Gutta-percha masterbatch co-blended material capable of being directly used as traditional rubber material

A technology of rubber material and eucommia gum, which is applied in the field of eucommia rubber masterbatch blending new materials and preparation, can solve the problems of difficult adhesion of tread joints, difficulty in tire blank molding, and prolonged time for rubber to fill the mold cavity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

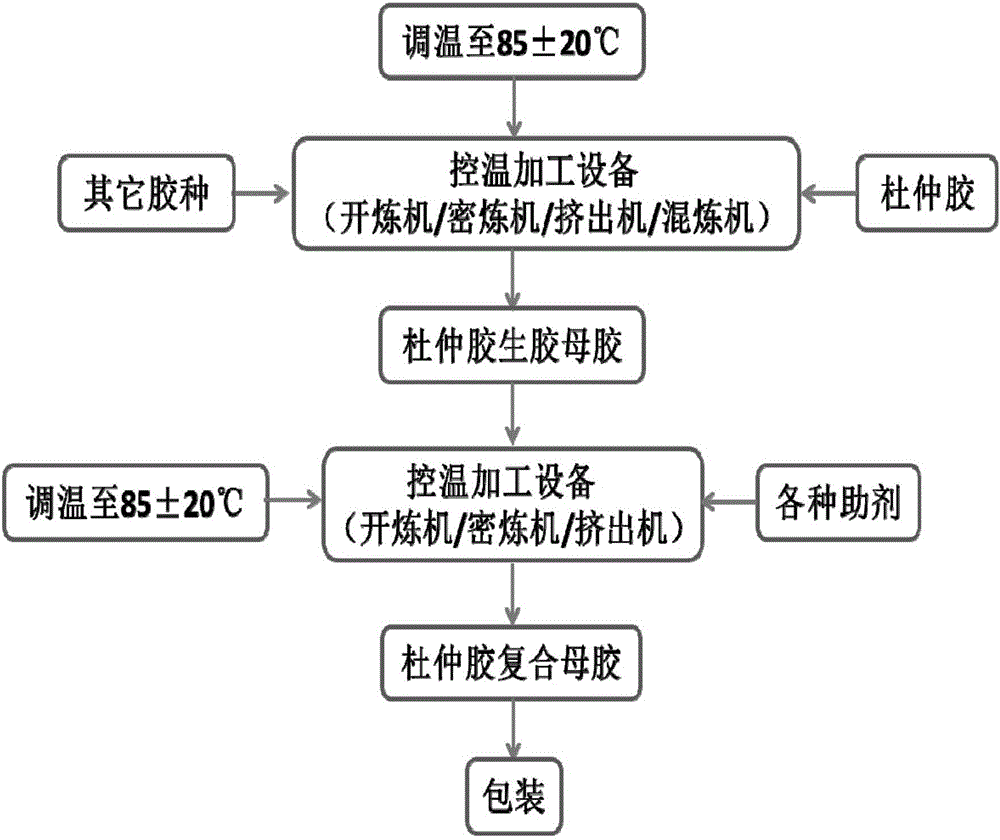

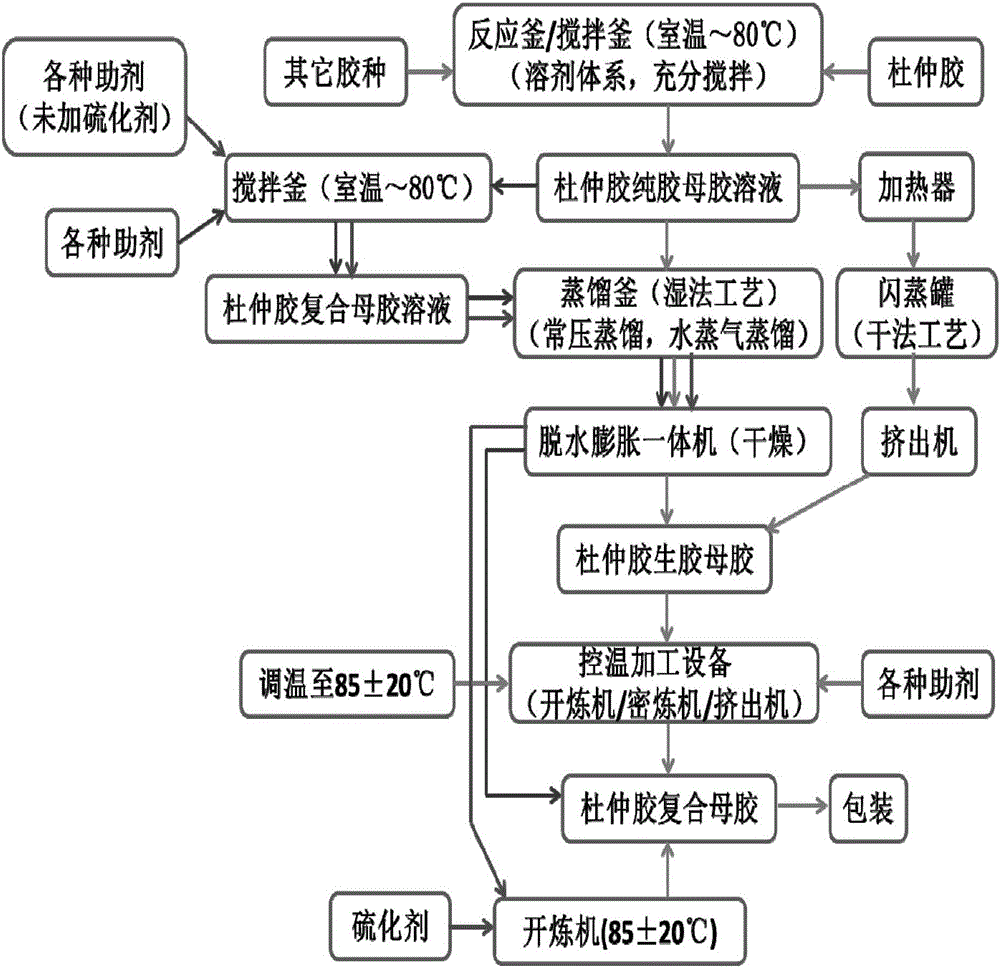

Method used

Image

Examples

Embodiment 1

[0038] Eucommia gum / styrene-butadiene rubber to prepare passenger car tread raw rubber masterbatch and composite masterbatch: select a temperature-controllable internal mixer, and control the processing temperature at 65±5°C. Determine the total mass of batch rubber mixing according to the model size of the internal mixer, and the ratio of Eucommia gum to styrene-butadiene rubber is 1:99. Then add Eucommia gum to the internal mixer for plasticating, the plasticizing time is 30 seconds, during which the Eucommia gum gradually softens, and then add the remaining proportion of styrene-butadiene rubber for blending, the blending time is 5 minutes, and the blending rubber is mixed Evenly smelted, the raw rubber masterbatch for passenger car eucommia rubber / styrene butadiene rubber tread can be obtained. After testing, the Mooney viscosity is 54, and the hardness is 43 degrees (Shore A). It meets the requirements of the rubber industry for the use of raw rubber.

[0039] The formu...

Embodiment 2

