Preparation method of modified natural gutta-percha with improved elasticity

A eucommia gum and modification technology, which is applied in the field of preparation of modified natural eucommia gum, can solve the problems of lack of natural rubber resources and the inability to widely use eucommia gum, and achieve the effects of improving resource scarcity, expanding the scope of use, and increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

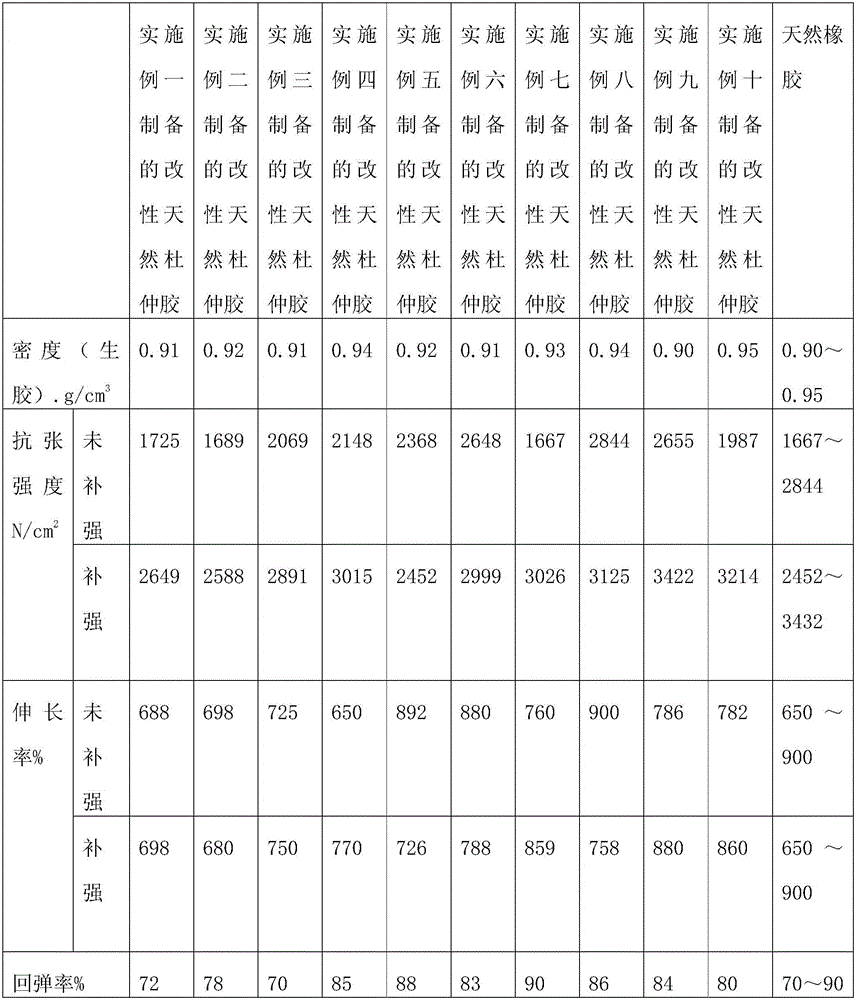

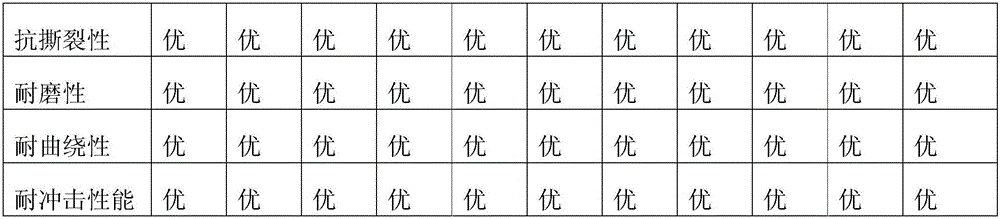

Examples

Embodiment 1

[0018] The preparation method of the modified natural Eucommia gum improving the elasticity of Eucommia gum, the steps are as follows:

[0019] Get eucommia gum and dissolve it in 200ml toluene to make a eucommia gum solution with a mass concentration of 3%, then add the eucommia gum solution into a polytetrafluoroethylene liner reactor, and then put 4.21g of 1,3 -butadiene, 0.1056g of AlCl 3 The reaction was carried out at a temperature of 90°C, and the reaction time was 6 hours. After the reaction, the reaction kettle was taken out, placed in the freezer of the refrigerator and cooled rapidly to room temperature, and the purified product was obtained by precipitation and washing with organic solvent acetone, and finally the purified product was The modified natural Eucommia gum was obtained by drying in a vacuum drying oven to constant weight.

Embodiment 2

[0021] The preparation method of the modified natural Eucommia gum improving the elasticity of Eucommia gum, the steps are as follows:

[0022] Get eucommia gum and dissolve it in 200ml cyclohexane to make a mass concentration of 3% eucommia gum solution, then add the eucommia gum solution into a polytetrafluoroethylene liner reactor, then in the reactor, drop 5.81g of cyclohexane Pentadiene, 0.1257g of AlCl 3 The reaction was carried out at a temperature of 110°C, and the reaction time was 5 hours. After the reaction, the reaction kettle was taken out, placed in the freezer of the refrigerator and cooled rapidly to room temperature, and the purified product was obtained by precipitation and washing with organic solvent acetone, and finally the purified product was The modified natural Eucommia gum was obtained by drying in a vacuum drying oven to constant weight.

Embodiment 3

[0024] Take eucommia gum and dissolve it in 200ml heptane to form a eucommia gum solution with a mass concentration of 2.5%, then add the eucommia gum solution into a polytetrafluoroethylene liner reactor, and then put 4.72g of isoamyl in the reactor Diene, 0.1237g of AlCl 3 The reaction was carried out at a temperature of 130°C, and the reaction time was 4 hours. After the reaction, the reaction kettle was taken out, placed in the freezer of the refrigerator and cooled rapidly to room temperature, and the purified product was obtained by precipitation and washing with organic solvent acetone, and finally the purified product was The modified natural Eucommia gum was obtained by drying in a vacuum drying oven to constant weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com