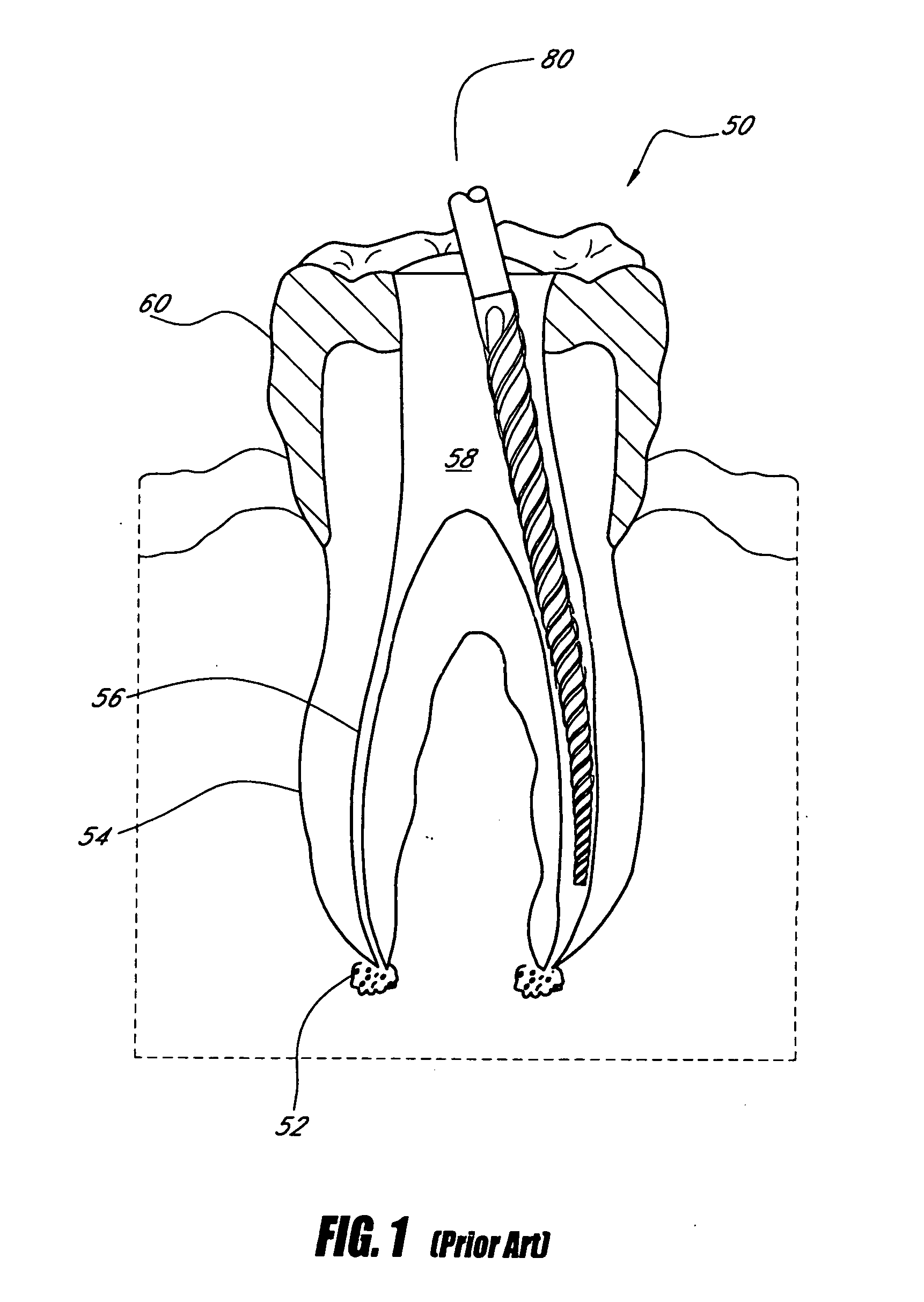

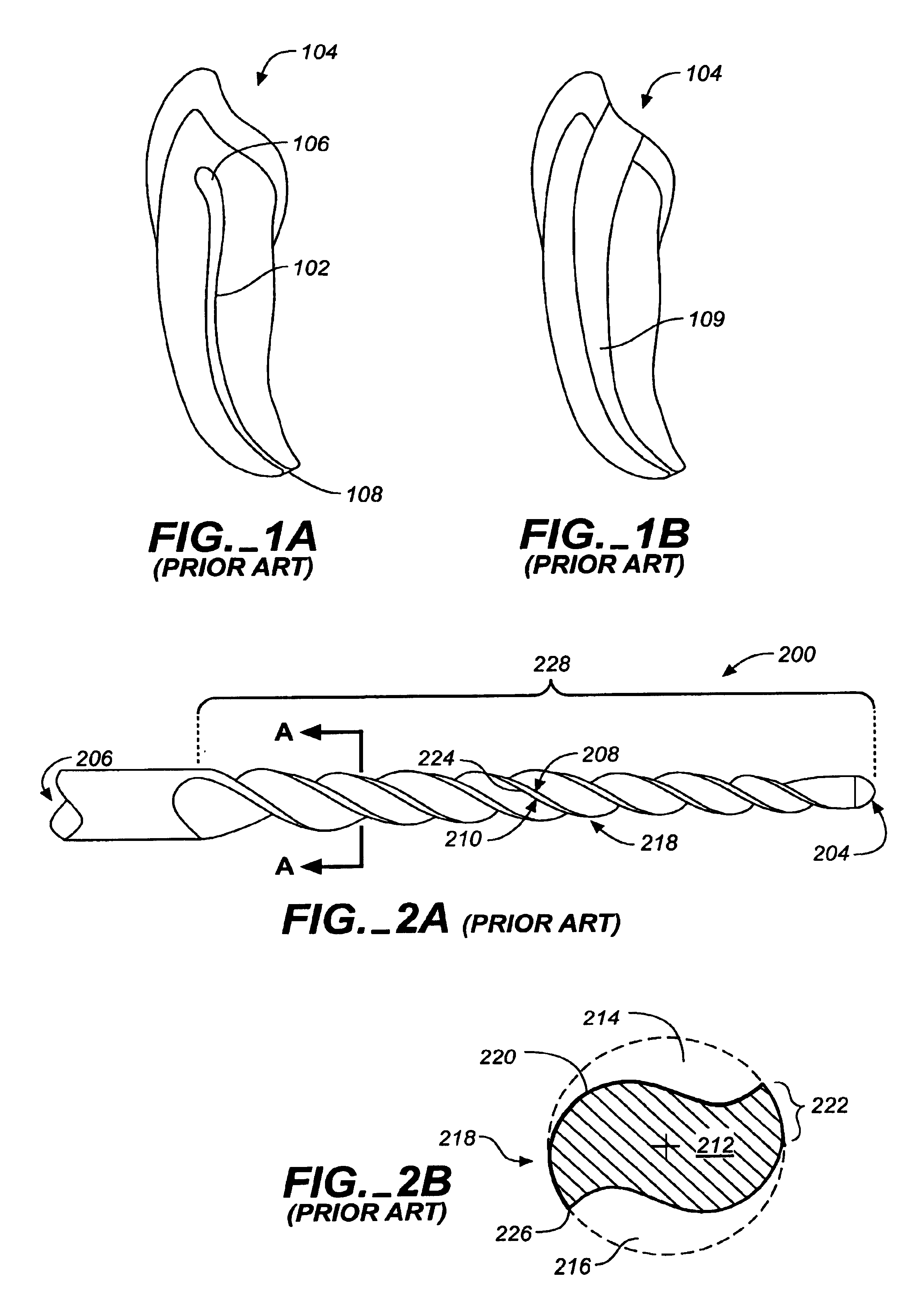

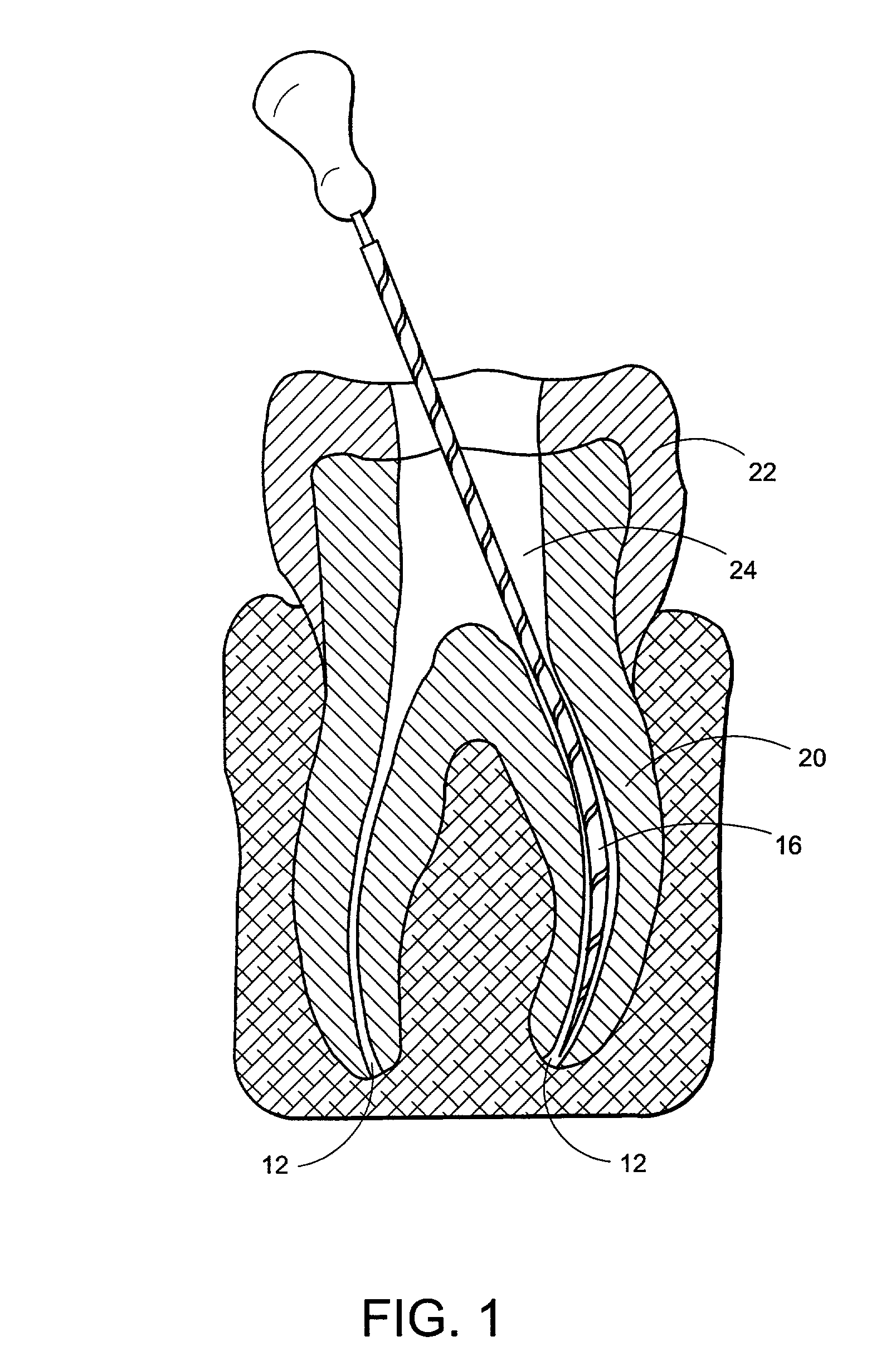

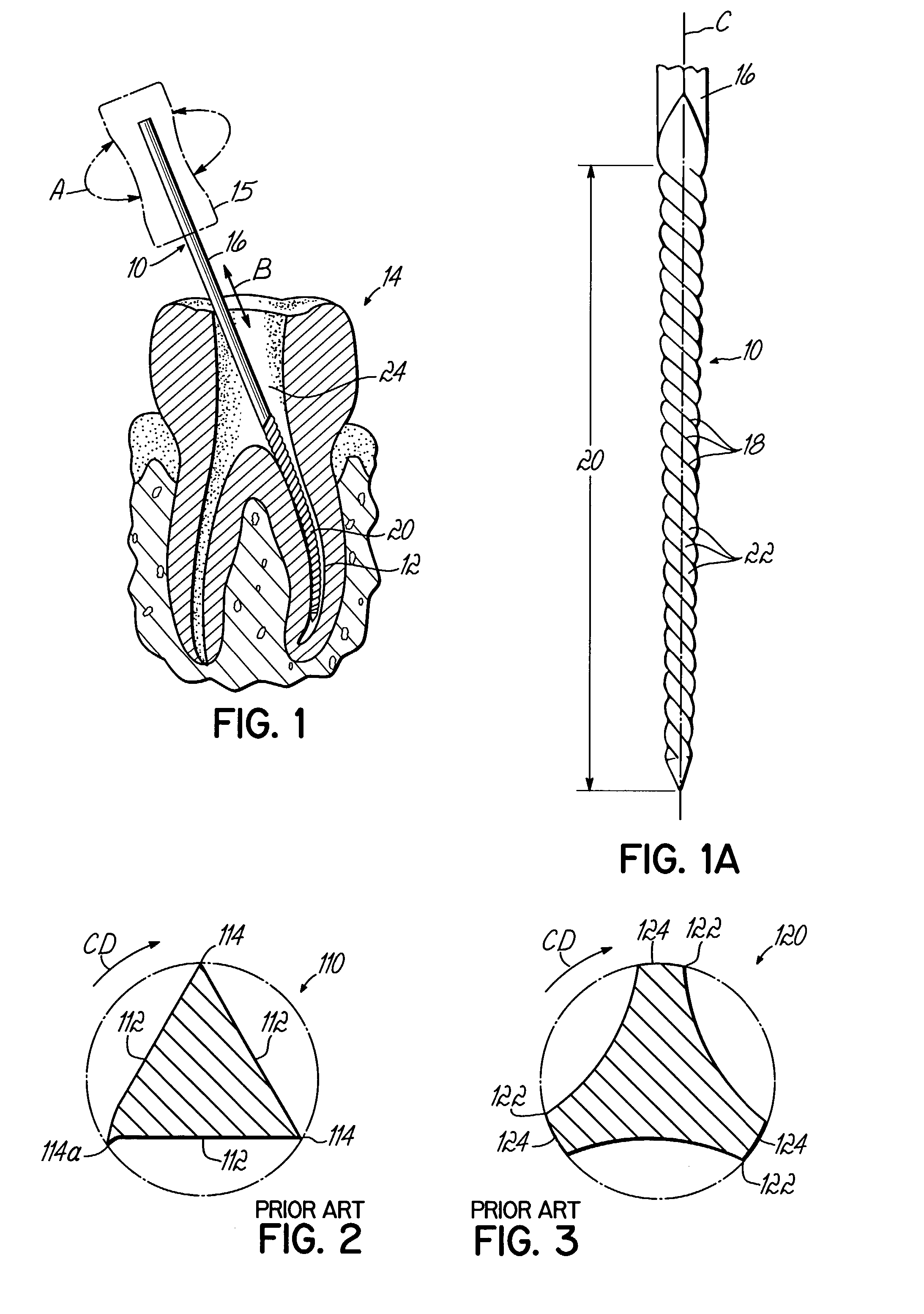

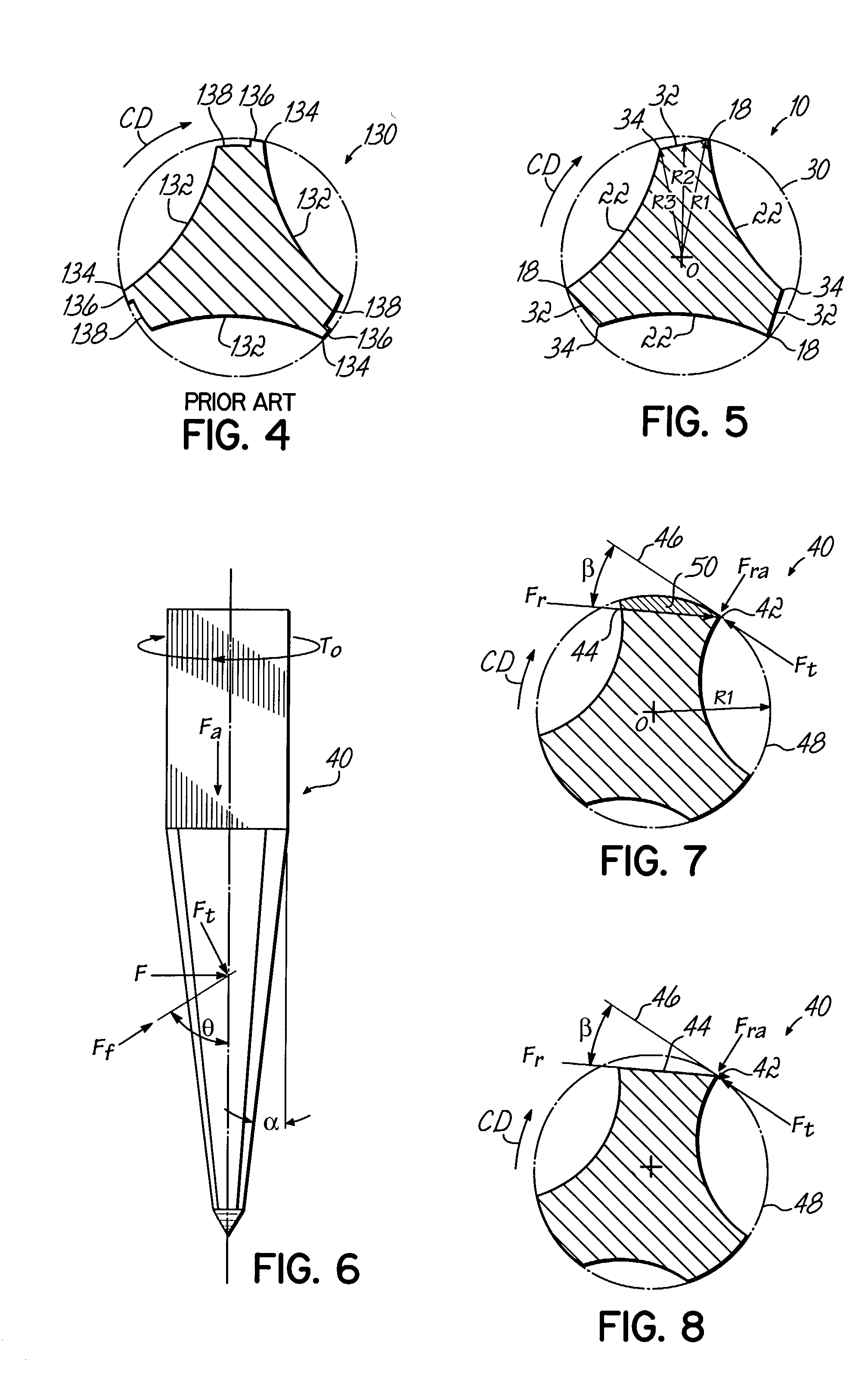

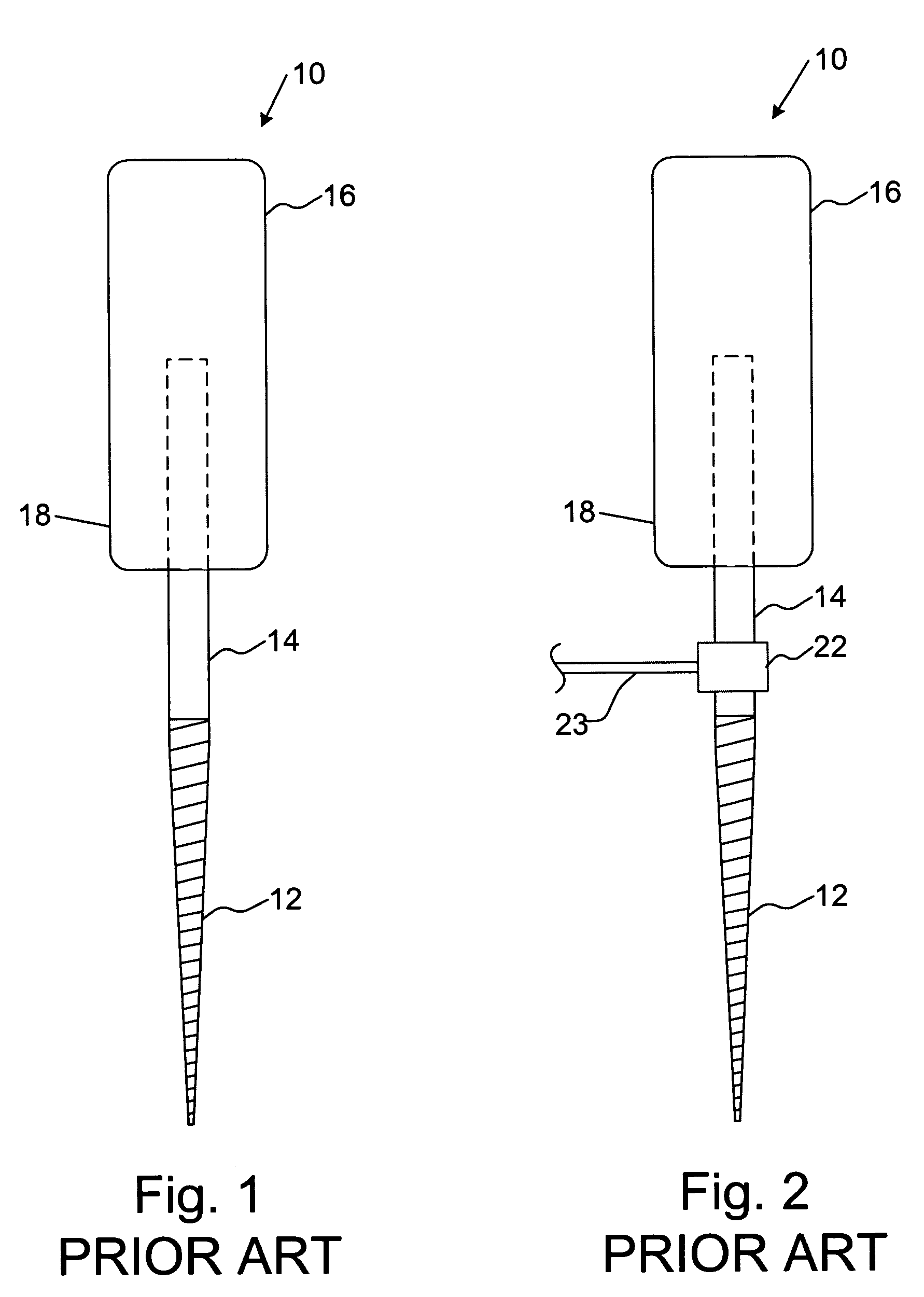

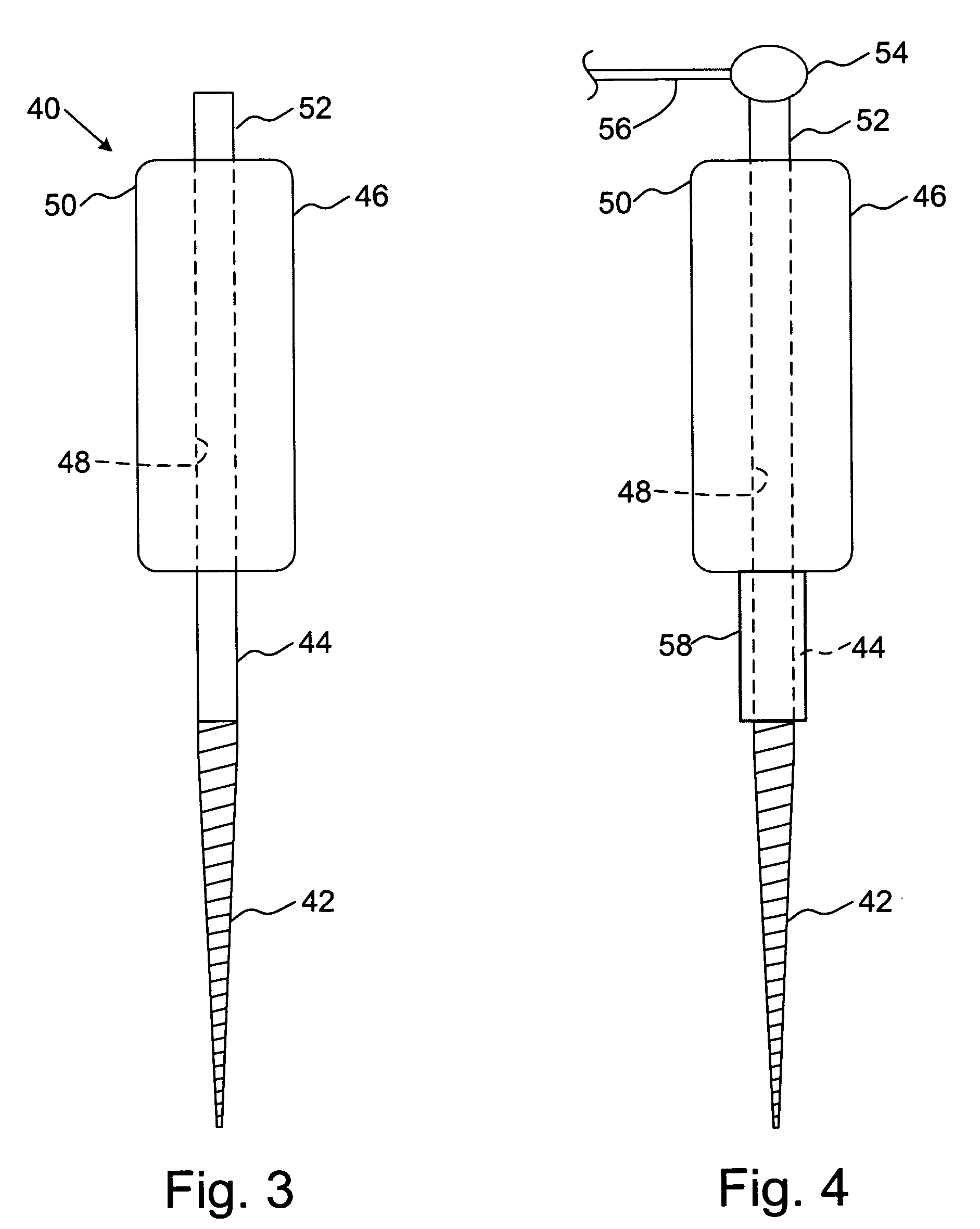

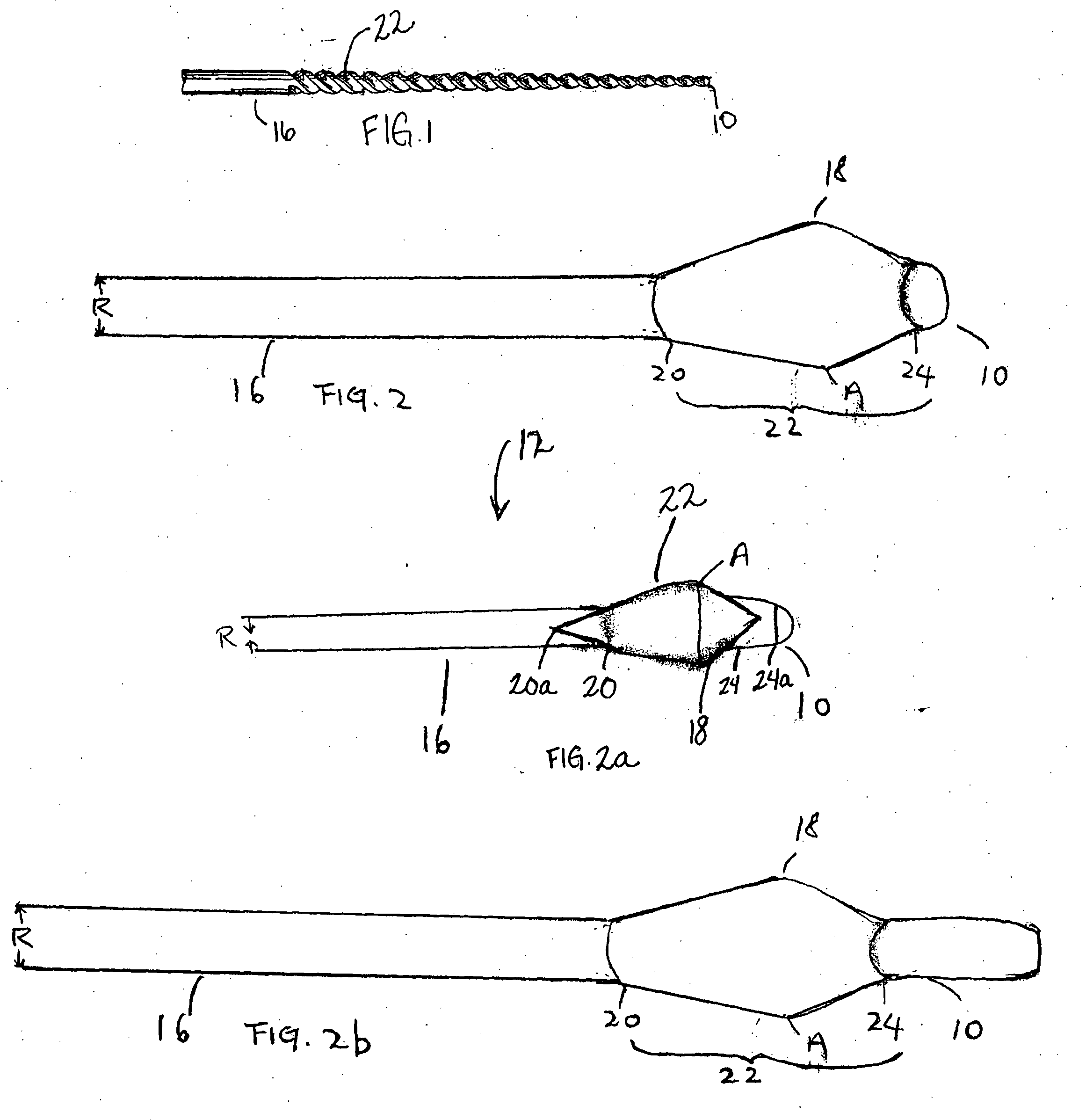

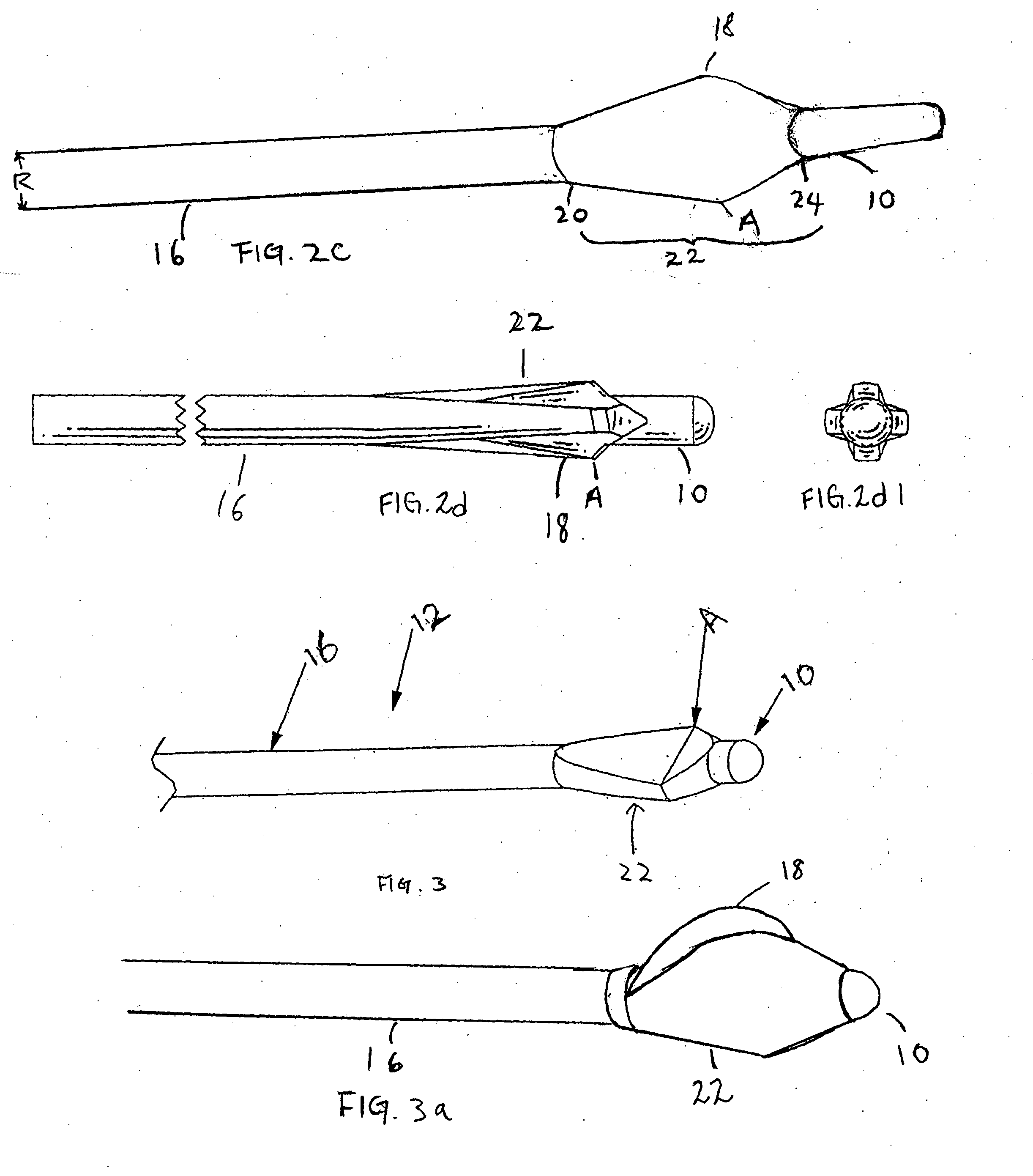

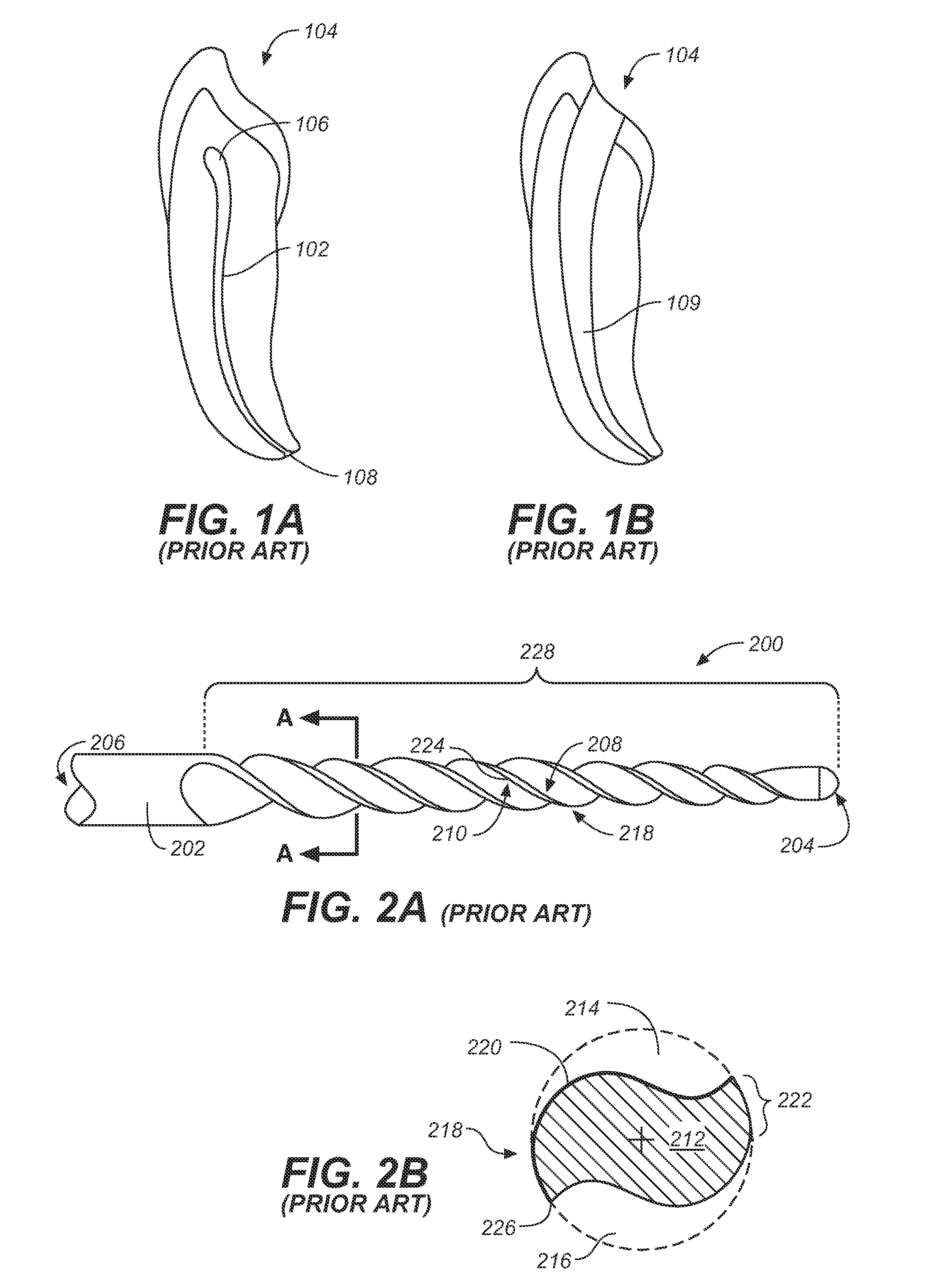

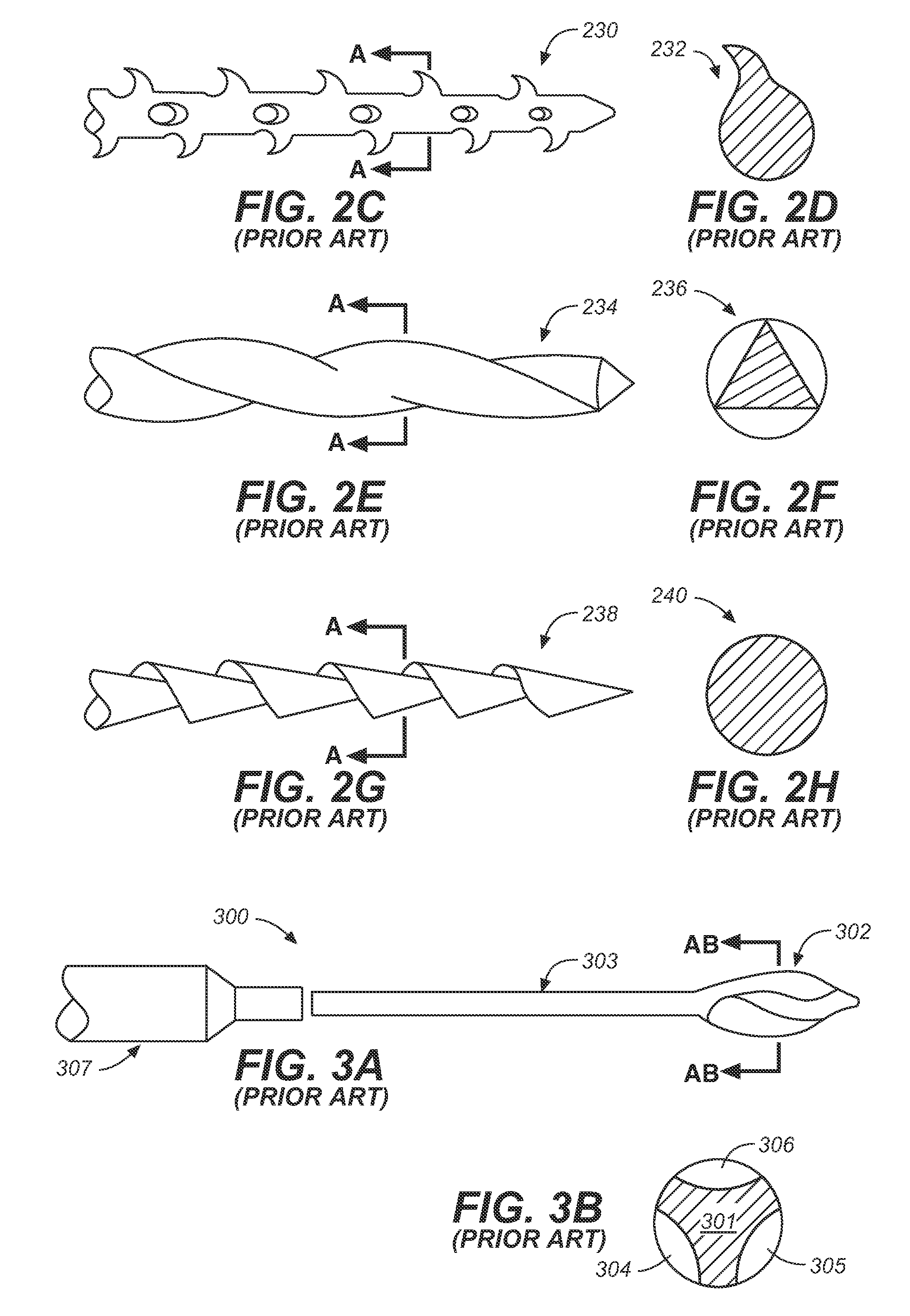

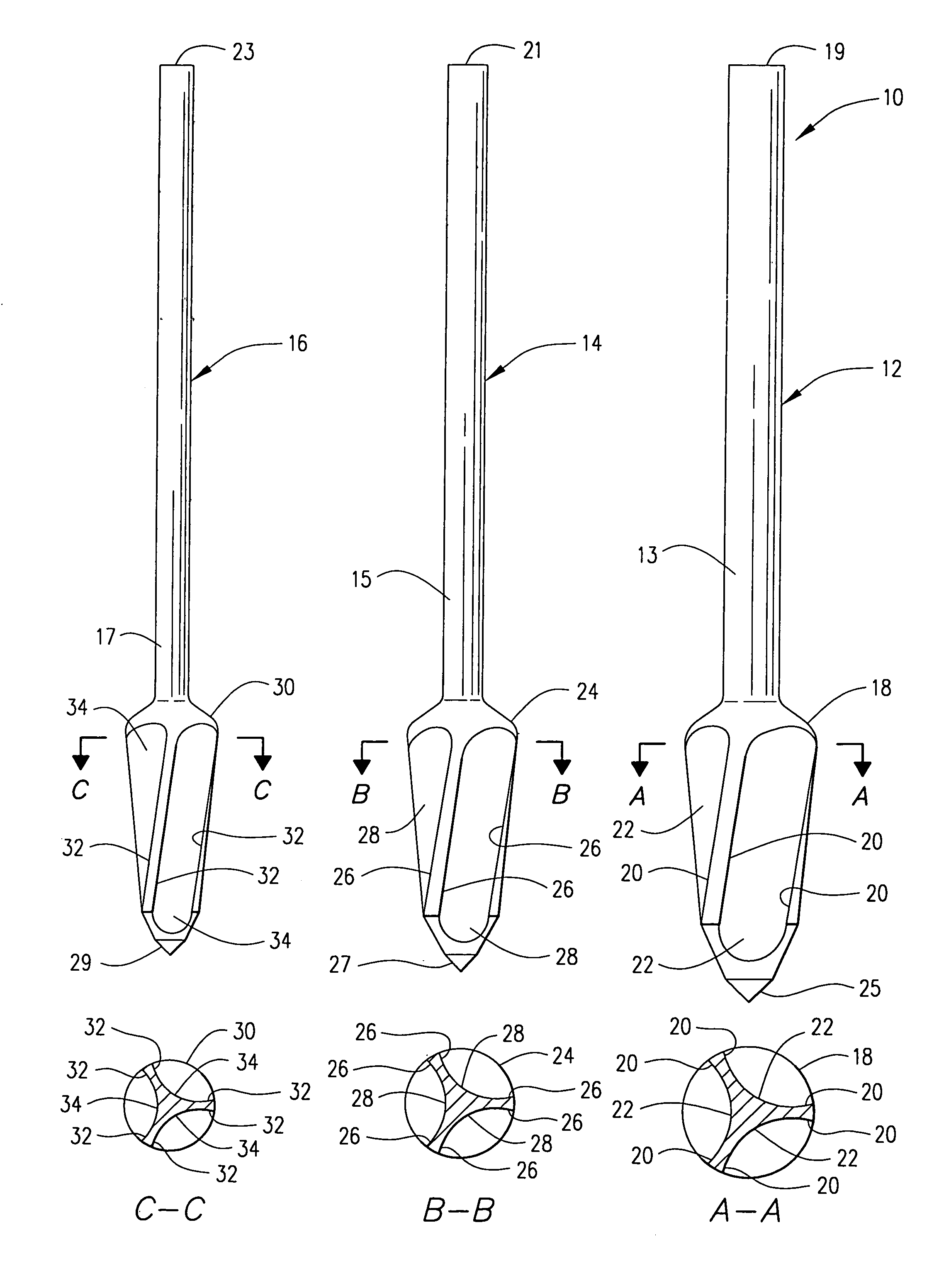

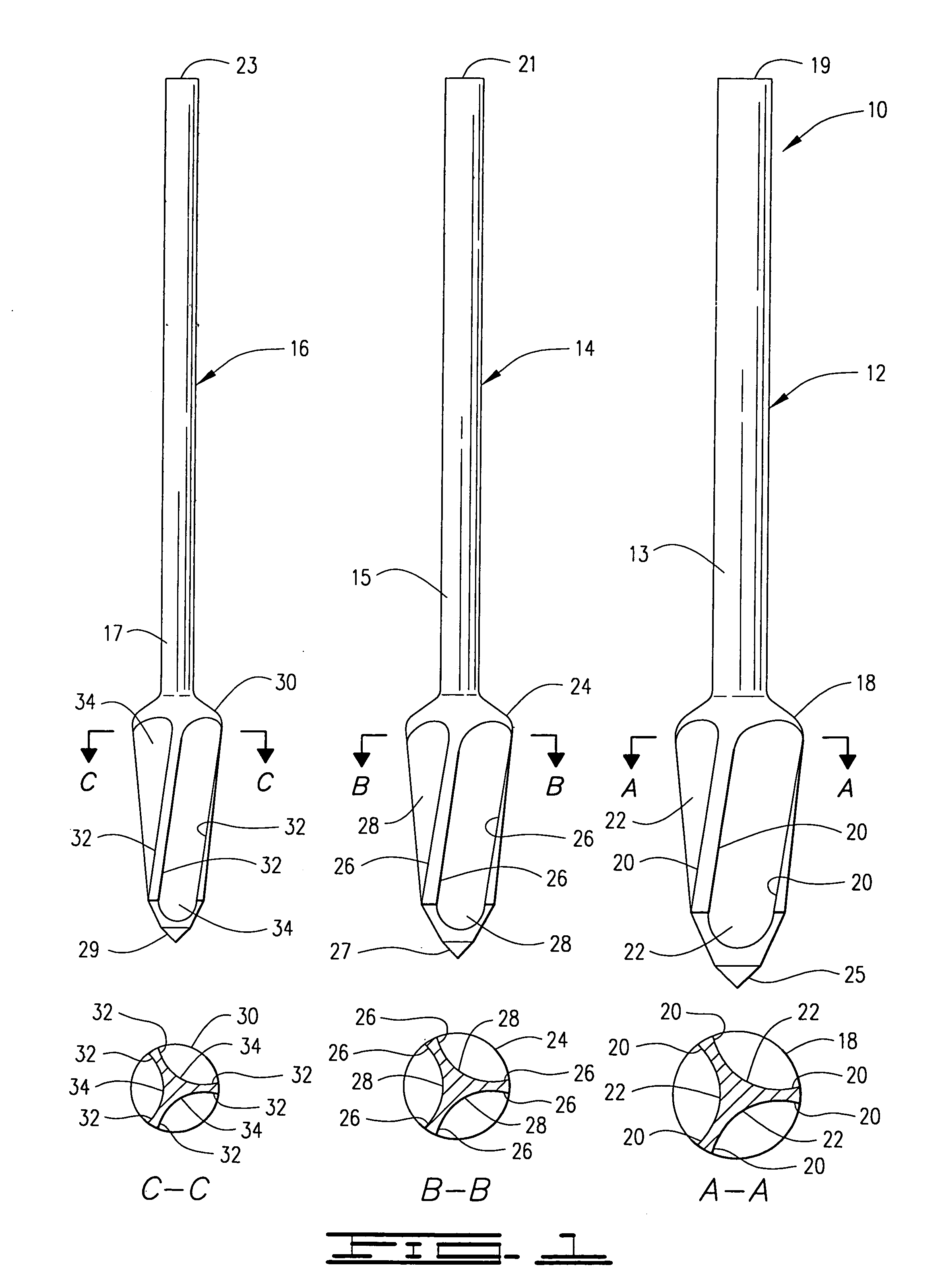

Endodontic instruments, including files, reamers, and condensers, that lack margins or radial lands. The instruments include at least one edge that does not provide significant tissue-cutting action and at least one cutting edge. The elimination of margins or radial lands reduces the surface area over which the root canal wall is contacted by the working length of the instrument.

