Buccal multi-bending spring space three-dimensional dynamometer

A three-dimensional dynamometer, buccal technology, applied in medical science, dentistry, etc., can solve problems such as poor retention of appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

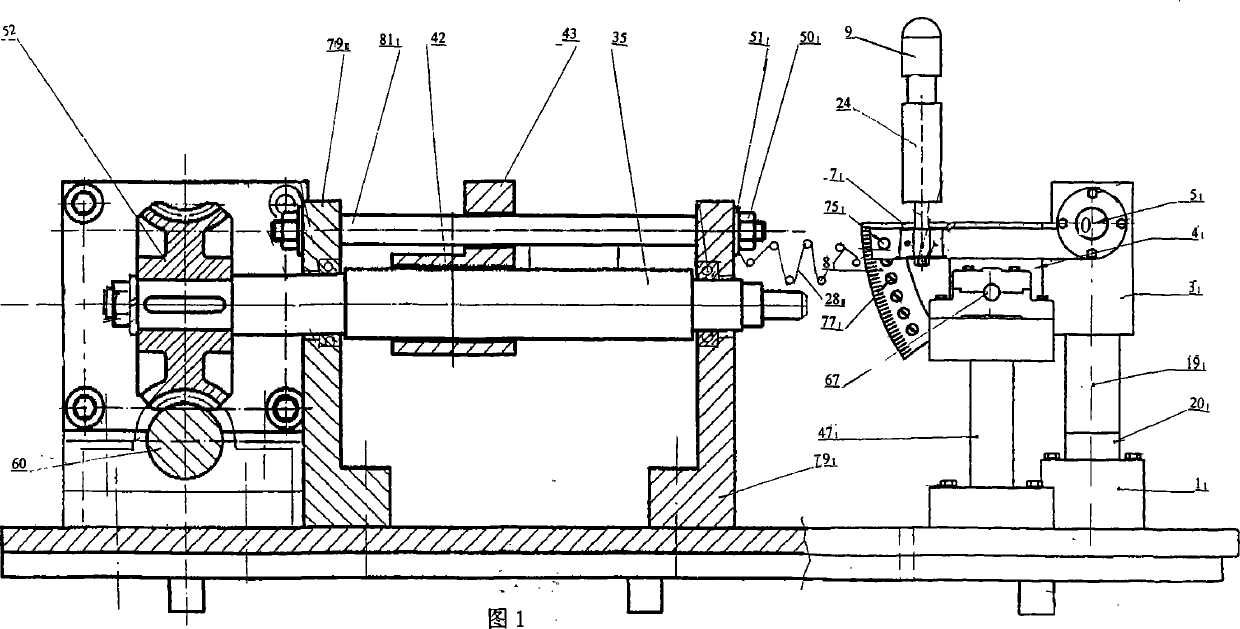

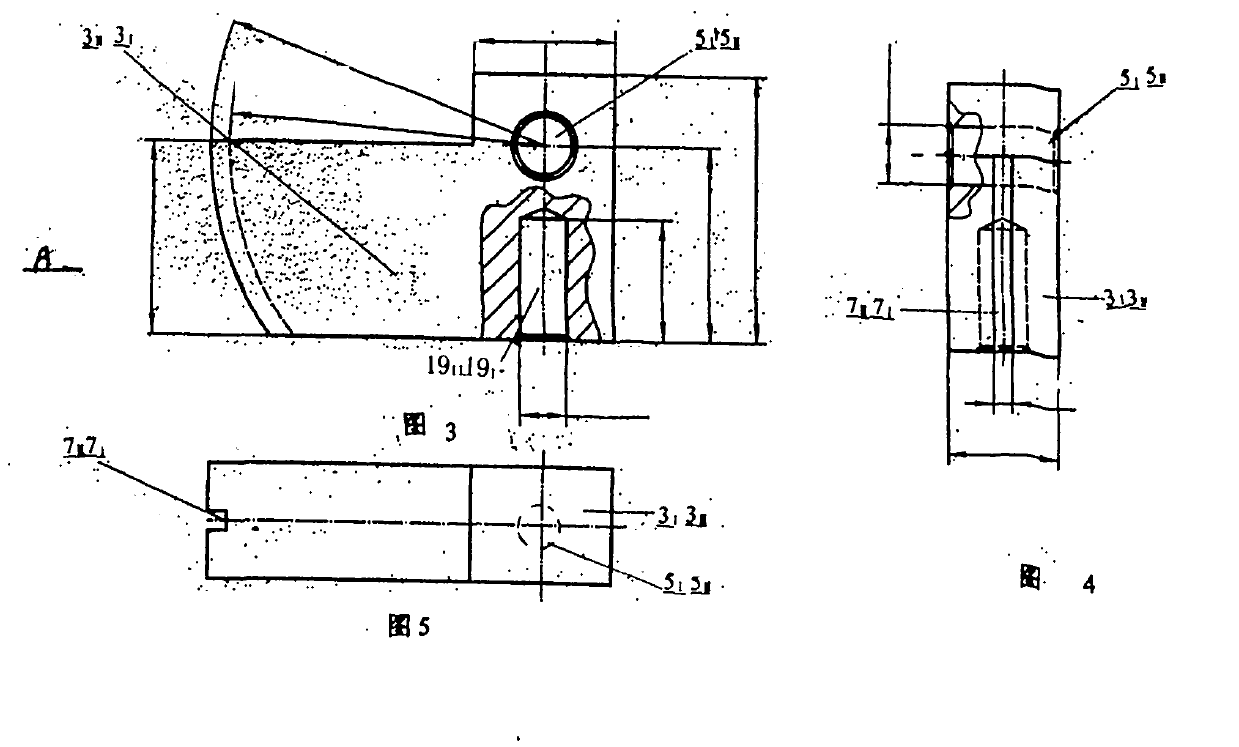

[0034] Clinicians correct patient errors Deformity, before wearing the buccal multi-curved spring movable appliance in the mouth, the mandibular overshoot on both sides of the buccal multi-curved spring is simulated on the buccal multi-curved spring space three-dimensional dynamometer. point, in the process of opening and closing the mouth, its motion trajectory (three-dimensional space) is consistent with that of the maxillary The changing law of the point compressive stress value (from the maximum compressive stress to the minimum compressive stress or change to tensile stress) can comprehensively predict the force on the entire dentition of the upper and lower jaws, that is, simulate the mandibular transition. The point (both sides) is simplified as the multi-curved spring on the buccal side goes up and down The three-dimensional coordinate movement of a point in space.

