Adhesive-distributing device and method for adhesively bonding hollow profiles using an adhesive-distributing device

A technology for distribution devices and hollow profiles, applied in the direction of surface coating liquid devices, spray devices, spray devices, etc., can solve the problems of increased difficulty in assembly and repair, high labor intensity, insufficient bonding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

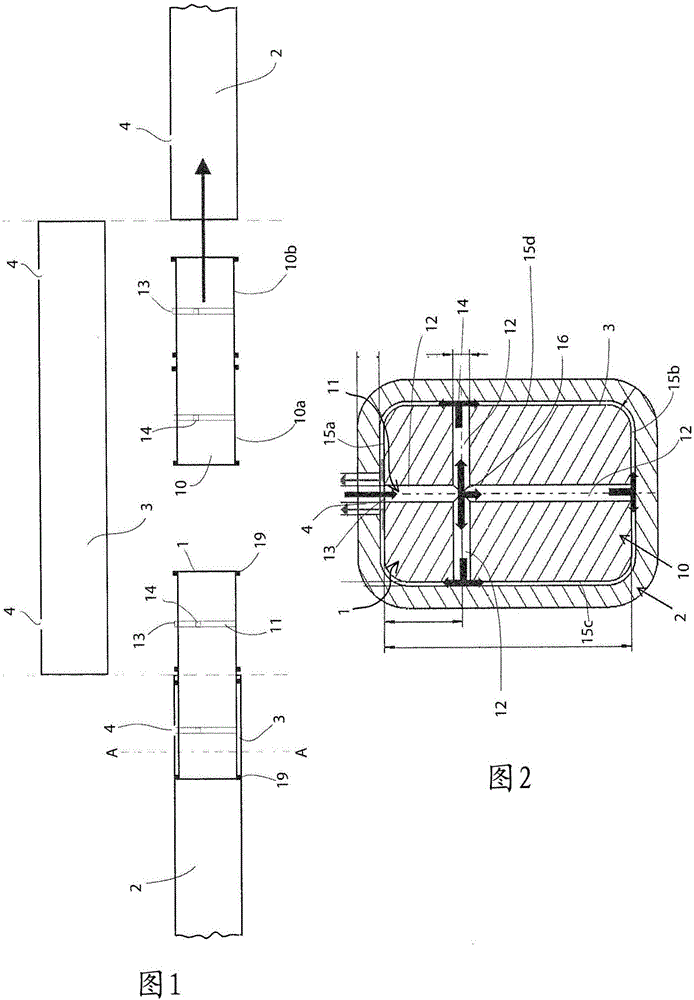

[0036] FIG. 1 shows a schematic side view of a hollow profile 2 divided in the middle, from which a hollow profile section (not shown) has been separated for repair or restoration purposes. A repair profile 3 of suitable length is shown above the separated section. Furthermore, two adhesive distribution devices 1 according to the invention are shown, wherein the left adhesive distribution device 1 is partially pushed into the hollow profile 2 .

[0037] FIG. 2 shows the adhesive distribution device 1 as a sectional view along the line A-A in FIG. 1 . The adhesive distribution device 1 shown in FIG. 2 comprises a connecting body 10 in which two separate channel systems 11 are arranged respectively in a left connecting body section 10a and a right connecting body section 10b, as schematically as shown in Figure 1.

[0038] The channel system 11 comprises four interconnected channels 12 , of which two run vertically and two horizontally through the connecting body 10 . The fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com