Owner:ORMCO CORP

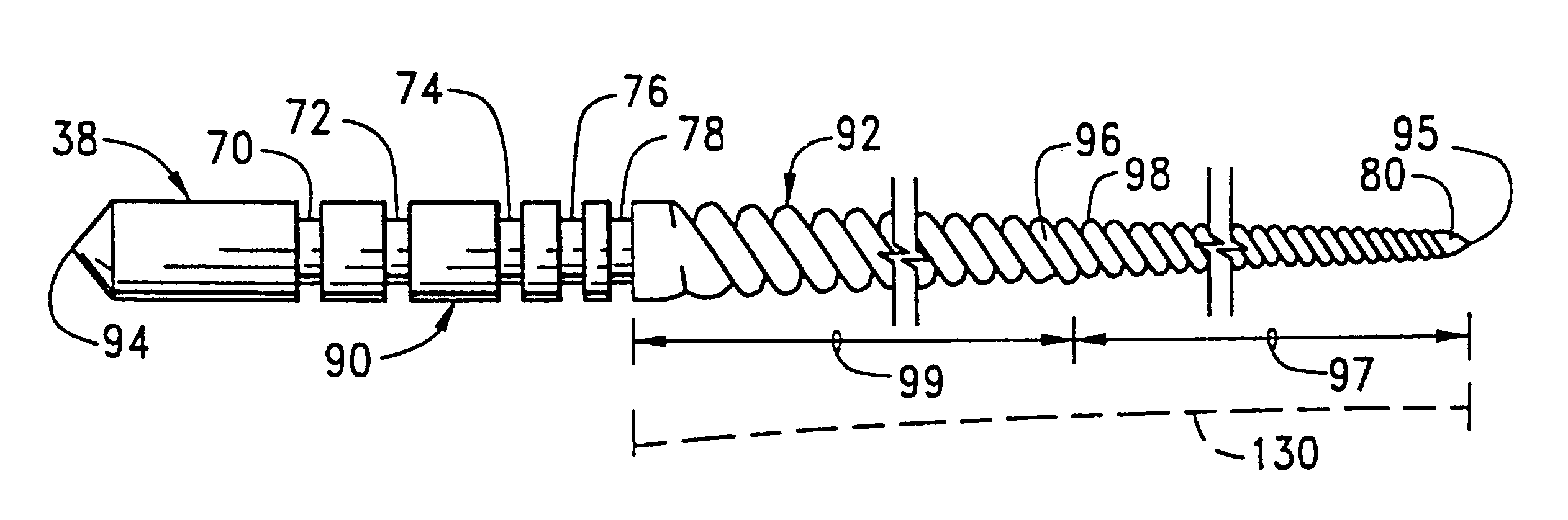

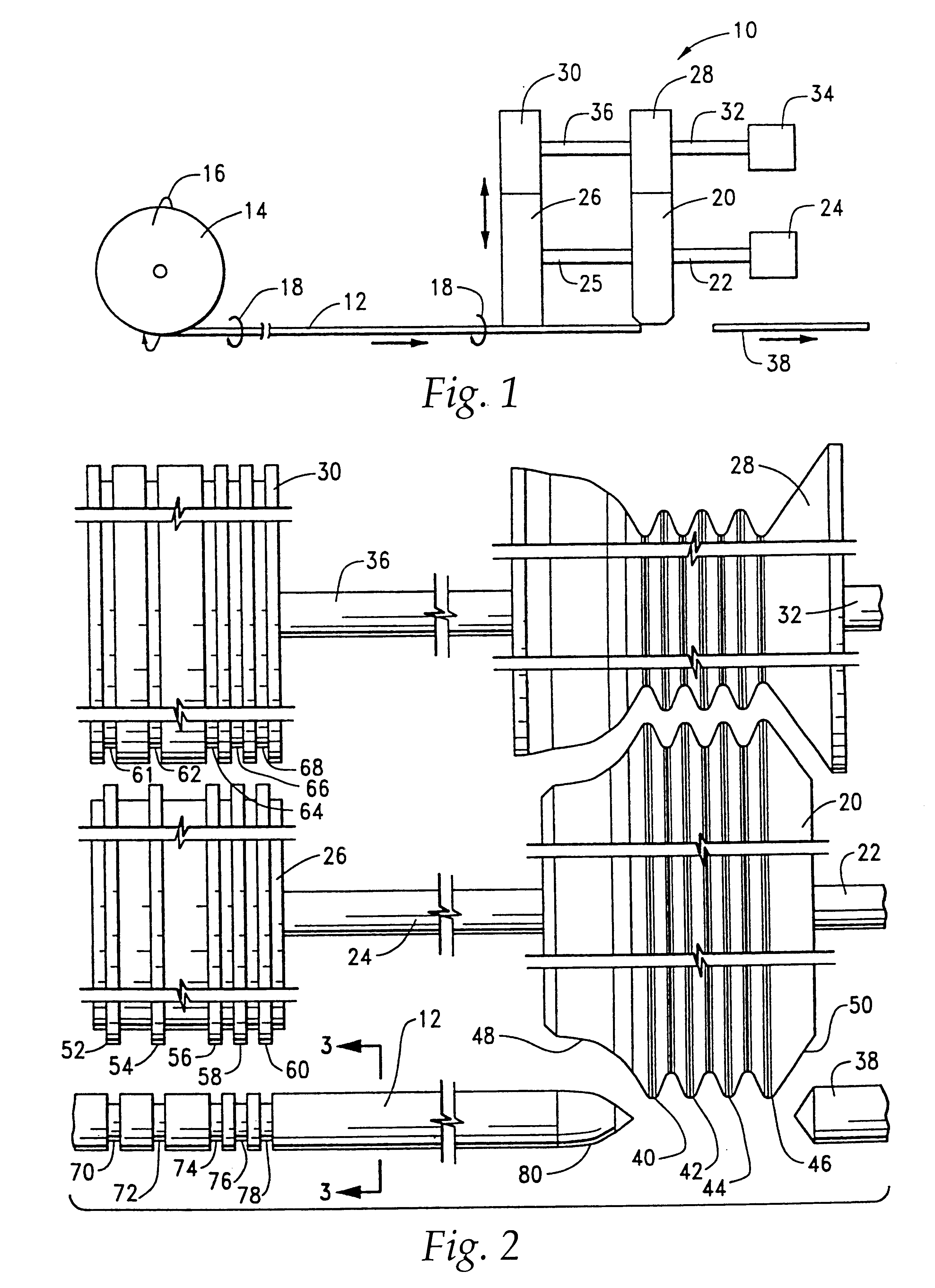

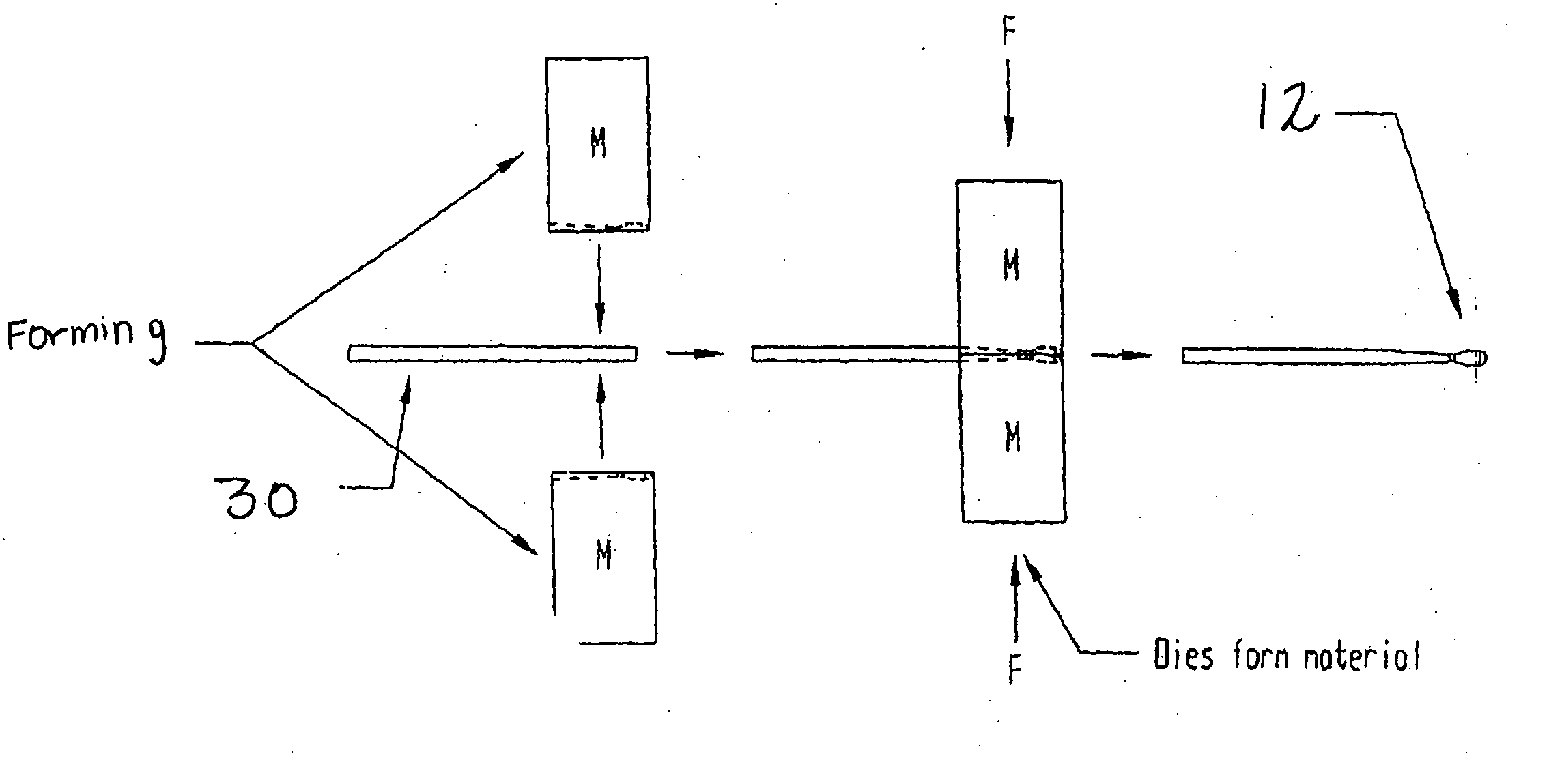

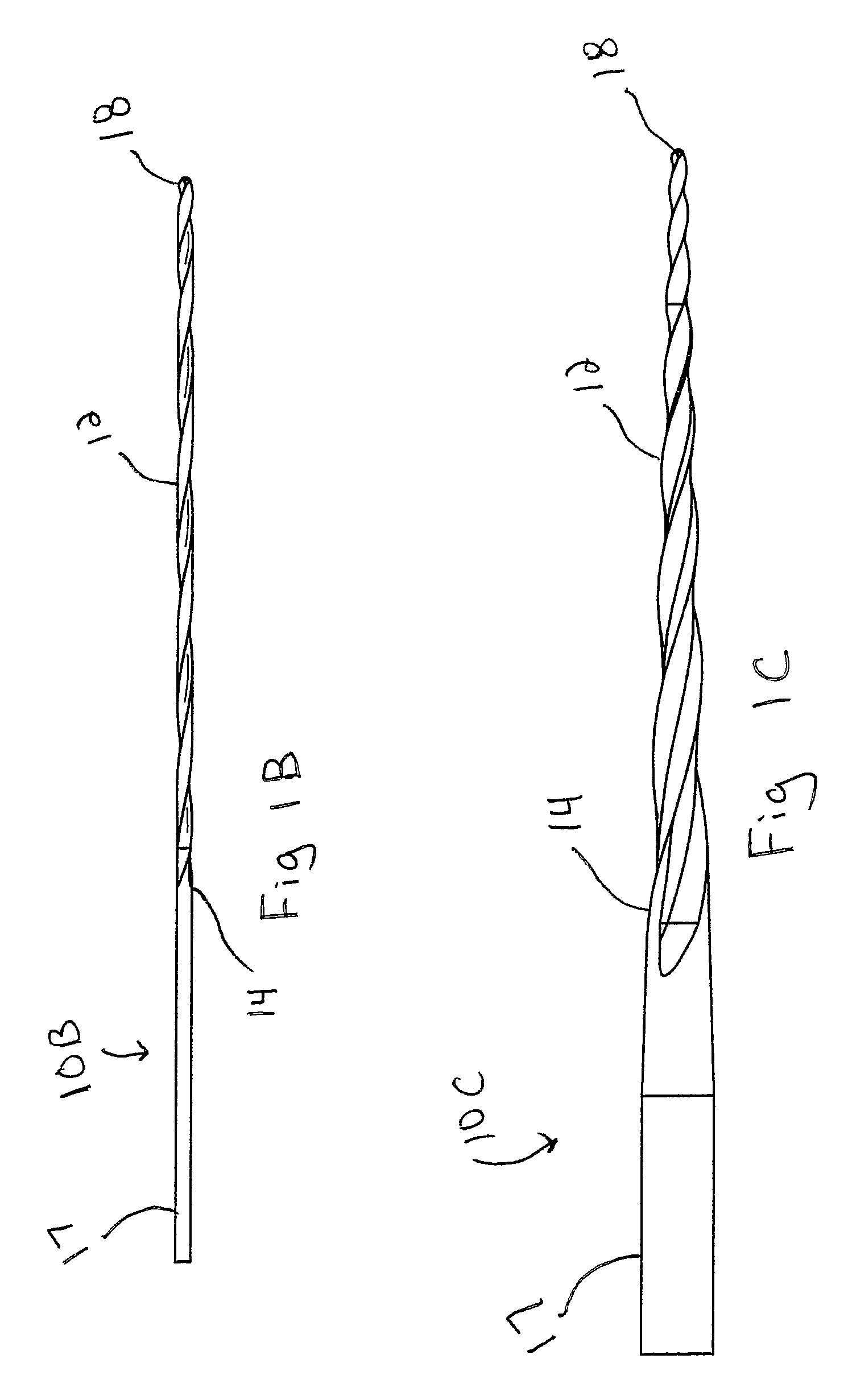

Endodontic instruments and process for producing the same

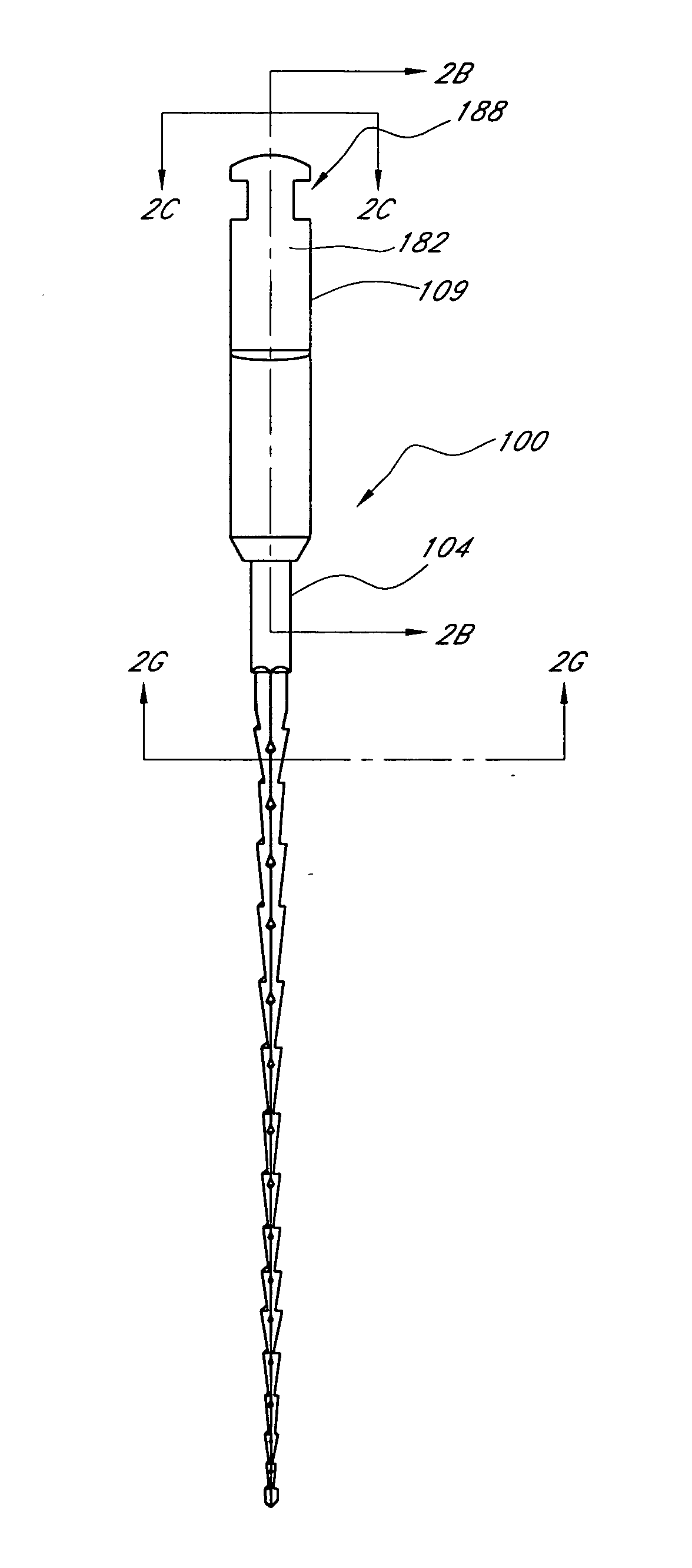

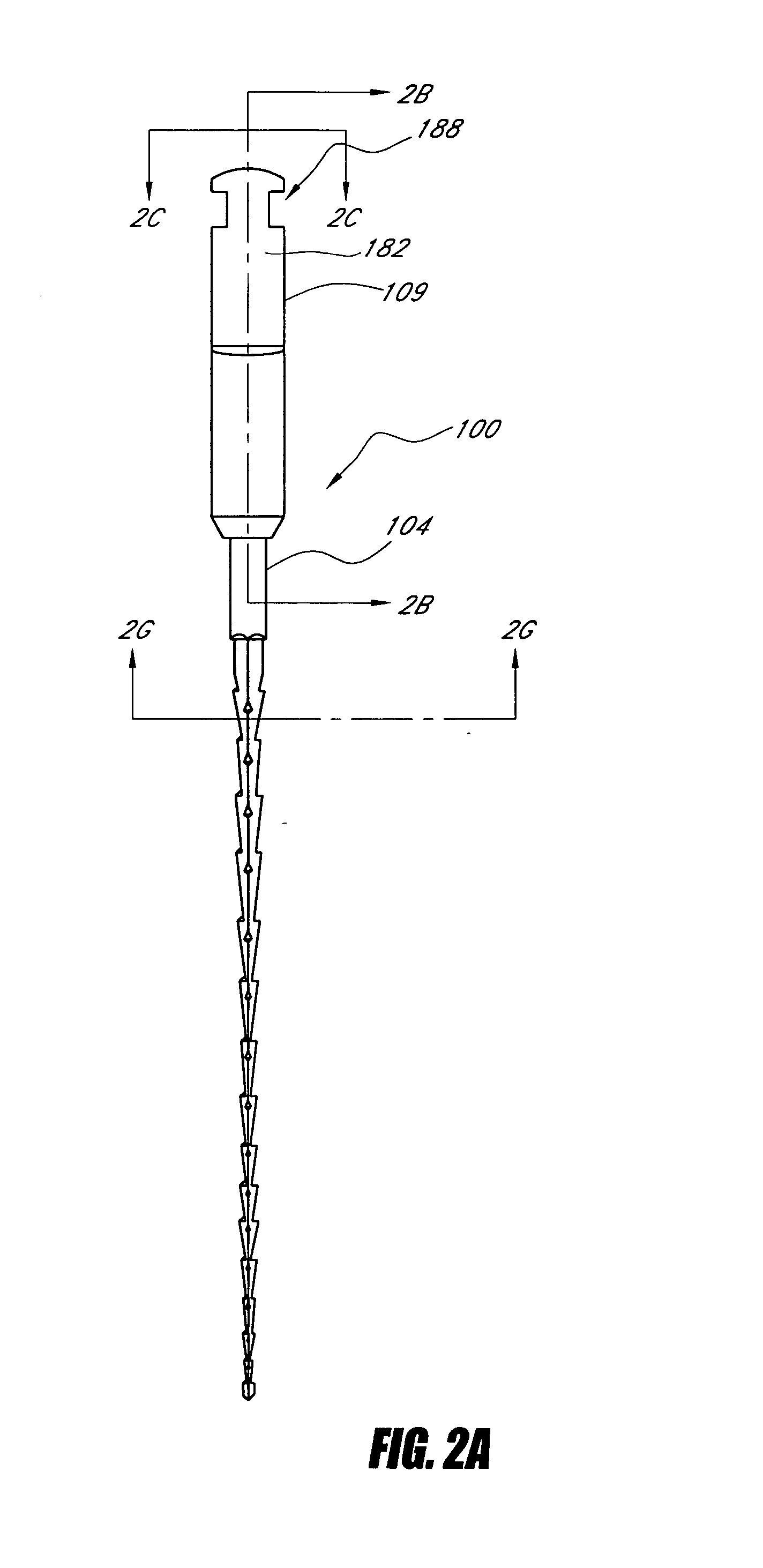

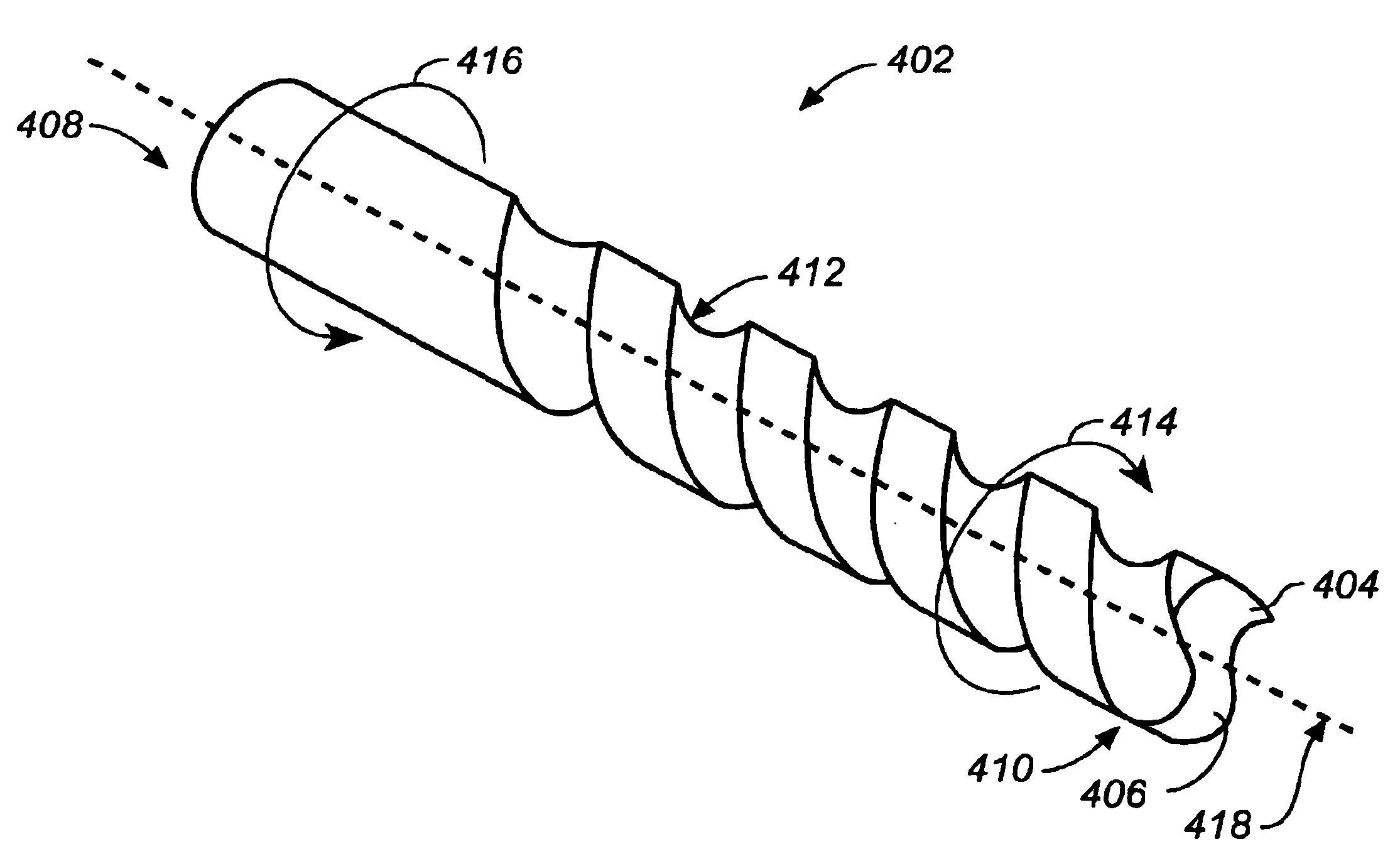

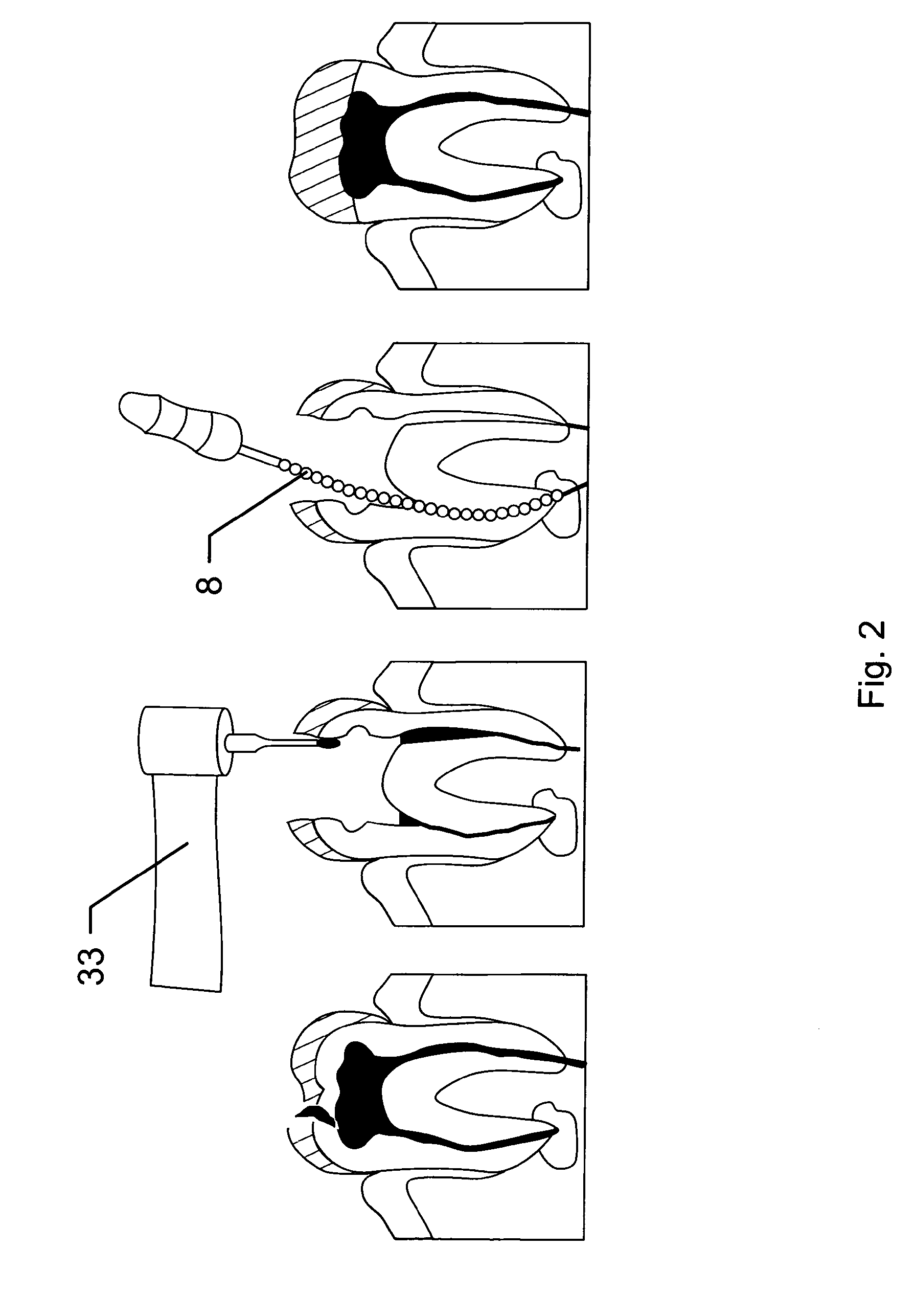

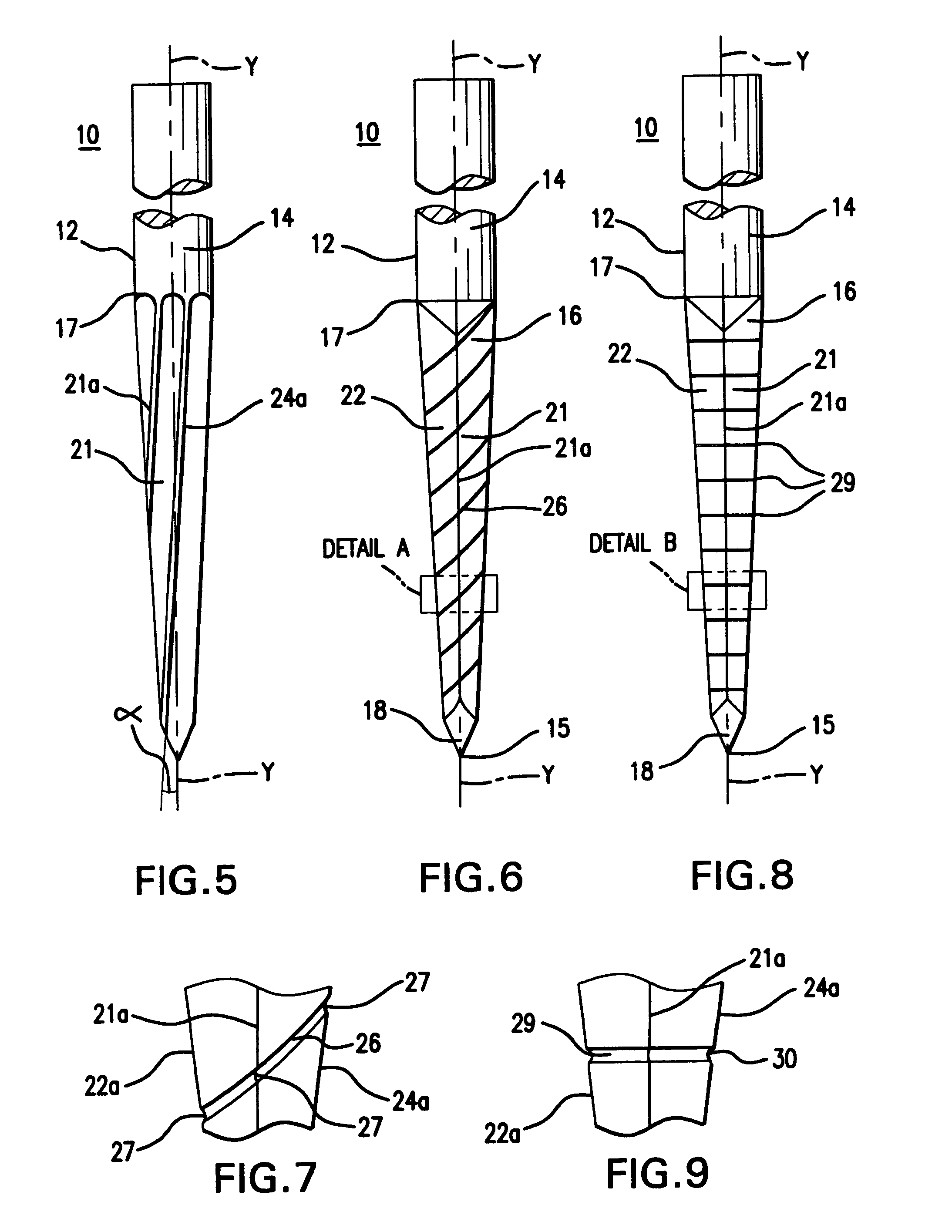

Improved endodontic instruments having multiple tapers and instruments which prevent self-feeding or threading into a root canal during root canal therapy on a tooth are provided as well as a process for producing such instruments. The process basically comprises providing a grinding wheel rotated about a first axis having a plurality of flute grinding ribs and an extra flute grinding rib extending from a periphery thereof. A rotating wire stock is fed past the plurality of flute grinding ribs and the extra flute grinding rib at a feed rate and rotation rate such that a separate spiral flute is ground on the wire stock by each of the plurality of flute grinding ribs and the extra grinding rib. The feed rate and rotation rate of the wire stock is changed during the grinding of the instrument whereby the extra grinding rib follows the spiral path of the first flute grinding rib to thereby reduce the number of spiral flutes being ground on the instrument.

Owner:SWEET PEA TECH

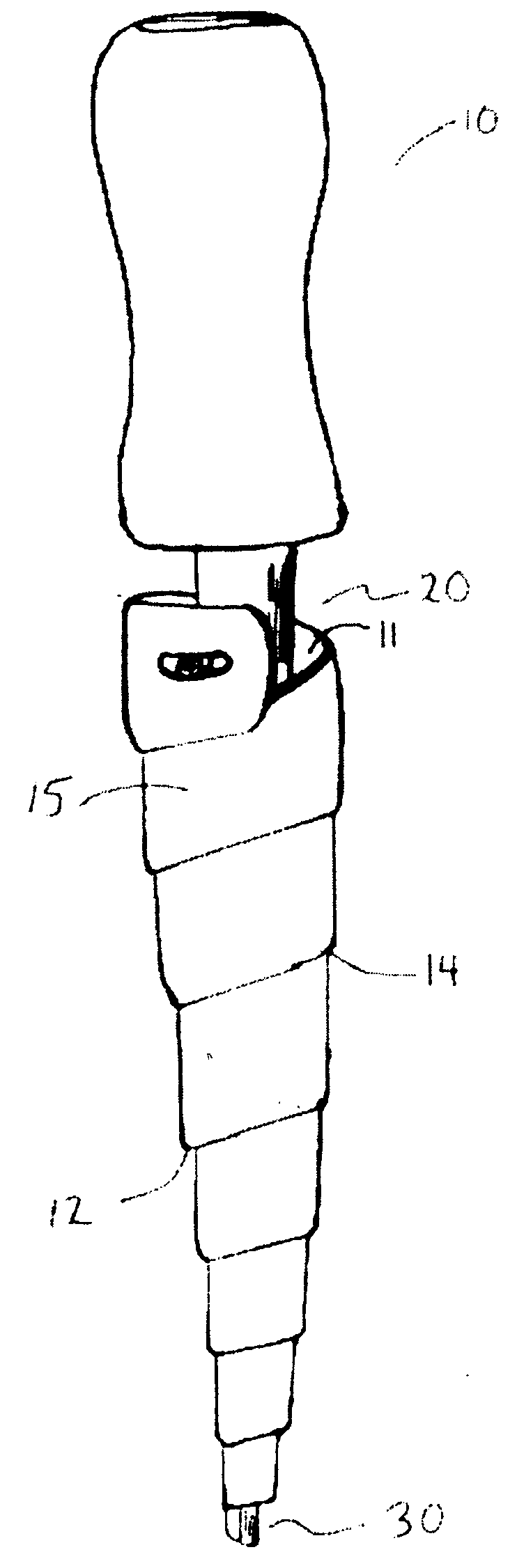