[0035] The first type: lower jaw point (both sides) from the closed state to the maximum openi...

specific Embodiment approach 3

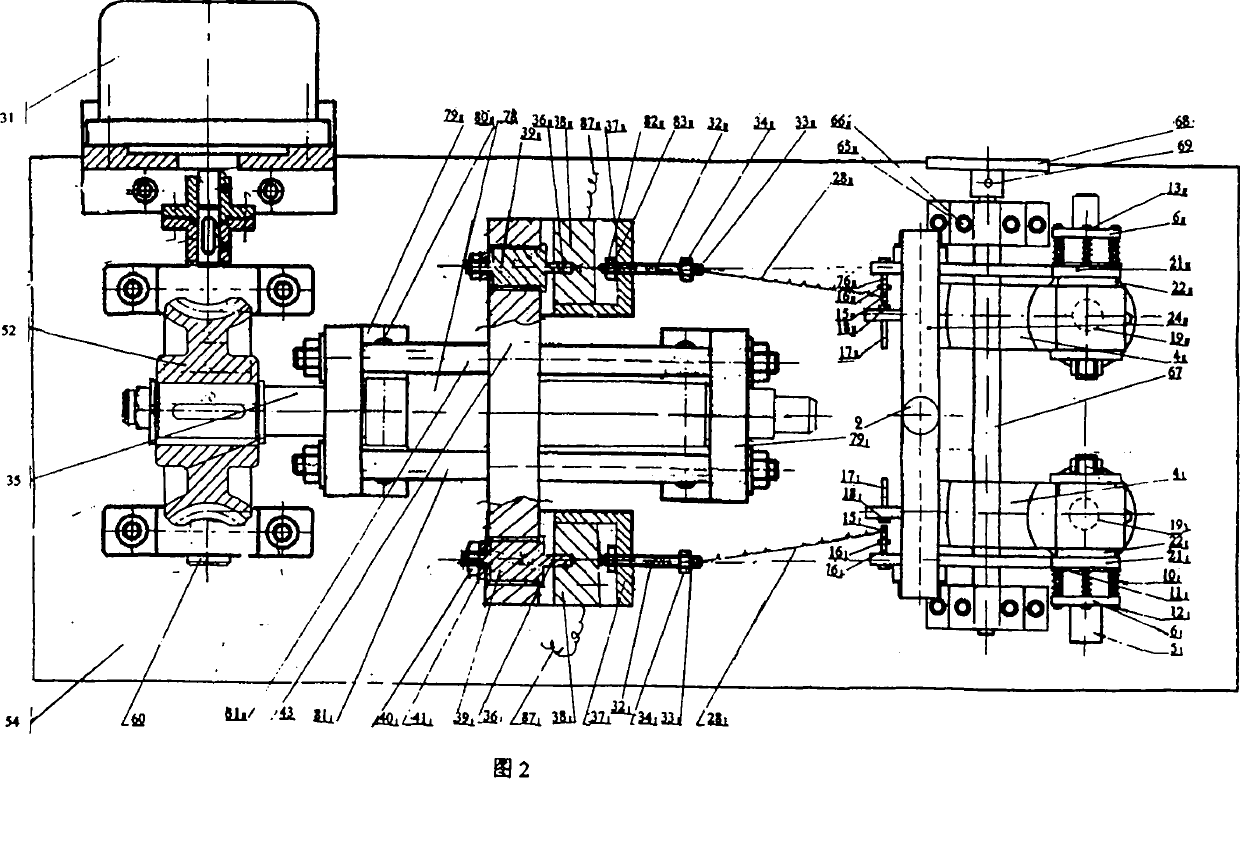

[0038] The motor 31 can be changed to a continuously variable speed motor, and then through the worm gear variable speed transmission, completes the uniform motion and completes the drive; the synchronous three-dimensional mobile handle 9 and the synchronous displacement plate 24 can also be changed to a continuously variable speed motor to drive and complete the displacement stress test. before (see attached figure 2 , 8 , 9, 10).

[0039] working principle:

[0040] The invented space three-dimensional dynamometer is based on the orthodontic error of clinical patients. During the correction process, the condyle is regarded as a simple rotational movement (hinge movement) without sliding. The resulting opening range (hinge opening) is 18-20mm between the incisal margins of the upper and lower incisors. The mandible moves in a three-dimensional space. point, chin point, and its landmark points are displaced relative to the coordinate system. Considering that the hinge c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com