Clamp and method for testing tensile shear creep of adhesive by cross method

A criss-cross, stretching and shearing technology, applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable tension/compression, measuring devices, etc., can solve errors and cannot be tensile load sheared Cut creep test and other issues to achieve the effect of reducing error, saving test cost and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

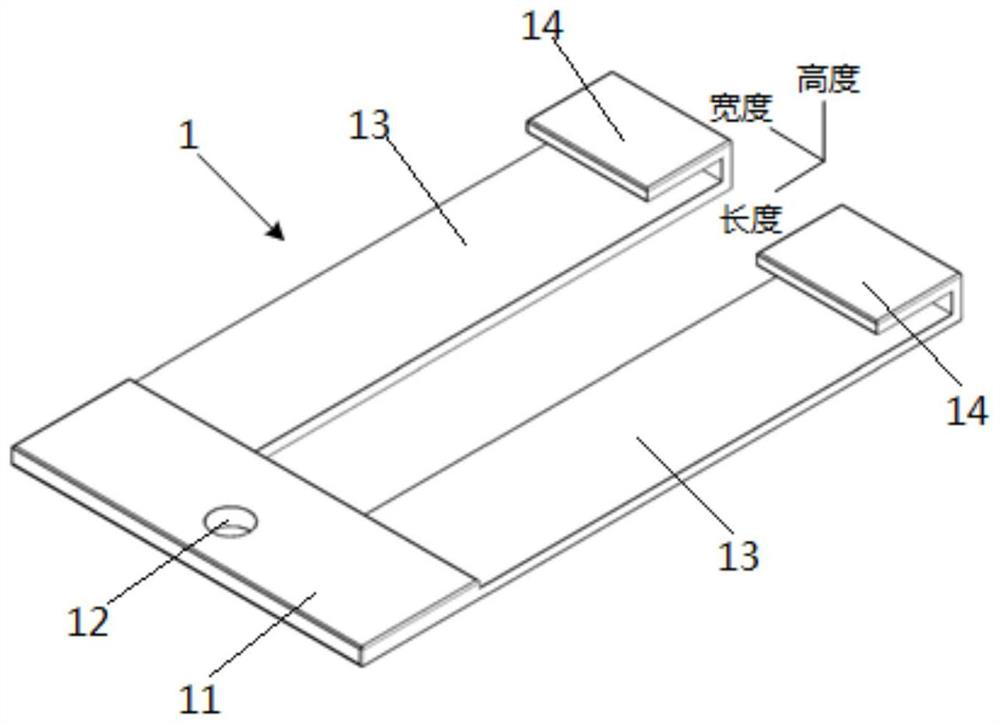

[0043] An embodiment of the present invention provides a fixture for testing the tensile shear creep of an adhesive by the cross method. The fixture is used in conjunction with an instrument that can provide tension to hold the Fixed criss-cross specimen.

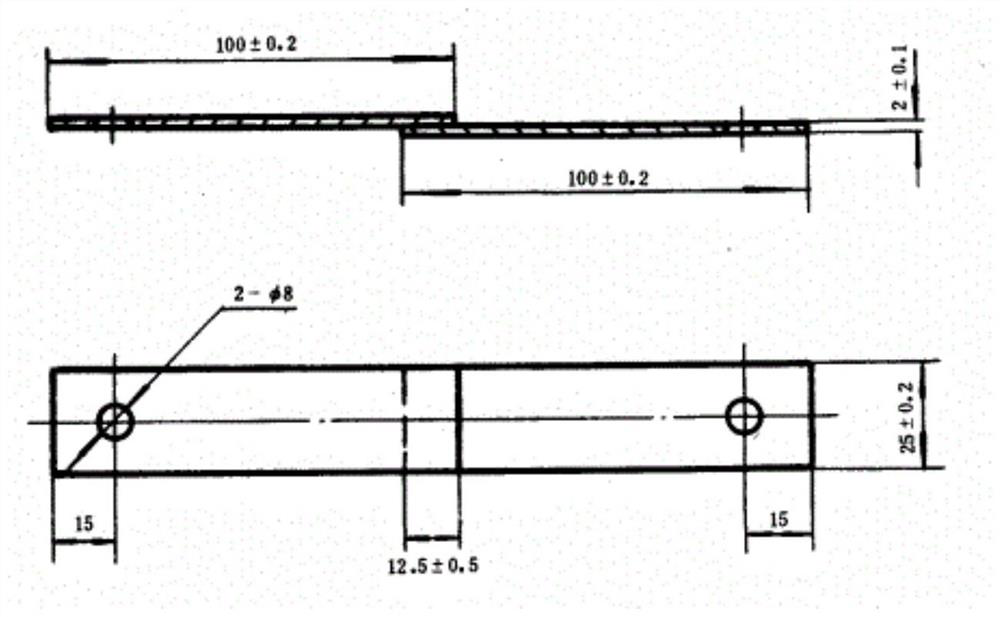

[0044] like Figure 5 As shown, the crisscross sample 100 includes two bonded substrates and adhesives arranged in a crisscross pattern. For convenience of description, Figure 5The direction shown is a reference, and the two substrates to be bonded are respectively a horizontal substrate 200 and a vertical substrate 300, and the horizontal substrate 200 and the vertical substrate 300 are vertically bonded by an adhesive 400, and the horizontal substrate 200 and the vertical substrate The dimensions of the substrates 300 can be the same or different, and their materials can be the same or different, and the materials can be rigid solids such as metal, ceramics, glass, plastic, and wood.

[0045] like image 3 , 4 As sho...

Embodiment 2

[0072] The embodiment of the present invention provides a method of using the clamp of embodiment 1 to perform the tensile shear creep test of the adhesive, the method comprising:

[0073] S1: Measure the bonding interface area S of the adhesive in the cross sample and the length dimension X of the adhesive in the direction of the tensile load.

[0074] S is the bonding interface area between the substrate to be bonded and the adhesive, and X is the length of the adhesive in the direction of the tensile load. S and X can be measured by a steel ruler or a vernier caliper.

[0075] S2: Connect the first connection structure of the first clamping plate with the upper connection mechanism of the tensile instrument, embed the transverse base material in the cross sample in the first J-shaped hook groove, and make the cross sample The adhesive layer passes through the gap between the two first connecting parts, such as Figure 9 , 10 shown.

[0076] S3: The second clamping plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com