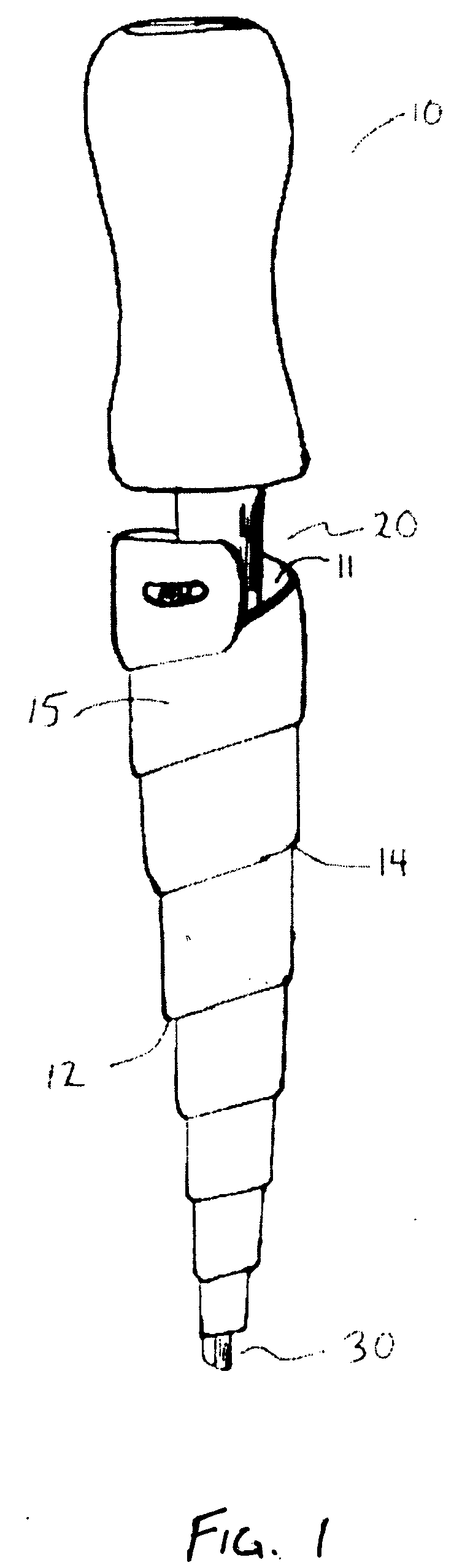

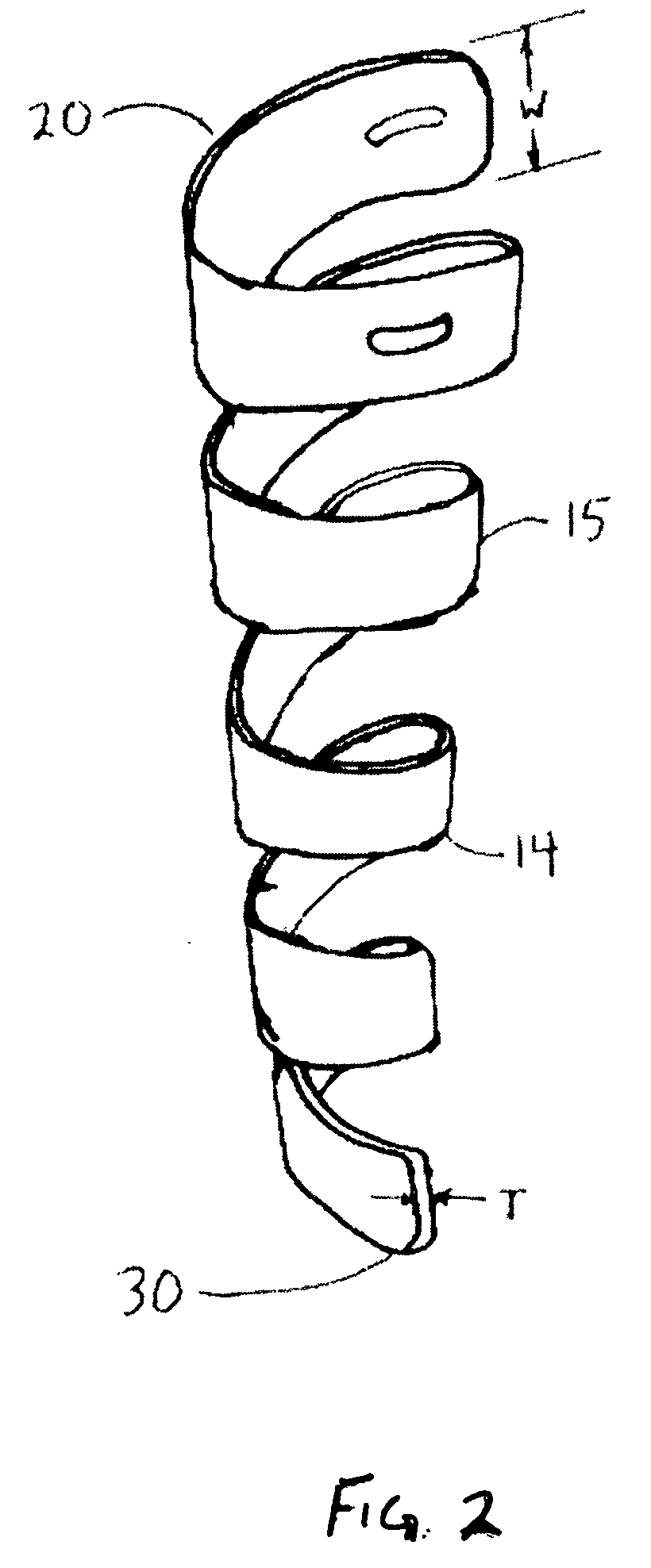

Endodontic instrument and method of manufacturing

InactiveUS20100233648A1Good curative effectReduce in quantitySurgeryWheelchairs/patient conveyanceENDODONTIC PROCEDURESEngineering

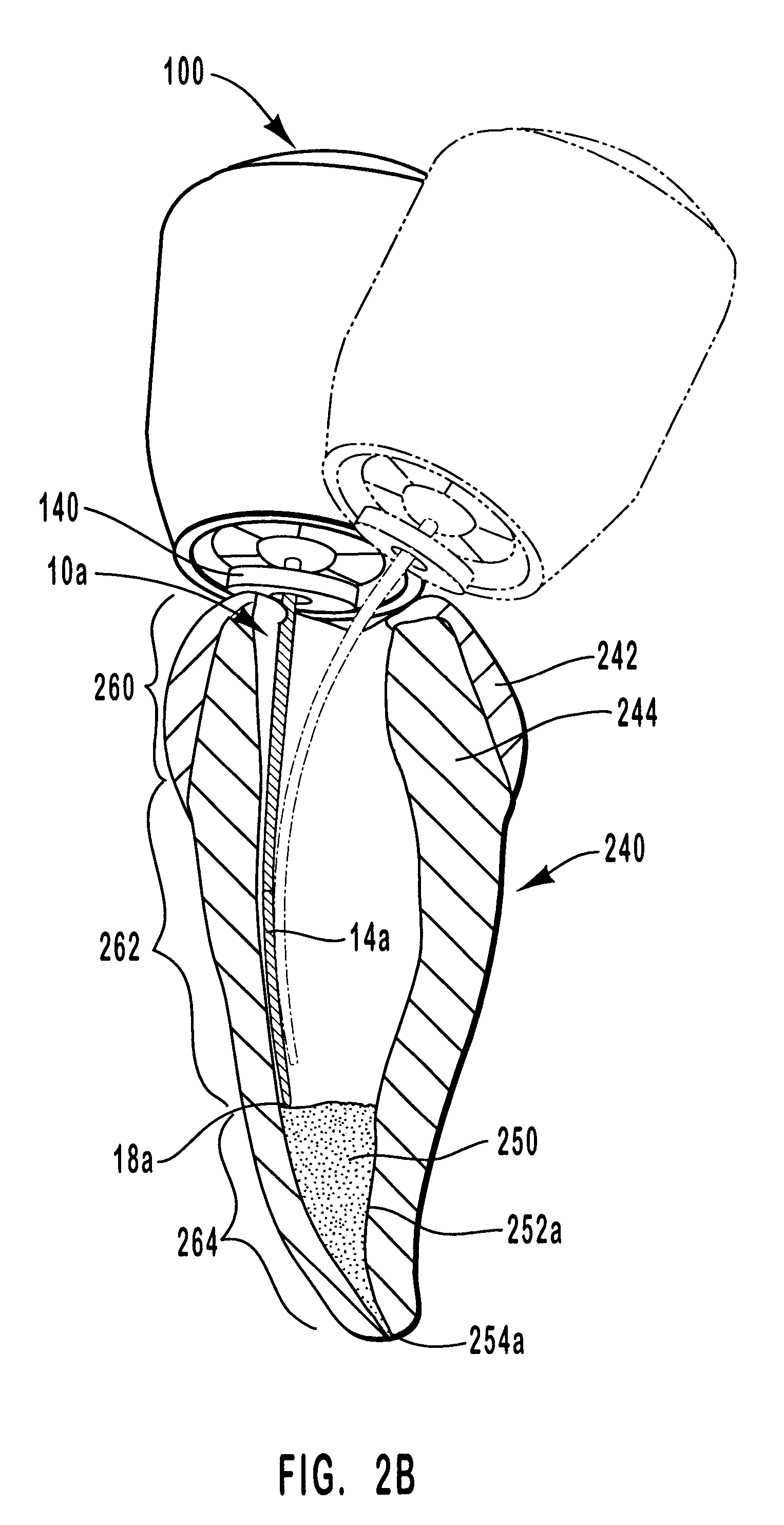

An endodontic instrument and method for making same is provided. A rod of superelastic material is set into a shaped configuration to form an instrument, such that the instrument may be inserted into a root canal in a configuration different than the shaped configuration and revert towards its shaped configuration during the endodontic procedure.

Owner:FERBER MARK S

Endodontic instruments

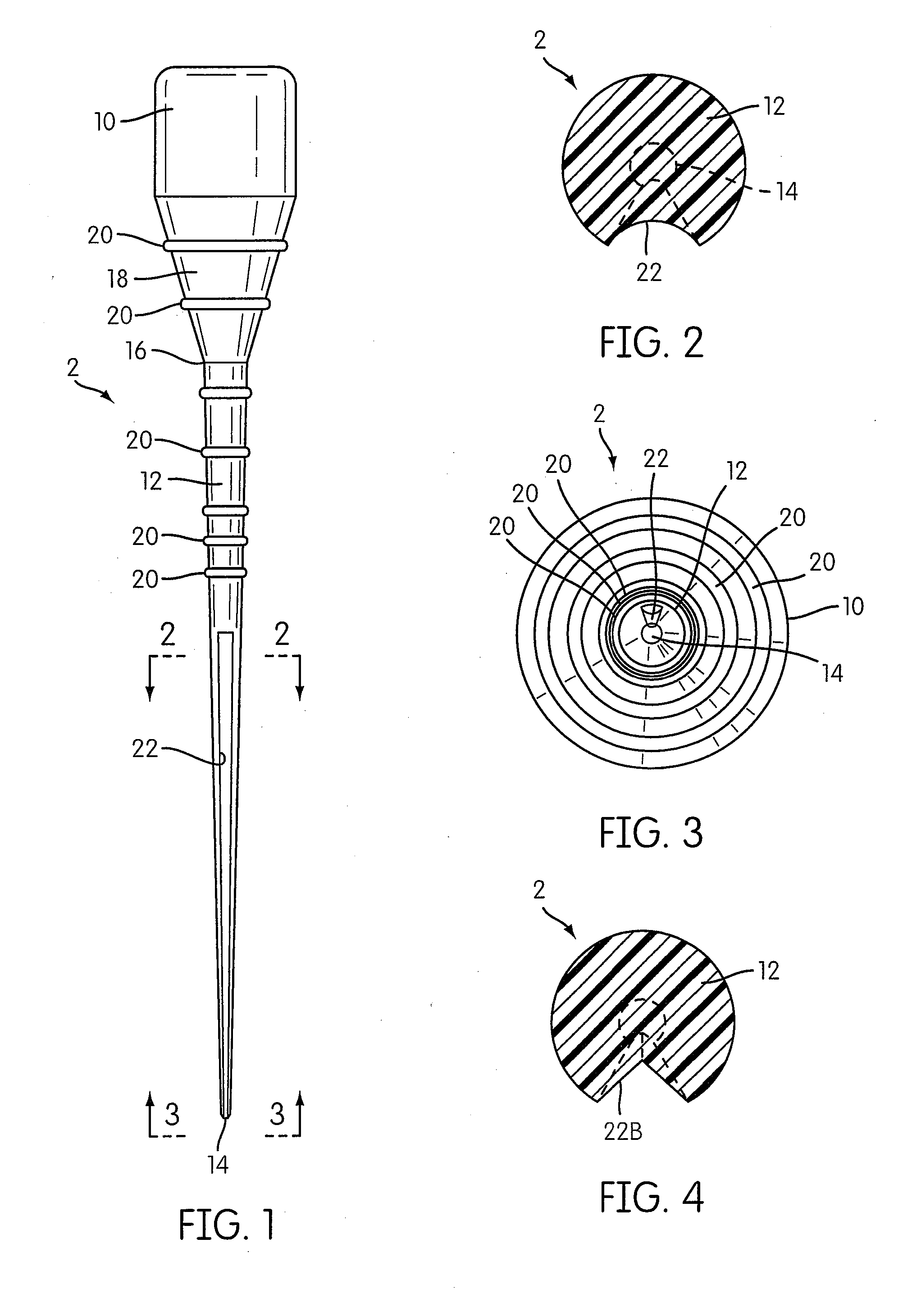

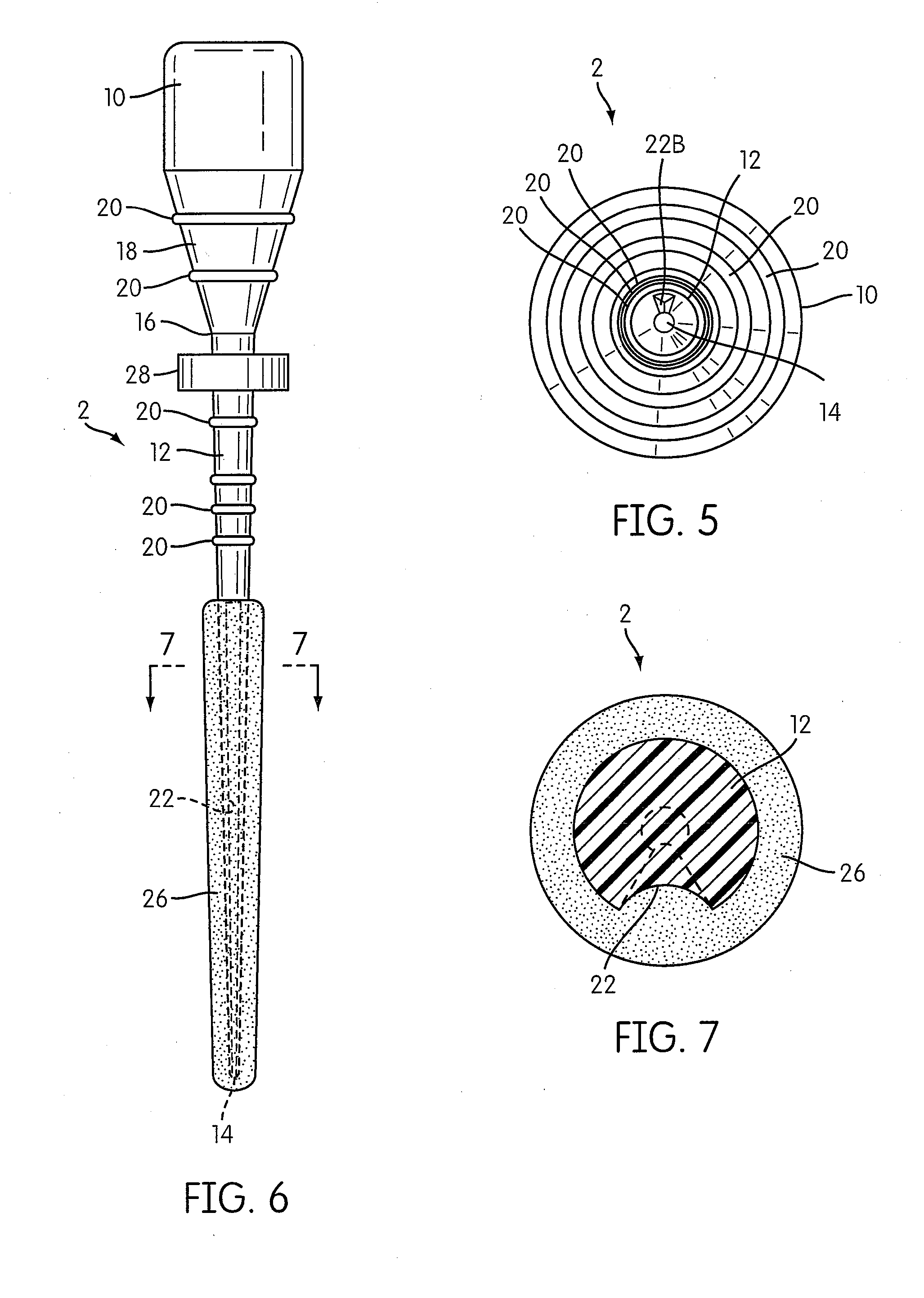

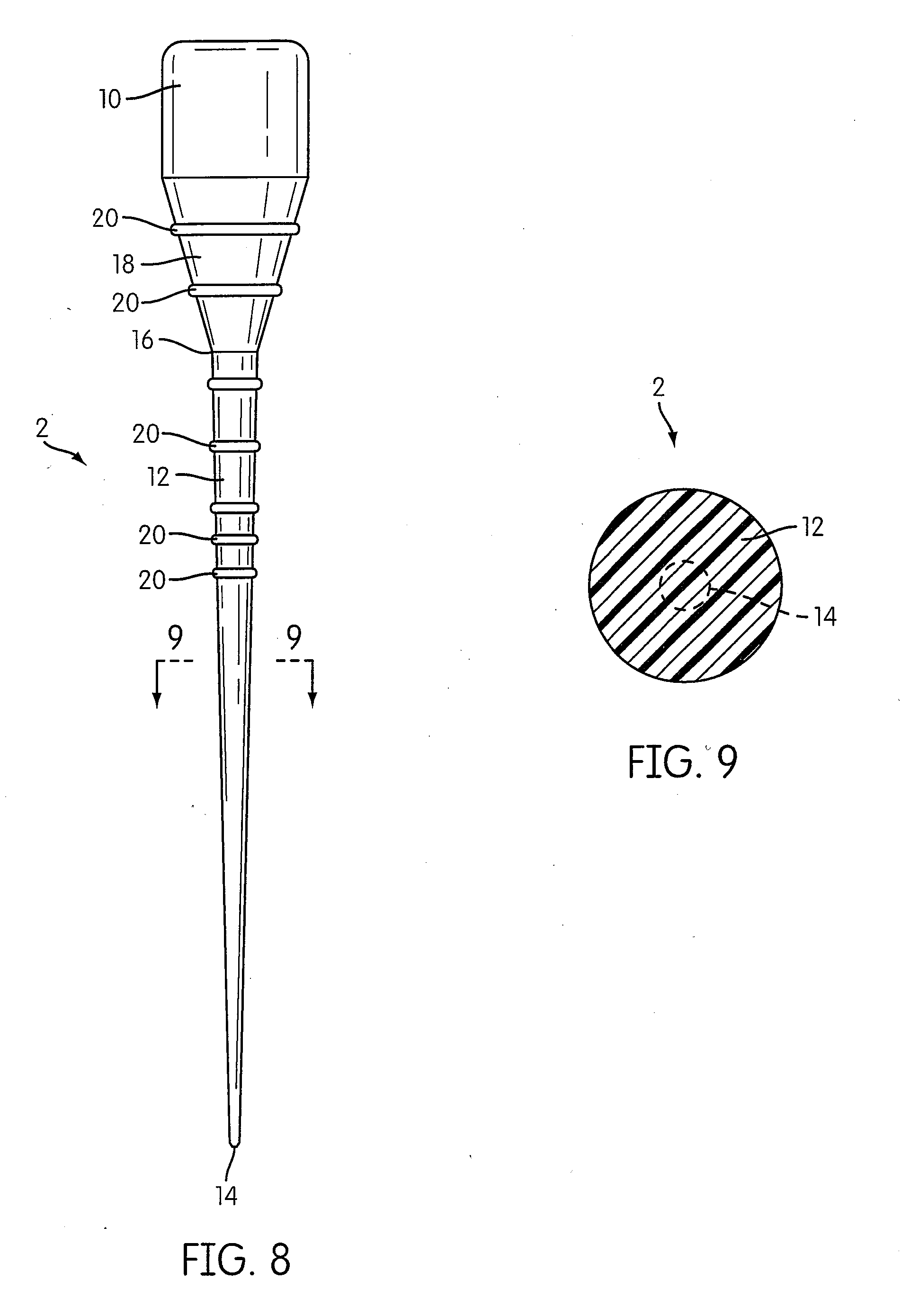

The present invention provides an improved endodontic instrument. The instrument can be constructed of a ribbon of material such as any material that has a suitable edge for cutting and can be twisted or bent into any desired shape. The ribbon can be made of a metal, a polymeric film or combinations thereof. The ribbon can have a straight edge or a serrated one. The instrument is in the shape of a cone, tapering towards one end. It has a hollow interior and cutting edges disposed in a helical pattern along its length. The instrument can perform various or all of the functions of any endodontic instrument used in the root canal procedure.

