Broach with honeycomb-like microstructures and preparation method of broach

A microstructure and honeycomb-like technology is applied in the field of broaches with a honeycomb-like microstructure and their preparation. Heat buildup, the effect of protecting the tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

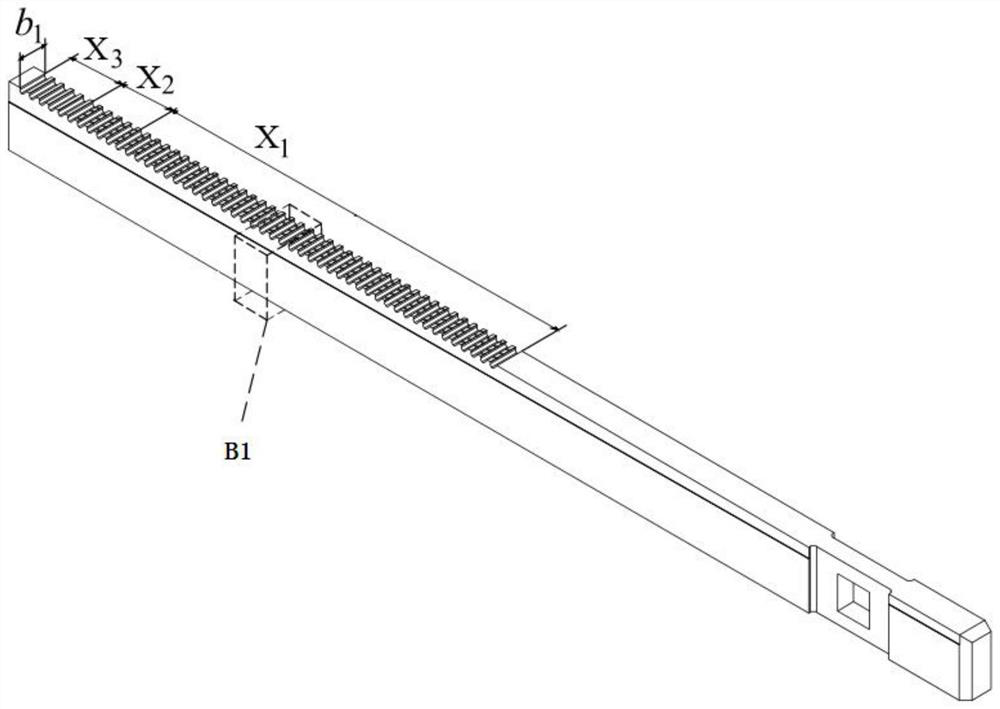

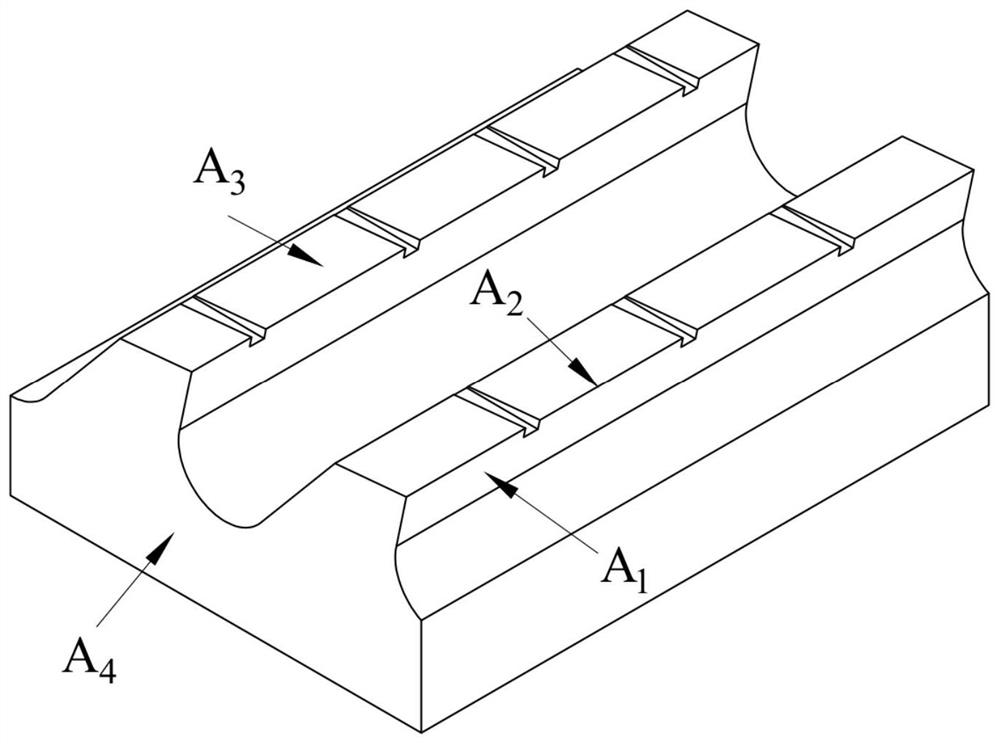

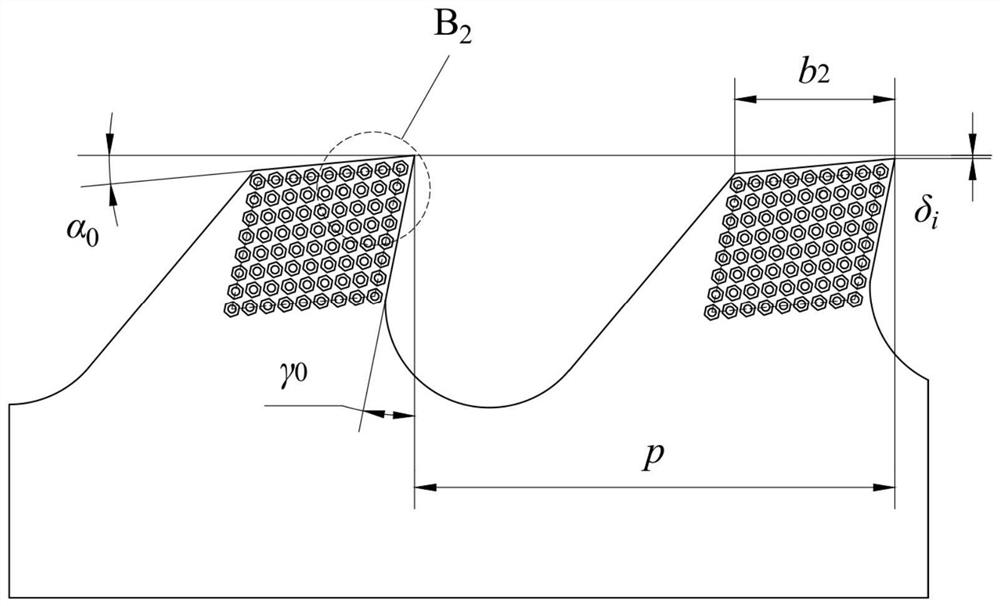

[0041] like Picture 1-1 , 1-2 Shown in and 1-3, in the embodiment of the present invention, the broach with imitative honeycomb microstructure is a keyway broach, and the material adopts high-speed steel (W6Mo5Cr4V2). As a preferred embodiment, the specific size of the broach is: the total length is 600mm, tooth width b 1 is 16mm, the horizontal width of the flank b 2 is 2mm, and the number of teeth is 50. Rake angle of cutter teethγ 0 is 12°, relief angle α 0 is 6°, and the tooth pitch p is 6mm. As a preferred embodiment, the first 40 teeth are rough drawing area X 1 , tooth lift δ in the rough drawing zone i 0.04mm, the 41st to 45th teeth are semi-finishing areas X 2 , tooth lift δ in the semi-finishing zone i 0.01mm, the 46th to 50th tooth is the fine drawing area X 3 , tooth lift δ in the finishing area i is 0mm. Tooth including rake face A 1 , Blade ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com