Plunger pump

A plunger pump and plunger technology, applied in the field of fluid pumps, can solve the problems of large leakage and insufficient suction of the plunger pump, and achieve the effects of reliable performance, improved service life and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

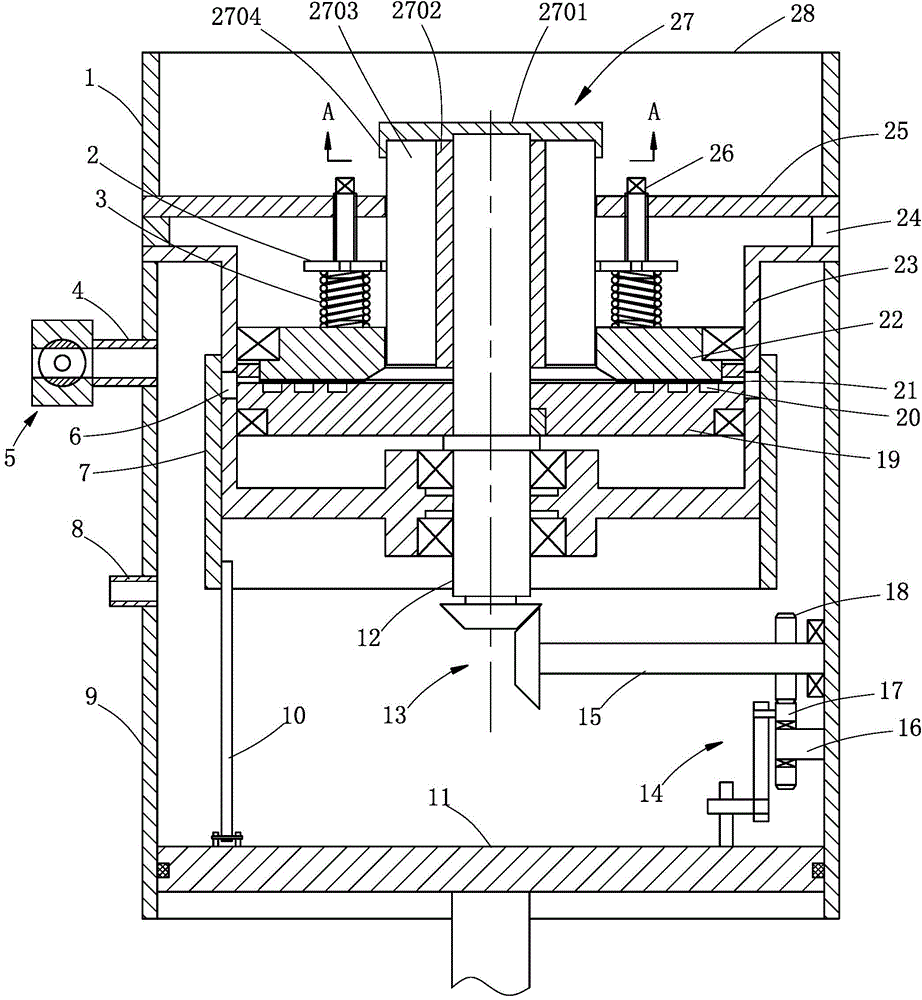

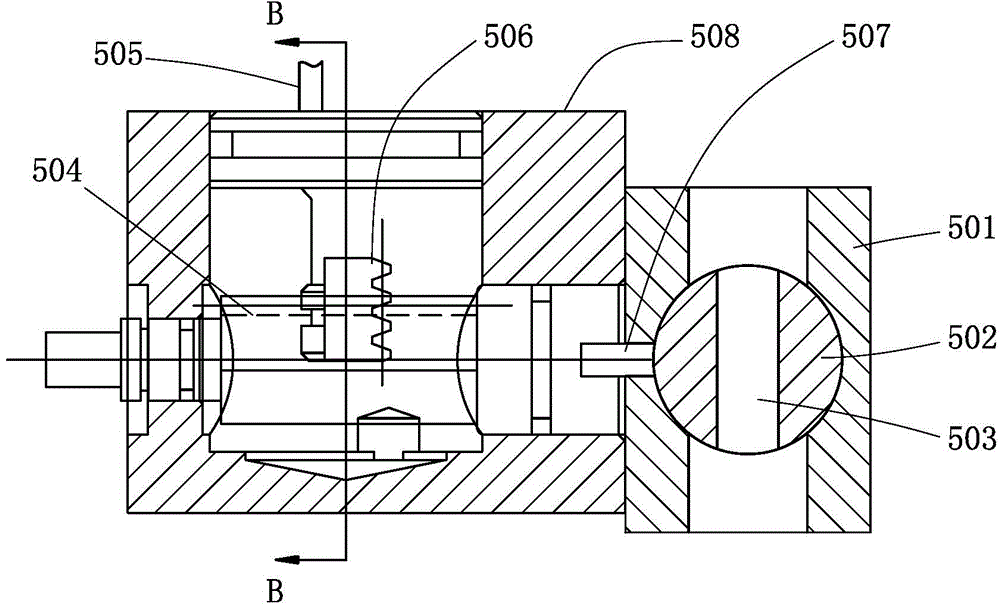

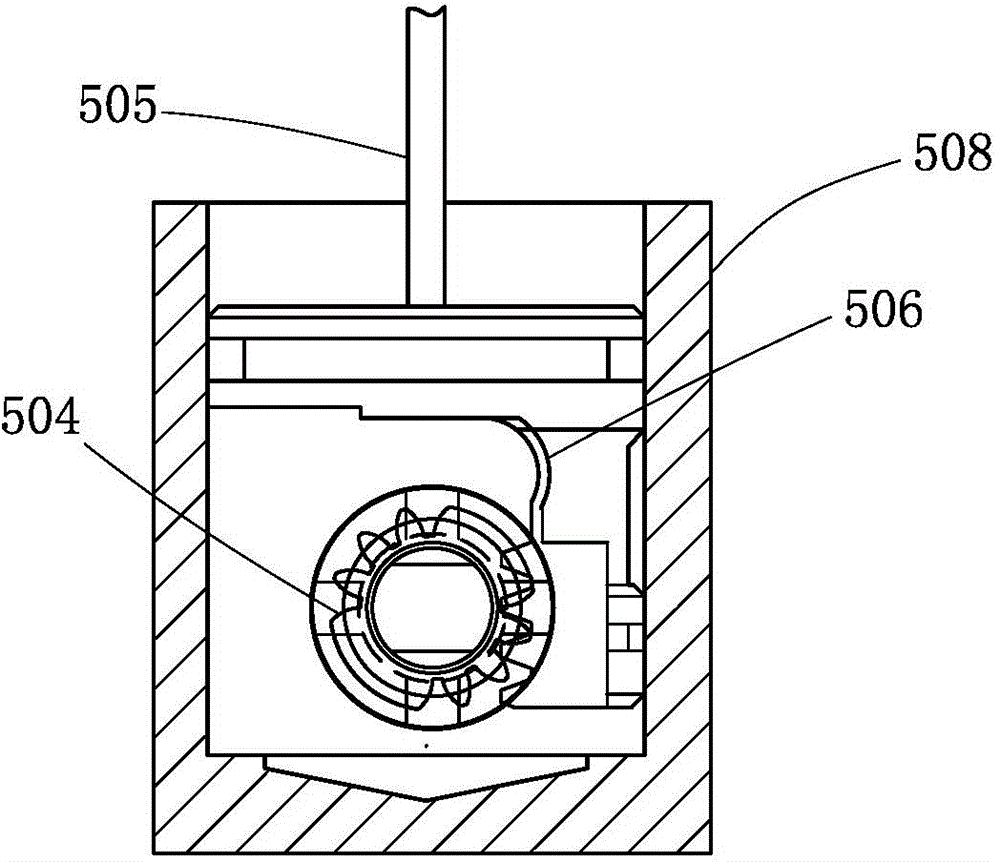

[0030] Such as figure 1 and Figure 4Commonly shown, the present invention provides a plunger pump, including a pump body, the pump body is a straight cylindrical structure, one end of the pump body is provided with a feed port 28, and the other end is slidably installed with a plunger 11, the plunger 11 is connected to drive The unit makes a reciprocating linear motion. A partition wall 25 is provided in the pump body close to the feed port 28. A mounting cylinder 23 is provided in the pump body between the partition wall 25 and the plunger 11. A closed installation is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com