Fire sprinkler head used for dust collector

A sprinkler head and dust collector technology, which is applied in fire rescue and other directions, can solve the problems of water sprinkler head waste, vitreous body burst, increase cost, etc., achieve the effect of simple and reliable structure, improve precision, and avoid mis-spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

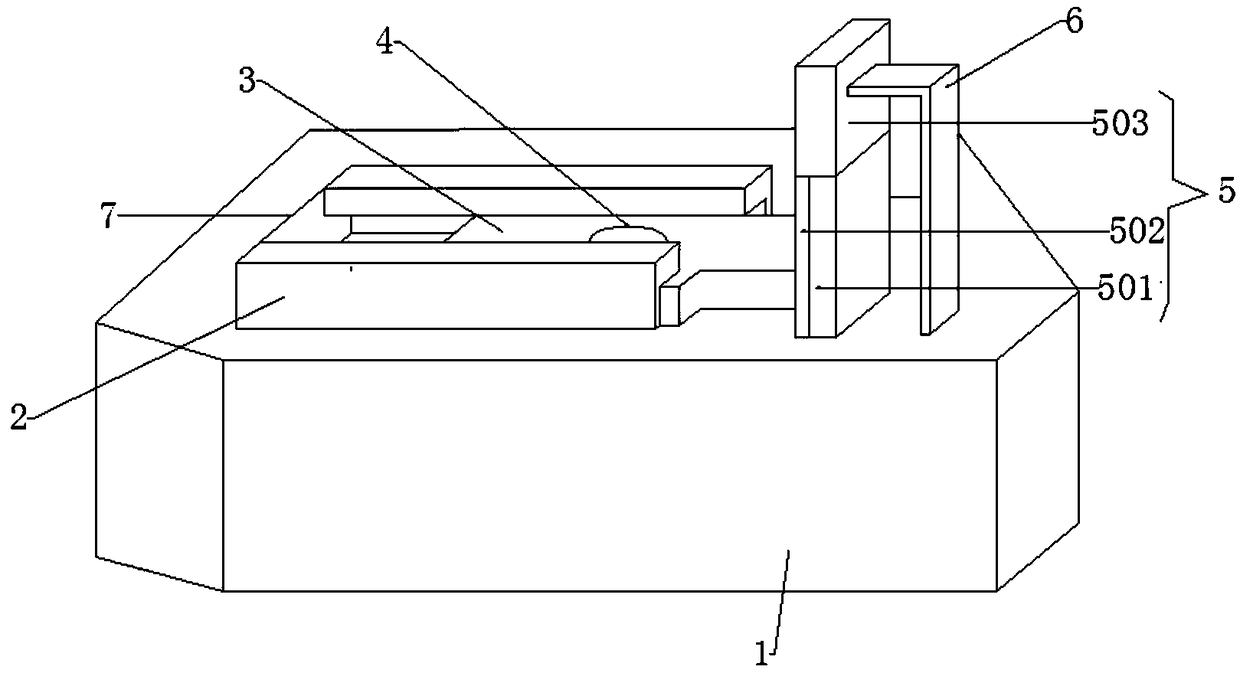

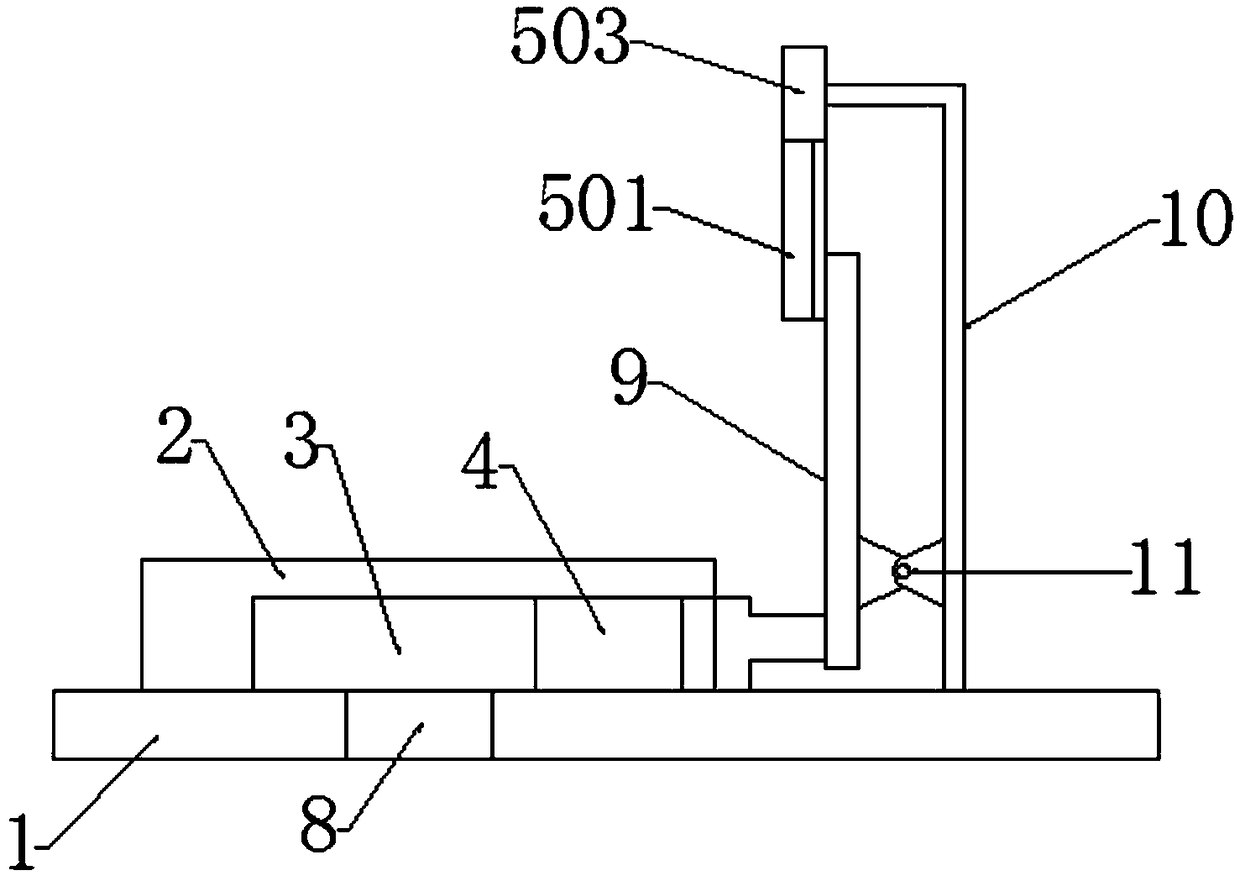

[0020] Such as figure 1 As shown, the present invention is a fire-fighting sprinkler head for a dust collector, which includes a sprinkler frame and a splash plate. hole, the splash plate includes a disc and splash grooves evenly distributed around the disc, the disc is fixedly connected to the upper end of the nozzle frame, the axis of the disc coincides with the axis of the through hole, and the base 1 A slot 2 is provided on the top, and a matching board 3 is arranged in the slot 2, and a second through hole 4 matched with the position of the first through hole is provided on the board 3; the top of the base A bimetal member in contact with the board is provided on the surface, and the bimetal member is arranged at one end of the board and resists it, and is used to push the board so that the second through hole on the board is aligned with the first through hole.

[0021] The bimetal component includes a bimetal 5 and a support frame 6, the bimetal 5 includes a welding se...

Embodiment 2

[0029] Such as figure 1 As shown, the present invention is a fire-fighting sprinkler head for a dust collector, which includes a sprinkler frame and a splash plate. Hole 8, the splash plate includes a disc and splash grooves evenly distributed around the disc, the disc is fixedly connected to the upper end of the nozzle frame, the axis of the disc coincides with the axis of the through hole, and the base 1 is provided with a slot 2, and a matching board 3 is arranged in the slot 2, and a second through hole 4 matching the position of the first through hole is provided on the board 3; the base The top surface is provided with a bimetal member in contact with the board, and the bimetal member is arranged at one end of the board and is in contact with it, and is used to push the board so that the second through hole 4 on the board is aligned with the first through hole 8 . align.

[0030] Described bimetal member comprises the bimetal sheet that is arranged perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com