Owner:DISCUS DENTAL LLC

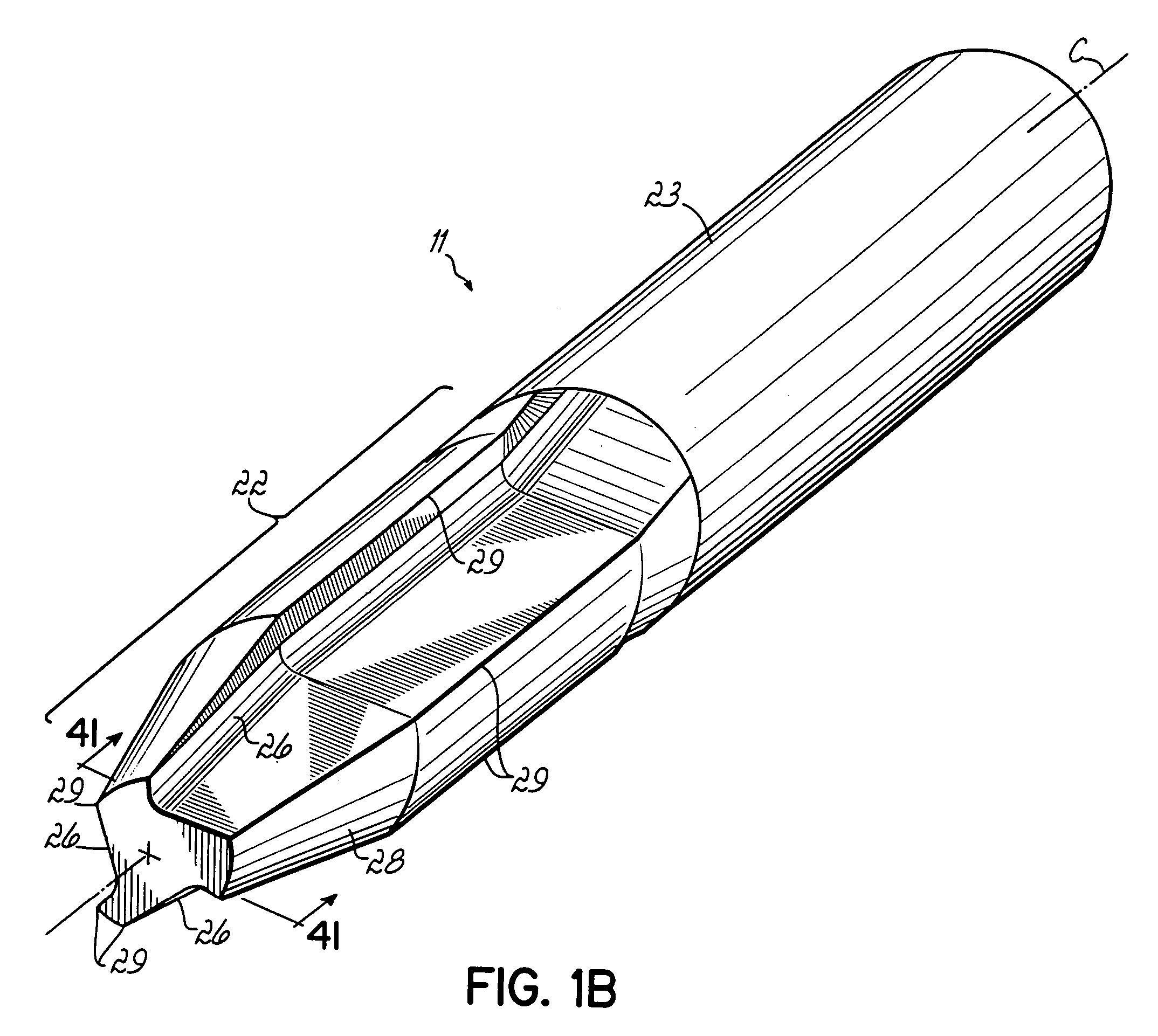

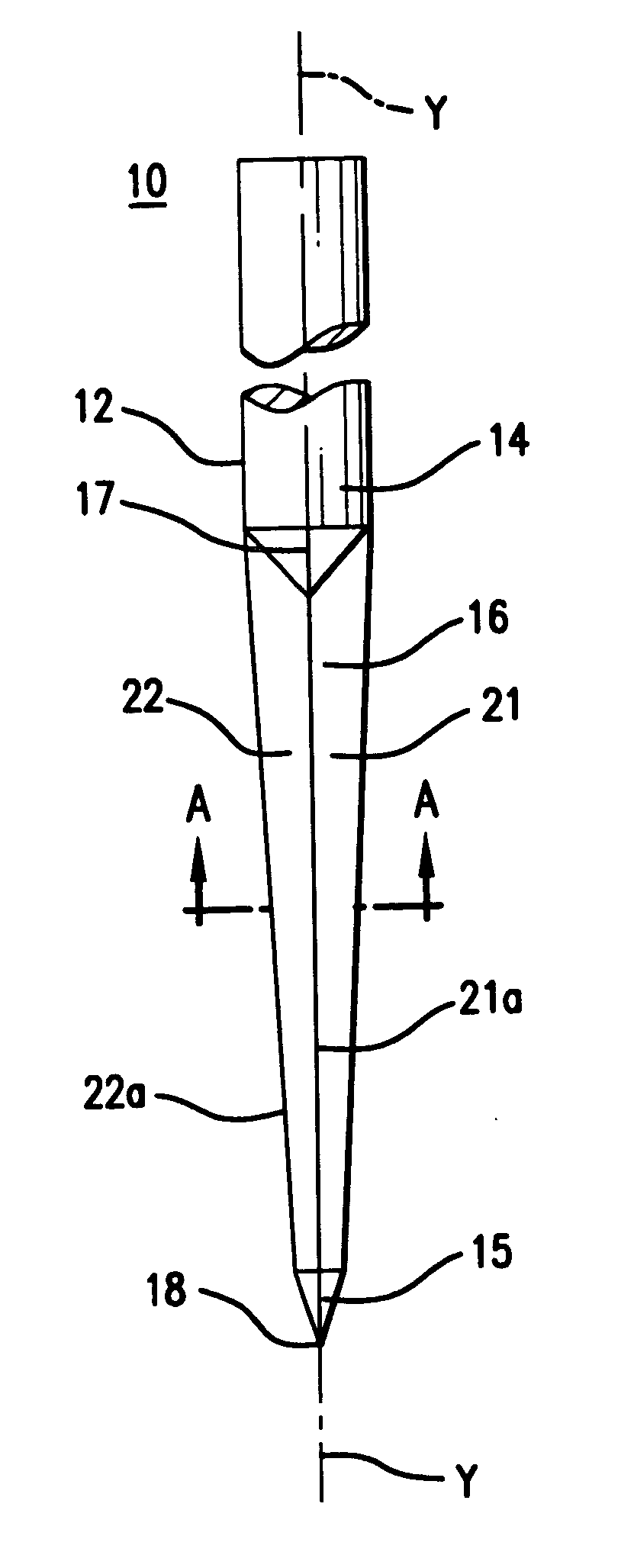

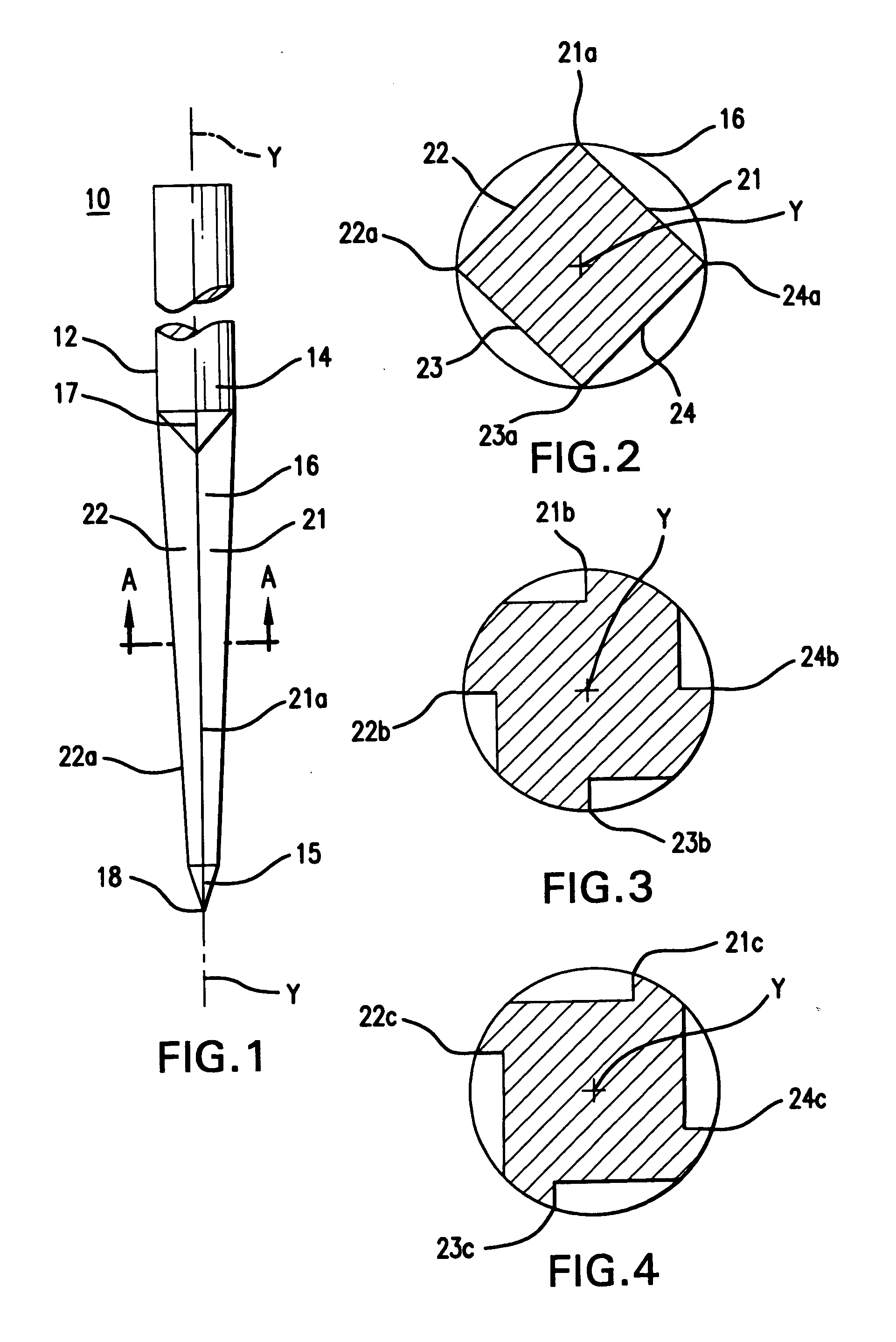

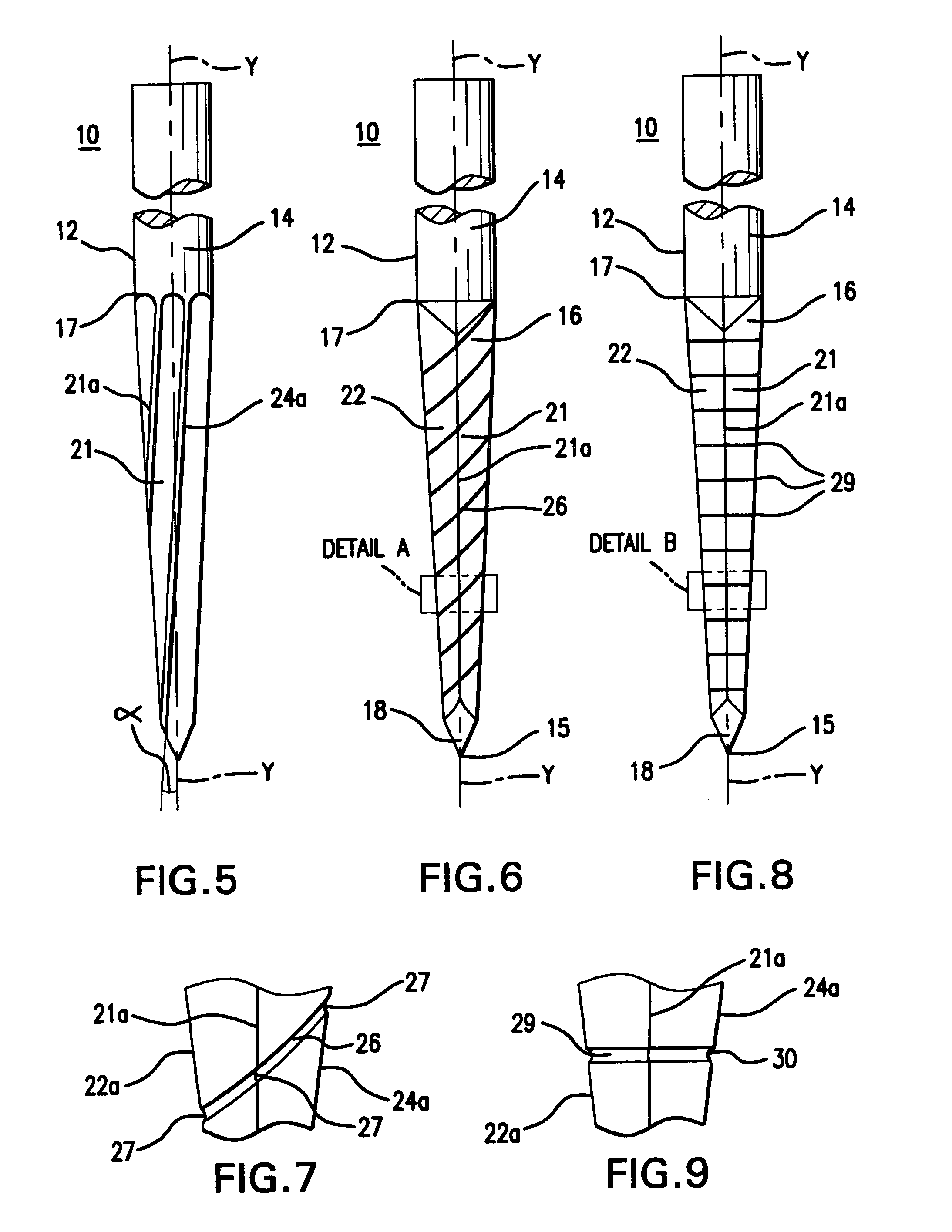

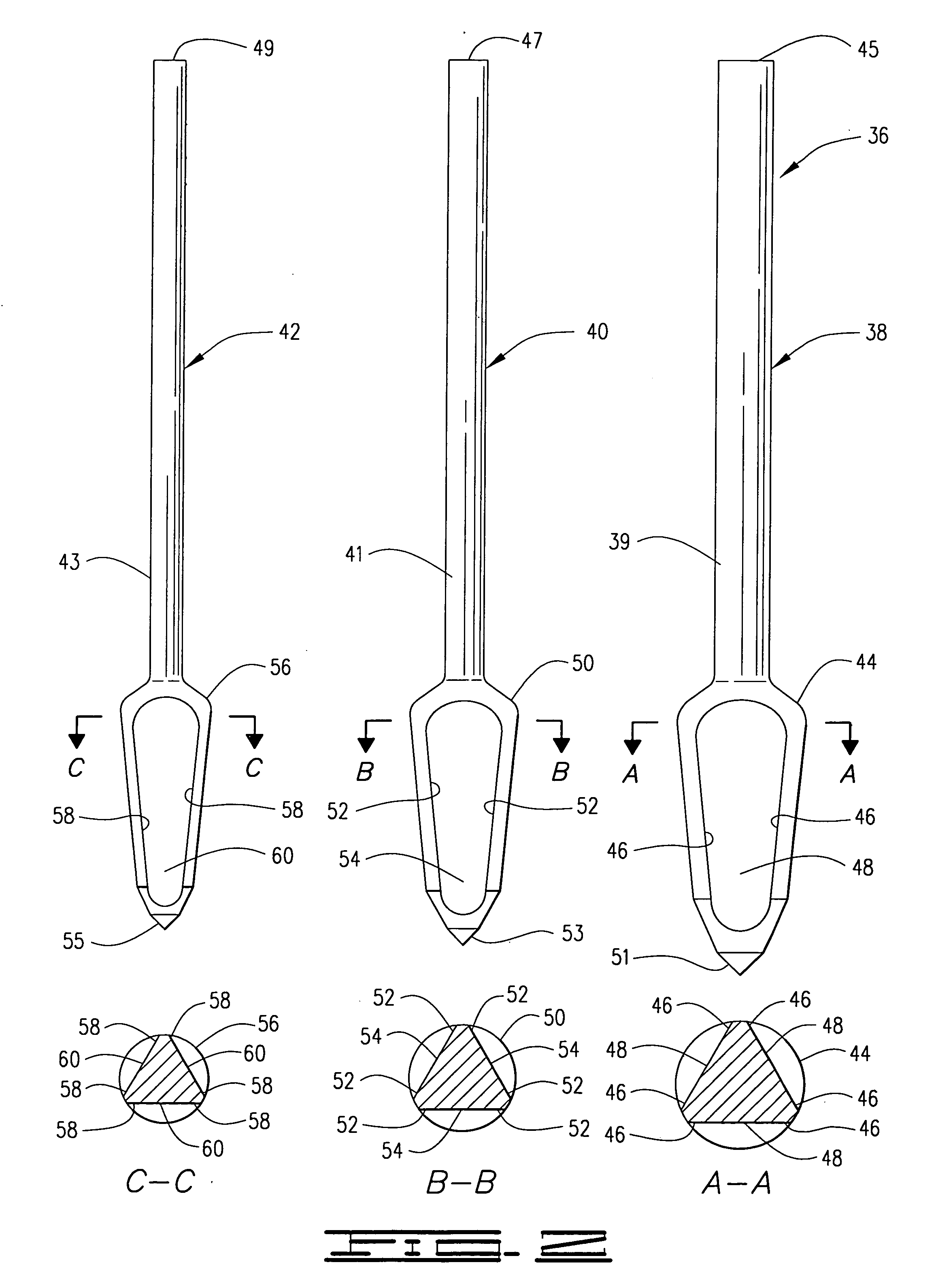

Endodontic instrument having notched cutting surfaces

InactiveUS20050266375A1Trend downGood curative effectTeeth cappingTeeth nerve/root treatment implementsFile designRasp

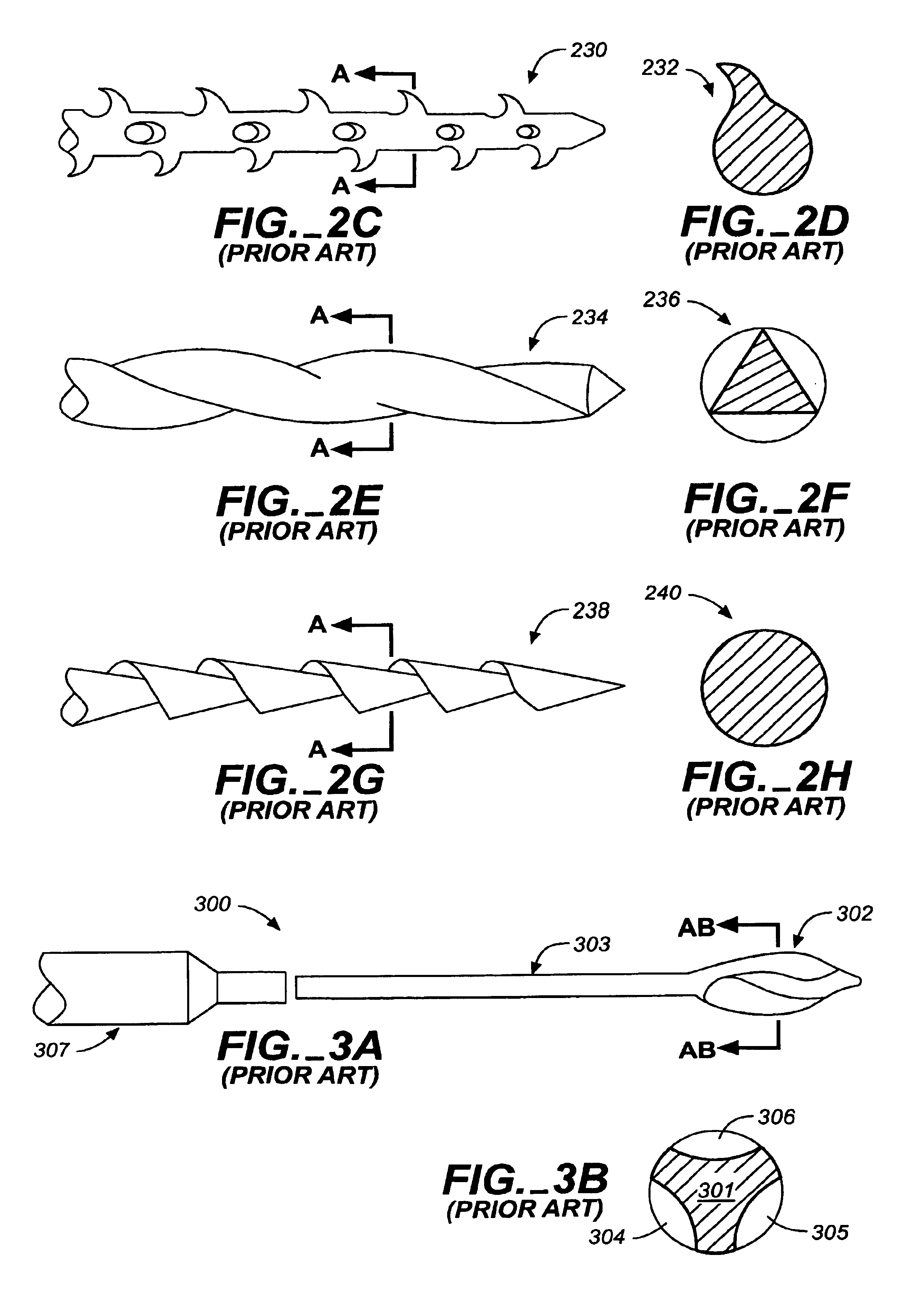

A fluteless endodontic file is provided, formed from a tapered shaft of material having a prismatic shape generally defined by three or more side surfaces and three or more interposed corners. A plurality of notches are cut into one or more corners defining cutting surfaces, points and / or edges. The notched cutting surfaces are formed such that the file, when rotated and / or reciprocated within a root canal, effectively cuts / debrides hard tissue (known in the art as dentin) as well as soft tissue, thus, forming an optimal canal shape. The cutting surfaces are also preferably formed at an angle to the centerline of the instrument to provide optimal cutting efficiency and material removal. The fluteless file design exhibits increased efficacy, with less tendency to bind and break within the root canal and also significantly reduces manufacturing and capital equipment costs.

Owner:BROCK G MATTHEW +1

Method of manufacturing an endodontic instrument

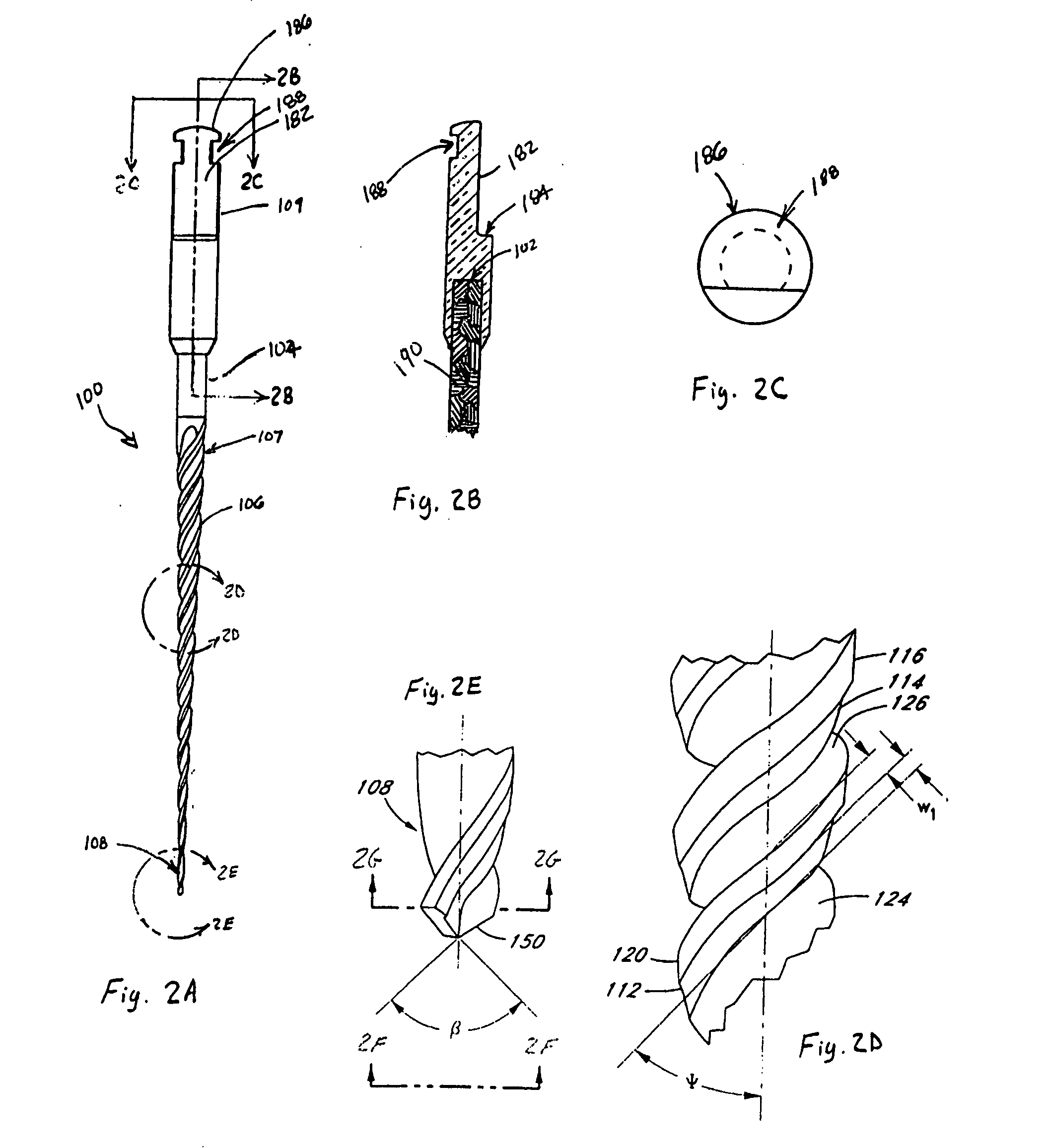

InactiveUS7207111B2Flexibility and resistance to torsional breakageHarder and more resilient cutting edgeWire articlesMetal-working drilling toolsFluteHardness

Method for manufacturing endodontic instruments having either helical or non-helical flutes with hard surfaces and resilient cutting edges by either an EDM or ECM process, wherein material is removed from the instrument blank in the desired flute pattern. The EDM or ECM process disintegrates the surface material, and as it cools, at least a portion of the removed material re-deposits onto the surface being machined to form a recast layer having a surface hardness that is at least about 15% greater than the hardness of the material forming the instrument blank.

Owner:ORMCO CORP

Precision cast dental instrument

InactiveUS20070184406A1Resistance to breakageResistance to wearTransportation and packagingWristbandsDental structureInstrumentation

An endodontic file (200) is provided particularly adapted for the removal of tooth structure, decayed or damaged nerve tissues or dentine material on the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The endodontic instrument includes a shaft (202) having a shank portion (204) and a generally elongated working portion (206). The working portion preferably includes cutting or abrading features (232) adapted upon rotation and / or reciprocation of the instrument to cut, abrade or remove tissue from the interior walls of a root canal or dentine and / or enamel from the external tooth wall. The working portion extends from a proximal end (207) adjacent the shank portion to a distal end (208) terminating at a tip (250). The entire instrument and / or at least the working portion thereof is formed of an amorphous or essentially amorphous material having no or essentially no detectable crystalline structure and / or from a nanocrystalline material having an average crystalline grain size less than about 1 μm. The instrument may be formed by conventional grinding operations or by direct casting, forging or molding, in a manner producing an integral as-molded instrument having one or more sharp cutting edges. The instrument is inexpensive to manufacture and exhibits improved cutting-edge sharpness, wear resistance, lubriciousness and resistance to breakage.

Owner:CLOUDLAND INST

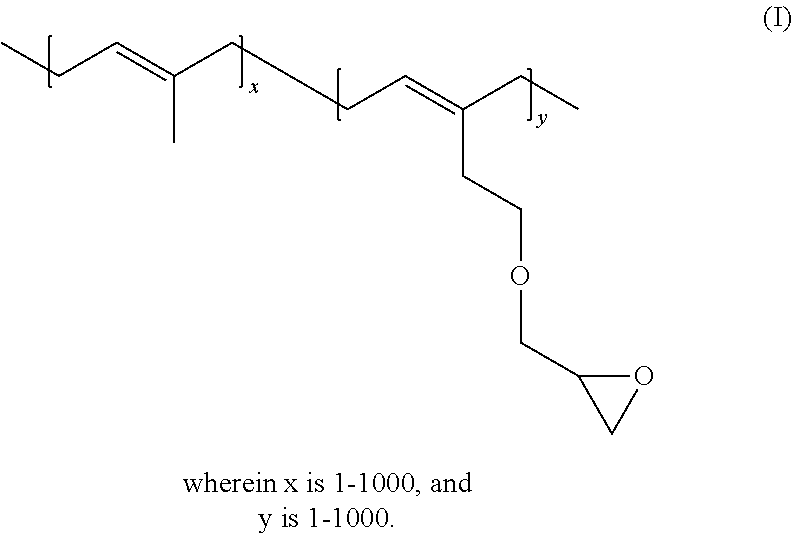

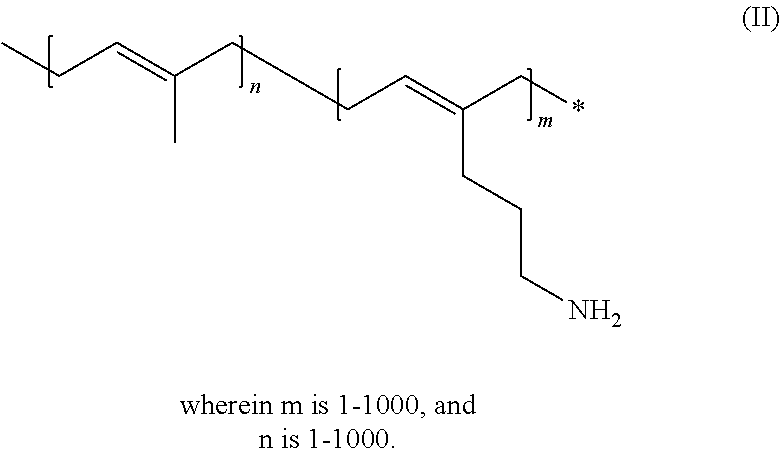

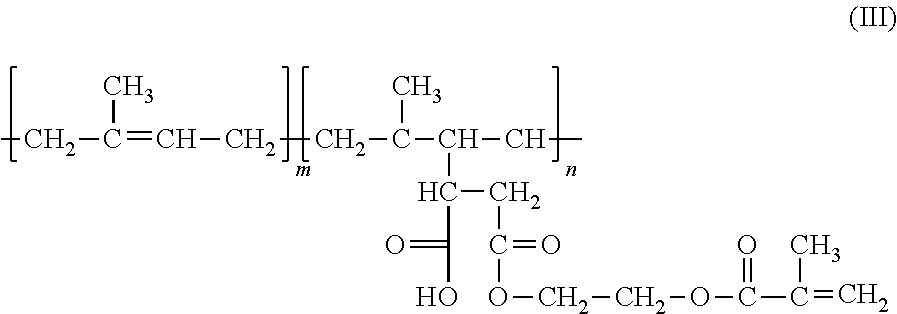

Compositions for endodontic instruments

Owner:DENTSPLY SIRONA INC

Endodontic instrument having notched cutting surfaces

InactiveUS20060265858A1Improved endodonticTeeth cappingTeeth nerve/root treatment implementsEngineeringMechanical engineering

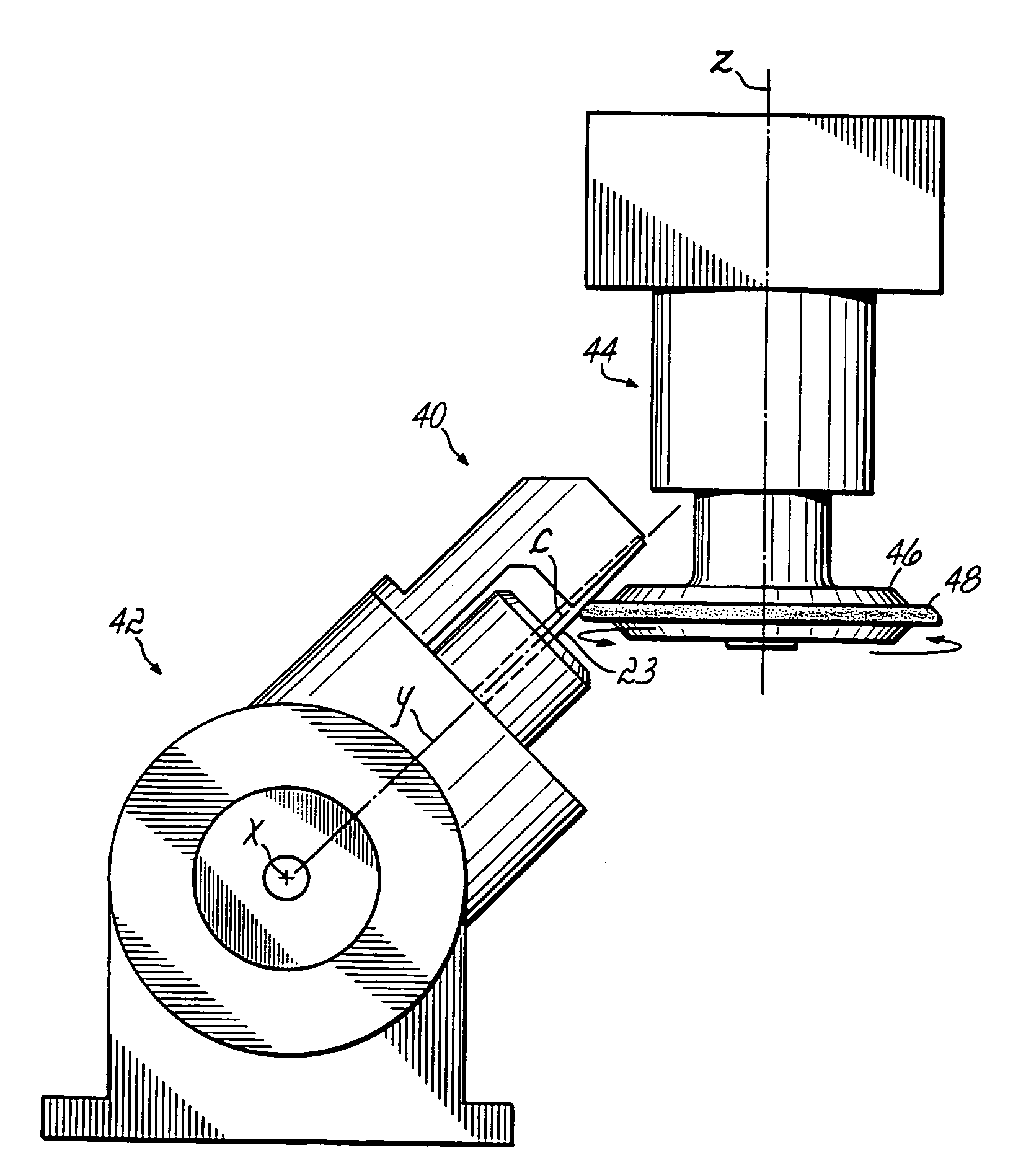

A method and apparatus for fabricating endodontic instruments for cleaning and extirpating a root canal. A grinding assembly may be used to form multiple cutting surfaces in elongate shafts in a single pass. A working surface holding a plurality of shafts may also be used to allow cutting surfaces to be formed in multiple shafts during one pass by the grinding assembly.

