Ladle nozzle casting conduction plug and use method thereof

A technology for ladles and nozzles, applied in the field of drainage devices for casting molten steel in block nozzles, can solve the problems of large manpower, material resources and time, small coverage area, low strength, etc., and achieve improved drainage success rate, accurate setting position, and coverage area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

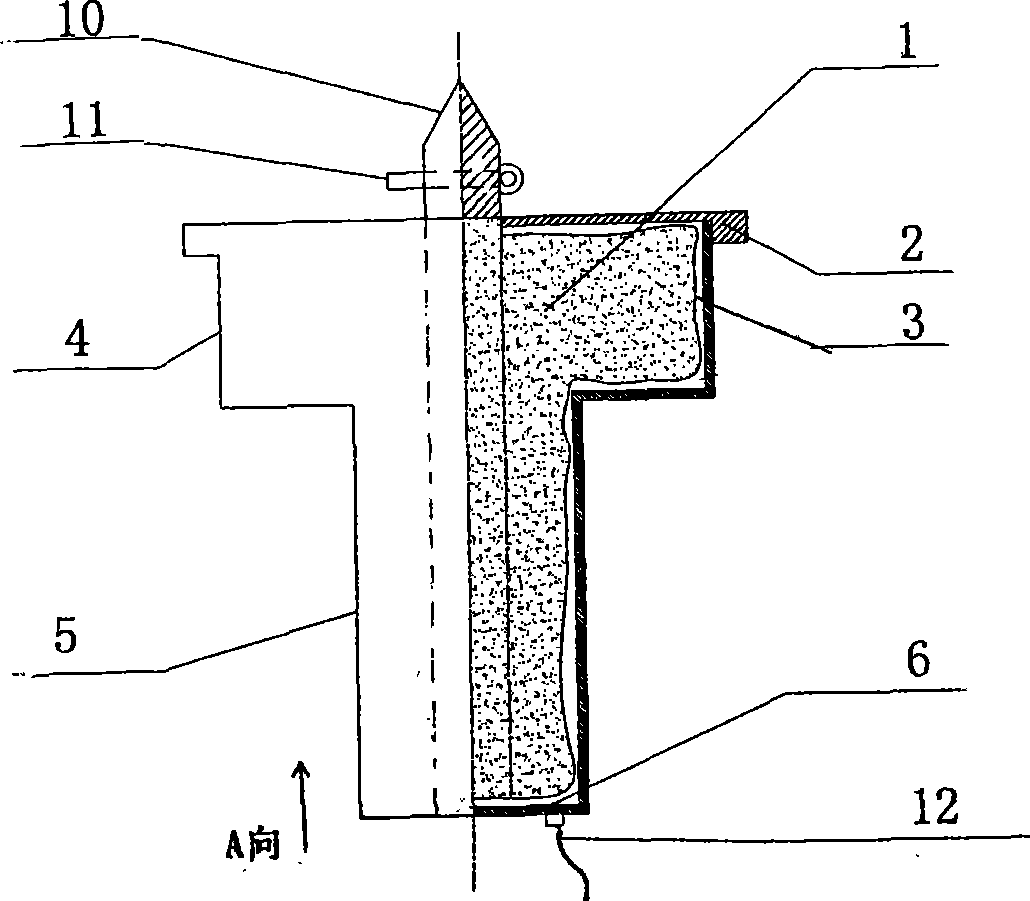

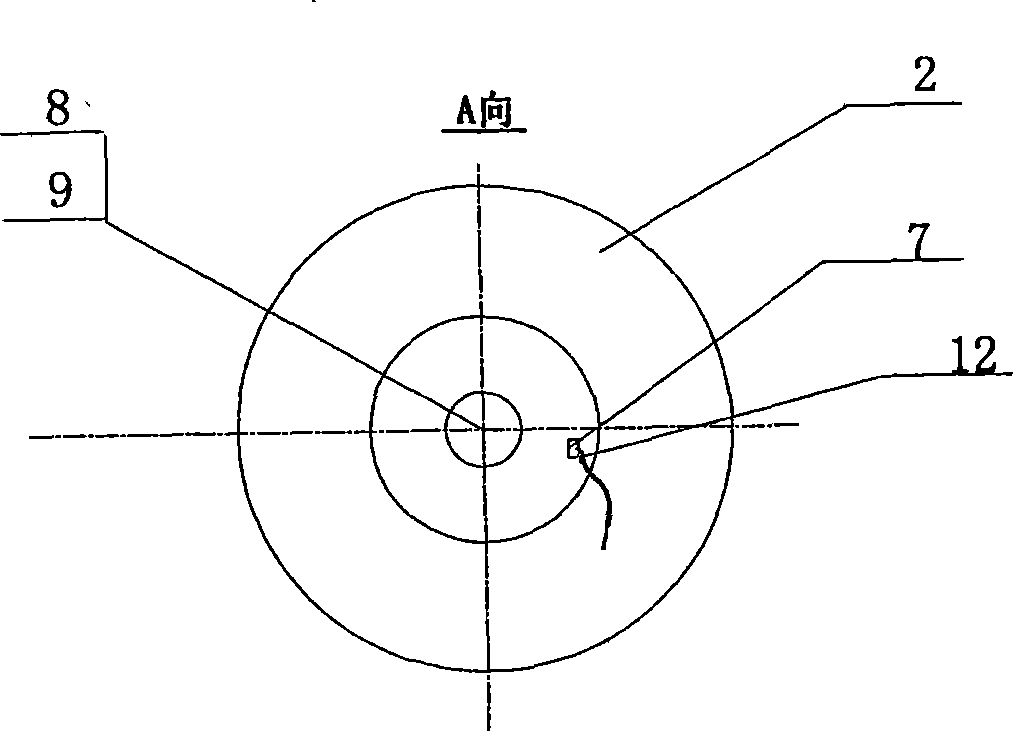

[0027] Depend on figure 1 , figure 2 It can be seen that the ladle nozzle casting drain plug is a circular cylindrical body with a variable diameter composed of the plug cap 4 , the plug cover 2 , the plug post 5 and the bottom plate 6 . Drainage agent is packed in soft bag 3, and soft bag 3 is placed in circular cylinder body, and soft bag 3 is heat-resistant 800-1000 ℃. The center of the plug cover 2 and the bottom plate 6 is provided with a guide rod hole 8, which is slidably matched with the guide rod 10, and the bottom plate 6 is provided with a ring buckle 7 to cooperate with the traction rope 12. There is a movable cover 9 next to the guide hole 8. When storing and transporting the drainage plug, close the movable cover to prevent the leakage of the drainage agent; when in use, the movable cover 9 is uncovered, and the guide rod 10 passes through the guide hole 8 and is slid on the drainage plug. middle. The guide rod 10 is also provided with a pin hole, and the rin...