[0043] Eucommia gum / butadiene rubber / natural rubber to prepare passenger car tire side raw rubber masterbatch and composite masterbatch: select a temperature-controllable open mill, and control the processing temperature at 70±5°C. Determine the total mass of batch rubber mixing according to the model size of the open mill, and the ratio of Eucommia gum / butadiene rubber / natural rubber is 5:50:45. Then add Eucommia gum to the open mill for plasticating. The plasticizing time is 5 minutes. During this period, the Eucommia gum gradually softens and wraps the roll. Then add the remaining proportion of butadiene rubber and styrene-butadiene rubber for blending. The blending time is 15 minutes. , and other blended rubbers are mixed evenly to obtain passenger car eucommia rubber / butadiene rubber / natural rubber passenger car tire side raw rubber masterbatch. After testing, the Mooney viscosity is 48 and the hardness is 39 degrees (Shore A). It meets the requirements of the rubber ind...

Embodiment 3

[0048] Eucommia rubber / natural rubber / styrene-butadiene rubber / butadiene rubber to prepare heavy-duty tread raw rubber masterbatch and composite masterbatch: select a single-screw extruder with temperature control, the parameters are: screw diameter 30mm, aspect ratio 25 :1, the maximum speed is 115rpm, the maximum output is 11kg / hour, and the processing temperature is controlled at 75±5℃. The ratio of eucommia gum / natural rubber / styrene-butadiene rubber / butadiene rubber is 15:35:30:20. First, crush Eucommia gum / natural rubber / styrene-butadiene rubber / butadiene rubber to particles with a particle size of about 5mm, and then use a mixer to disperse the blended rubber particles evenly. The rubber blend granules described above were then fed into the extruder. Under the action of the extruder, the blended masterbatch is continuously extruded from the extruder. In order to make the mixing of the masterbatch more uniform, a 2-stage mixing process is adopted in this embodiment. S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com