Owner:MCSPADDEN JOHN T

Endodontic instrument

Present invention relates to an endodontic instrument comprising a shaft and a work portion connecting to the shaft. The work portion has a plurality of helically extending blades to form a rectangular cross section in which the opposite edges of one set are longer edges and the opposite edges of the other set are shorter edges, the work portion having each apex of a right angle.

Owner:MANI INC

Precipitation hardenable stainless steel endodontic instruments and methods for manufacturing and using the instruments

InactiveUS6514076B1Resistant to wearEasy to useTeeth cappingTeeth nerve/root treatment implementsEndodontic filesChromium nickel

Precipitation hardenable stainless steel endodontic files and methods for their manufacture, wherein the most preferred precipitation hardenable stainless steel is 17-4PH and aging is preferably not one of the manufacturing steps. Precipitation hardenable stainless steels used in embodiments of this invention are iron-chromium-nickel grades that have the desired properties of flexibility, strength, hardness, wear resistance, stiffness, resistance to permanent deformation, resistance to variable torque, and biocompatibility for endodontic files.

Owner:ULTRADENT PROD INC

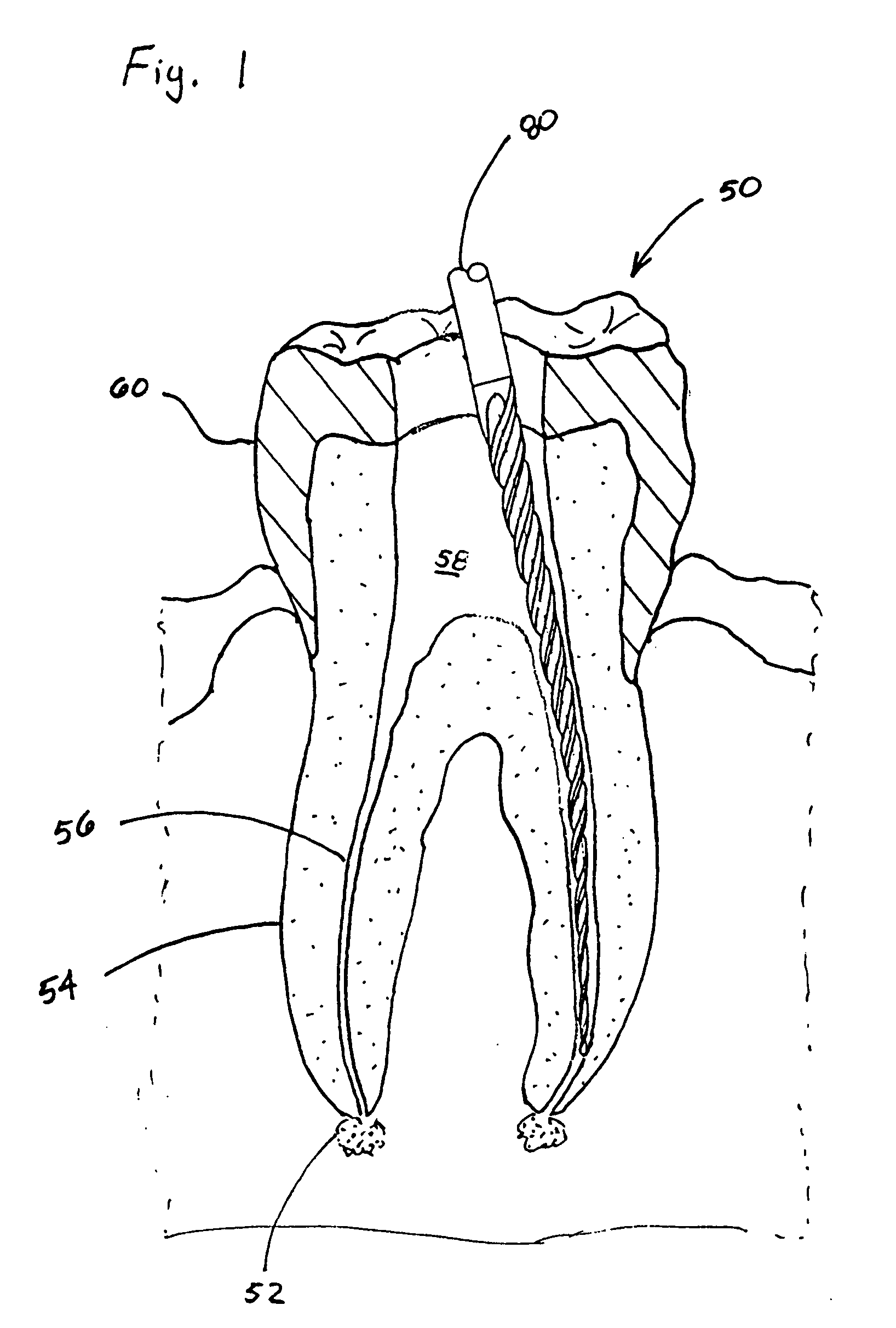

Critical path endodontic instruments for preparing endodontic cavity spaces

ActiveUS6942484B2Increase flexibilityImprove cutting effectTeeth cappingTeeth nerve/root treatment implementsCritical path methodEngineering

Methods and apparatus providing a critical set of endodontic instruments. The set includes a first endodontic instrument, a second endodontic instrument, and a third endodontic instrument. Each endodontic instrument includes a working portion that has a cone-like shape. Each working portion having an effective contact area defined by the exposed surface area of the working portion's respective cone-like shape. The difference between the effective contact areas of the first endodontic instrument and second endodontic instrument being substantially the same as the difference between the effective contact areas of the second endodontic instrument and third endodontic instrument.

Owner:SCIANAMBLO MICHAEL J

Barbed endodontic instrument

InactiveUS7018205B2Trend downQuickly and economically producedTeeth cappingTeeth nerve/root treatment implementsEngineeringKnife blades

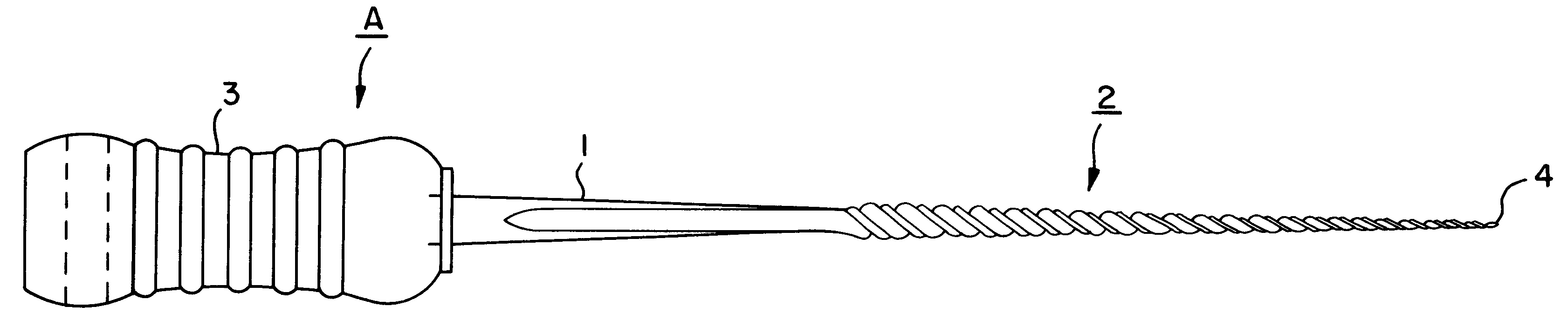

A process for producing an endodontic instrument by selectively hacking burr-like cutting projections or barbs into an elongated metal rod. A cylindrical hacking blade or other suitable blade having a convex cutting edge is preferably used to produce generally cup-shaped or concave barbs for greater strength and cutting efficiency. The barbs may be formed in a variety of shapes, sizes, orientations and patterns, such as regular or irregular helical or linear patterns, on the instrument.

Owner:ABELITY

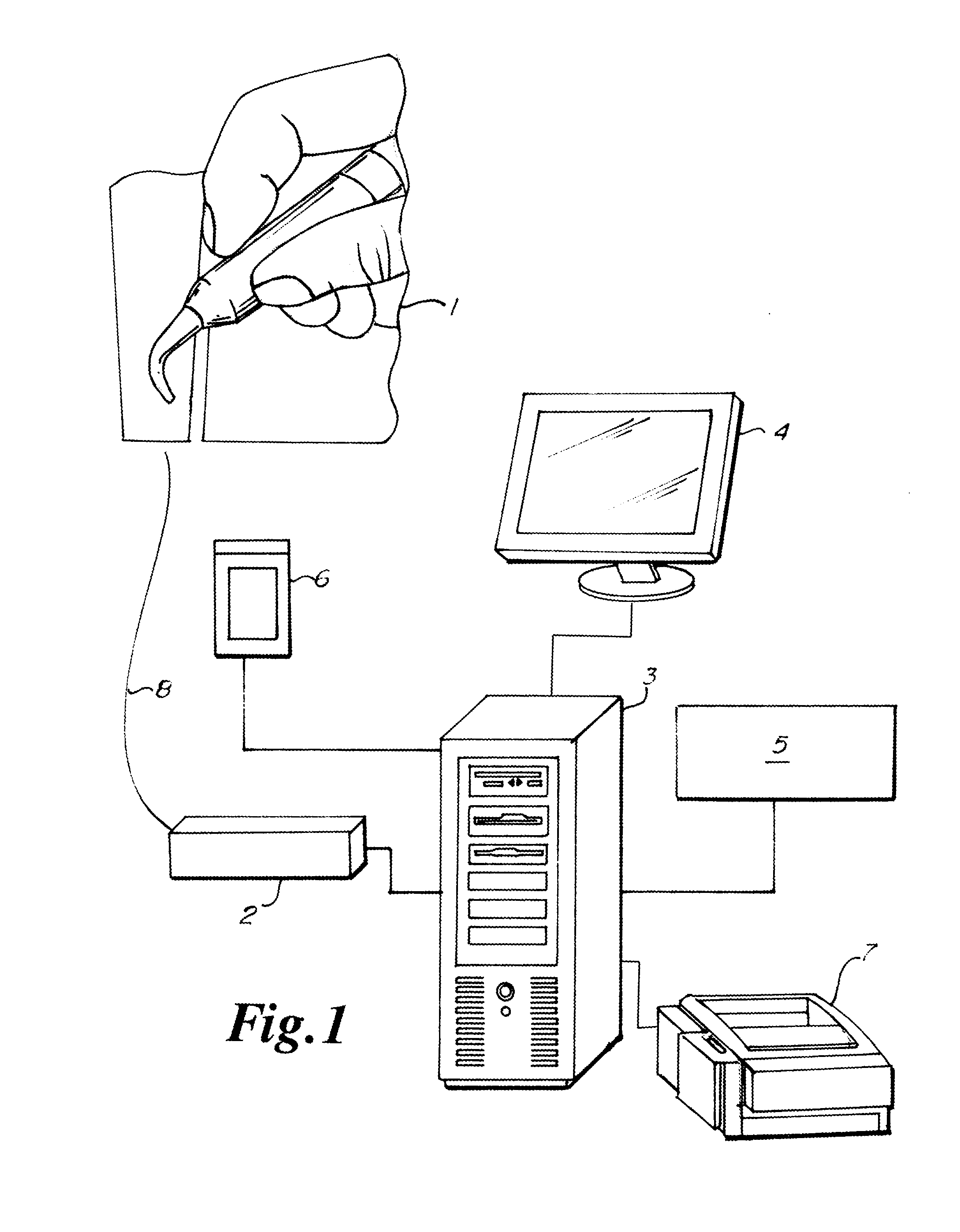

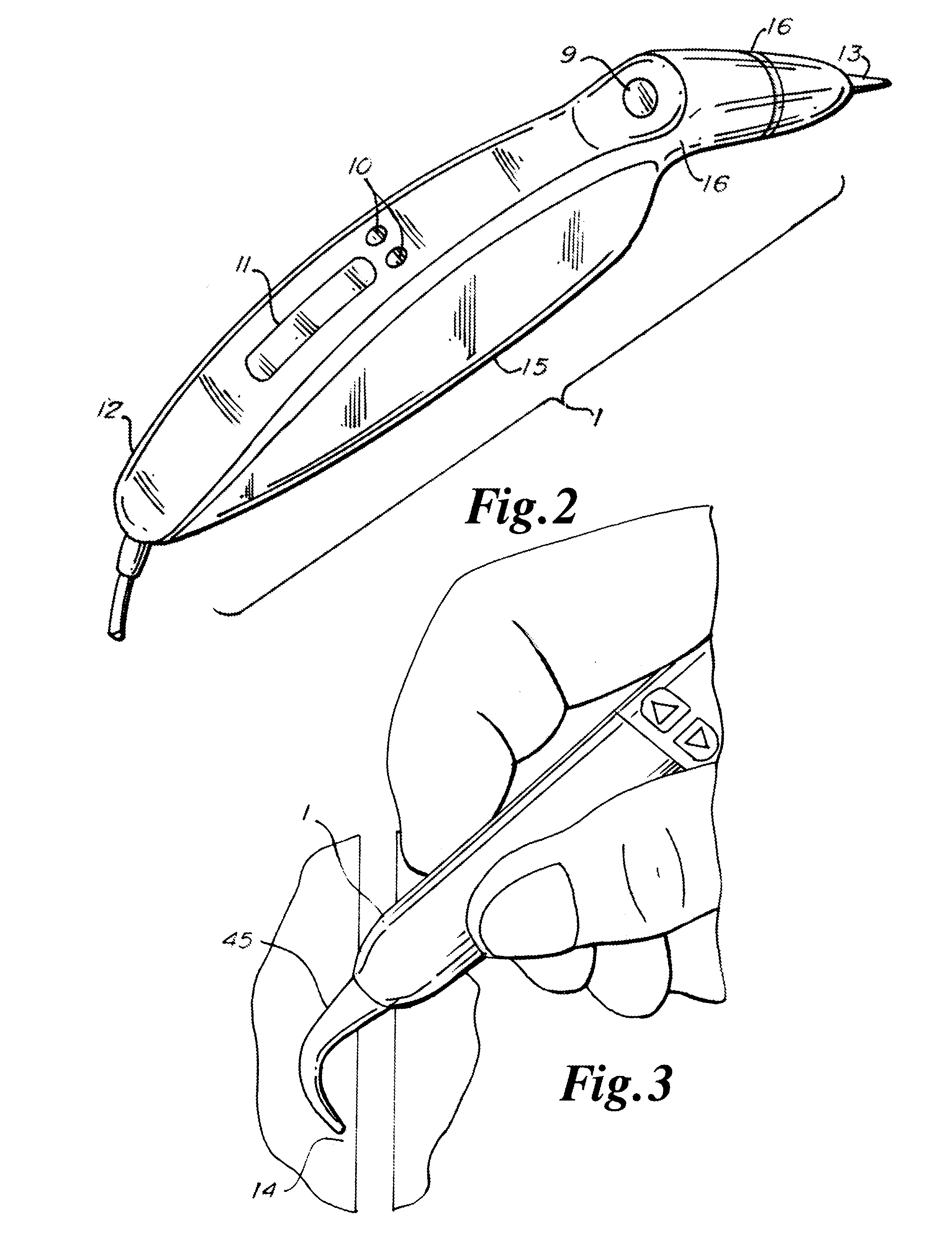

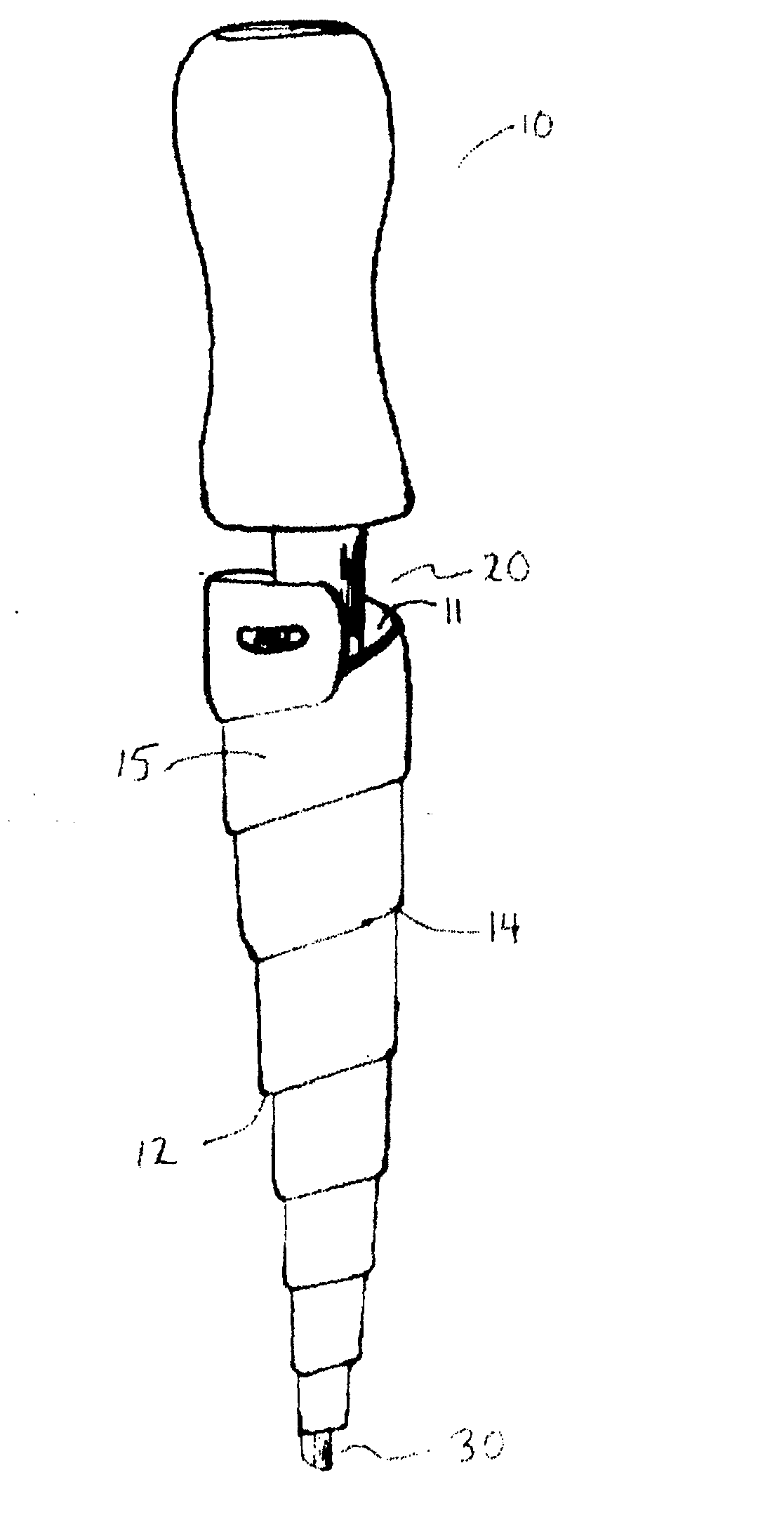

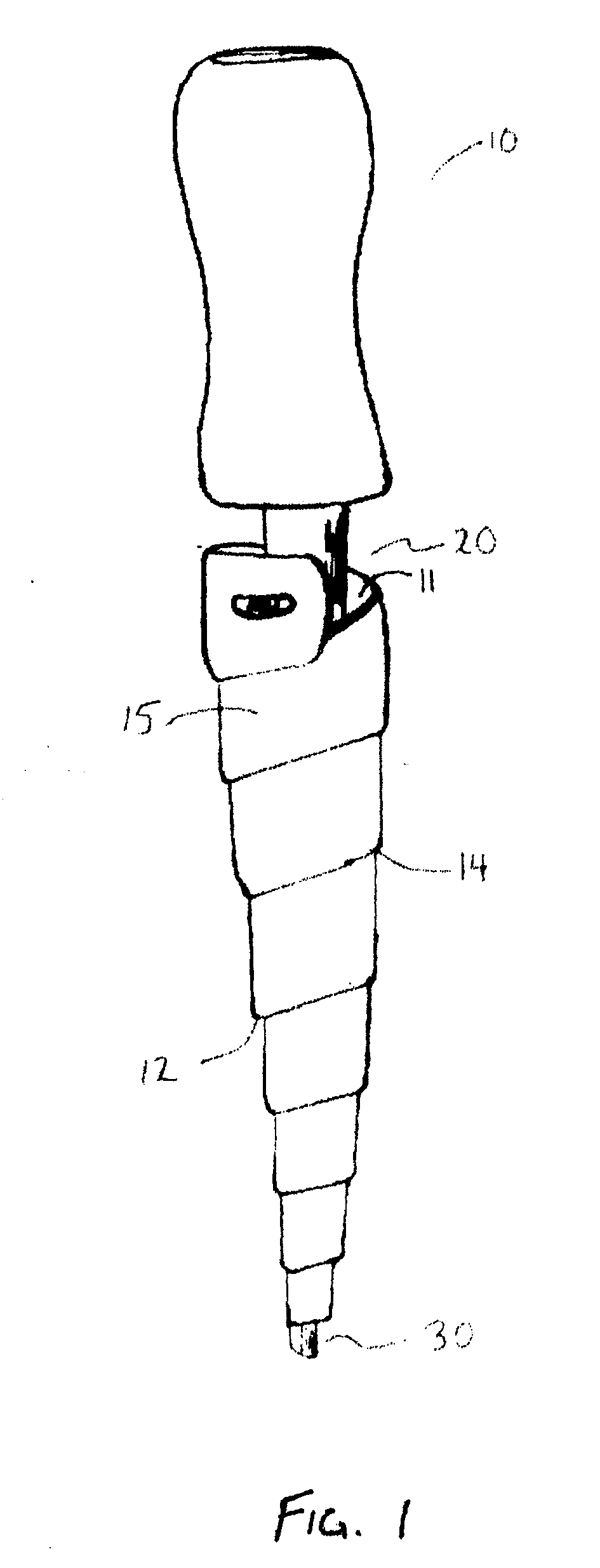

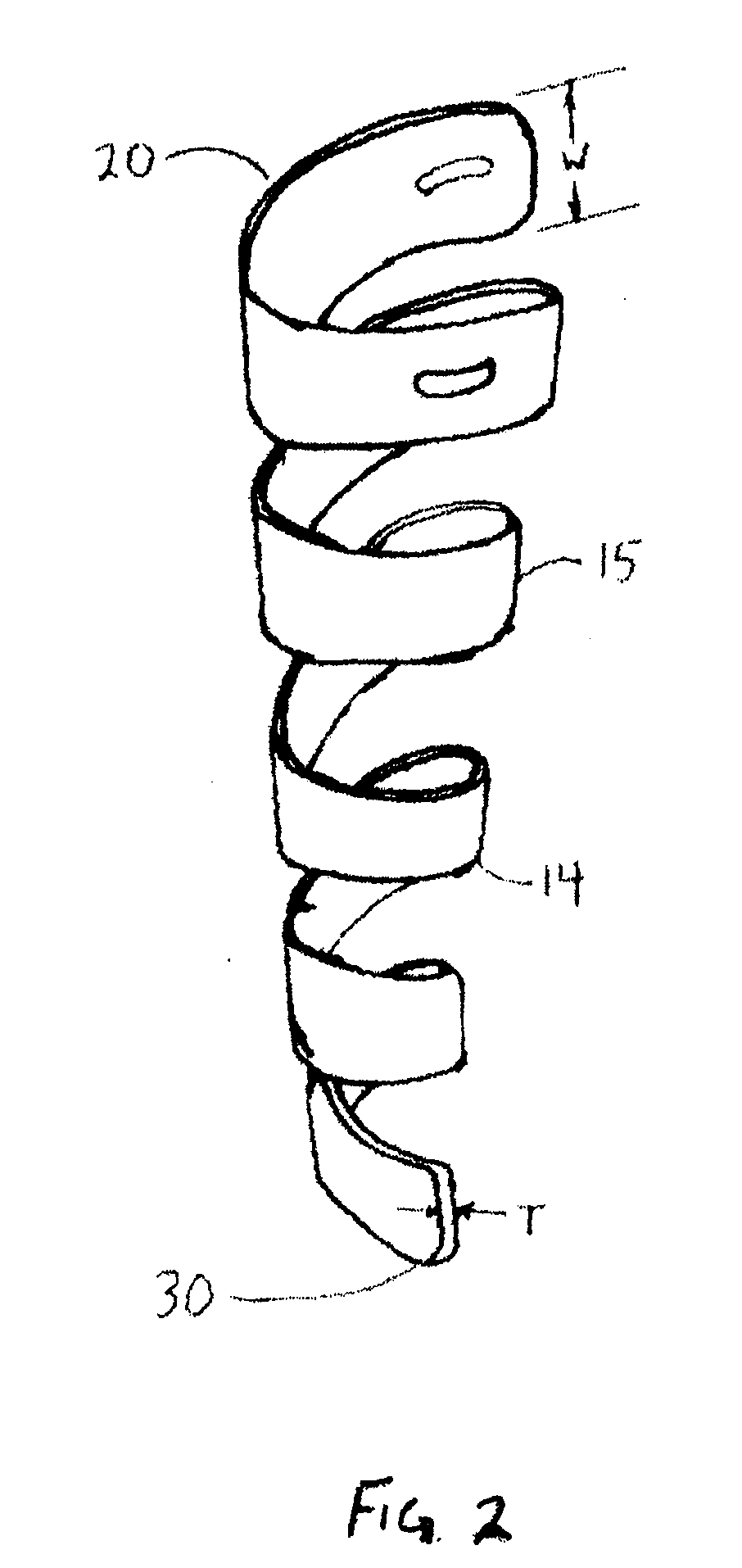

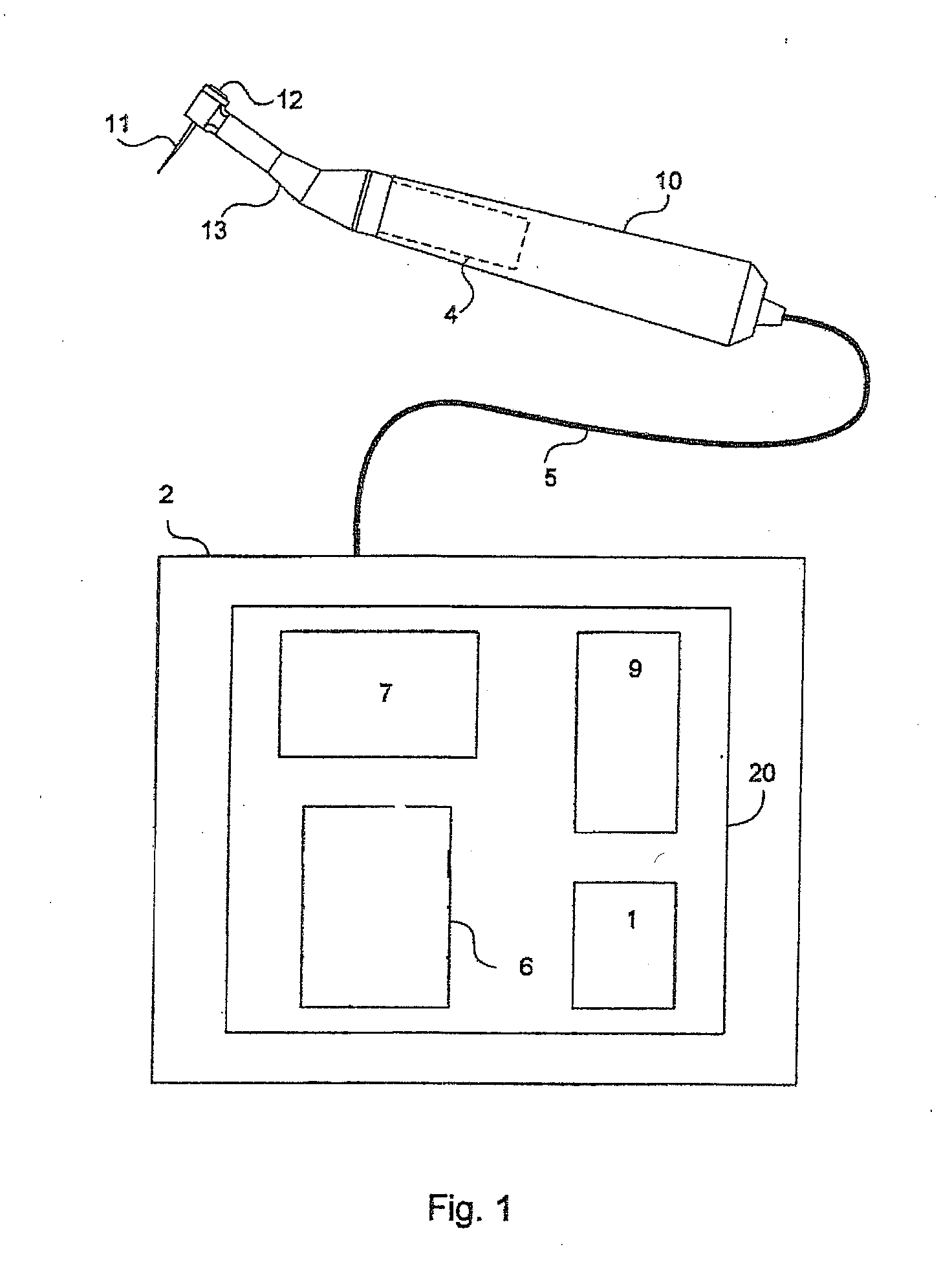

Computer aided canal instrumentation system and a unique endodontic instrument design

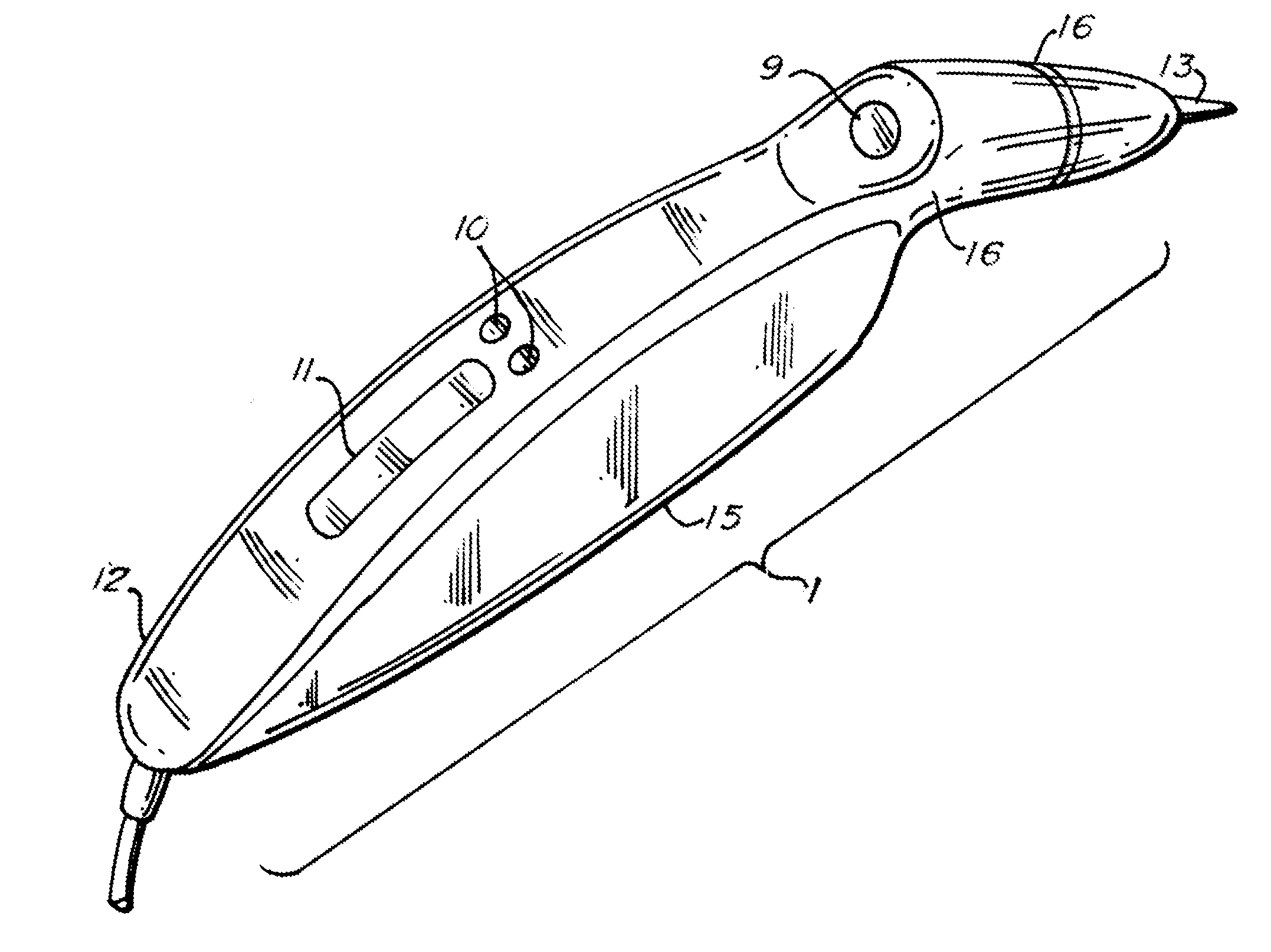

InactiveUS20110039229A1Easy to disassembleLarge caliberNerve needlesTeeth cappingCamera imageComputer-aided

A dental handpiece with an integrated camera and computer. Computer receives information input by dental professionals and data retrieved from integrated sensors. Computer allows pre-programmed procedural steps and information supplied by dental professional to be stored for later use. Computer transmits camera image, stored information and real-time procedural data to dental professional via attached monitor. Computer assists dental professional in handpiece set-up and procedural steps including feedback as treatment proceeds. Based on data received from the user and sensors, the computer dynamically makes adjustments to the procedural steps as well as handpiece mechanical motion, such as, but not limited to, rotational speed, rotational direction, torque, advance feed rate, and withdraw rate.

