Gutta-percha and nanocellulose composite film and preparation method thereof

A technology of nanocellulose and composite film, applied in the field of composite film, can solve the problems of pollution and high cost of modification of eucommia gum, and achieve the effect of expanding the field of preparation and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

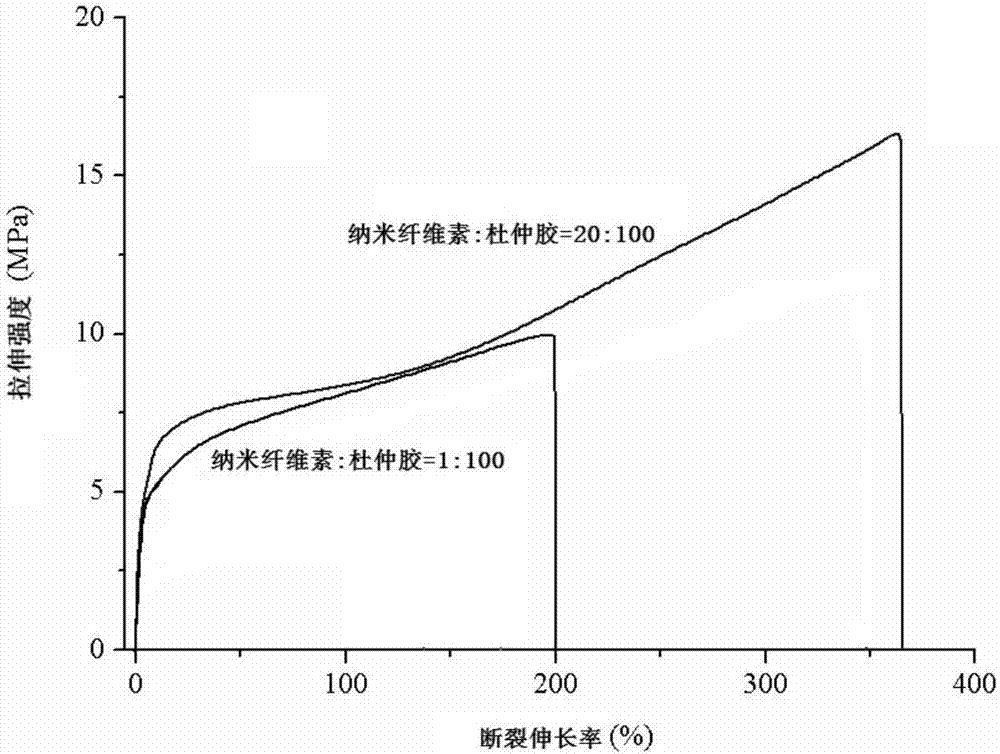

Embodiment 1

[0025] Weigh 1g of eucommia gum, stir at 50°C and 100rpm for 10min, dissolve it in 5ml of petroleum ether to obtain eucommia gum solution; weigh 0.01g of nanocellulose, add it to the above Eucommia gum solution, and stir at 100rpm for 10min Finally, the mixed solution is obtained; the above mixed solution is poured on a glass plate, and after ventilating and drying at room temperature for 3h, a composite film of Eucommia gum and nanocellulose is obtained. After measuring, the maximum tensile strength of the above-mentioned composite film is 10MPa, and the elongation at break to 200%.

Embodiment 2

[0027] Weigh 1g of eucommia gum, stir for 20min at a temperature of 60°C and a speed of 500rpm, dissolve it in 10ml of cyclohexane to obtain a eucommia gum solution; weigh 0.1g of nanocellulose, and add it to the above Eucommia gum solution, and stir at a speed of 200rpm After 15 minutes, the mixed solution was obtained; the above mixed solution was poured on a flat plastic plate at the bottom, and after ventilating and drying at room temperature for 4 hours, a composite film of Eucommia gum and nanocellulose was obtained. The maximum tensile strength of the above composite film was determined to be 12.4MPa , The elongation at break was 241%.

Embodiment 3

[0029] Weigh 1g of eucommia gum, stir for 15min at a temperature of 50°C and a speed of 300rpm, dissolve it in 15ml of dichloromethane to obtain a eucommia gum solution; weigh 0.15g of nanocellulose, and add it to the above Eucommia gum solution, and stir at a speed of 500rpm After 20 minutes, the mixed solution was obtained; the above mixed solution was poured into a glass mold with a flat bottom, and after ventilating and drying at room temperature for 5 hours, a composite film of Eucommia gum and nanocellulose was obtained. The maximum tensile strength of the above composite film was determined to be 14.8MPa , The elongation at break was 295%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Maximum tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com