A full dentition plastic splint type transparent tooth fixer

A splint-type, fixator technology, applied in dentistry, orthodontics, prosthetics, etc., can solve the problems of difficult to maintain oral hygiene, poor tooth fixation, poor tooth fixation, etc., to reduce labor and material costs. , Good fixation effect, relieve discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

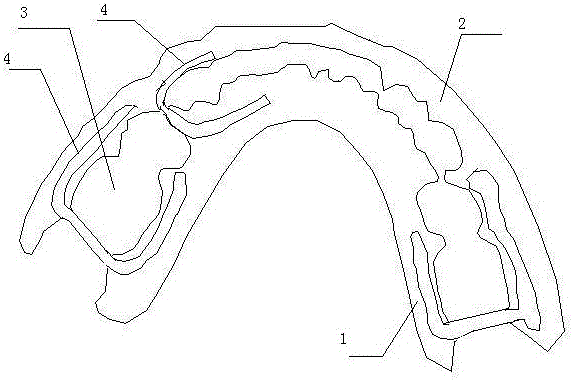

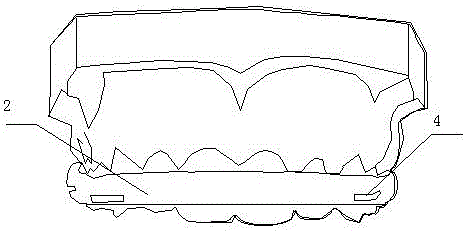

[0014] Such as figure 1 As shown, the present embodiment provides a full dentition plastic splint type transparent tooth fixer, comprising an inner frame body 1 and an outer frame body 2, the inner frame body 1 and the outer frame body 2 are fixedly connected by embedding a wire 4, and the inner frame body The body 1 and the outer frame body 2 are close to the cheeks, tongue surface and part of the lingual alveolar mucosa. The cavity 3 between the inner frame body 1 and the outer frame body 2 is made according to the size of the teeth, so that the occlusal surface of the teeth can be completely exposed. The inner frame body 1 is a base-shaped structure, which fits closely with the teeth and gums, and the outer frame body 2 is a plastic strip structure, which closely fits with the teeth. The metal wire and the inner frame body 1 and The joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com