Owner:ORMCO CORP

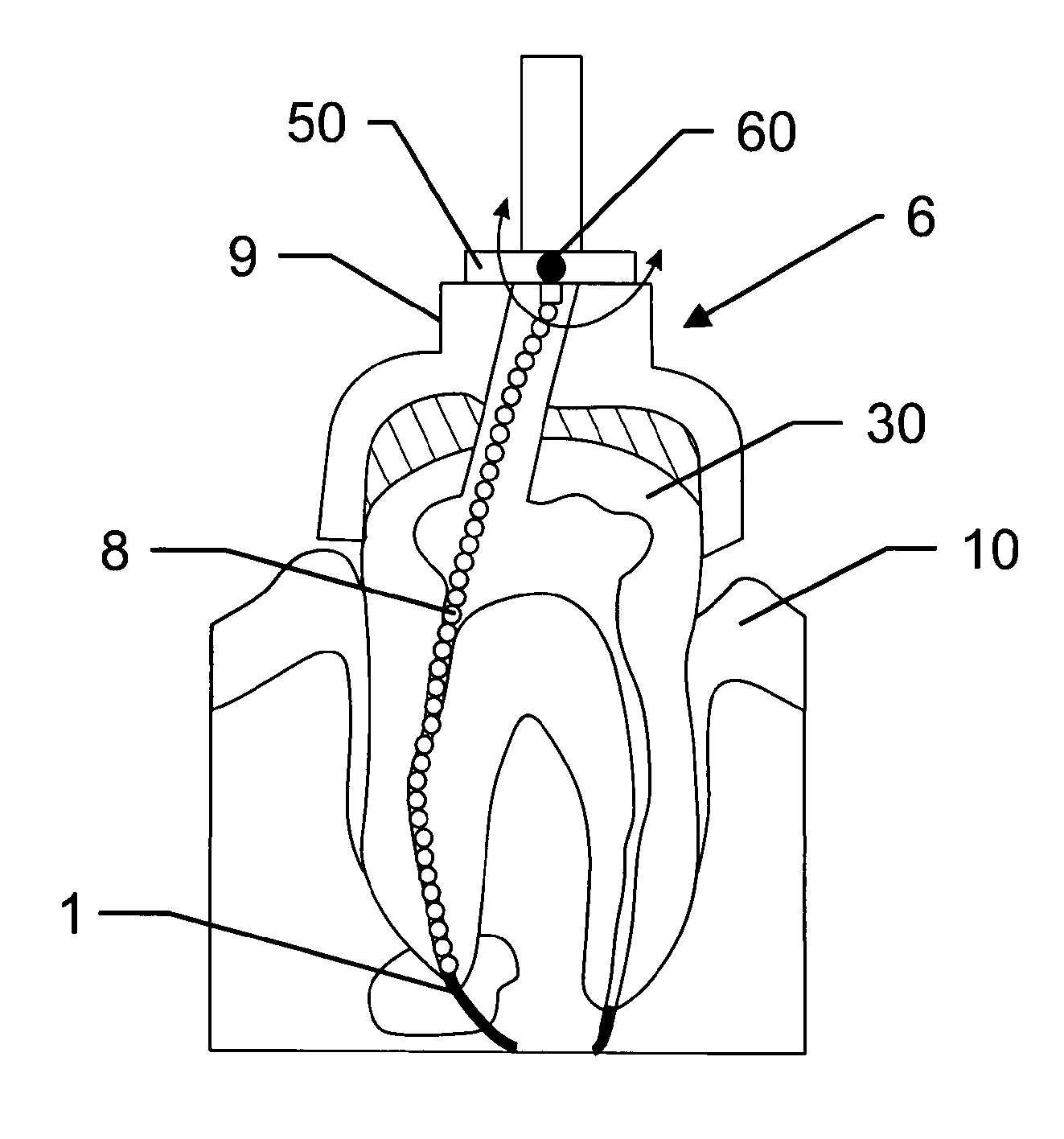

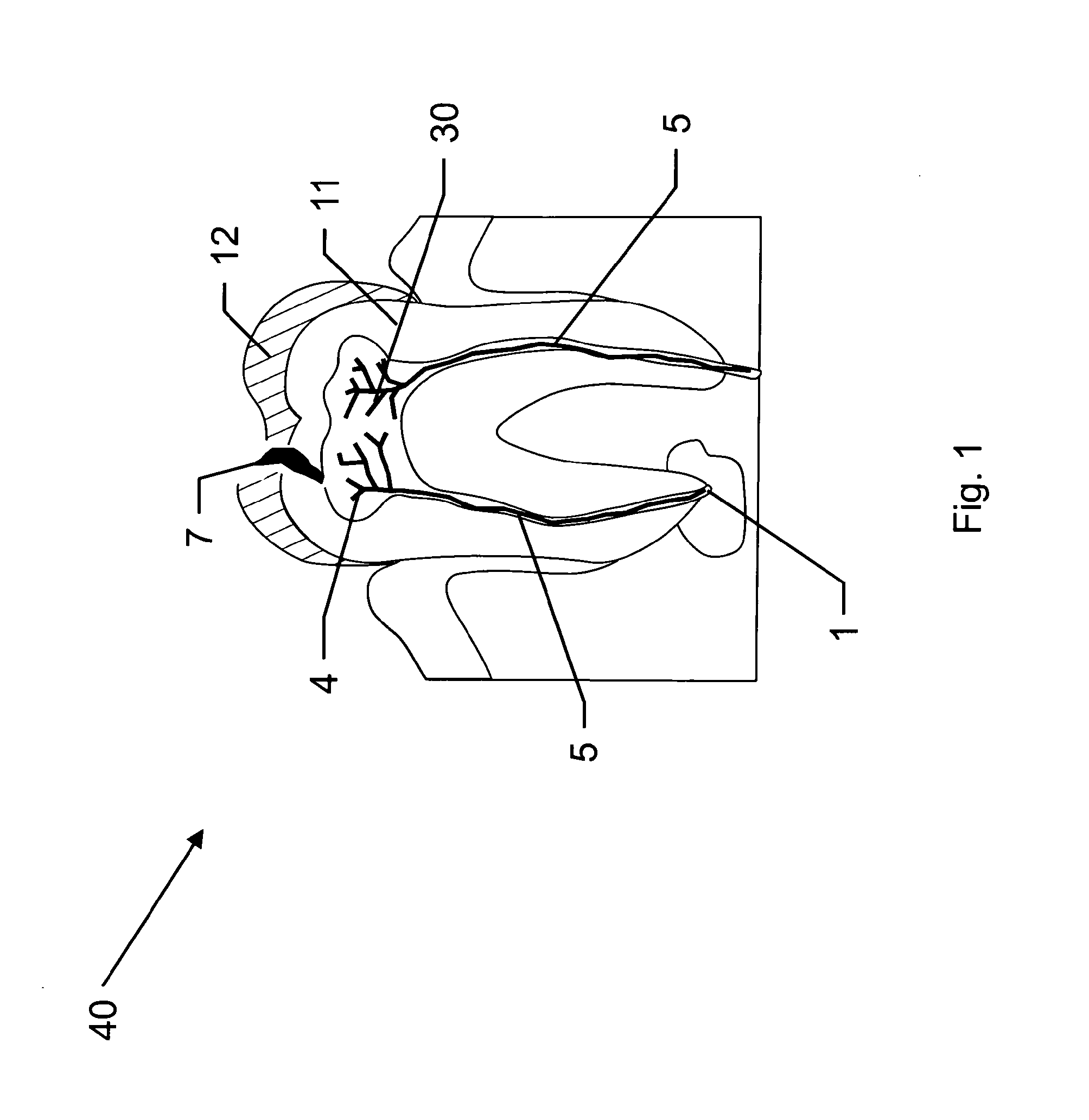

3D digital endodontics

PendingUS20130171580A1Avoid mistakesIncrease irrigationImpression capsDental tools3d imageSurgical template

A method and system are described for 3D digital endodontics characterized in that 3D imaging equipment such as a CT or MRI scanner, ultrasound or the like are used to digitize the infected tooth or teeth, a 3D representation of the root canal system is extracted from the image data and visualized on a computer screen, a surgical template is designed to guide the endodontic instruments to localize the root canal(s) intra-operatively and said guide is manufactured by means of a computer driven system (e.g. milling, rapid prototyping, etc.).

Owner:MATERIALISE DENTAL NV +1

Endodontic instrument

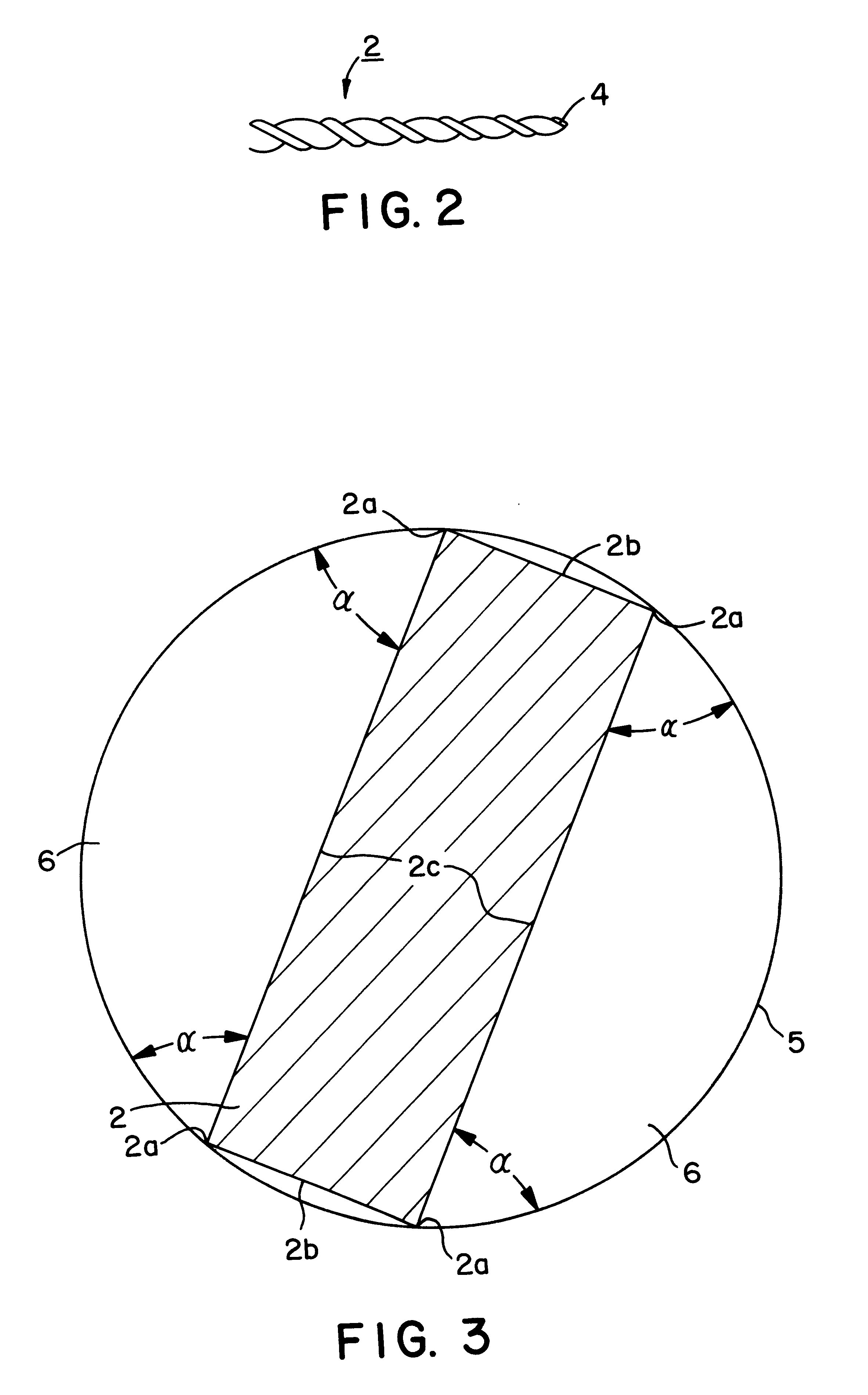

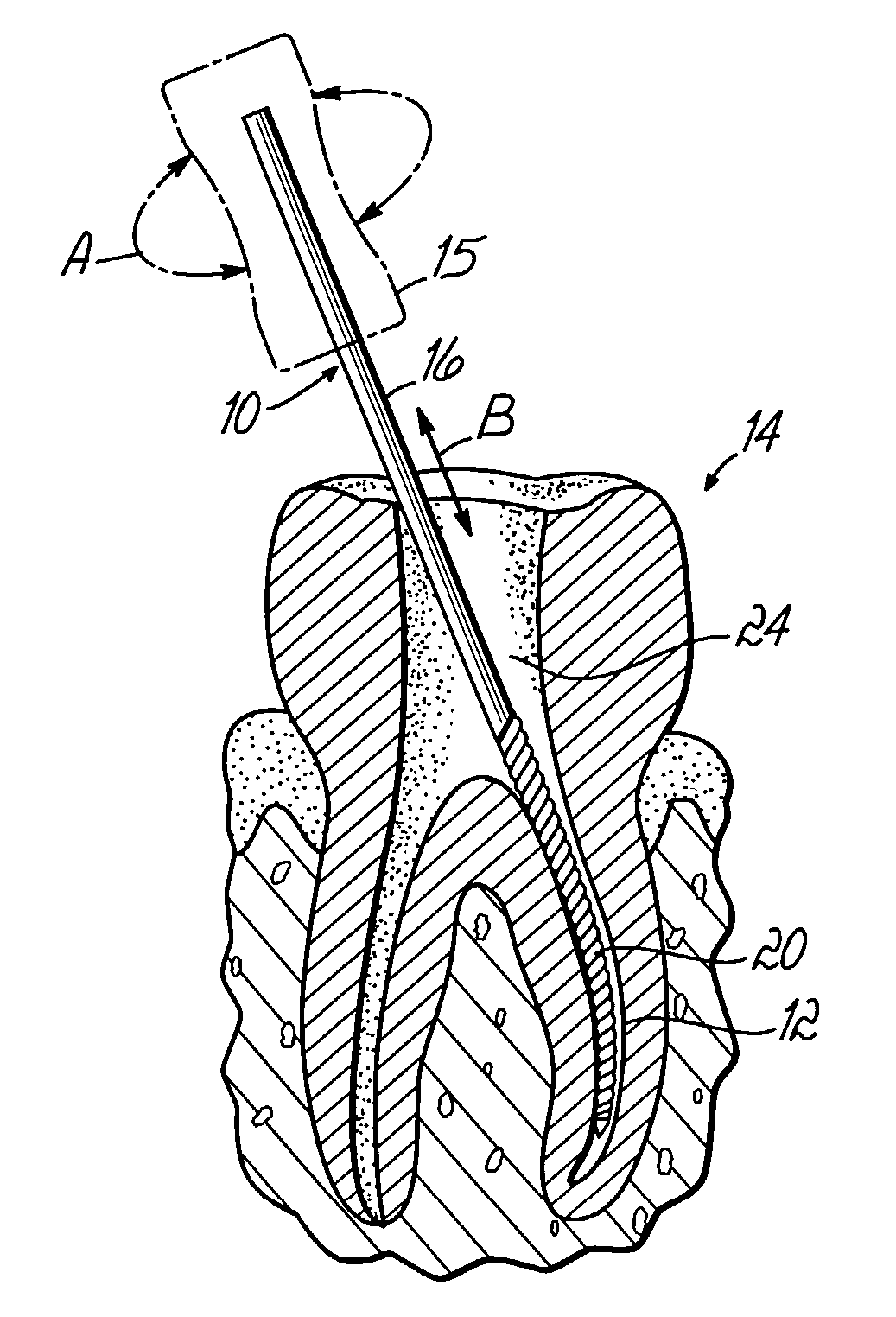

A non-landed endodontic instrument has flutes formed along a working length of the instrument shaft. The flutes define cutting edges for shaping a root canal of a tooth. The cutting edges lie at a major diameter of the shaft and peripheral flute surfaces behind the cutting edges extend along decreasing radial distances from the center of the shaft, in a direction opposite the cutting direction of the instrument.

Owner:ORMCO CORP

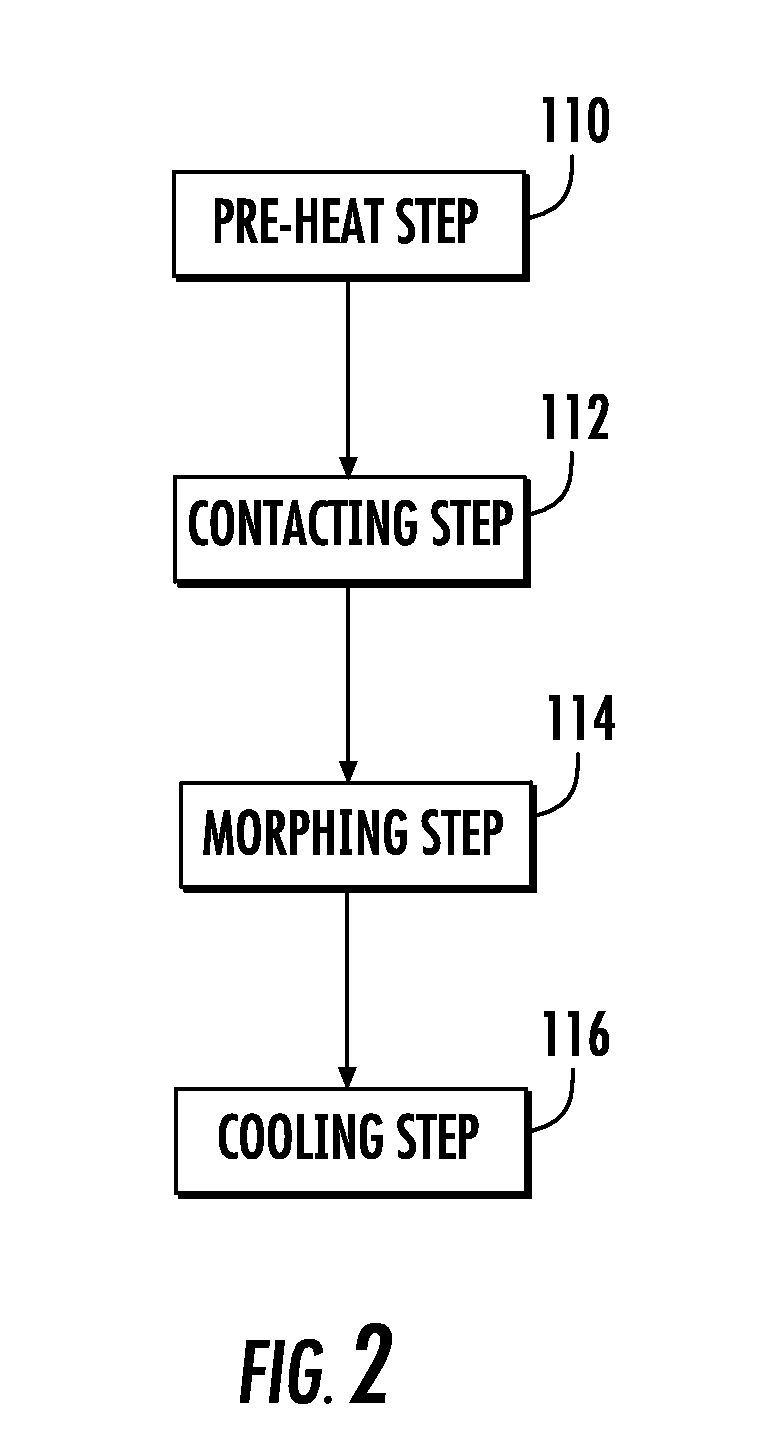

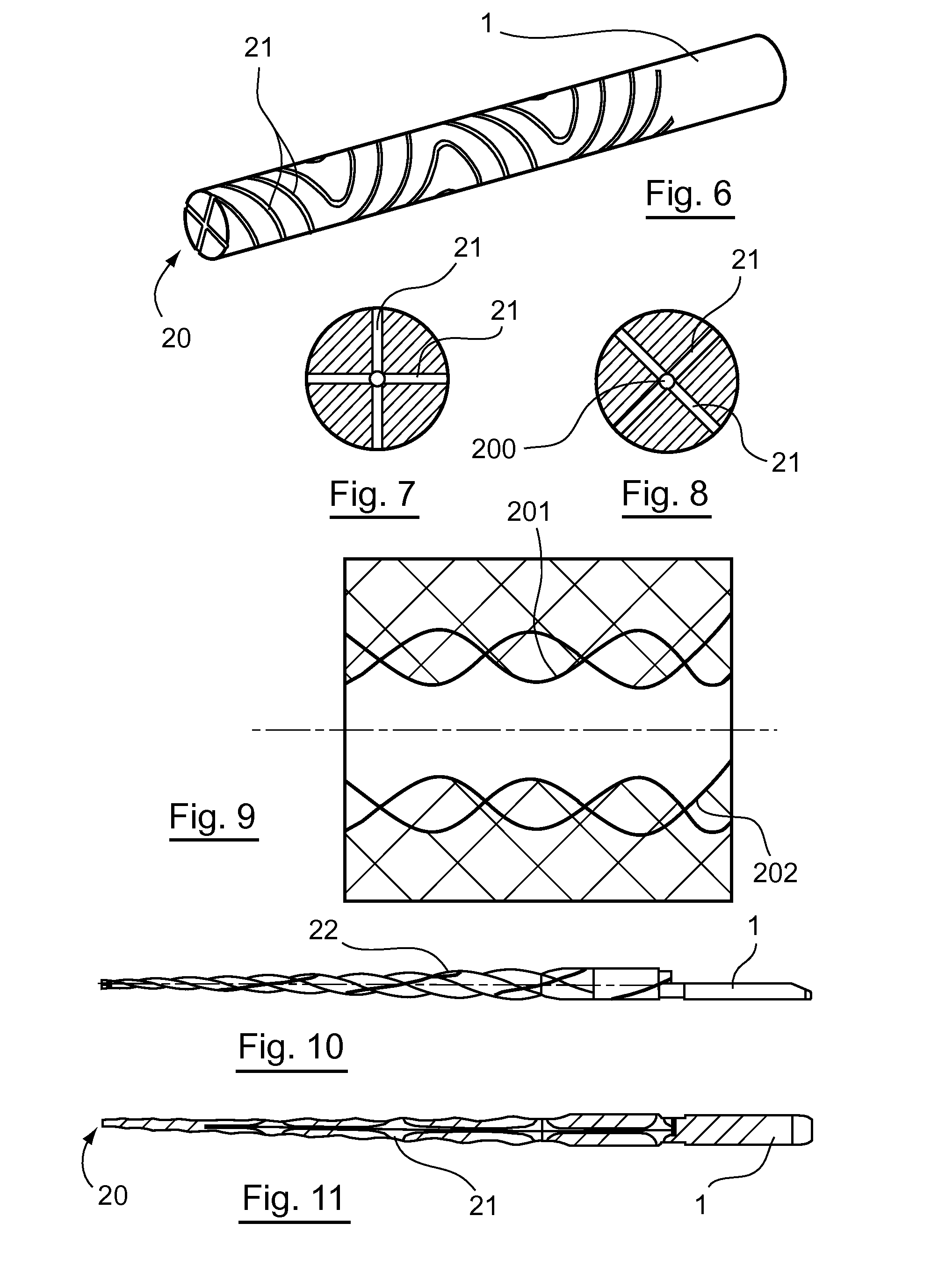

Endodontic instruments and methods of manufacturing thereof

ActiveUS20120282571A1Avoid damageMaintain geometryFurnace typesTeeth cappingPartial heatingComputer science

Owner:DENTSPLY SIRONA INC

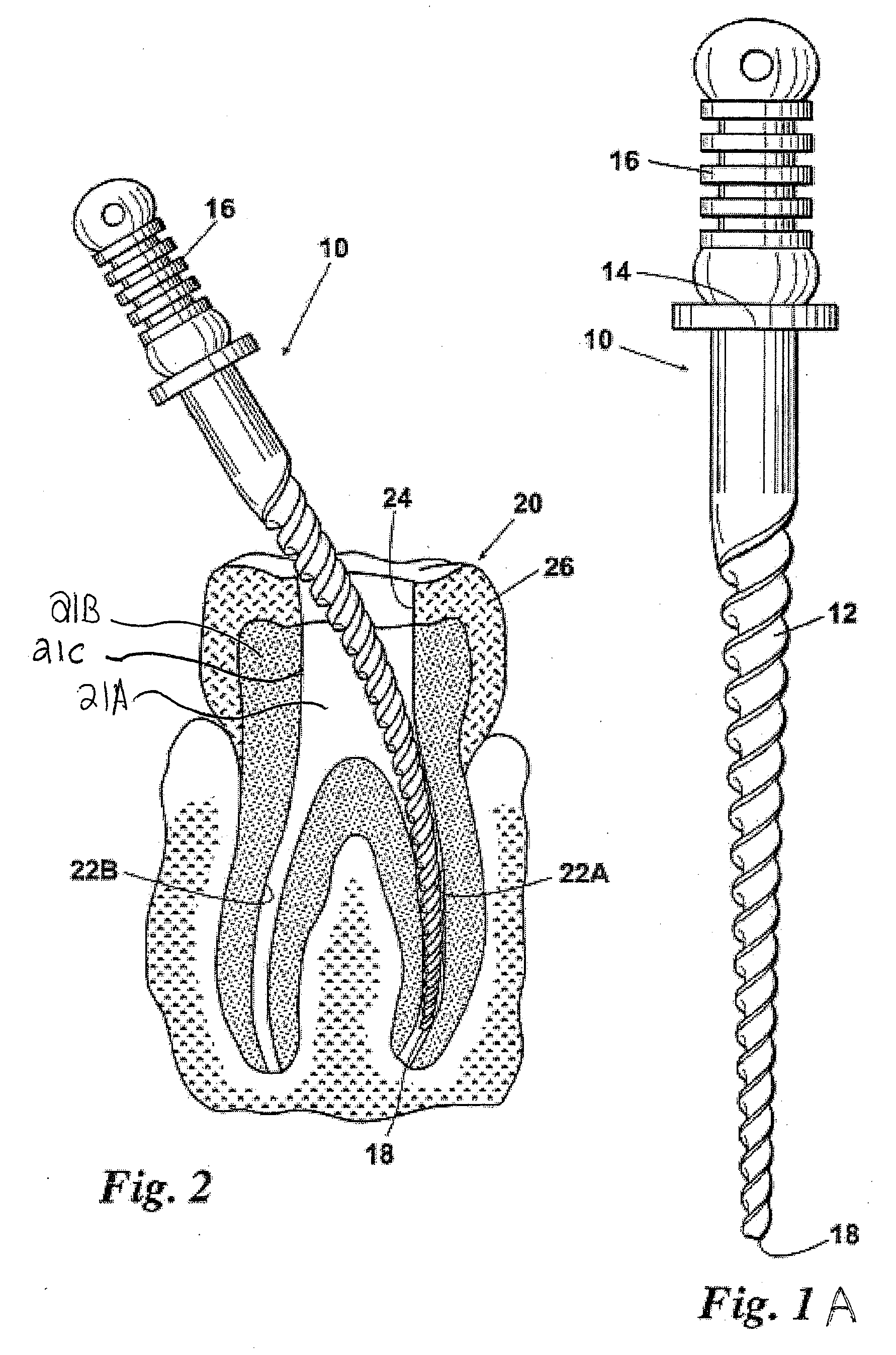

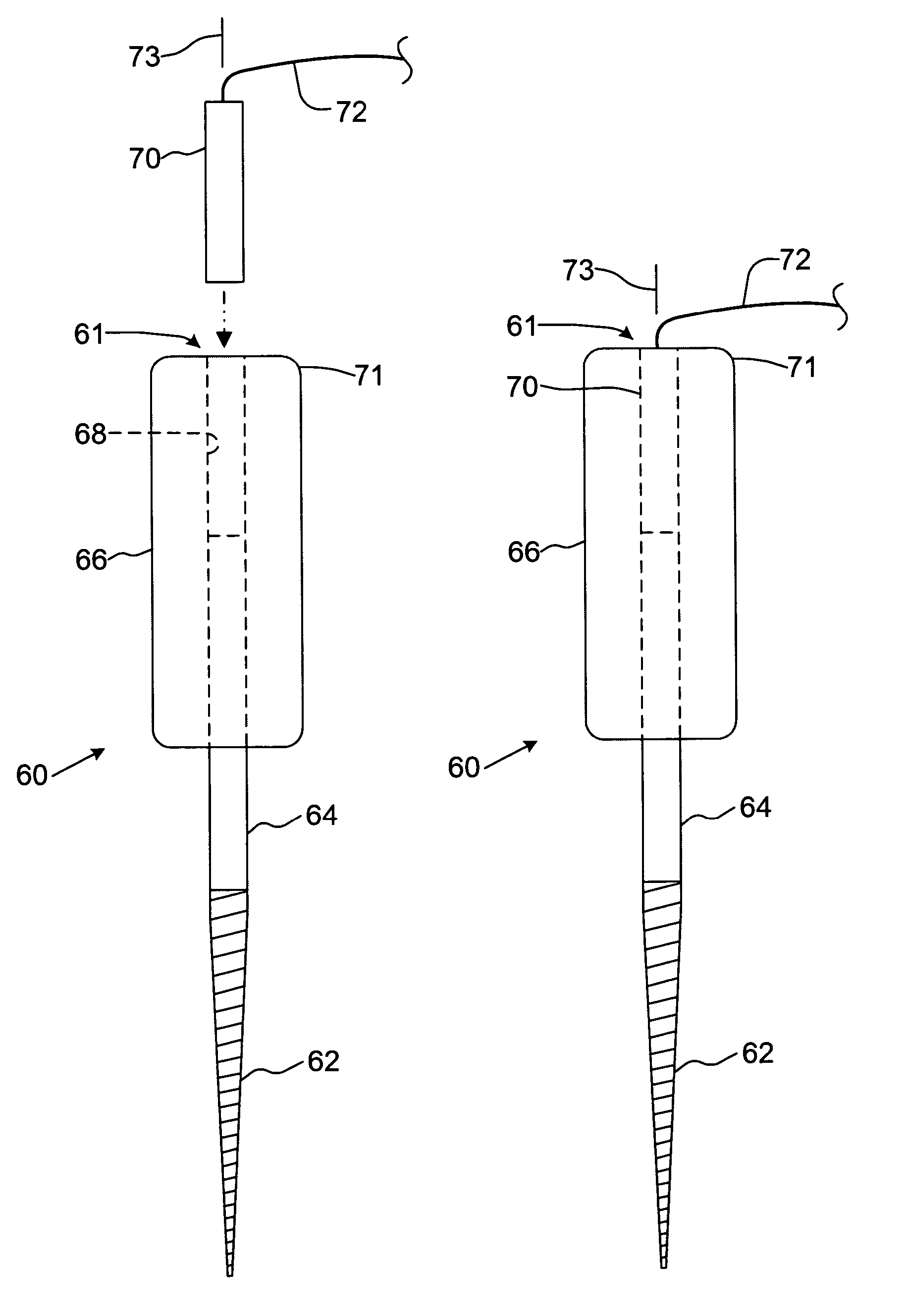

Endodontic instrument

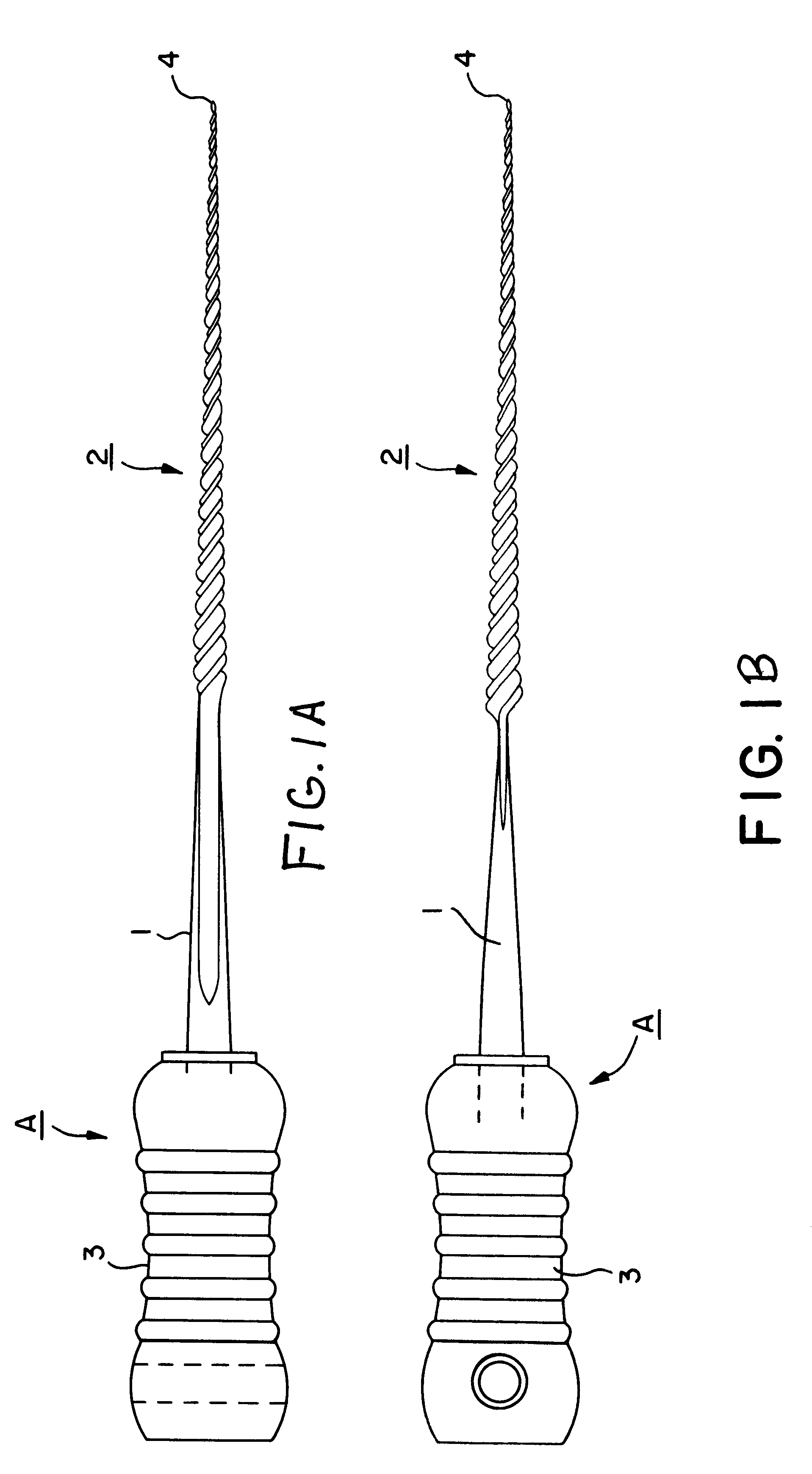

InactiveUS7121827B2Improves manipulationImprove visibilityTeeth cappingTeeth nerve/root treatment implementsElectronic apex locatorComputer science