Embodiment 2

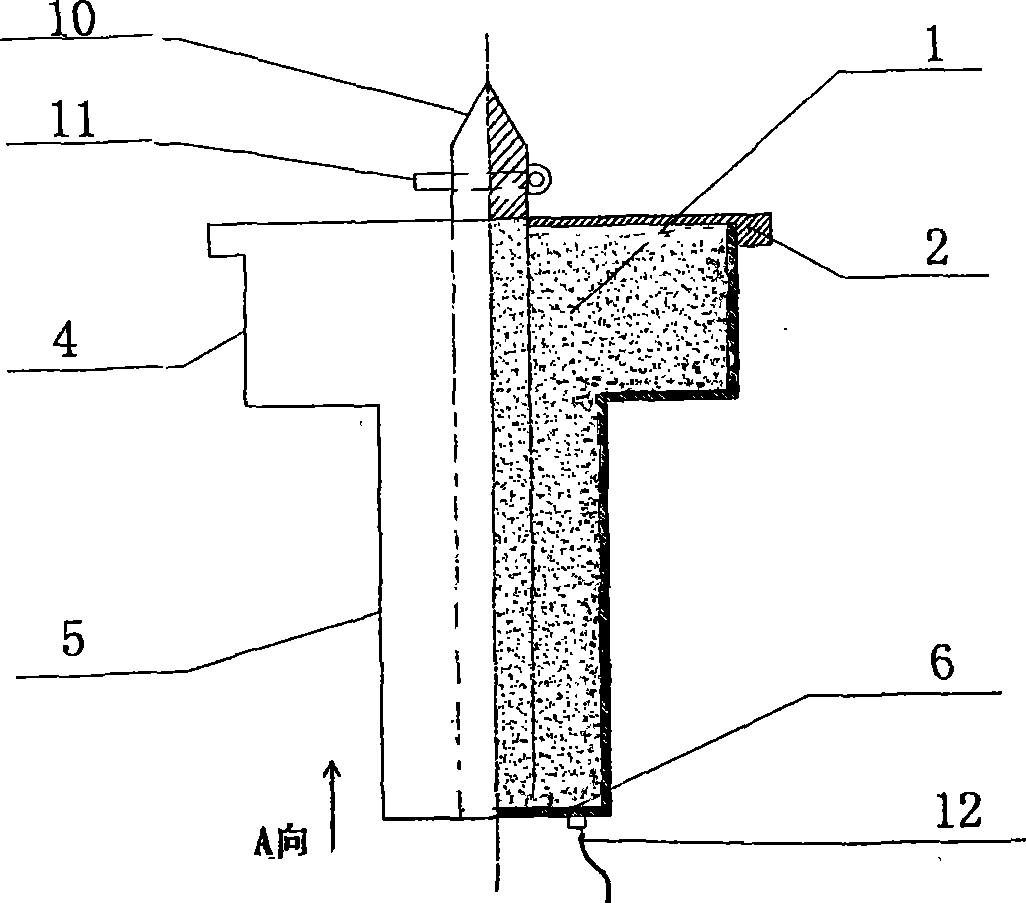

[0029] Depend on image 3 , Figure 4 It can be seen that the ladle nozzle casting drain plug is a circular cylindrical body with a variable diameter composed of the plug cap 4 , the plug cover 2 , the plug post 5 and the bottom plate 6 . The drainage agent is filled in the circular cylinder, the center of the plug cover 2 and the bottom plate 6 is provided with a guide rod hole 8, which slides and fits with the guide rod 10, and the bottom plate 6 is provided with a ring buckle 7 to cooperate with the traction rope 12. There is a movable cover 9 next to the guide hole 8. When storing and transporting the drainage plug, close the movable cover to prevent the leakage of the drainage agent; when in use, the movable cover 9 is uncovered, and the guide rod 10 passes through the guide hole 8 and is slid on the drainage plug. middle. The guide rod 10 is also provided with a pin hole, and the ring pin 11 with a ring is inserted into the pin hole, and the traction rope 12 is hooked ...

Embodiment 3

[0031] Depend on Figure 5 , Figure 6 It can be seen that the drainage plug is fixed by the bent iron wire 13 and the ring 14 to form a circular cage shape with reduced diameter, and the consolidation method can be welding or binding connection. The ring consists of three kinds of rings, the small ring and the guide rod are slidingly matched, the upper and lower ends of the plug cover 4 and the plug post 5 are fixedly connected by the small ring and the iron wire 13, and the middle ring and the iron wire 13 are fixedly connected to form the plug cap 5. The large ring and the iron wire 13 are solidly formed into a plug cap 4, and the drainage agent 1 is packed into the metal mesh bag 3 and placed in a circular cage. The iron wire 13 and the circular ring 14 have a single bending shape and are easy to consolidate and form. When casting, they have a large contact area with molten steel and are easy to melt, which is more beneficial to drainage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com