Auxiliary machining method for aviation thin-wall micro-structure part

An auxiliary processing, thin-walled technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of difficult to control the size of the burr on the bottom edge, weak rigidity of the thin-walled structure, and large size of the burr. , to achieve the effect of efficient cleaning and separation, low-efficiency material removal, and reduction of elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

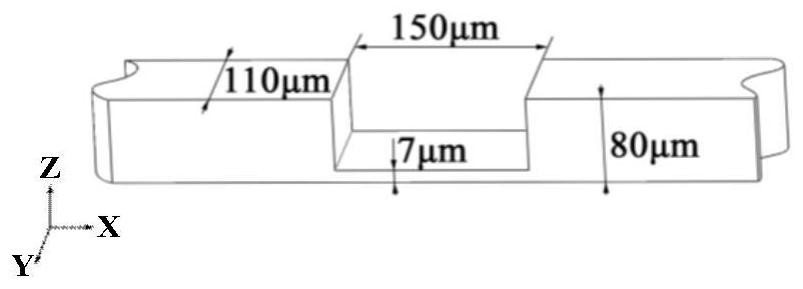

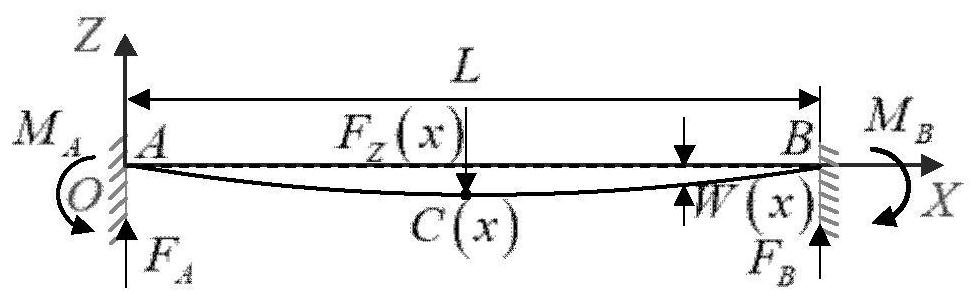

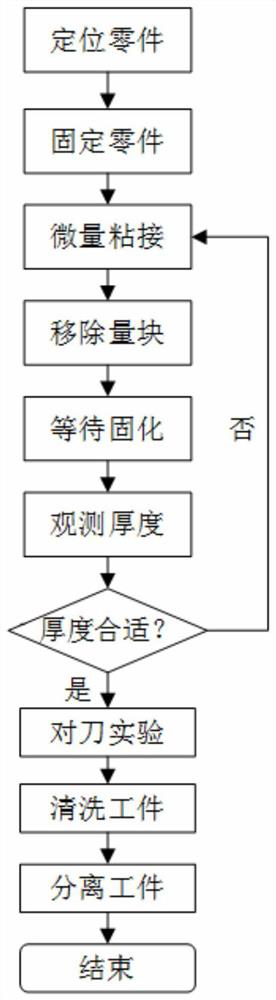

[0042] This embodiment discloses an auxiliary processing method for aerospace thin-walled microstructure parts, figure 1 It is the characteristic dimension diagram of aerospace thin-walled micro-structured part 1. It can be seen from the figure that the part will undergo elastic deformation in the Z and Y directions during the micro-milling process. First, the deformation of the aerospace thin-walled micro-structured part 1 during processing is calculated. Such as figure 2 As shown, if the thin-walled microstructure part 1 is simplified as a beam fixed at both ends, the deformation in different directions is calculated as:

[0043] (1) Deformation calculation in the Z direction

[0044] The redundant constraints are:

[0045]

[0046] The deformation boundary condition at the microstructure is:

[0047]

[0048] According to the solution of material mechanics, it can be known that the deflection W at any point on the section is:

[0049]

[0050] In formula (3),...

Embodiment 2

[0085] This embodiment provides a relatively basic implementation method, an auxiliary processing method for aerospace thin-walled microstructure parts, figure 1 It is the characteristic size diagram of aerospace thin-walled microstructure part 1. It can be seen from the diagram that the part will undergo elastic deformation in the Z and Y directions during the micro-milling process. First, the deformation of the aerospace thin-walled micro-structured part 1 during processing is calculated. Such as figure 2 As shown, if the thin-walled microstructure part 1 is simplified as a beam fixed at both ends, the deformation in different directions is calculated as:

[0086] (4) Deformation calculation in the Z direction

[0087] The redundant constraints are:

[0088]

[0089] The deformation boundary condition at the microstructure is:

[0090]

[0091] According to the solution of material mechanics, it can be known that the deflection W at any point on the section is:

...

Embodiment 3

[0123] The main steps of this embodiment are the same as those in Embodiment 2. Further, the vertical high-precision gauge block 2 and the horizontal high-precision gauge block 3 are both square, and the material is GCr15, which has high hardness, high thickness, high contact fatigue and uniform structure. Its modulus of elasticity is 219GPa, hardness is 25.8HRC, yield strength is 518.42MPa, and the precision is 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com