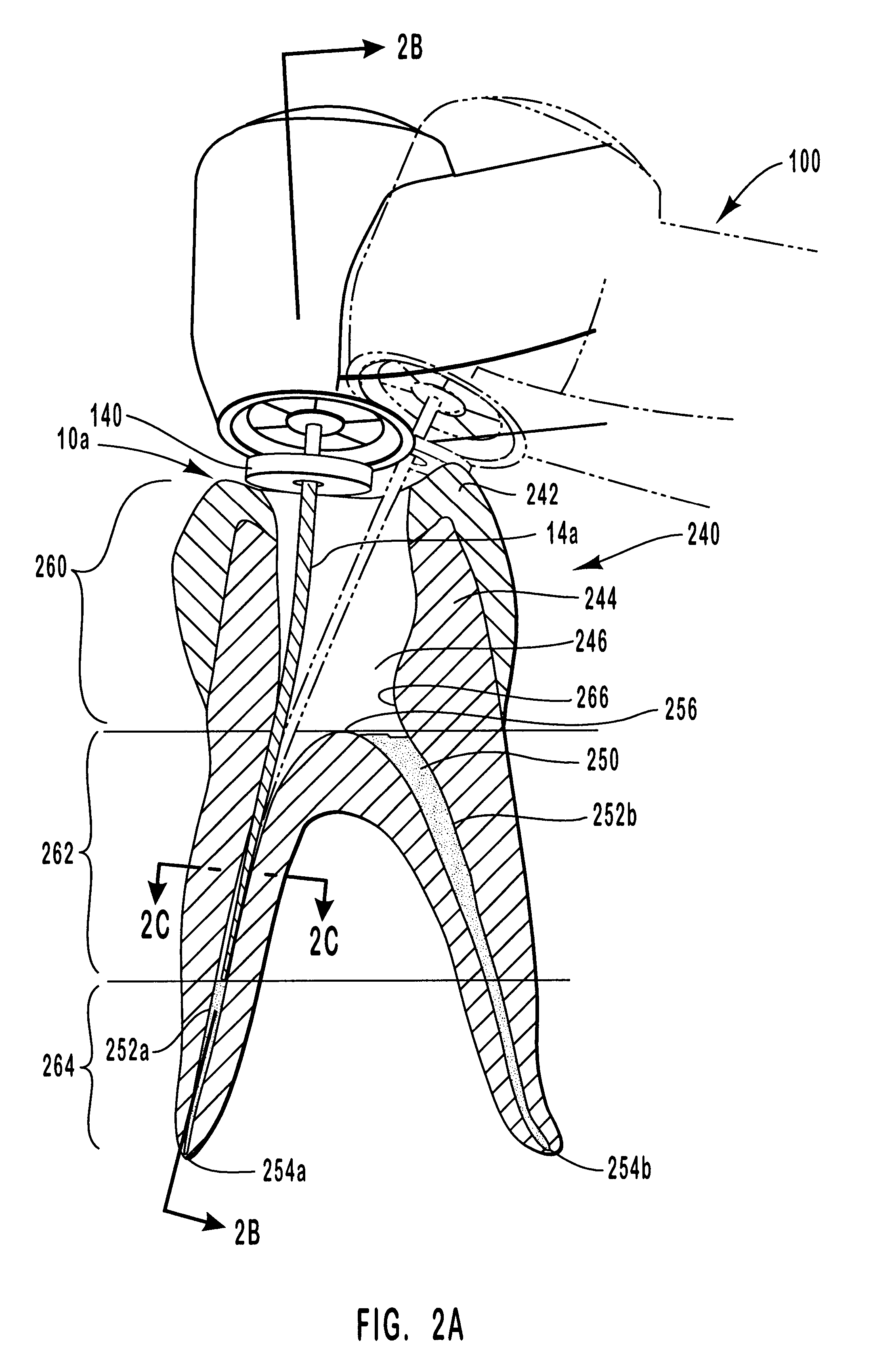

An endodontic instrument for root canal treatment is provided having a working portion manipulated by a handle and a connection assembly for attachment with an electronic apex locator. The connection assembly allows the electronic apex locator to be connected to the instrument at or through the coronal end of the handle. Preferably, the connection assembly includes a male / female assembly located within or on the surface the file handle.

Owner:LAMPERT CHRISTOPHER

Compositions for endodontic instruments

Owner:DENTSPLY SIRONA INC

Endodontic Instrument

The present invention provides an improved endodontic instrument. The instrument can be constructed of a ribbon of material such as any material that has a suitable edge for cutting and can be twisted or bent into any desired shape. The ribbon can be made of a metal, a polymeric film or combinations thereof. The ribbon can have a straight edge or a serrated one. The instrument is in the shape of a cone, tapering towards one end. It has a hollow interior and cutting edges disposed in a helical pattern along its length. The instrument can perform various or all of the functions of any endodontic instrument used in the root canal procedure.

Owner:DISCUS DENTAL LLC

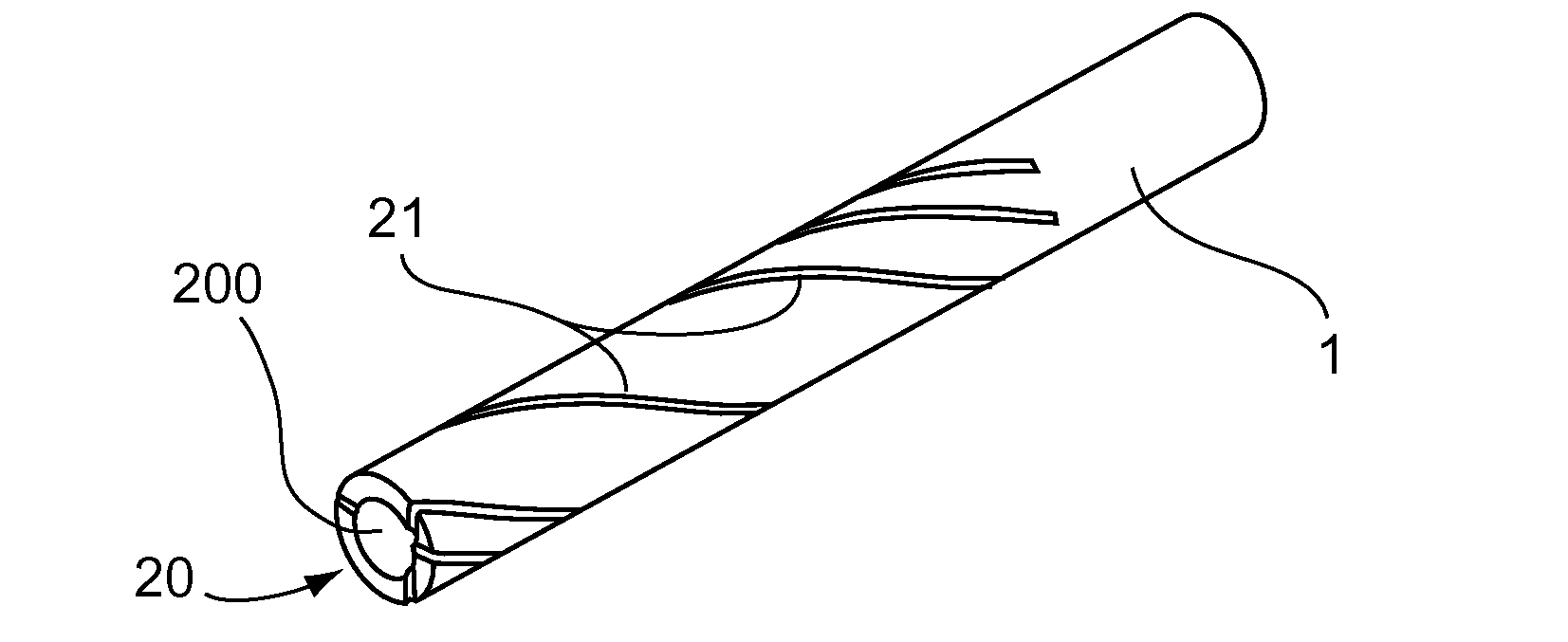

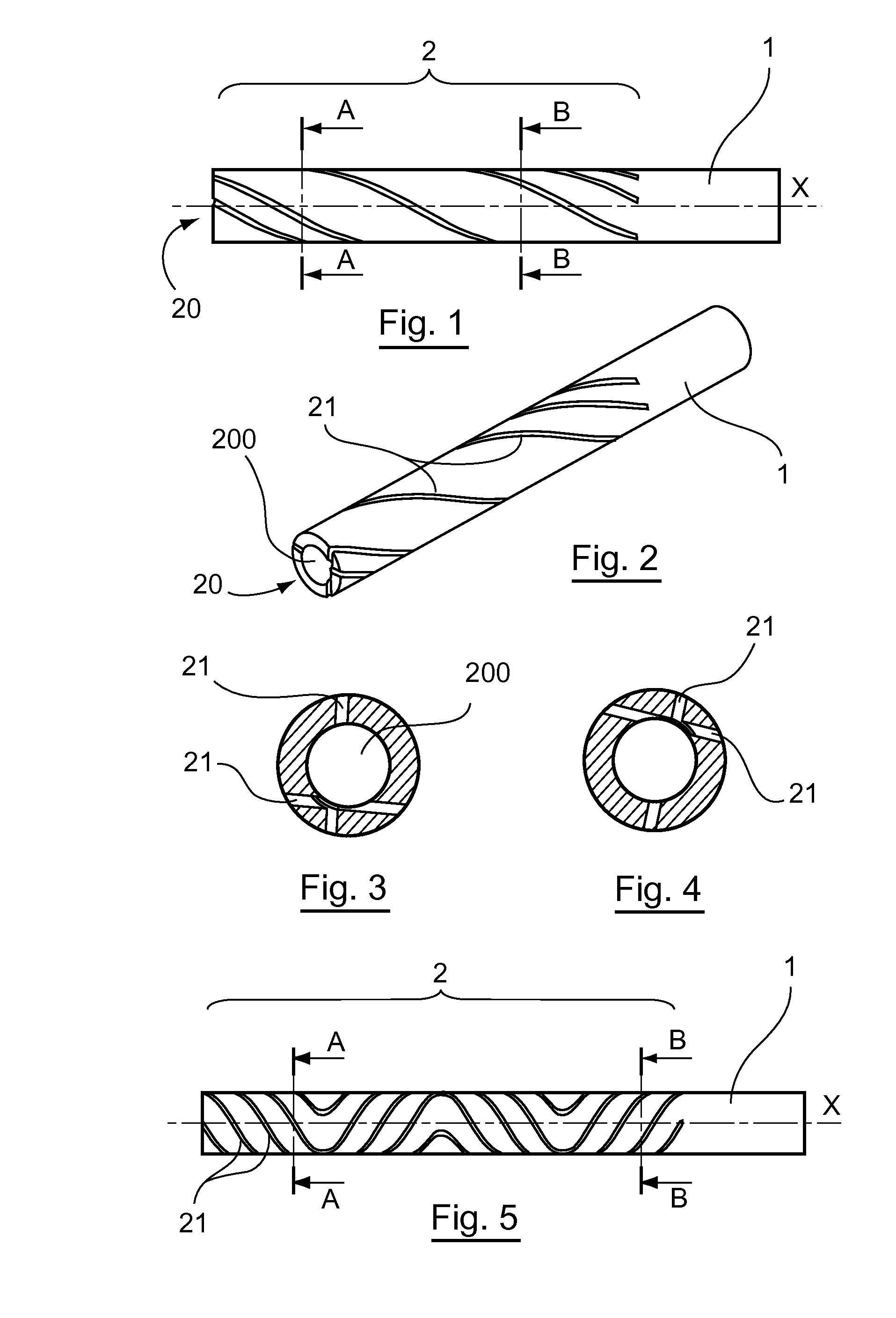

Endodontic instrument, the active portion of which has a slot forming a passage for a fluid.

ActiveUS20130260334A1Improve fluid flowSelective curettage of the necrotic tissuesWheelchairs/patient conveyanceTeeth cappingSurgeryEndodontic instrument

The invention relates to an endodontic instrument used for working on a canal in a tooth, having a base from which an active portion for working on the canal extends longitudinally, characterized in that said active portion has at least one slot extending longitudinally and forming a passage for fluid.

Owner:NEOLIX

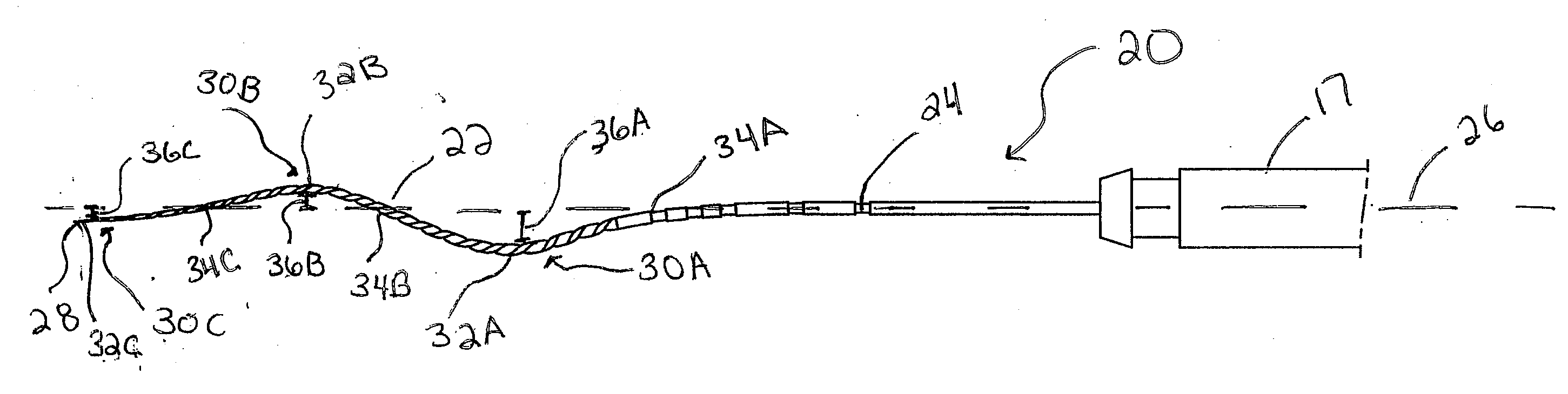

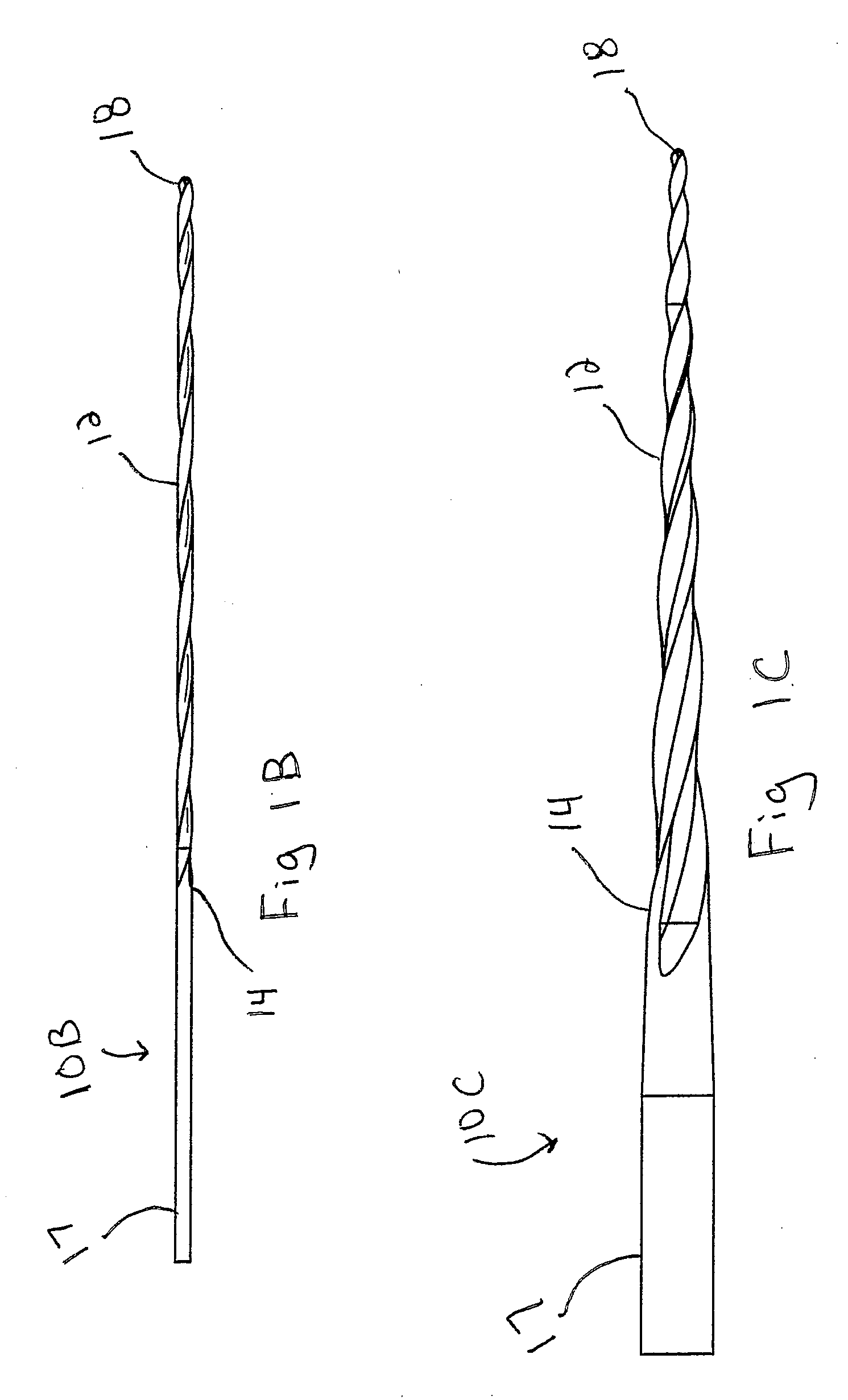

Endodontic instruments

InactiveUS20070101797A1Improve adhesion strengthMinimizes separationShaping toolsDental toolsEngineeringShort length

A method of manufacturing endodontic instruments is disclosed. Each of the instruments includes a substantially non-cutting pilot portion, a relatively short working portion, and a flexible shank portion which is of a substantially smaller average circumferential span than the working portion. The working portion of the instrument has a maximum circumferential span larger than that of the blank from which it is made. The instrument may have a handle at its distal end for manual manipulation, or may be adapted for attachment to a mechanical handpiece. The non-cutting pilot, the short length of the working portion, and the flexibility of the shank combine to allow the instrument to be used in curved root canals without causing undue change in the natural root canal contours.

Owner:DISCUS DENTAL LLC

Endodontic instrument having notched cutting surfaces

InactiveUS6966774B2Trend downQuickly and economically manufacturedTeeth cappingTeeth nerve/root treatment implementsFile designEndodontic files

A fluteless endodontic file is provided, formed from a tapered shaft of material having a prismatic shape generally defined by three or more side surfaces and three or more interposed corners. A plurality of notches are cut into one or more corners defining cutting surfaces, points and / or edges. The notched cutting surfaces are formed such that the file, when rotated and / or reciprocated within a root canal, effectively cuts / debrides hard tissue (known in the art as dentin) as well as soft tissue, thus, forming an optimal canal shape. The cutting surfaces are also preferably formed at an angle to the centerline of the instrument to provide optimal cutting efficiency and material removal. The fluteless file design exhibits increased efficacy, with less tendency to bind and break within the root canal and also significantly reduces manufacturing and capital equipment costs.

Owner:CLOUDLAND INST

Endodontic instruments and method of manufacturing same

A method of manufacturing an endodontic instrument using an electrochemical (ECG) grinding process. An instrument blank is formed from stock material, and an electric current is applied between an electrically conductive grinding wheel, acting as a cathode, and the instrument blank, acting as an anode. A continuous stream of electrolyte fluid, a conductive aqueous solution, is applied at an interface between the grinding wheel and the instrument blank, the electrolyte fluid having an associated volume and pressure. The instrument blank is advanced past the electrically conductive grinding wheel to remove material from the instrument blank to form at least one cutting flute. The electric current applied between the grinding wheel and the instrument blank is reduced, and the instrument blank is advanced past the grinding wheel again to form a finish surface, e.g., a sharp cutting edge, on the at least one cutting flute. The process may be repeated to form an endodontic instrument having a plurality of cutting flutes. The cutting flutes may be helically or non-helically shaped. The instrument blank is formed of an electrically conductive material, such as nickel titanium or stainless steel. In one variation, the electric current may be eliminated entirely during the final finishing pass. The volume and pressure of the electrolyte may be varied. Endodontic instruments formed by the method of the present invention are also disclosed.

