Novel squeeze roller type roller surface structure

A squeezing roller and a new type of technology, applied in the field of squeezing rollers, can solve the problems of unfavorable studs, single replacement of roller sleeves, sustainable use, increased equipment maintenance cycle and cost, damage or breakage, etc., to achieve performance improvement, abrasion resistance and other problems. Strong, long-life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

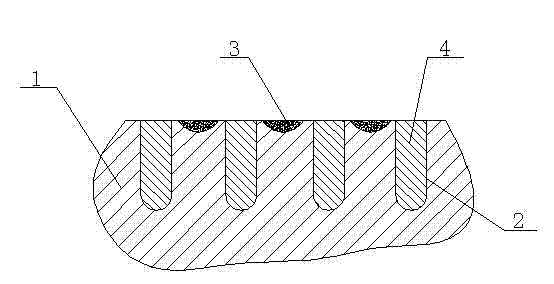

[0032] Such as figure 1 As shown, the roll surface structure: the outer surface of the roller sleeve 1 is provided with staggered column holes 2 and arc-shaped grooves 3, and the column holes 2 are provided with studs 4 that are flush with the surface of the roller sleeve 1. The nail 4 is arranged in the column hole 2 in the form of a clearance fit, and an adhesive is provided on the outer surface of the column nail and the inner surface of the column hole, and the high-strength adhesive combines the two firmly into one.

Embodiment 2

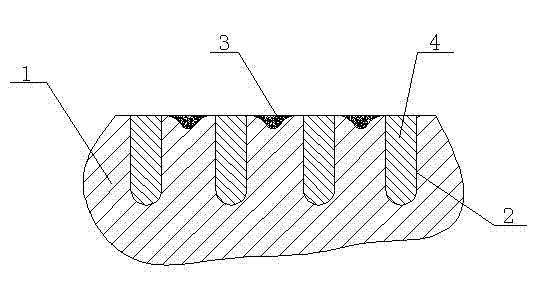

[0034] Such as figure 2 As shown, the roll surface structure: the outer surface of the roller sleeve 1 is provided with staggered column holes 2 and spherical grooves 3, the opening edge of the spherical groove and the surface of the roller sleeve are chamfered, and the column holes There is a stud 4 which is flush with the surface of the roller sleeve. The stud is arranged in the stud hole in the form of clearance fit, and an adhesive is provided on the outer surface of the stud and the inner surface of the stud hole. The high-strength adhesive binds the two firmly combined into one.

Embodiment 3

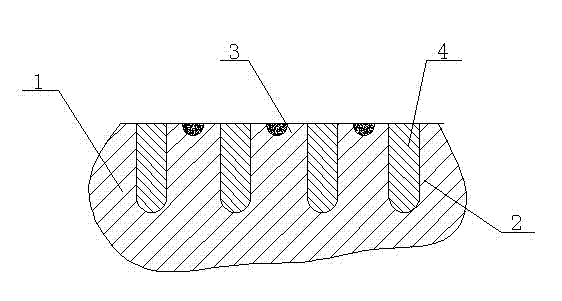

[0036] Such as image 3 As shown, the roll surface structure: the outer surface of the roller cover 1 is provided with staggered post holes 2 and hemispherical grooves 3, and the post holes are provided with studs 4 that are flush with the surface of the roll cover. The matching form is arranged in the column hole, and an adhesive is provided on the outer surface of the column nail and the inner surface of the column hole, and the high-strength adhesive combines the two firmly into one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com