Aluminium alloy casting device

An aluminum alloy, high-temperature technology, applied in the field of metal casting equipment, can solve the problems of high casting cost, long casting cycle, increased casting cost, etc., and achieve the effect of simple operation process, fast casting and smooth casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

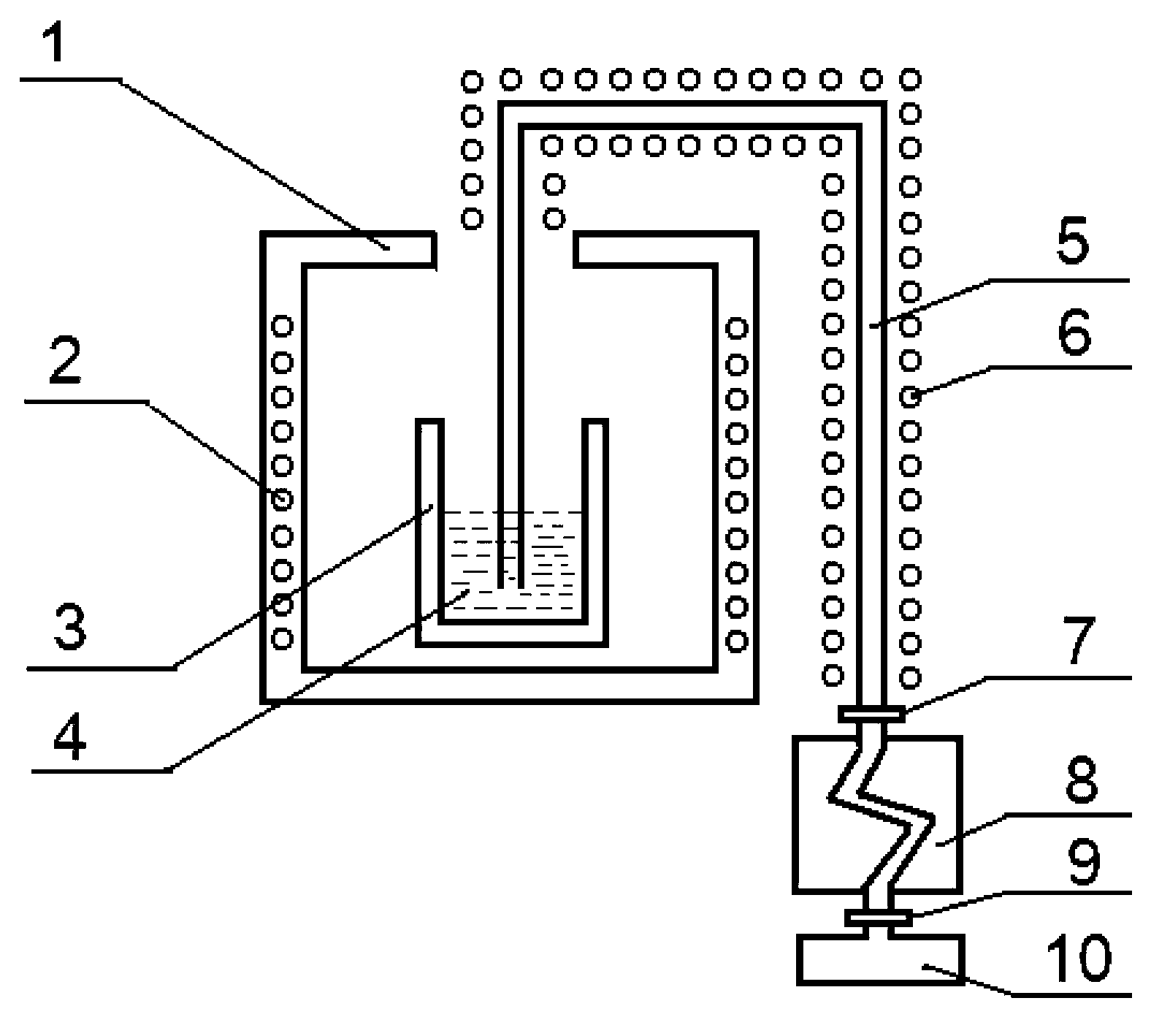

[0012] The present invention selects the metal shell and the insulating asbestos material as the high-temperature atmospheric furnace body 1, and the crucible 3 made of corundum is placed in the high-temperature atmospheric furnace body 1. Add the 6063 aluminum alloy ingredients into the crucible 3, and heat up to 660°C. The riser pipe 5 adopts a corundum ceramic tube with a pipe diameter of 1 cm. The end of the riser pipe 5 facing the mouth of the crucible 3 is immersed in the aluminum alloy melt above the bottom of the crucible 3, and the horizontal part of the riser pipe 5 is kept away from the aluminum alloy. The distance between the liquid surface of the alloy melt 4 is less than 3 cm, and the other end of the riser pipe 5 is airtight and seamlessly communicated with the upper end of the cavity 8 through a ceramic valve 7 . The lower end of the cavity 8 is airtightly and seamlessly connected with the vacuum pump 10 through the ceramic valve 29, and the vacuum pump 10 is u...

Embodiment 2

[0014] The present invention selects the metal shell and the insulating asbestos material as the high-temperature atmospheric furnace body 1, and the crucible 3 made of corundum is placed in the high-temperature atmospheric furnace body 1. Add the 7075 aluminum alloy ingredients into the crucible 3, and heat up to 670°C. The riser pipe 5 adopts a corundum ceramic tube with a pipe diameter of 1.5 cm. The end of the riser pipe 5 facing the mouth of the crucible 3 is immersed in the aluminum alloy melt at the position above the bottom of the crucible 3. At the same time, the distance between the horizontal part of the riser pipe 5 The distance between the liquid surfaces of the aluminum alloy melt 4 is less than 2 cm, and the other end of the riser pipe 5 is airtight and seamlessly communicated with the upper end of the cavity 8 through a ceramic valve 7 . The lower end of the cavity 8 is airtightly and seamlessly connected with the vacuum pump 10 through the ceramic valve 29, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com