Owner:INTEGRA YORK PA

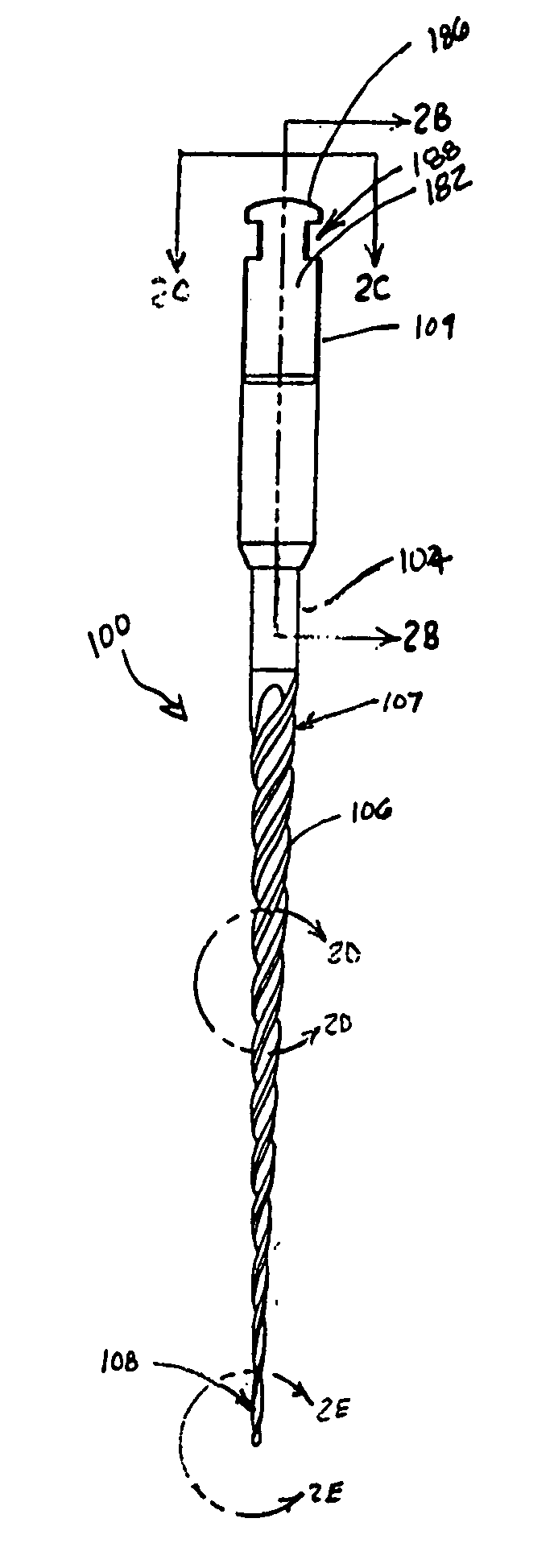

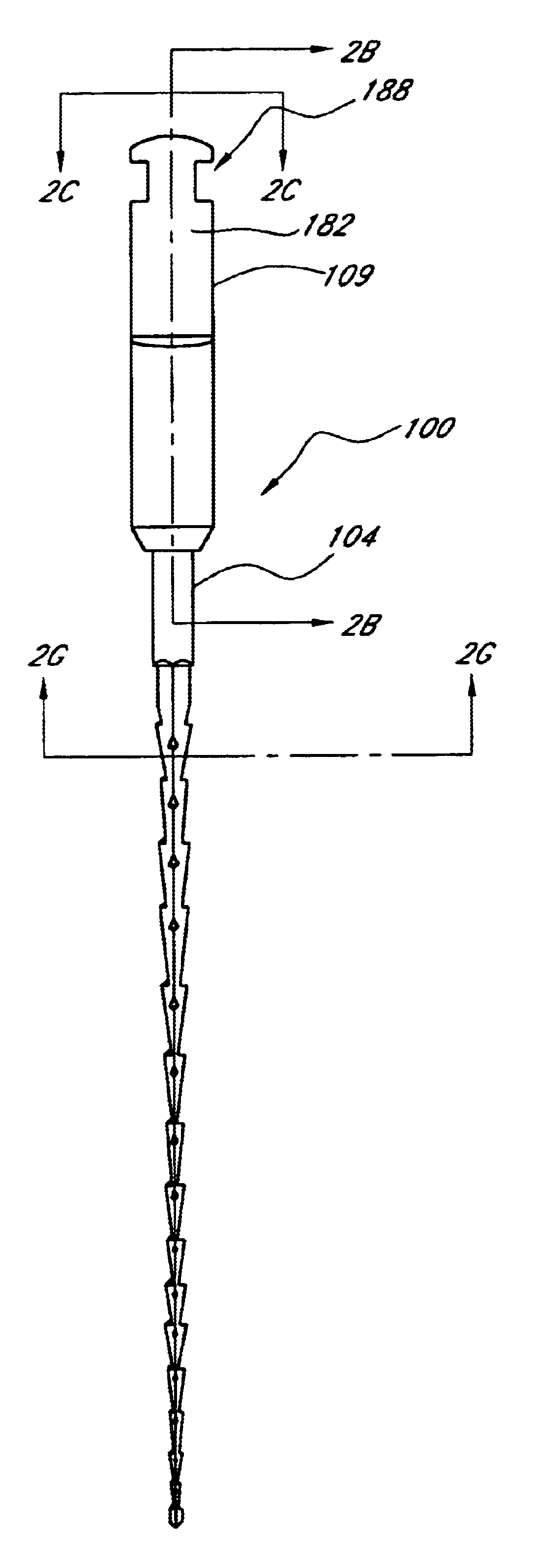

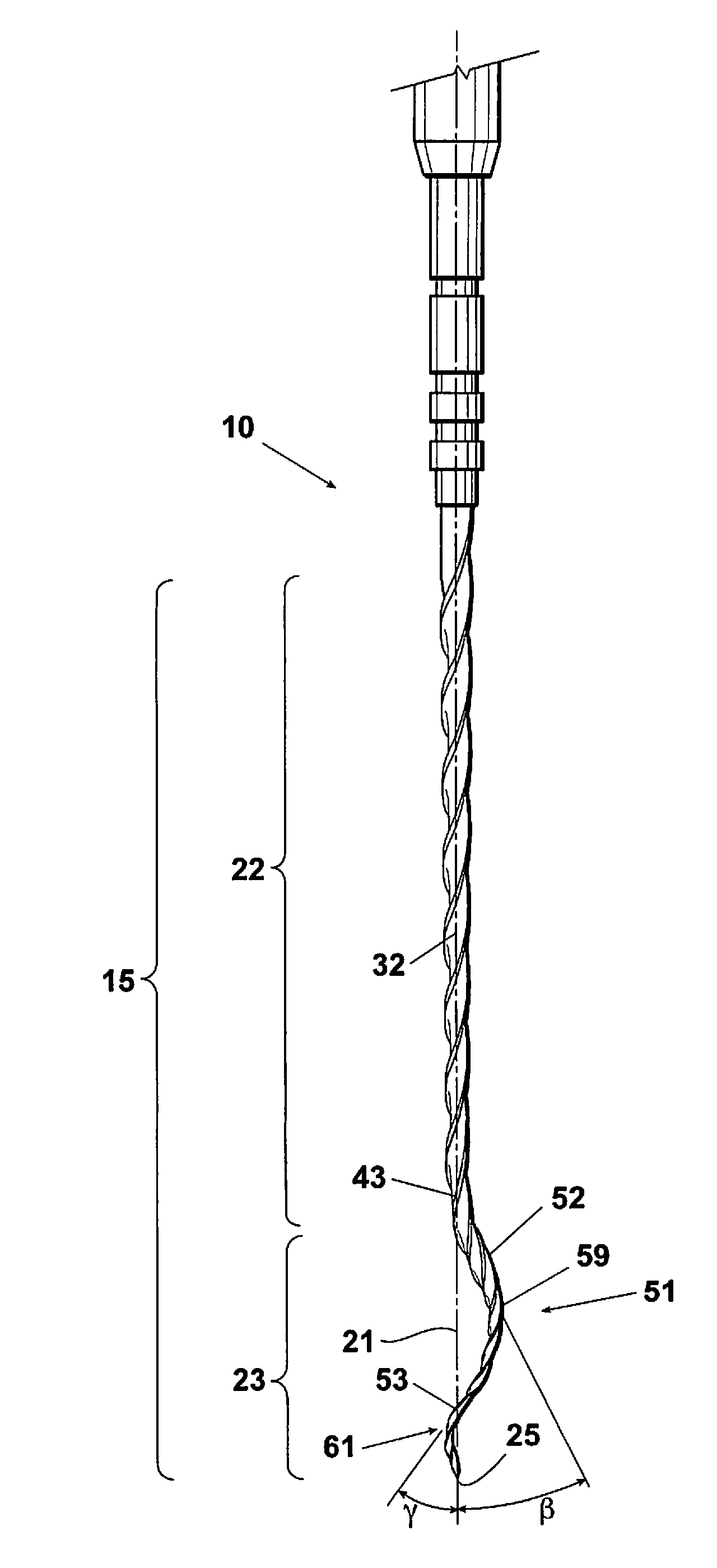

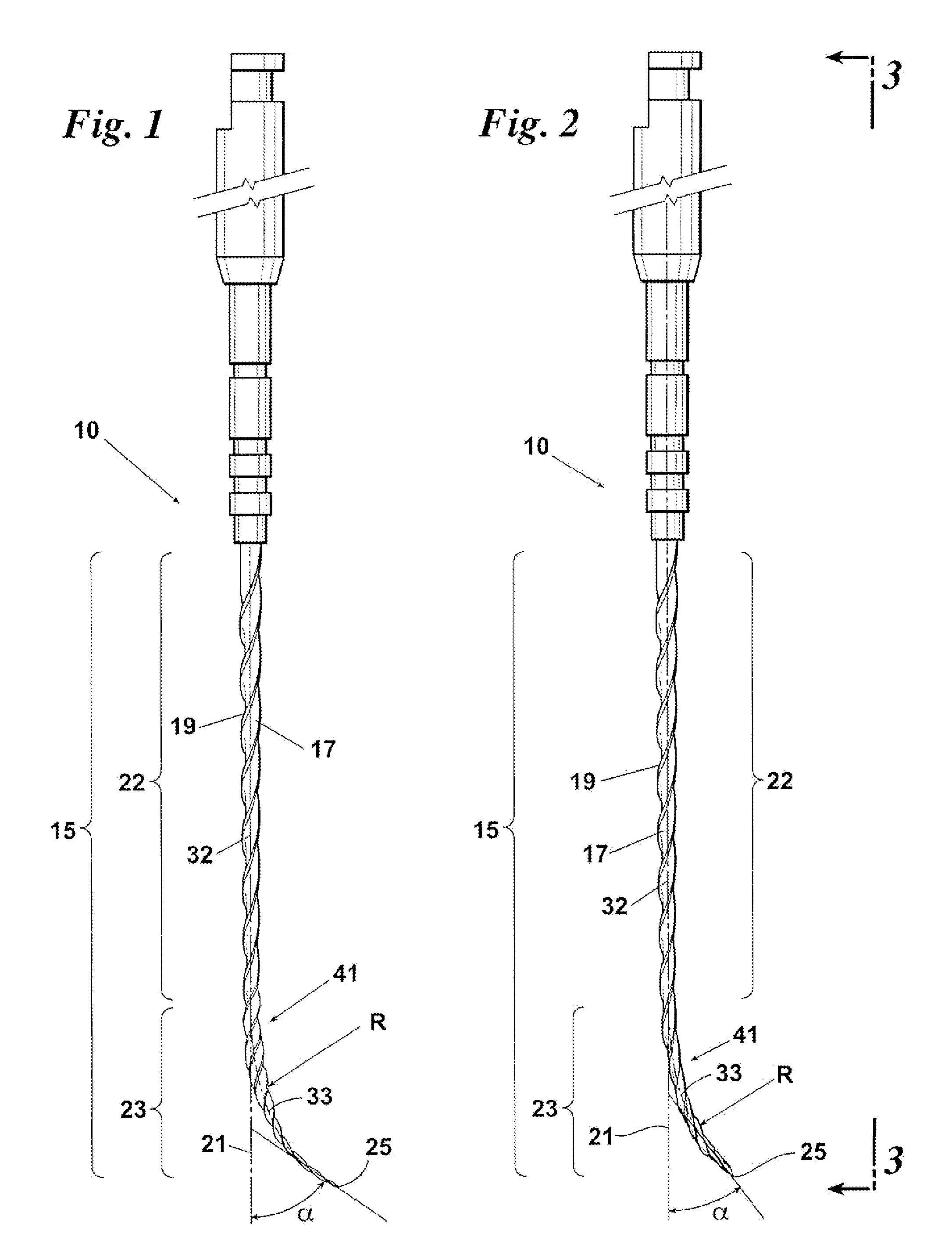

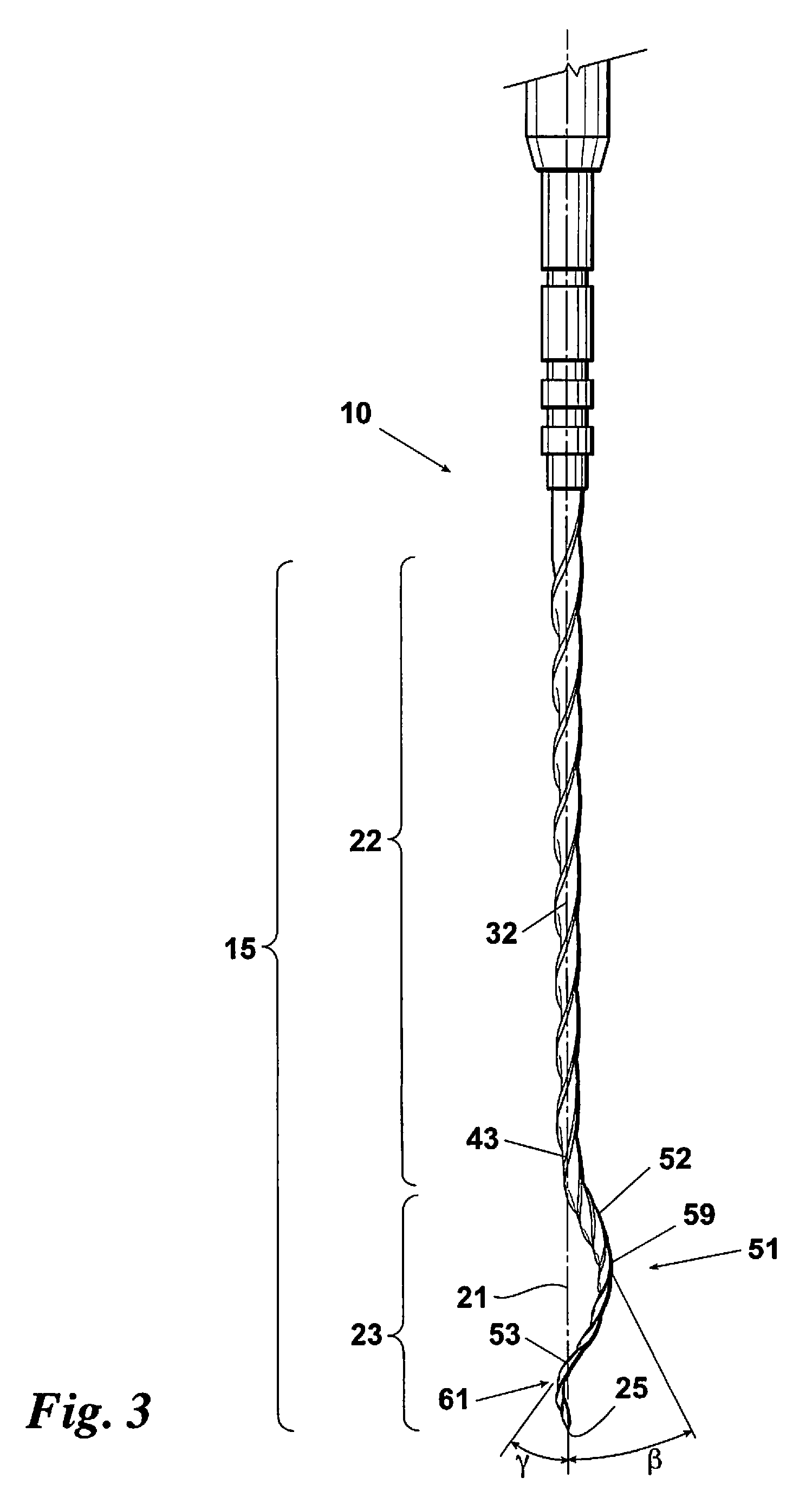

Endodontic system and method

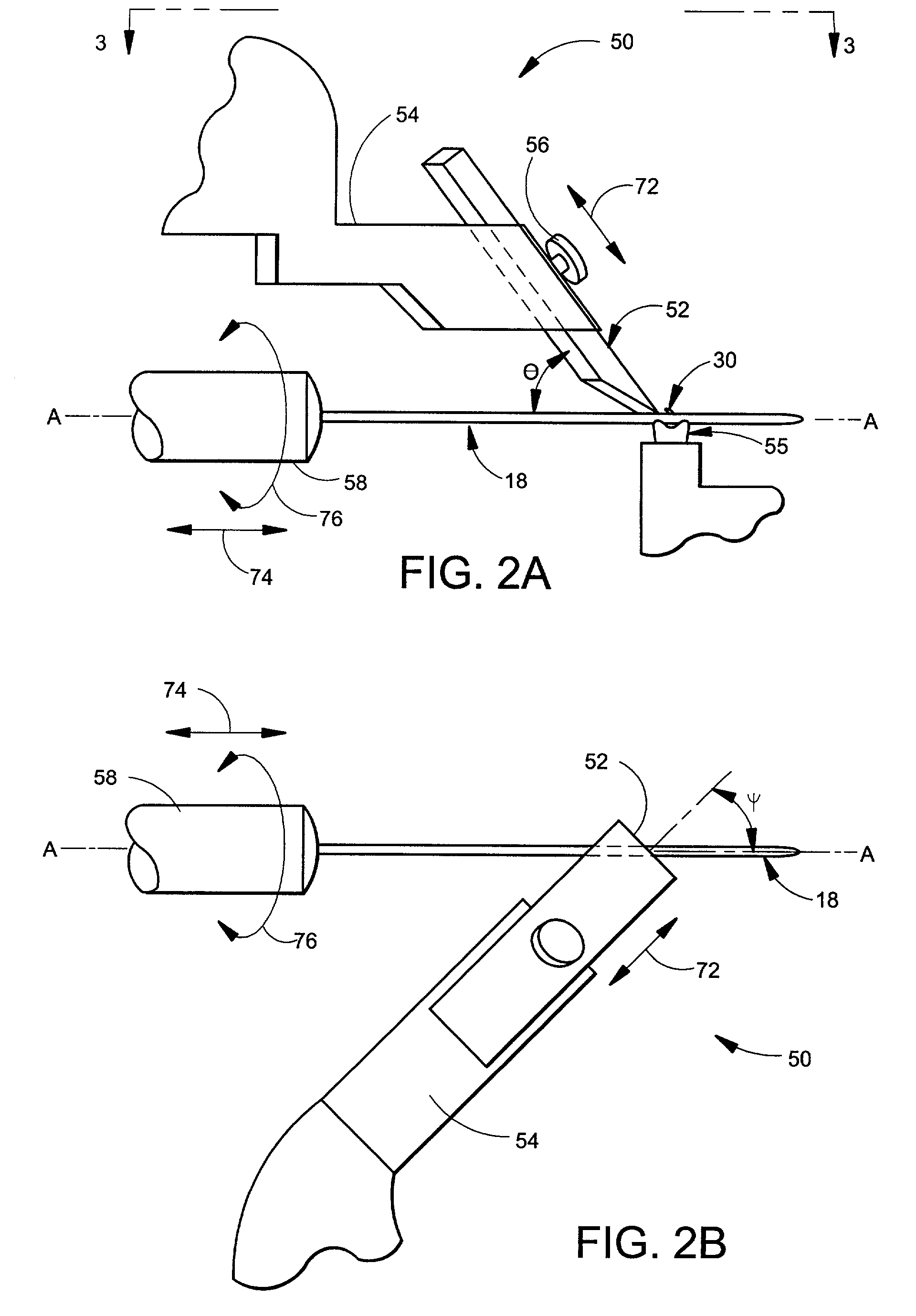

ActiveUS20120107766A1Reduce morbidityConvenient in teethDental toolsNerve needlesDrive motorEngineering

The present invention provides a system for the endodontic treatment of a root canal, comprising(i) an endodontic instrument;(ii) an endodontic handpiece having a drive motor for rotating the endodontic instrument releasably attached to the handpiece;(iii) a control unit for controlling the rotation of the endodontic instrument according to one or more predetermined rotational sequences;the rotational sequences comprising reciprocating the endodontic instrument by continuously sequentially rotating the endodontic instrument in a first direction followed by reversing the direction of rotation so that0.5×Ψ≦α<Ψ and 3≦α / β≦20,wherein α represents a rotational angle in a direction in which the rotating endodontic instrument removes debris from the root canal, β represents a rotational angle in the opposite direction, and Ψ represents the elastic angle of the endodontic instrument at which plastic deformation occurs in the direction of α.

Owner:DENTSPLY SIRONA INC

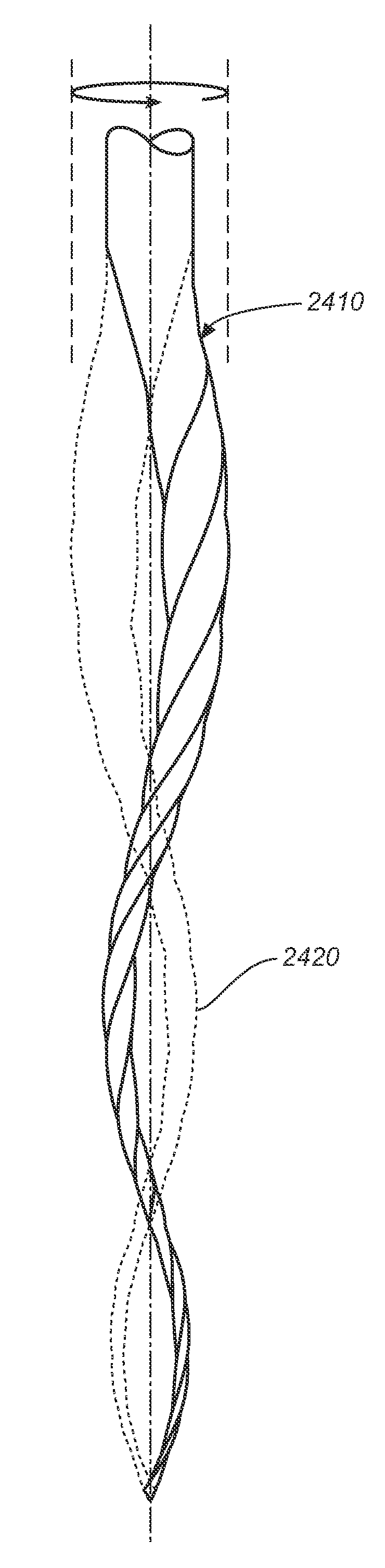

Swaggering Endodontic Instruments

Endodontic instruments are described which have at least a section with a center of mass offset from an axis of rotation so that when the instrument is rotated, the section bends away from the axis of rotation.

Owner:SCIANAMBLO MICHAEL J

Endodontic instrument set and method of using the same

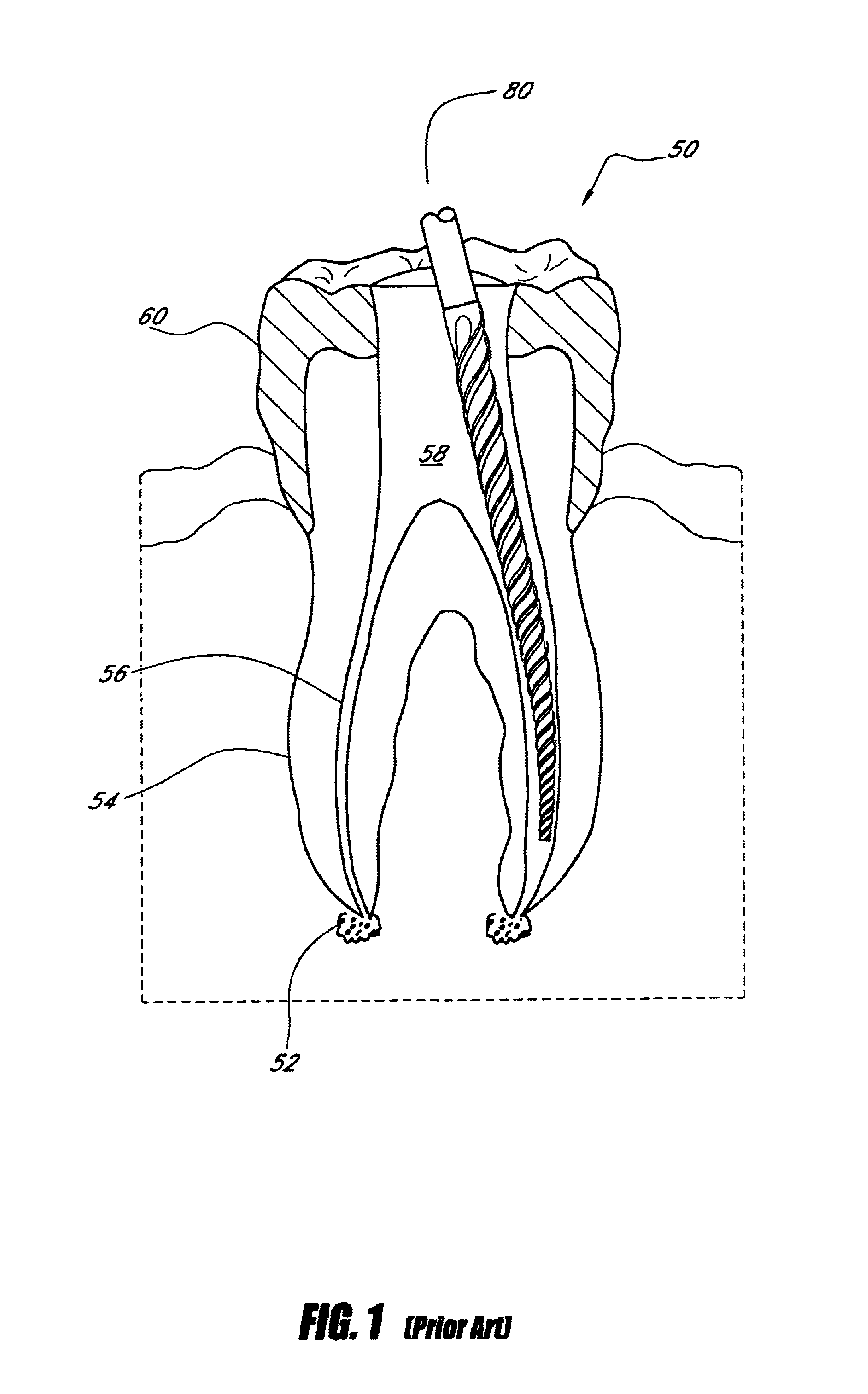

InactiveUS20050186534A1Small fragile tipEasily brokenTeeth cappingTeeth nerve/root treatment implementsMedicineSurgery

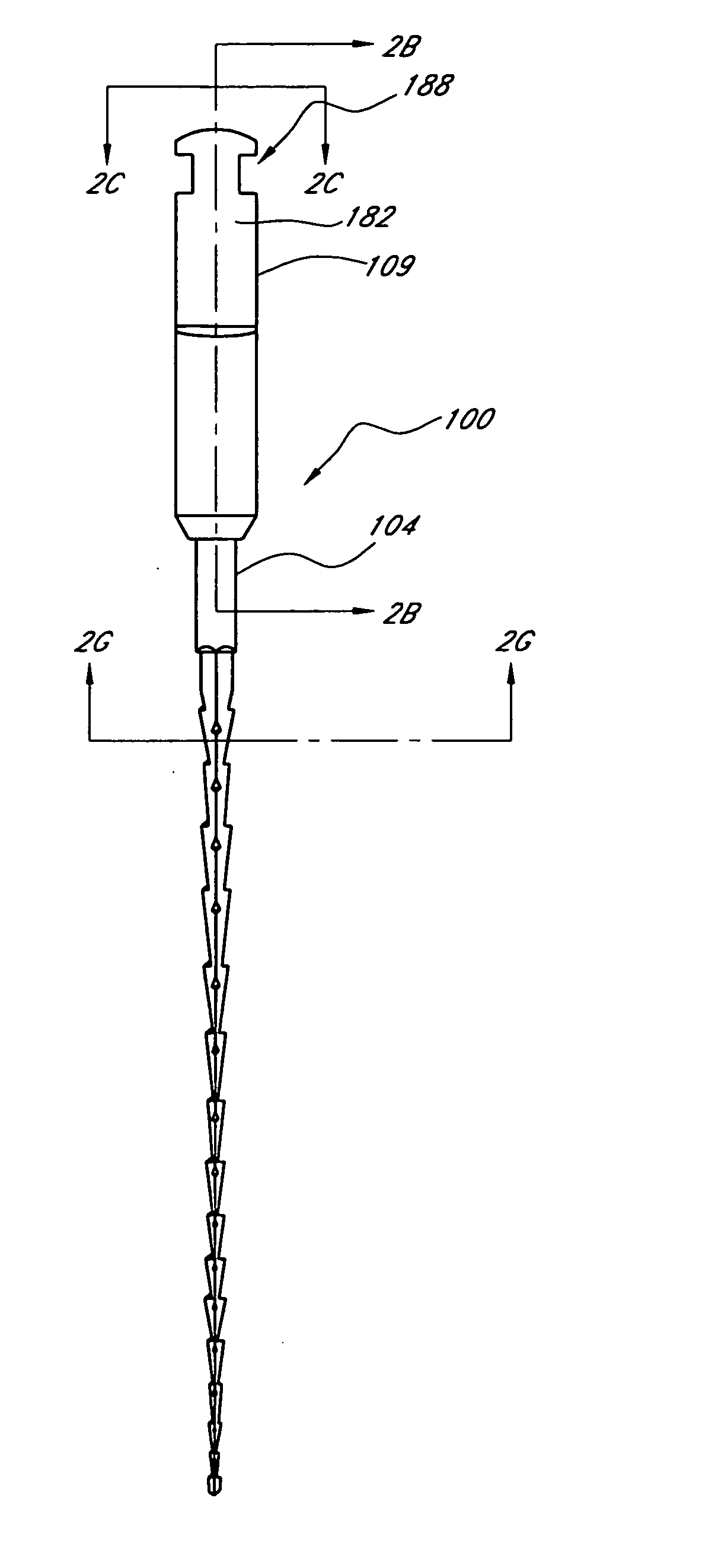

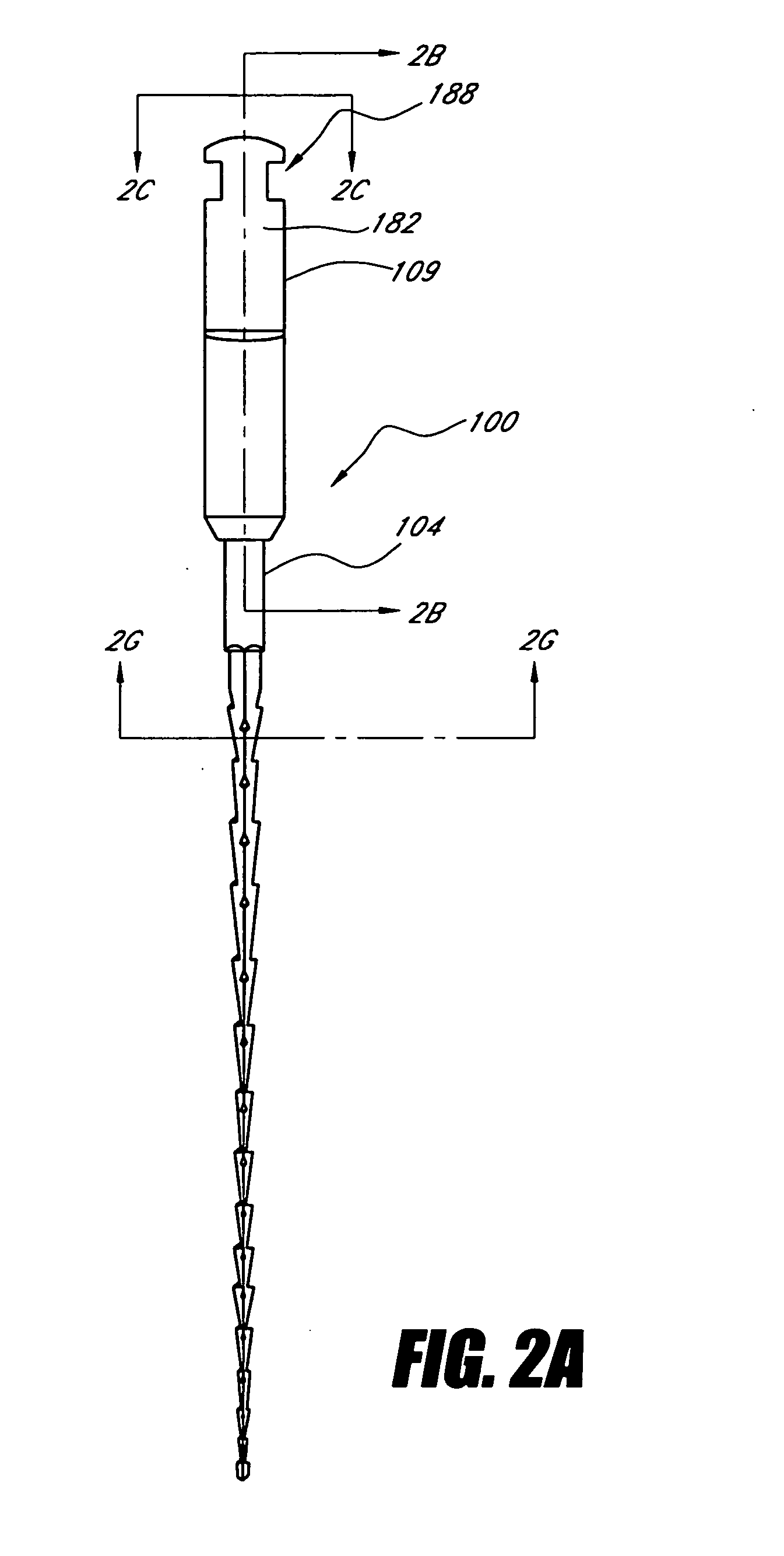

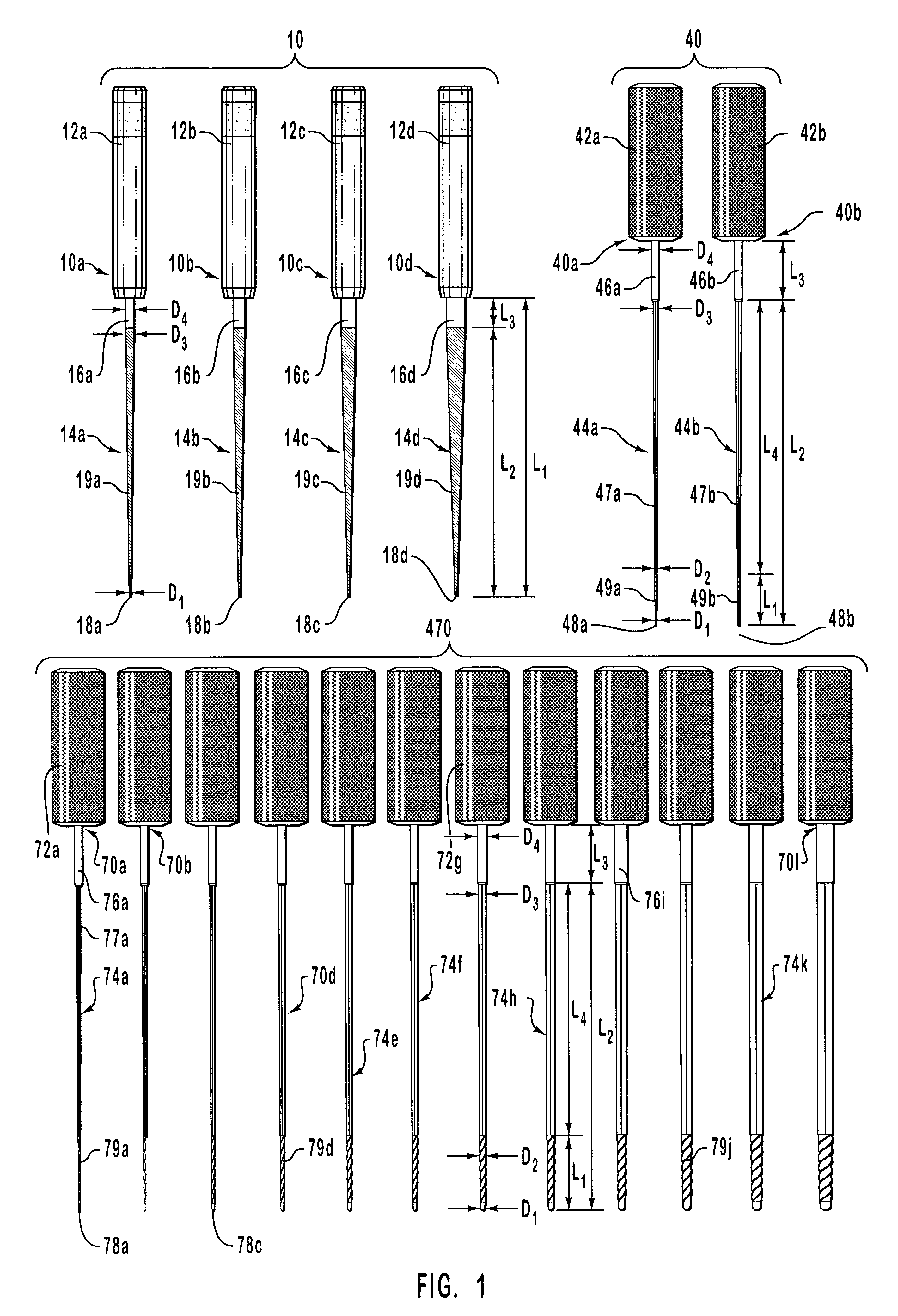

An endodontic instrument set of progressively smaller sizes adapted for use in performing root canal therapy and a method of using the instrument set are provided. Each of the instruments have an elongated shaft comprising a proximal end and a distal end and a short enlarged continuously tapered working length formed on the shaft adjacent to the distal end. The short enlarged continuously tapered working length has at least one continuous cutting edge thereon.

Owner:ROANE JAMES B

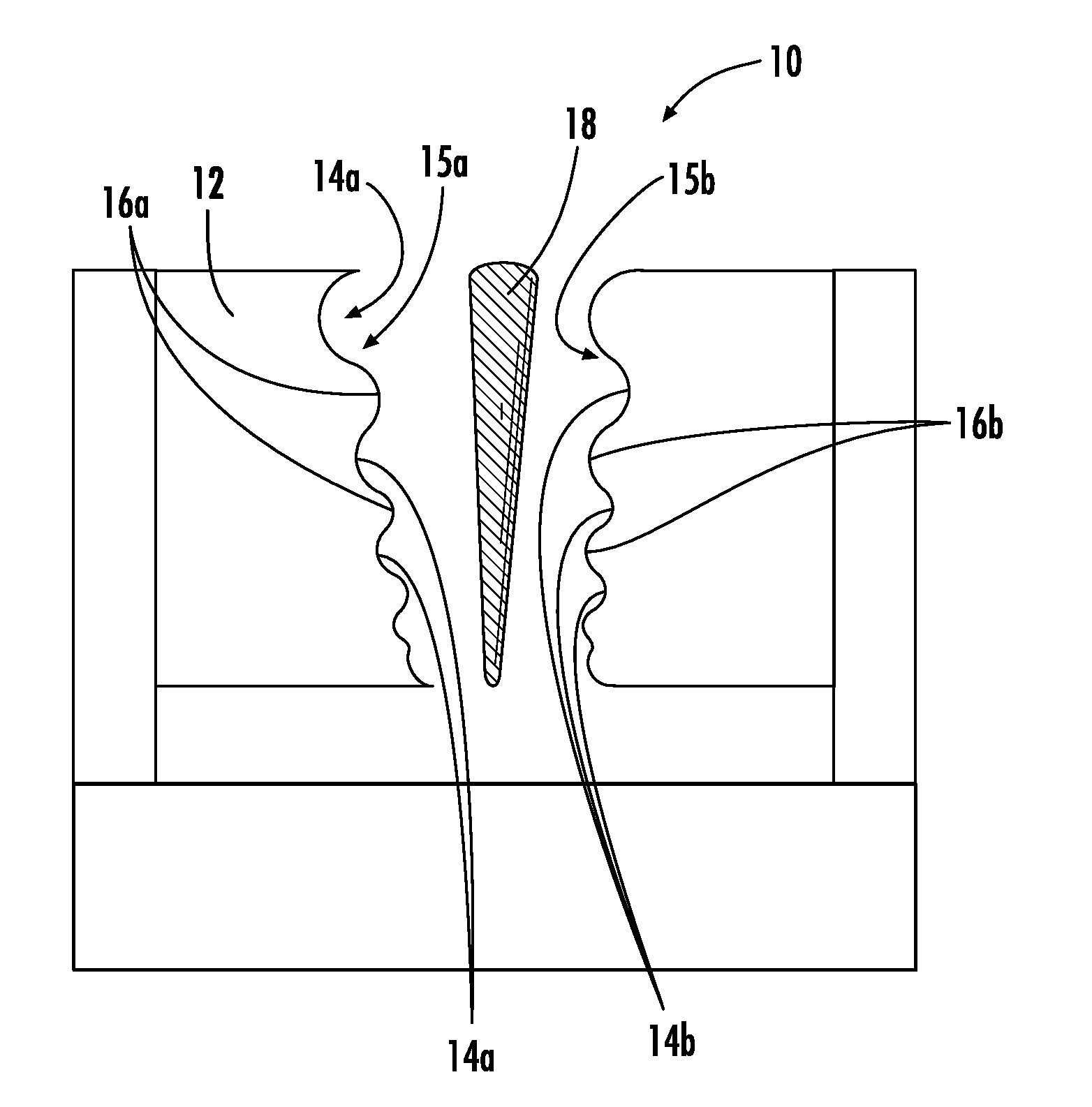

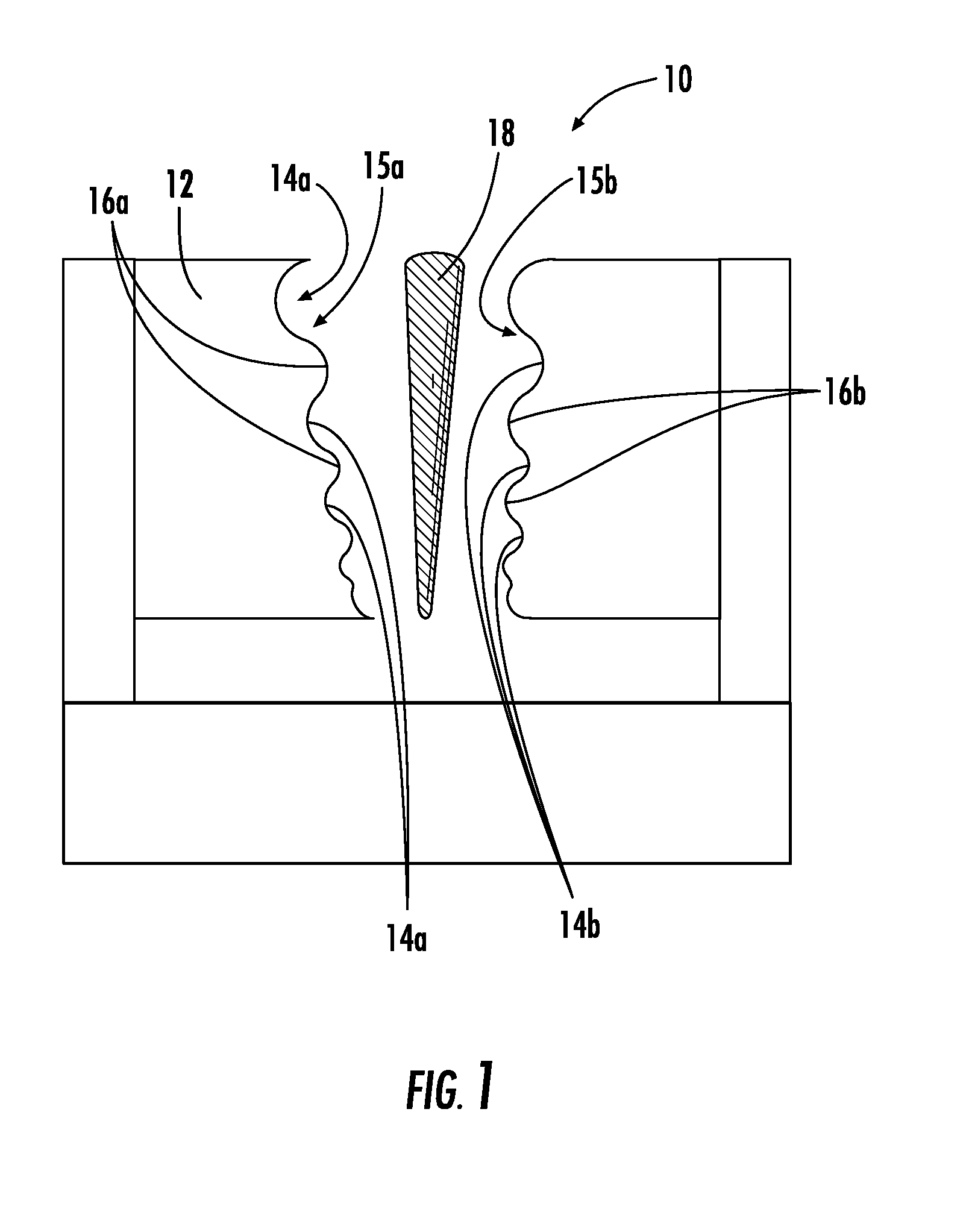

Multi-planar pre-curved rotary endodontic file

ActiveUS9078722B2Reduce torqueEffective maintenanceTeeth cappingTeeth nerve/root treatment implementsEndodontic filesComputer science

An improved rotary endodontic file includes a multi-planar pre-curved apical portion having a first and a second curvature. The pre-curved apical portion begins at about one-third to one-quarter of the working length as measured from the tip end of the endodontic instrument. The first and second curvature permit the file to continually search and engage the walls of a tooth root canal in a forced inside-forced outside manner. As the file works its way down, it breaks free of any ledges encountered, probes lateral- and delta-type openings, and does not allow the file to stray from the curvature of the canal.

Owner:DENTSPLY SIRONA INC

Endodontic instruments and method of manufacturing same

A method of manufacturing an endodontic instrument using an electrochemical (ECG) grinding process. An instrument blank is formed from stock material, and an electric current is applied between an electrically conductive grinding wheel, acting as a cathode, and the instrument blank, acting as an anode. A continuous stream of electrolyte fluid, a conductive aqueous solution, is applied at an interface between the grinding wheel and the instrument blank, the electrolyte fluid having an associated volume and pressure. The instrument blank is advanced past the electrically conductive grinding wheel to remove material from the instrument blank to form at least one cutting flute. The electric current applied between the grinding wheel and the instrument blank is reduced, and the instrument blank is advanced past the grinding wheel again to form a finish surface, e.g., a sharp cutting edge, on the at least one cutting flute. The process may be repeated to form an endodontic instrument having a plurality of cutting flutes. The cutting flutes may be helically or non-helically shaped. The instrument blank is formed of an electrically conductive material, such as nickel titanium or stainless steel. In one variation, the electric current may be eliminated entirely during the final finishing pass. The volume and pressure of the electrolyte may be varied. Endodontic instruments formed by the method of the present invention are also disclosed.

Owner:INTEGRA YORK PA

Endodontic instruments and methods of manufacturing thereof

ActiveUS8916009B2Avoid damageMinimizes and removeFurnace typesTeeth cappingEngineeringMechanical engineering

Owner:DENTSPLY SIRONA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com