Pouring ladle with controlling mechanism of iron water flow

A technology of flow control and ladle, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems that the quality of castings cannot be guaranteed, the molten iron is not very accurate, the result is not very accurate, etc., and the molten iron outflow can be achieved. Accurate control, high control accuracy and repeatability, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

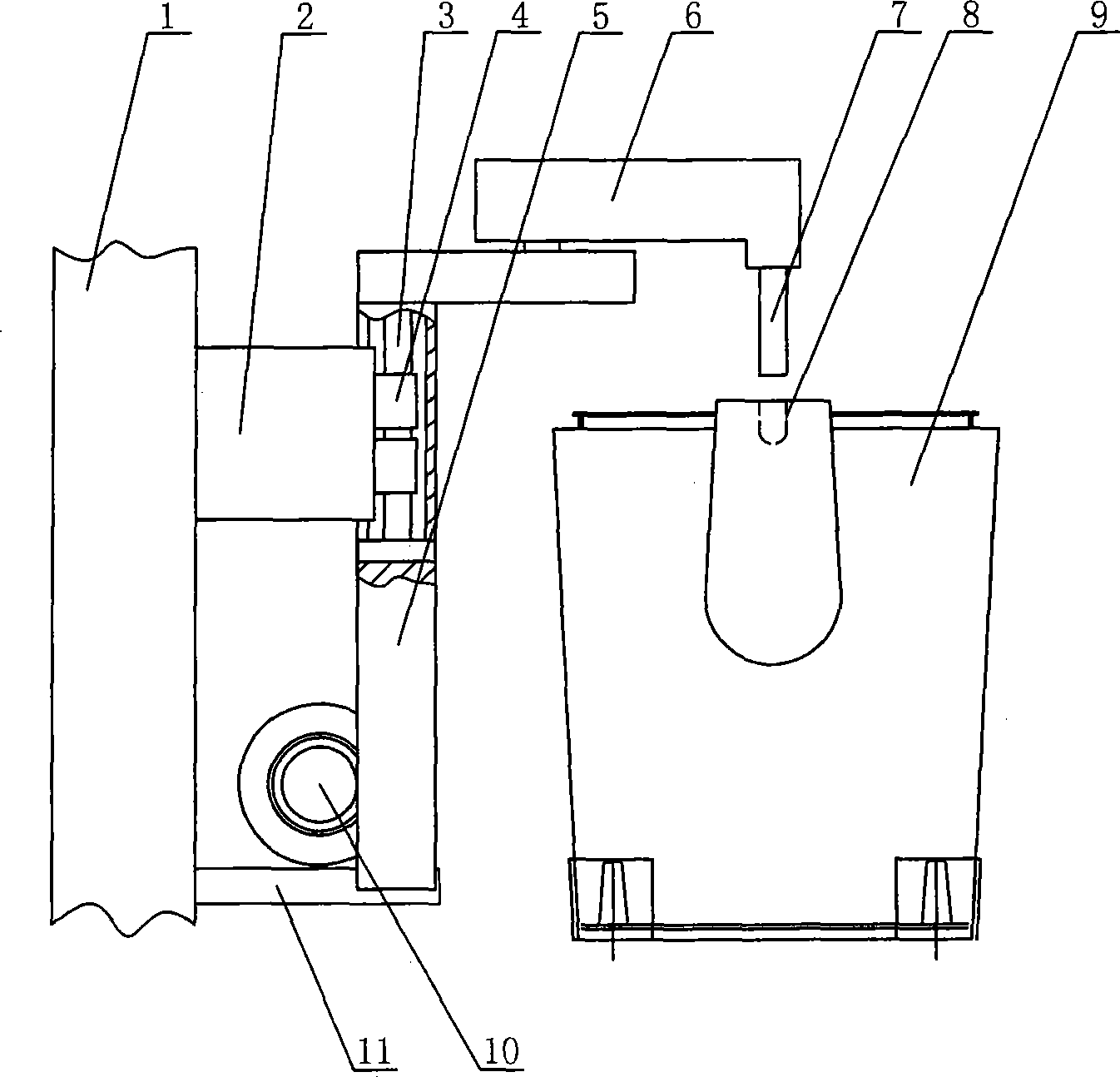

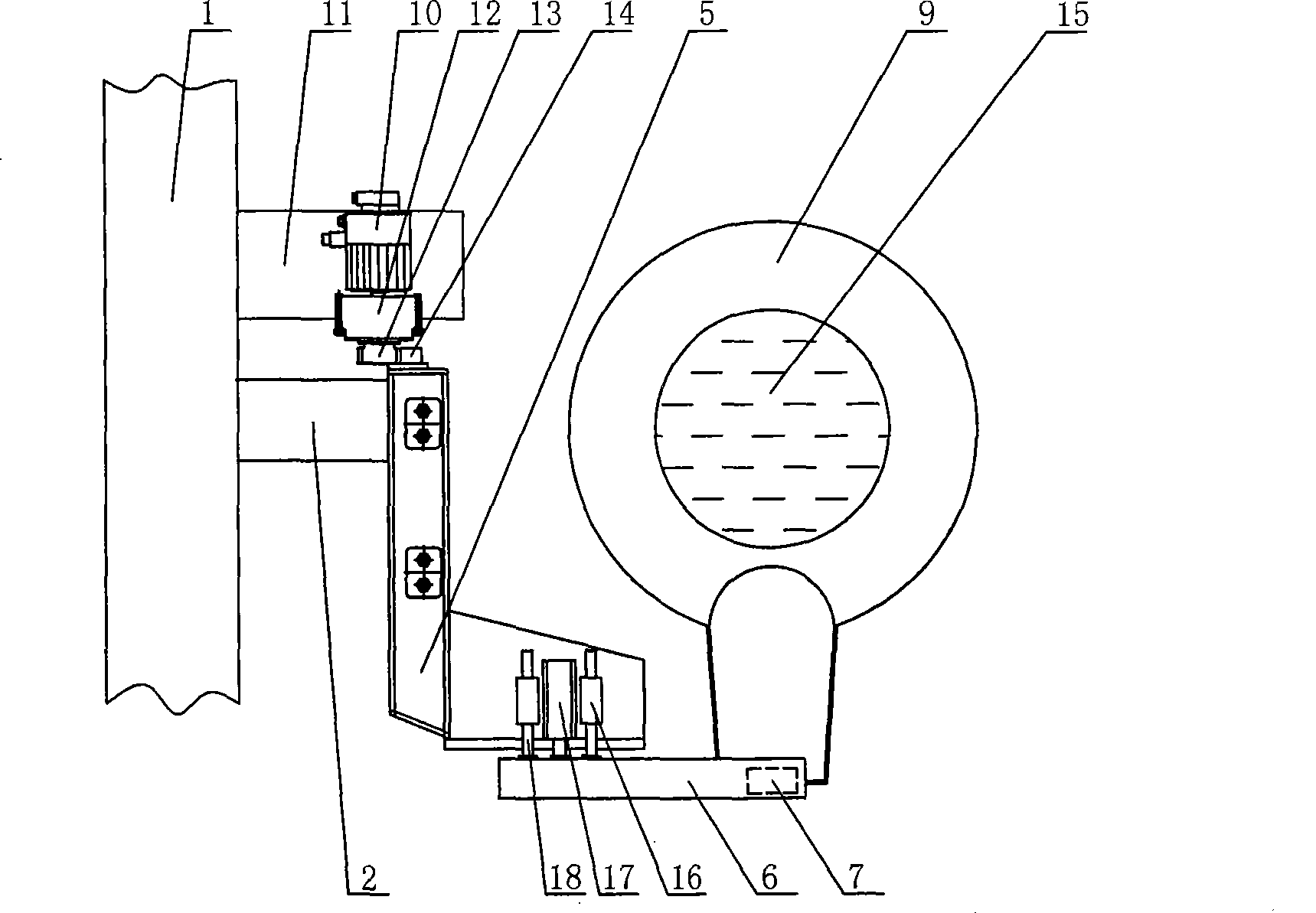

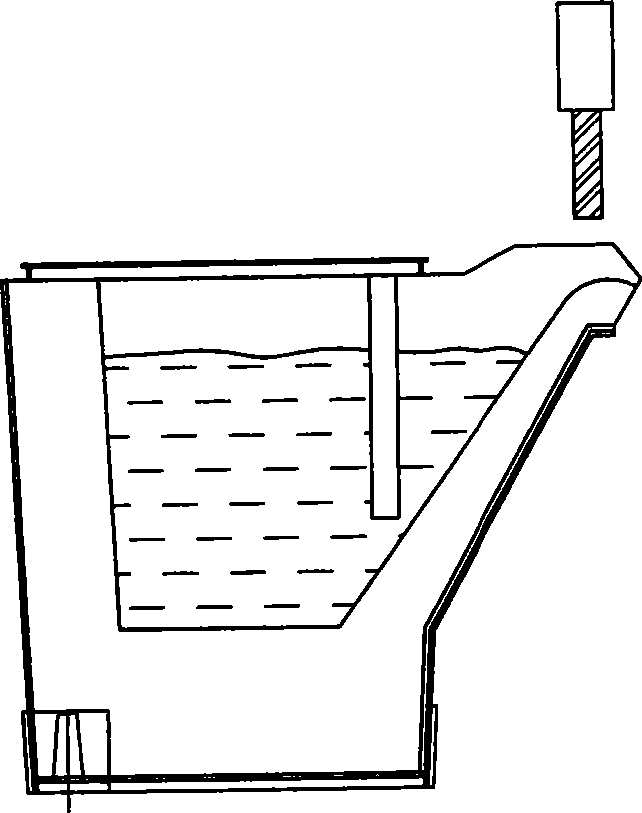

[0022] Such as figure 1 , figure 2 As shown, a ladle with a molten iron flow control mechanism is composed of a ladle frame 1 and a ladle 9, the ladle carries molten iron 15, and a fixed frame 2 is arranged on the ladle frame, and one end of the fixed frame is fixed with a The slide block 4 of the linear guide rail is provided with the slide rail 3 of the linear guide rail on the inner wall or the outer wall of the vertical beam 5, and the vertical beam is slidably connected with the fixed frame through the linear guide rail. A cylinder 17 is installed on the upper end of the vertical beam, and a horizontal beam 6 is installed on the top of the piston of the cylinder. The guide post 18 provided on the surface of the horizontal beam slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com